Experimental Research on Processing of a Silver-bearing Copper Ore in Inner Mongolia

-

摘要:

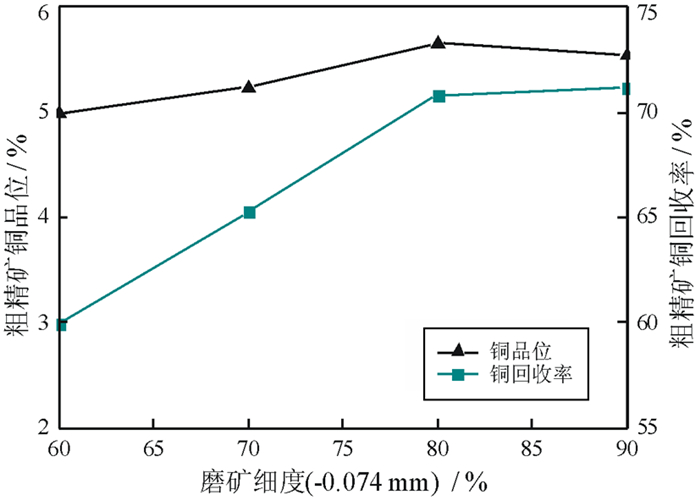

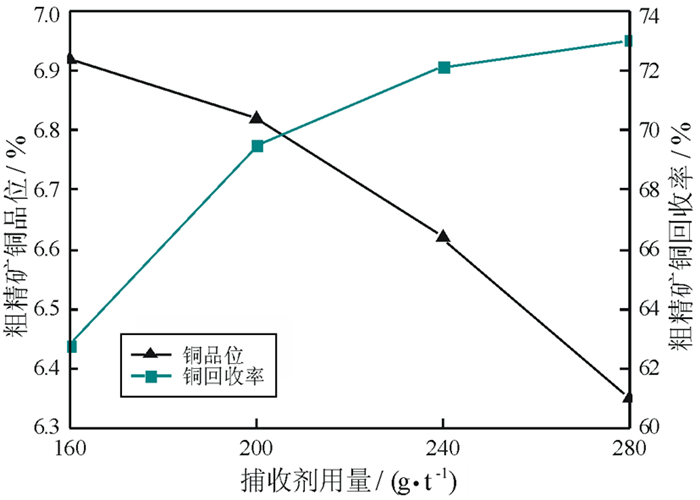

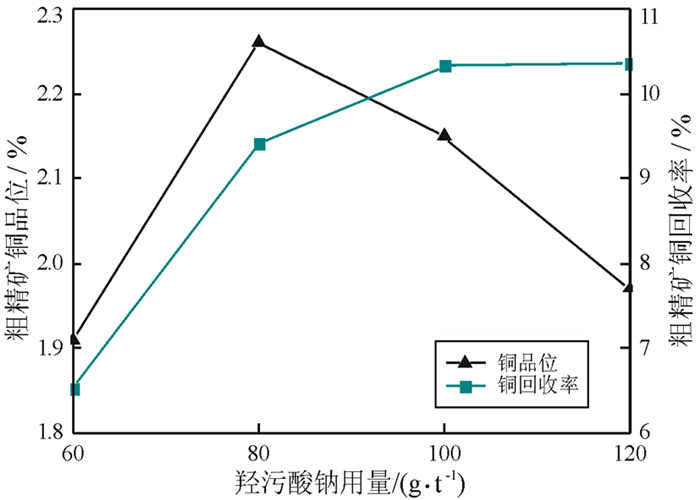

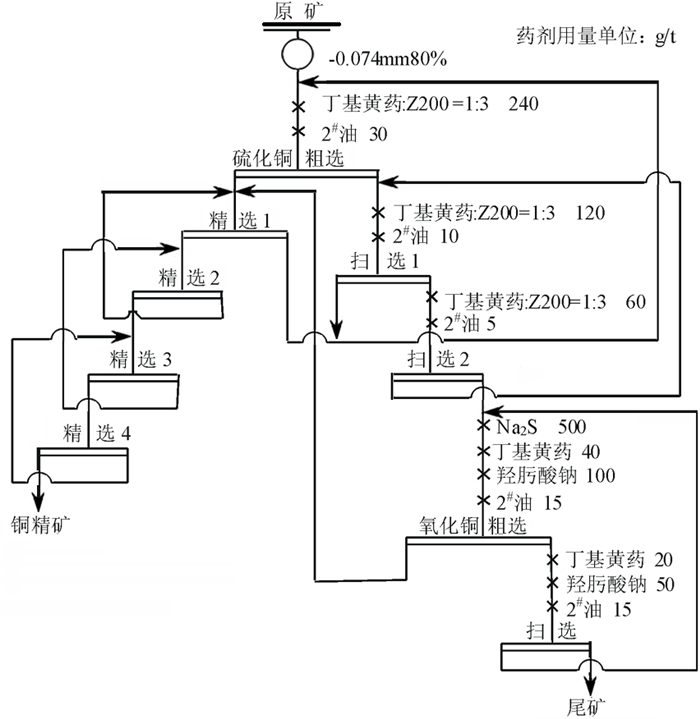

内蒙古某含银铜矿石,由于其铜氧化率达20.16%,采用常规浮选工艺回收率较低。针对这种情况,采用优先浮选硫化铜后浮选氧化铜的原则流程,以丁基黄药与Z200质量比为3 GA6FA 1的组合捕收剂为硫化铜的捕收剂,以Na2S为氧化铜调整剂,采用丁基黄药与羟肟酸钠混合捕收剂为氧化铜捕收剂。在磨矿细度为-0.074 mm占80%的条件下进行闭路试验,硫化铜经1次粗选和2次扫选,氧化铜经1次粗选1次扫选,所获得的硫化铜和氧化铜粗精矿混合产物经过4次精选,最终可获得铜品位为19.18%、银品位为2 308 g/t,铜回收率为80.90%、银回收率为81.03%的铜精矿产品。

Abstract:Due to the copper oxidation rate of 20.16%, the low recovery is obtained by the conventional flotation processing of a silver-bearing copper ore in Inner Mongolia. In view of this situation, the principle of preferential flotation of copper sulfide minerals followed by flotation of copper oxide minerals is adopted. The combined collector of butyl xanthate and Z200 with a mass ratio of 3 GA6FA 1 is used for copper sulfide mineral collector, Na2S is used for copper oxide minerals regulator, and the mixture of butyl xanthate and Sodium hydroxamic acid is used for copper oxide minerals collector. By the closed-circuit test consisting of one roughing and two scavenging for copper sulfide minerals, of one roughing and one scavenging for copper oxide minerals and of four cleaning for mixing rough concentrate of copper sulfide and copper oxide minerals. The copper concentrate can be obtained with the copper grade of 19.18%, recovery of 80.90%, silver grade 2 308 g/t and its recovery of 81.03%.

-

Key words:

- silver-bearing copper ore /

- copper oxide ore /

- combined collector /

- floatation

-

-

表 1 矿石化学成分分析结果 /%

Table 1. The chemical constitutions of ores

成分 Cu Pb Zn Ag Au S As SiO2 Al2O3 Fe2O3 K2O CaO MgO TiO2 含量 1.24 0.025 0.086 149 0.20 0.64 0.025 61.81 16.19 8.16 4.96 1.77 0.821 0.519 注:Au、Ag的含量单位为g/t。 表 2 原矿铜的化学物相分析结果 /%

Table 2. Chemical phase analysis results of cupper

铜物相 铜含量 分布率 硫化铜 0.99 79.84 氧化铜 0.25 20.16 总铜 1.24 100.00 表 3 捕收剂种类粗选试验精矿指标 /%

Table 3. Rougher results with different kinds of collectors

捕收剂种类 产率 铜品位 铜回收率 Z200 7.04 8.85 50.25 丁铵黑药 7.80 8.37 52.65 丁基黄药 8.25 8.59 57.15 丁基黄药: Z200=4 : 1 7.88 8.61 54.72 丁基黄药: Z200=3 : 1 11.25 6.92 62.78 丁基黄药: Z200=2 : 1 10.56 7.09 60.38 表 4 闭路流程试验结果 /%

Table 4. The results of closed circuit test

产品 产率 品位 回收率 Cu Ag Au Cu Ag Au 铜精矿 5.23 19.18 2308 0.85 80.90 81.03 22.67 尾矿 94.77 0.25 29.82 0.16 19.10 18.97 77.33 原矿 100.00 1.24 149.0 0.20 100.00 100.00 100.00 注:Au、Ag的含量单位为g/t。 -

[1] 胡为柏.浮选[M].北京:冶金工业出版社, 1982.

[2] 马龙秋, 周世杰.内蒙古某高硫铜铅锌多金属矿浮选试验[J].金属矿山, 2012(7):71-75. doi: 10.3969/j.issn.1001-1250.2012.07.018

[3] 王晓慧, 刘厚明, 陈晓青.某多金属矿石选矿试验及新药剂作用机理研究[J].金属矿山, 2011(10):99-100. http://d.old.wanfangdata.com.cn/Periodical/jsks201110023

[4] 杨君臣, 费涌出.我国锡矿产资源利用情况及问题[J].金属矿山, 2004(8):41-46. http://d.old.wanfangdata.com.cn/Conference/3204622

[5] 选矿设计手册编委会.选矿设计手册[M].北京:冶金工业出版社, 2007:81-84.

[6] 魏德洲.固体物料分选学:第3版[M].北京:冶金工业出版社, 2015:428-431.

[7] 见百熙.浮选药剂[M].北京:冶金工业出版社, 1985.

[8] 邵伟华, 杨波, 戈保梁.某铜铁矿厂降低铁精矿含硫的试验研究[J].矿冶工程, 2006(2):48-49. doi: 10.3969/j.issn.0253-6099.2006.02.012

[9] 张文彬.氧化铜矿浮选研究与实践[M].长沙:中南大学出版社, 1992.

[10] 杨秀媛, 姜广大.氧化铜矿的浮选[J].有色矿冶, 1992(1):15-17. http://d.old.wanfangdata.com.cn/Periodical/fjsk201701007

-

下载:

下载: