Study on the Curing Mechanism of Chloride Ions from Gold Tailings

-

摘要:

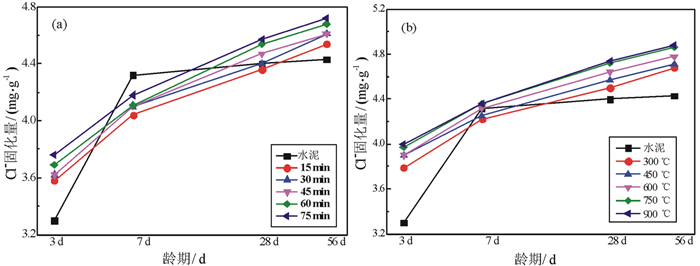

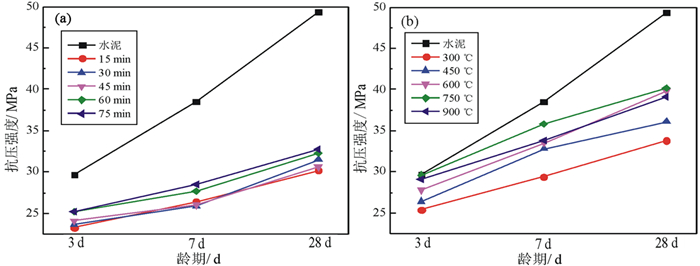

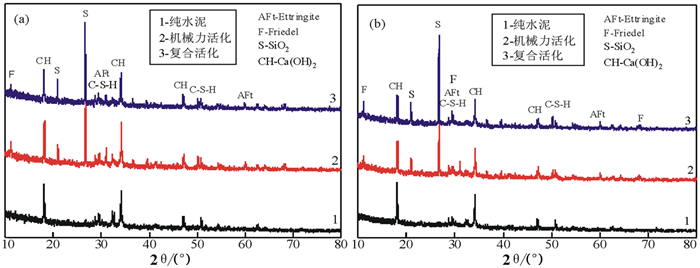

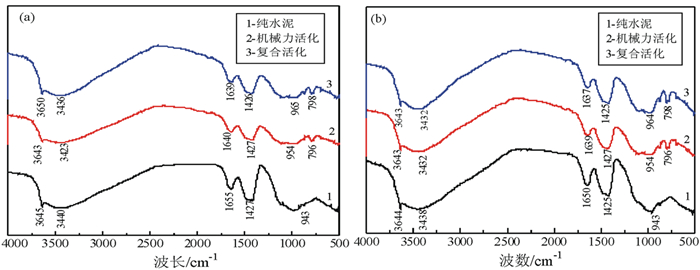

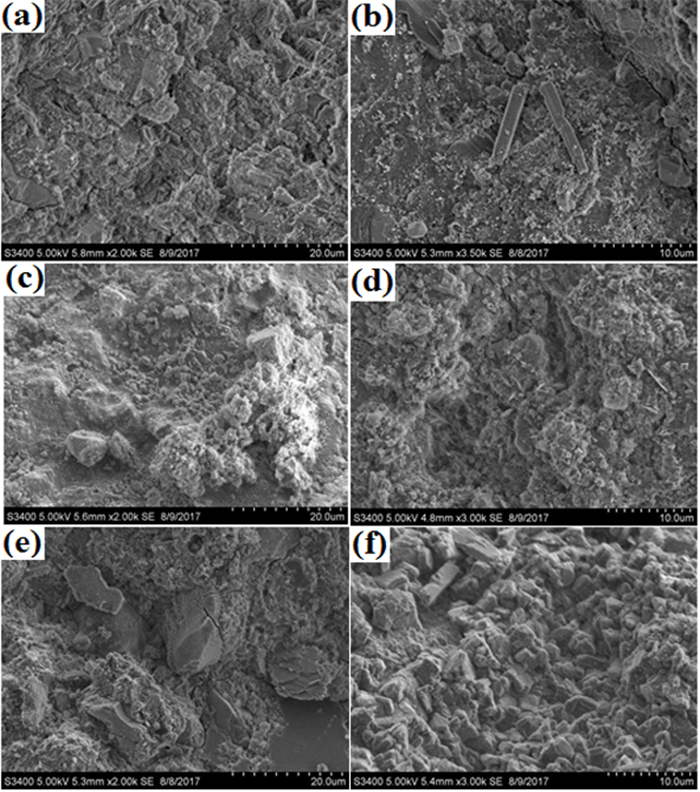

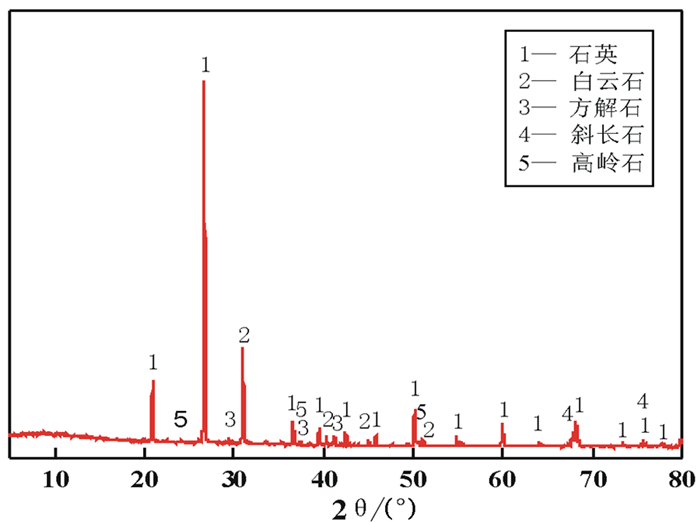

以火山灰质金尾矿为原材料,通过机械力活化和复合活化工艺(将机械力活化后的金尾矿进行热活化)激发尾矿硅铝活性,采用XRD、SEM、FT-IR测试手段测试水化产物,分析了胶凝材料水化机理及其对氯离子的固化机理。试验结果表明:由粉磨60 min再经750℃热活化1 h的金尾矿粉组成的胶凝材料固氯效果良好,胶砂块力学性能更加优异,活性尾矿粉的掺入促进了铝酸三钙(C3A)、铁铝酸四钙(C4AF)等矿物与氯离子化学结合生成Friedel盐的能力,同时掺入复合活化金尾矿粉的试样中有更多能吸附氯离子的硅酸钙凝胶(C-S-H)和钙矾石(AFt)产物,试样密实度提高的同时其固化氯离子的能力也提升。

Abstract:Using the pozzolanic gold tailings as the main raw materials, mechanical grinding and chemical activations were used to stimulate the pozzolanic activity of gold tailings, where the gold tailings are treated by mechanical activation and then thermal activation). Hydration mechanism of cementing material and its curing mechanism of chloride ions are analyzed by X-ray diffraction analysis (XRD), Fourier transform infrared spectroscopy (FT-IR), and scanning electron microscope (SEM). The results show that the gold tailings treated at the conditions of grinding 60 min and heating 750℃, has a favorable effect of chlorine fixation and mechanical properties. The highly active tailings promote the C3A, C4AF to combine with chlorine ions and produce more Friedel salt. In addition, more C-S-H gels and ettringite (AFt) hydration products appear with the addition of active tailings, which makes the structure of the hardened slurry dense and have good chlorine retention ability.

-

Key words:

- gold tailings /

- cementitious materials /

- C-S-H /

- AFt /

- curing mechanism

-

-

表 1 原材料的化学成分 /%

Table 1. Chemical compositions of raw materials

成分 SiO2 Al2O3 TiO2 Fe2O3 CaO MgO MnO SO3 K2O LOI 金尾矿 80.74 2.45 0.07 1.23 5.27 1.39 0.08 0.08 0.38 6.09 水泥 21.80 4.55 — 3.45 64.40 2.90 — 2.45 — 1.27 表 2 水泥净浆及砂浆配合比

Table 2. Mix proportions of cement paste and cement mortar

样品 水胶比 配合比/% 水泥 机械力活化尾金矿粉 复合活化金尾矿粉 标准砂 A1 0.4 100 — — — B1 70 30 — — C1 70 — 30 — A2 0.5 100 — — 300 B2 70 30 — 300 C2 70 — 30 300 -

[1] Michael D A T, Phil B B. Modelling cholride diffusion in concrete effect of fly-ash and slag[J]. Cement and Concrete Research, 1999(29):487-495.

[2] Tang L, Nilsson L O. Chloride binding capacity and binding isotherms of OPC pastes and mortars[J]. Cement and Concrete Research, 1993, 23(2):247-253. doi: 10.1016/0008-8846(93)90089-R

[3] 胡融刚. 钢筋/混凝土体系腐蚀过程的电化学研究[D]. 厦门: 厦门大学, 2004.

http://dspace.xmu.edu.cn/handle/2288/35173 [4] 梁哲兵. 氯离子入侵水泥基材料过程分析[D]. 天津: 河北工业大学, 2012.

[5] Zibara H. Binding of external chloride by cement pastes[D]. Toronto: University of Toronto, 2001.

[6] 勾密峰, 管学茂, 张海波.钙矾石结合氯离子能力的研究[J].材料导报, 2013, 27(5):136-139. http://d.old.wanfangdata.com.cn/Periodical/cldb201310034

[7] 余红发, 翁智财, 孙伟.矿渣掺量对混凝土氯离子结合能力的影响[J].硅酸盐学报, 2007, 35(6):801-806. doi: 10.3321/j.issn:0454-5648.2007.06.028

[8] 刘斌云, 李凯, 赵尚传.复掺粉煤灰和硅灰对混凝土抗氯离子渗透性和抗冻性的影响研究[J].混凝土, 2011(11):83-85. doi: 10.3969/j.issn.1002-3550.2011.11.025

[9] 胡红梅, 马保国.矿物功能材料改善混凝土氯离子渗透性的试验研究[J].混凝土, 2004(2):16-20. http://d.old.wanfangdata.com.cn/Periodical/hnt200402006

[10] 谢友均, 马昆林, 龙广成, 等.矿物掺合料对混凝土中氯离子渗透性的影响[J].硅酸盐学报, 2006(11):1345-1350. doi: 10.3321/j.issn:0454-5648.2006.11.011

[11] 胡红梅. 矿物功能材料对混凝土氯离子渗透性影响的研究[D]. 武汉: 武汉理工大学, 2002.

http://cdmd.cnki.com.cn/Article/CDMD-10497-2002110737.htm [12] 中国地质调查局. 中国矿产资源报告(2017)亮点纷呈[N]. 中国矿业报, 2017-09-29(002).

[13] 谭明洋, 吕宪俊, 姜梅芬, 等.某金矿尾矿用作水泥混合材的试验研究[J].黄金, 2015, 36(4):78-82. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=huangj201504025

[14] Ye D D, He W, Li Z, et al. Functional substitution of coordination polyhedron in crystal structure of silicates[J]. Science in China, Ser. D, 2002, 45(8):702-708. doi: 10.1007/BF02878427

[15] 勾密峰, 管学茂.水泥基材料固化氯离子的研究现状与展望[J].材料导报, 2010, 24(6):124-127. http://d.old.wanfangdata.com.cn/Periodical/cldb201011028

[16] 曹青, 谭克锋.水泥基材料氯离子固化能力的研究[J].武汉理工大学学报, 2009, 31(6):24-27. doi: 10.3963/j.issn.1671-4431.2009.06.007

[17] Aryac, Buenfeld N R, Newman J B. Factors influencing chloride binding in concrete[J]. Cem Concr Res, 1990, 20(2):291-300. doi: 10.1016/0008-8846(90)90083-A

[18] Zibara H, Hooton R D. Influence of the C/S and C/A ratios of hydration products on the chloride ionbinding capacity of lime-SF and lime-MK mixtures[J]. Cem Concr Res, 2008, 38:422. doi: 10.1016/j.cemconres.2007.08.024

[19] 王晓刚, 史才军, 何富强, 等.氯离子结合及其对水泥基材料微观结构的影响[J].硅酸盐学报, 2013, 41(2):187-198. http://d.old.wanfangdata.com.cn/Periodical/gsyxb201302011

[20] Hanna R A, Barrie P J, Cheeseman C R, et al. Solid state Si and 27Al NMR and FTIR study of cement pastes containing industrial wastes and organics[J]. Cem Concr Res, 1995, 25(7):1435. doi: 10.1016/0008-8846(95)00138-3

[21] Yu P, Kirkpatrick R J, Poe B, et al. Structure of calcium silicate hydrate (C-S-H):nearmid and farinfrared spectroscopy[J]. Journal of the American Ceramin Society, 1999, 82(3):742-748. http://d.old.wanfangdata.com.cn/Periodical/gsyxb201012023

-

下载:

下载: