Study on the Influence of Central Cone Structure on Flow Field and Separation Efficiency of Hydrocyclone

-

摘要:

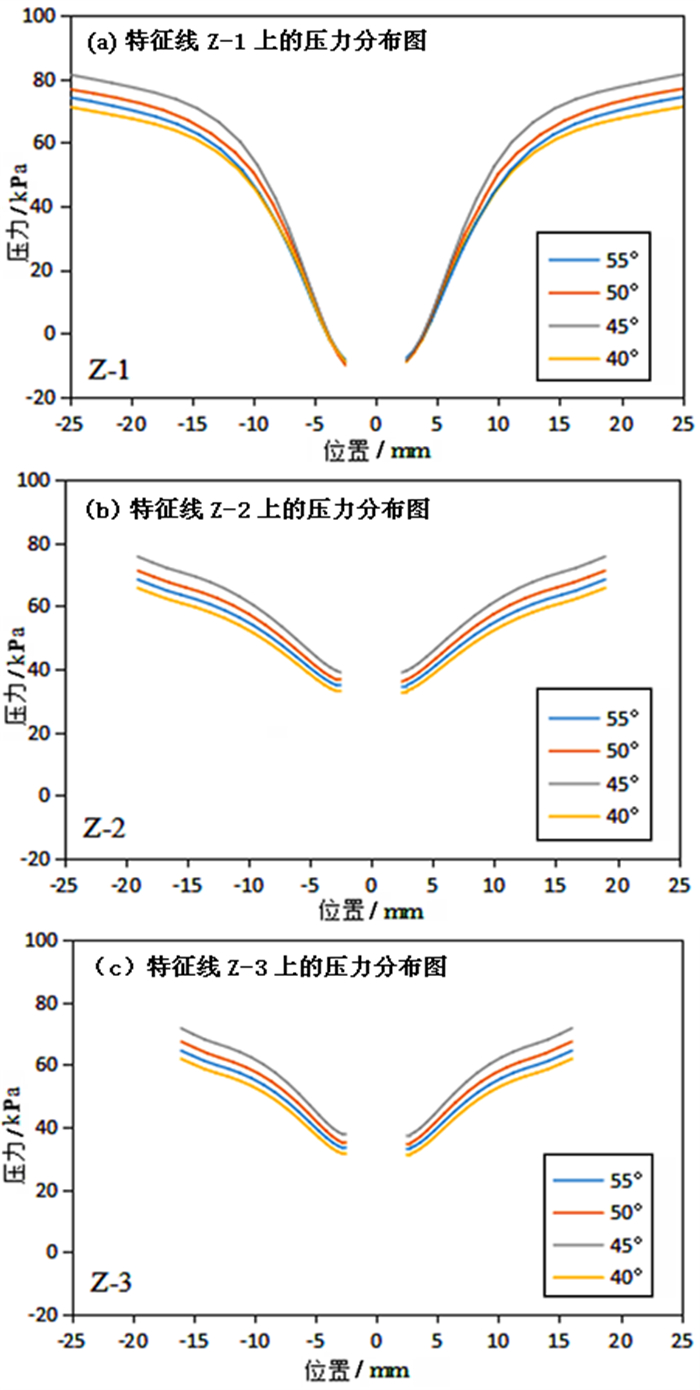

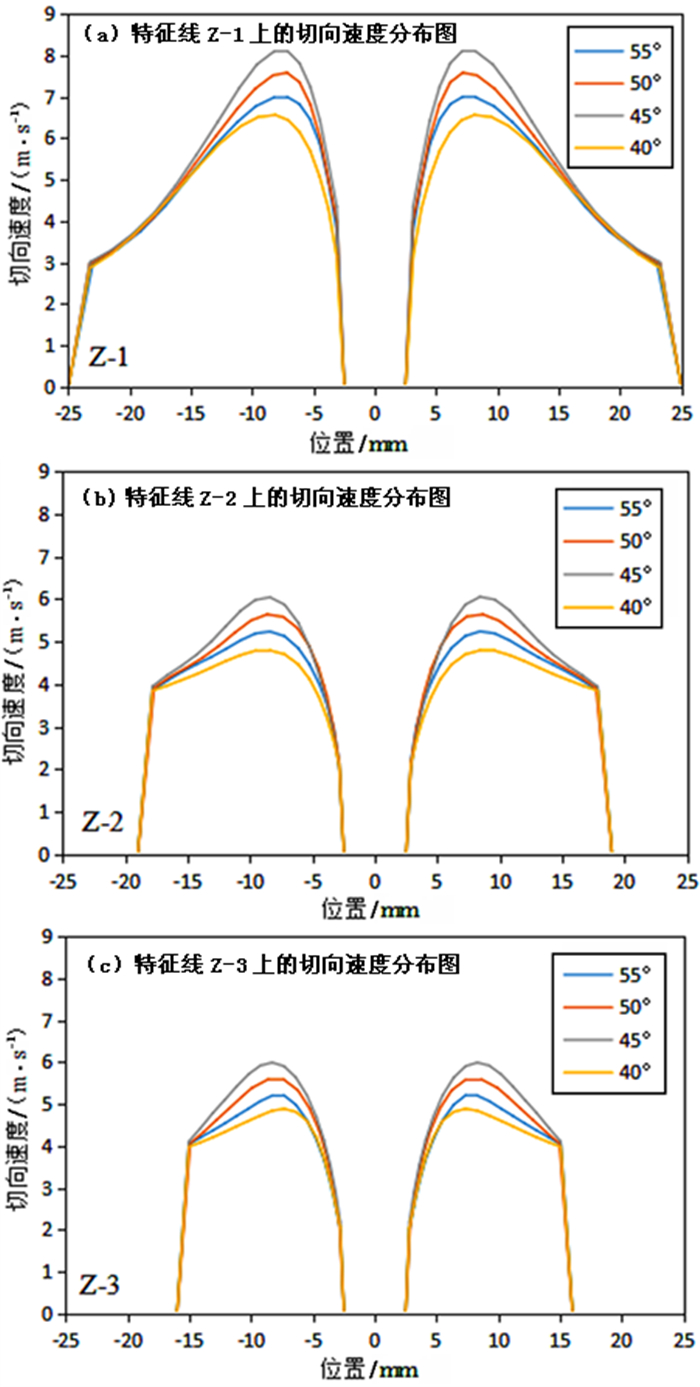

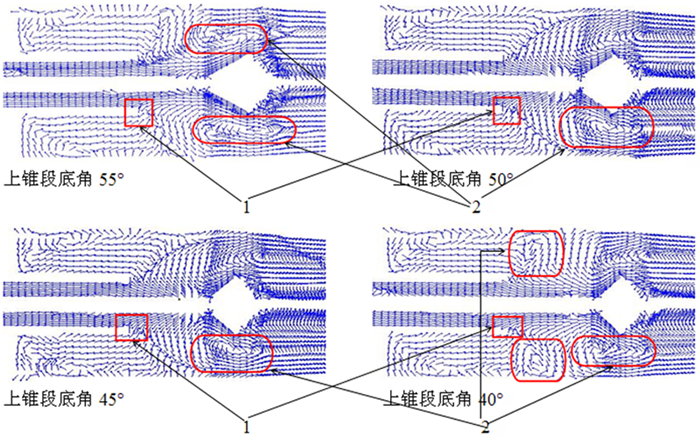

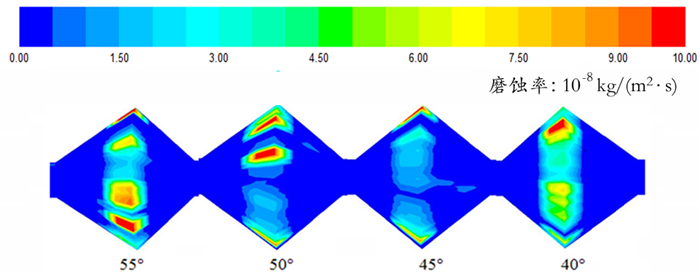

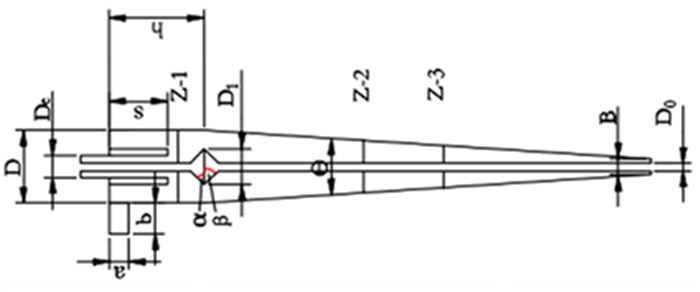

使用计算流体力学软件FLUENT15.0对中心锥上锥段底角为40°、45°、50°、55°水力旋流器进行了数值模拟,通过数值分析研究中心锥结构对水力旋流器内流场及分离效率影响,并考虑中心锥结构的磨损情况。模拟结果表明:适当的减小上锥段底角能提高分离效率,并改善上锥段的磨损情况,而过小的上锥段底角反而会降低分离效率,加重上锥段的磨损情况,说明中心锥上锥段底角在40°~50°之间存在着一个最佳角度,该角度能够得到较高的分离效率以及较小的磨损。模拟结果也为进一步优化中心锥结构提供了参考。

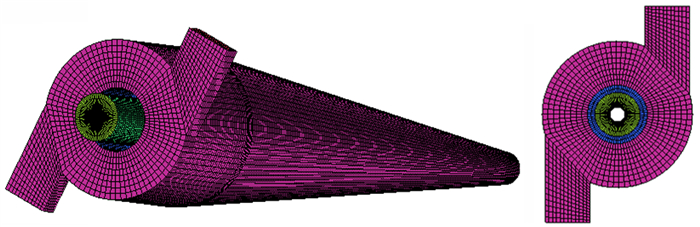

Abstract:FLUENT 15.0, a computational fluid dynamics software, was used to numerically simulate the hydrocyclone with 40°, 45°, 50° and 55° of the upper cone angle of the central cone. The influence of central cone structure on flow field and separation efficiency in hydrocyclone are studied by numerical analysis, and taking into account the erosion status of the central cone structure.The simulation results indicate that proper reduction of the upper cone angle can improve the separation efficiency and improve the erosion status of the upper cone section, while too small upper cone angle will reduce the separation efficiency and increase the erosion status of the upper cone section. It can be seen that there is an optimum angle between the 40° and 50° of the upper cone angle of the central cone, which can result in higher separation efficiency and less erosion. The simulation results also provide a reference for further optimization of the central cone structure.

-

Key words:

- hydrocyclone /

- computational fluid dynamics /

- central cone structure /

- erosion /

- separation efficiency

-

-

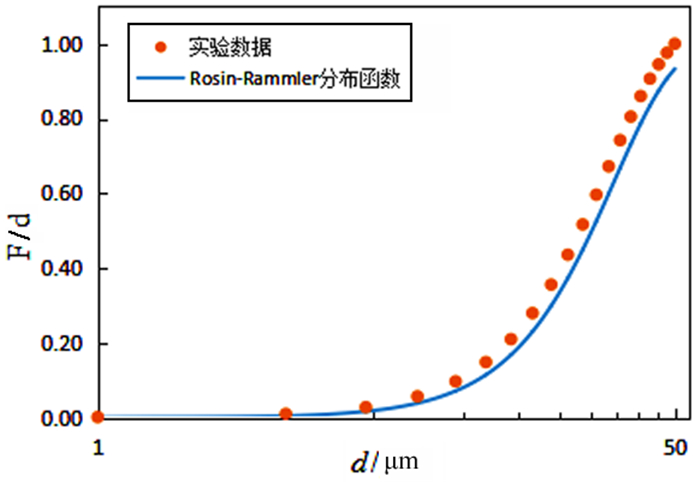

表 1 入口颗粒粒径累计分布

Table 1. Inlet particle size cumulative distribution

Range of sizes/μm d/μm F(d) < 1 1 0.002 < 3.58 3.58 0.010 < 6.16 6.16 0.028 < 8.74 8.74 0.057 < 11.32 11.32 0.097 < 13.89 13.89 0.149 < 16.47 16.47 0.210 < 19.05 19.05 0.280 < 21.63 21.63 0.356 < 24.21 24.21 0.436 < 26.79 26.79 0.517 < 29.37 29.37 0.596 < 31.95 31.95 0.672 < 34, 53 34, 53 0.742 < 37.11 37.11 0.805 < 39.68 39.68 0.860 < 42.26 42.26 0.907 < 44.84 44.84 0.945 < 47.42 47.42 0.976 < 50 50.00 1.000 表 2 不同上锥段底角旋流器分离效率

Table 2. Separation efficiency of different upper cone angle of hydrocyclone

角度/(°) 入口处进入的总颗粒数 溢流口逃逸的颗粒数 底流口捕集的颗粒数 分离效率/% 55 2 880 829 2 051 71.22 50 2 880 775 2 105 73.09 45 2 880 557 2 323 80.66 40 2 880 901 1 979 68.72 表 3 不同上锥段底角旋流器压降及分离效率对比

Table 3. Comparison of the pressure drop and separation efficiency of different upper cone angle of hydrocyclone

角度/(°) 55 50 45 40 压降/Pa 50 412.15 53 543.92 55 267.78 44 835.52 分离效率/% 71.22 73.09 80.66 68.72 -

[1] 何庆浪, 盛红光.大山选矿厂Krebs gMax水力旋流器的应用研究[J].矿产保护与利用, 2007(5):35-37. doi: 10.3969/j.issn.1001-0076.2007.05.009 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=4ff30406-29bf-4162-90bb-e1bab4570956

[2] 张鹏飞, 谢海云, 陈禄政, 等.水力旋流器在铁矿选矿中的应用及发展[J].新型工业化, 2016, 6(4):8-15. http://d.old.wanfangdata.com.cn/Periodical/xxgyh201604002

[3] 蔡有兴, 孙学强.水力旋流器超细分级研究[J].矿产保护与利用, 1998(3):38-41. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=ce0e3269-4f57-410e-9760-ec19ca87aecf

[4] 王志斌, 褚良银, 陈文梅, 等.基于高速摄像技术的旋流器空气柱特征研究[J].金属矿山, 2010(8):140-143. http://d.old.wanfangdata.com.cn/Periodical/jsks201008036

[5] Cullivan J C, Williams R A, Dyakowski T, et al. New understanding of a hydrocyclone flow field and separation mechanism from computational fluid dynamics[J]. Minerals engineering, 2004, 17(5):651-660. doi: 10.1016/j.mineng.2004.04.009

[6] 崔宝玉, 魏德洲, 翟庆祥, 等.水力旋流器内部流场的数值研究[J].东北大学学报(自然科学版), 2014, 35(6):894-897. doi: 10.3969/j.issn.1005-3026.2014.06.030

[7] 曹晓娟, 顾伯勤.旋流器内空气柱形成与发展及其对分离的影响[J].流体机械, 2009, 37(1):28-33. doi: 10.3969/j.issn.1005-0329.2009.01.007

[8] Chu L Y, Yu W, Wang G J, et al. Enhancement of hydrocyclone separation performance by eliminating the air core[J]. Chemical engineering & processing process intensification, 2004, 43(12):1441-1448. http://www.sciencedirect.com/science/article/pii/S0255270104000054

[9] 张恒, 王卫兵, 冯静安, 等.中心锥对水力旋流器性能影响[J].矿业研究与开发, 2016, 36(8):81-84. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QKC20162016101400056324

[10] 梁政, 吴世辉, 任连城.论水力旋流器流场数值模拟中湍流模型的选择[J].天然气工业, 2007(3):119-121, 161. doi: 10.3321/j.issn:1000-0976.2007.03.040

[11] 戴丽燕.关于Rosin-Rammler粒径分布函数的研究[J].有色矿冶, 2001, 16(3):15-17. doi: 10.3969/j.issn.1007-967X.2001.03.005

[12] 苏劲, 袁智, 侍玉苗, 等.水力旋流器细粒分离效率优化与数值模拟[J].机械工程学报, 2011, 47(20):183-190. http://d.old.wanfangdata.com.cn/Periodical/jxgcxb201120028

-

下载:

下载: