Study on Comprehensive Utilization Technology of a Low Quality Kaoline Ore in Jiangxi

-

摘要:

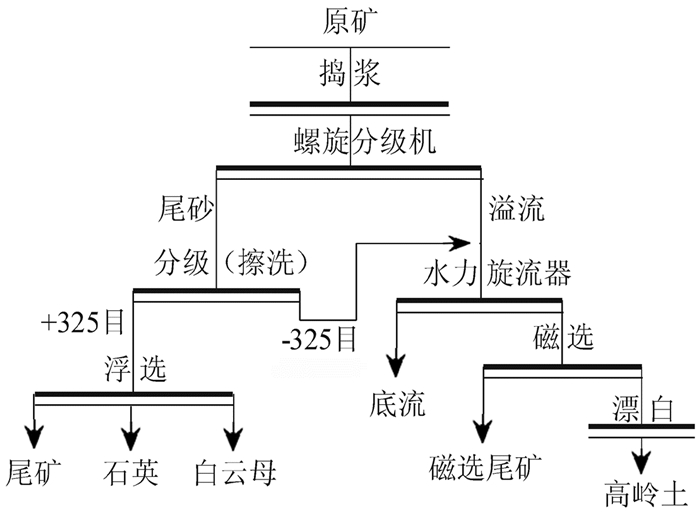

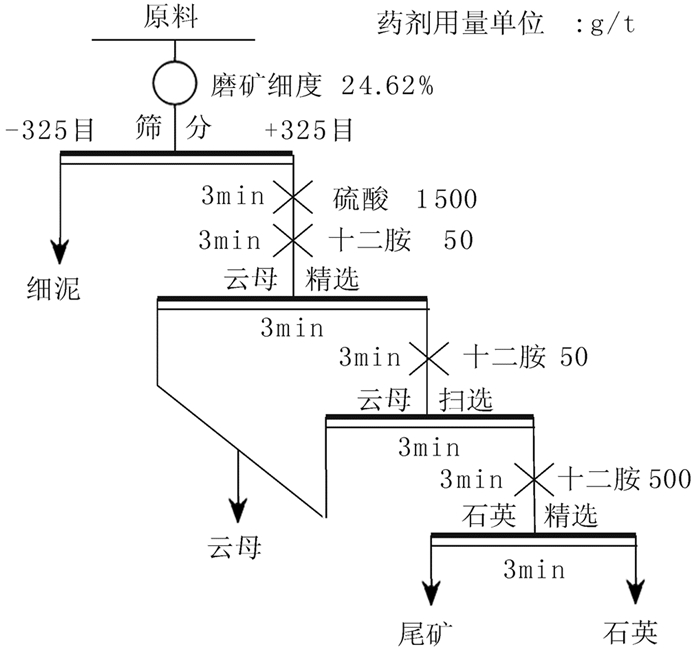

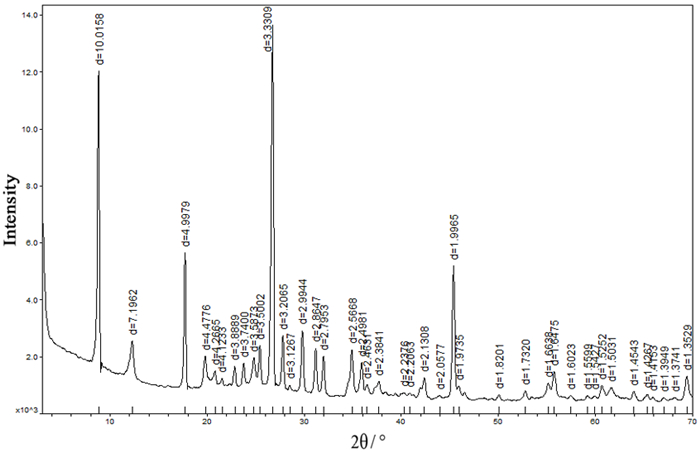

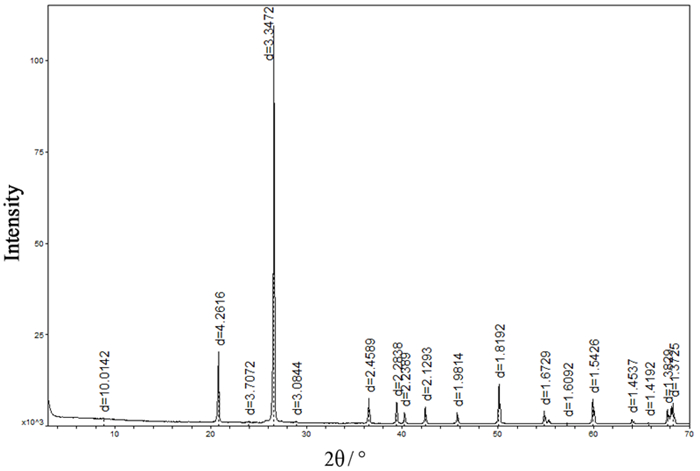

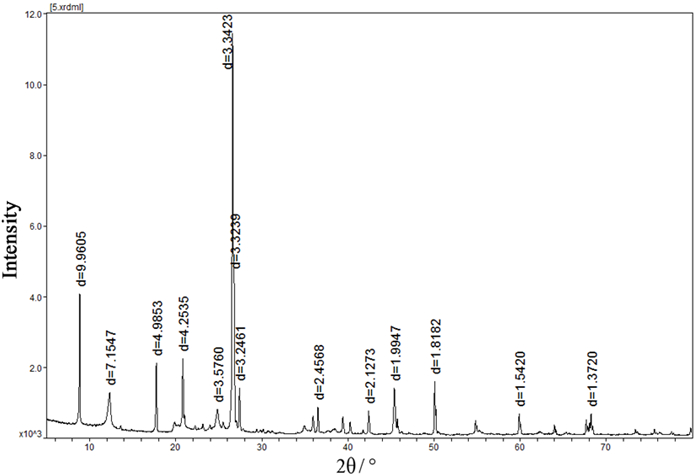

以江西某低品质高岭土矿为研究对象,在原矿化学元素、矿物组成等分析的基础上,制定了高岭土提纯工艺及尾矿综合利用技术方案。原矿采用"捣浆—分级—提纯—磁选—化学漂白"工艺进行选别,得到高岭土深加工产品,其高岭石含量82%,自然白度79.8%、烧成白度90.1%,Fe2O3含量0.54%;尾砂经分级、磨矿、浮选,分离白云母与石英两种产品,其中白云母产品中K2O含量达到7.89%,白云母矿物含量85%,石英产品中SiO2含量达到97.78%,石英矿物含量96%。工艺流程对该高岭土矿实现了全组分综合利用,解决了低品质高岭土矿利用率低、尾矿大量排放的难题。

Abstract:Taking a low quality kaolin ore in Jiangxi as the research object, basing on the analysis of ore mineral composition, chemical elements and so on, a technological process of purification of kaoline and of comprehensive utilization technology of its tailings was put forward. By studing on the processing technology of raw ore, such as pulp purification, magnetic separation and chemical bleaching, highly processed products of kaoline was obtained. The content of kaolinite reaches 82%, the natural whiteness 79.8%, the burning whiteness 90.1%, and the content of Fe2O3 is reduced to 0.54%. Following by classification, grinding, flotation for tailings, two products namely muscovite and quartz can be obtained. The content of K2O in muscovite obtained can reach 7.89% and the content of SiO2 in quartz obtined reaches 97.78%.The mineral content of Muscovite reaches 85% and the mineral content of quartz reaches 96%, respectively. The technological process realizes the comprehensive utilization of the kaoline ore, and solves the problem of the low utilization rate of low quality kaoline ore and large accumulation of tailings.

-

Key words:

- Kaoline /

- low quality /

- comprehensive utilization /

- purification /

- whiteness

-

-

表 1 原矿主要化学成分分析结果 /%

Table 1. Main chemical composition analysis results of raw ore

成分 SiO2 Fe2O3 Al2O3 TiO2 K2O Na2O CaO MgO 烧失量 含量 74.41 0.52 16.50 0.05 2.73 0.17 0.41 0.15 4.87 表 2 不同沉砂口直径下旋流器试验结果

Table 2. Results of hydrocyclone test as a function of sand diameter

沉砂口直径/mm 产品 浓度/% 产率/% Fe2O3/% Al2O3/% 4 溢流 9.91 69.31 1.61 33.75 底流 49.91 30.69 0.77 24.52 7 溢流 9.24 61.25 1.64 33.71 底流 53.90 38.75 0.84 25.20 11 溢流 8.66 53.83 1.74 33.30 底流 51.32 46.17 1.08 25.20 试验条件 进浆压力0.3 MPa,进浆浓度13.13% 表 3 不同进浆压力下旋流器试验结果

Table 3. Results of hydrocyclone test as a function of feed pressures

进浆压力/MPa 产品 浓度/% 产率/% Fe2O3/% Al2O3/% 0.15 溢流 10.20 73.86 1.44 33.07 底流 52.99 26.14 0.78 24.07 0.20 溢流 9.96 73.47 1.44 33.72 底流 49.84 26.53 0.67 24.72 0.25 溢流 9.65 71.54 1.51 33.71 底流 50.45 28.46 0.81 24.90 0.30 溢流 9.24 69.31 1.61 33.75 底流 53.90 30.69 0.84 25.20 试验条件 沉砂口直径4 mm,进浆浓度13.13% 表 4 不同进浆浓度下旋流器试验结果

Table 4. Results of hydrocyclone test as a function of feed concentration

进浆浓度/% 产品 浓度/% 产率/% Fe2O3/% Al2O3/% 8.92 溢流 5.95 68.53 1.52 33.72 底流 53.71 31.37 0.65 24.56 10.46 溢流 7.85 70.63 1.50 33.73 底流 51.01 29.37 0.65 24.51 13.13 溢流 9.96 73.47 1.44 33.72 底流 49.84 26.53 0.67 24.52 15.80 溢流 12.45 78.16 1.44 32.53 底流 46.34 21.84 0.78 24.78 试验条件 进浆压力0.20 MPa,沉砂口直径4 mm 表 5 旋流器溢流产品磁选试验结果

Table 5. Magnetic separation test results of hydrocyclone overflow product

磁选条件 产品 产率/% Fe2O3/% 自然白度/% 烧成白度/% 浓度/% 流速/(cm·s-1) 场强/T 7 0.6 1.9 精矿 63.55 0.81 64.2 85.7 尾矿 36.45 2.54 / / 10 1.0 1.9 精矿 77.55 1.16 63.2 85.2 尾矿 22.45 2.27 / / 10 0.6 1.9 精矿 73.93 0.79 64.3 86.1 尾矿 26.07 2.74 / / 13 0.6 1.9 精矿 72.27 0.86 64.1 85.5 尾矿 27.73 2.46 / / 表 6 药剂用量试验结果

Table 6. Test results as a function of dosage of agent

保险粉用量/% 漂白时间/h Fe2O3/% 自然白度/% 烧成白度/% 0 0 0.79 64.3 86.1 4 2 0.72 73.6 88.7 6 2 0.64 76.0 89.6 8 2 0.54 79.8 90.1 10 2 0.54 79.8 90.1 表 7 漂白时间试验结果

Table 7. Test results a function of bleaching time

保险粉用量/% 漂白时间/h Fe2O3/% 自然白度/% 烧成白度/% 8 1 0.60 77.2 89.7 8 2 0.54 79.8 90.1 8 3 0.54 79.8 90.1 表 8 尾砂粒度组成及主要化学元素分析结果

Table 8. Results of grain size composition and main chemical elements analysis

粒级/mm 产率/% 累计产率/% SiO2/% Fe2O3/% Al2O3/% K2O/% +1.0 11.29 11.29 93.97 0.19 2.94 0.36 -1.0+0.6 18.57 29.86 90.37 0.20 5.34 1.00 -0.6+0.3 26.05 55.91 86.94 0.24 7.95 2.79 -0.3+0.1 35.33 91.24 81.76 0.42 7.82 4.88 -0.1+0.074 1.59 92.83 69.56 0.54 17.41 7.72 -0.074+0.045 2.52 95.35 62.67 0.69 20.78 9.12 -0.045 4.65 100.00 50.47 1.49 31.84 3.62 表 9 尾砂各粒级矿物组成及含量

Table 9. Mineral composition and content of each particle size of tailings

粒级/mm 石英/% 白云母/% 高岭石/% 其他/% +1.0 76 11 13 / -1.0+0.6 65 10 7 18 -0.6+0.3 65 17 11 7 -0.3+0.1 39 33 12 16 -0.1+0.074 28 22 20 30 -0.074+0.045 26 18 25 31 -0.045 8 9 62 21 表 10 +0.045 mm浮选试验结果

Table 10. Results of +0.045 mm flotation test

产品 作业产率/% 对原矿产率/% 回收率/% SiO2/% Fe2O3/% Al2O3/% K2O/% 白云母/% 高岭石/% 石英/% 云母 12.47 7.66 50.08 47.33 1.77 33.03 7.89 85 15 / 石英 73.99 45.44 85.53 97.78 0.03 1.21 0.45 4 / 96 尾矿 6.52 4.00 / 47.03 2.06 28.73 4.31 / / / 细泥 7.02 4.31 / 62.88 2.94 22.73 3.39 / / / 合计 100.00 61.41 / / / / / / / / -

[1] 尤振根.国内外高岭土资源和市场现状及展望[J].非金属矿, 2005(S1):1-8. https://www.wenkuxiazai.com/doc/76b2340deff9aef8941e0695-3.html

[2] 申继学, 马鸿文.高岭土资源及高岭石合成技术研究进展[J].硅酸盐通报, 2016(4):1150-1158. http://www.cqvip.com/QK/90627X/201604/668865612.html

[3] 张凌燕, 张丹萍, 王浩, 等.广东砂质高岭土除铁增白试验研究[J].非金属矿, 2013(1):33-35, 49. https://www.wenkuxiazai.com/doc/db0617efaaea998fcd220ea2.html

[4] 管俊芳, 杨慧群, 高惠民, 等.淮北煤系高岭土增白实验研究[J].非金属矿, 2010(2):1-3, 10. https://www.wenkuxiazai.com/doc/6ad3ccfc700abb68a982fbd7.html

[5] 汪先三.我国高岭土开发利用现状及应用前景[J].中国非金属矿工业导刊, 2016(2):8-9, 19. http://www.cqvip.com/QK/92513A/201602/669422075.html

[6] 成岳, 欧克英, 胡张福.高岭土尾矿分级—浮选工艺的研究[J].矿产保护与利用, 1997(2):29-33, 57. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=0a1558da-8694-4cca-8694-347e1eb2d2f5

-

下载:

下载: