Progress in Resource Utilization and Harmless Treatment of Titanium and Aluminum Hazardous Wastes

-

摘要:

鉴于我国含钛和含铝危废引起的严重环境污染潜在风险和有价元素资源浪费等弊端,以硫酸法钛白粉行业产生的酸解废渣和铝冶炼过程产生的铝灰为典型代表,回顾了国内外近年来在钛铝危废资源利用和无害化方面取得的主要进展和成就。主要结论如下:(1)旋流器分离法和磁选法,是目前钛白行业处理酸解废渣应用最广的两种方法,但仍存在TiO2回收率不高和回收产品中TiO2品位低等问题;碱法虽解决了上述问题,实现了高效回收利用酸解废渣中钛资源,但其经济性差、规模小的现状有待进一步升级。(2)铝灰处理的研究繁多,主要集中在资源化利用方面,而其无害化处理才是彻底解决铝灰危废的根本手段,进一步制定铝灰的毒性检测标准和环境风险评估,加强对铝灰中氟和氮等元素的监测和无害化管理,实现铝灰资源化与无害化技术的推广是未来研究的方向。

Abstract:Because of serious environmental pollution potential risks and wasting marketable resources of hazardous solid waste in our country, we take tionite from sulfuric process and aluminum dross from aluminum smelting process as typical representatives to review their utilization technologies and harmless treatments at home and abroad. The main conclusions are as follows:(1) It is considered that the cyclone separation and magnetic separation are the two most widely used methods for the treatment of acid tionite in the titanium dioxide industry at present, but there are still problems such as low TiO2 recovery and low grade. Although alkali method has solved the above problems and realized efficient and green recovery of titanium resources from acid tionite. Its poor economy and small scale need to be further upgraded. (2) There are many studies on aluminum dross treatment, mainly focusing on the resource utilization, while harmless treatment is the fundamental mean to completely solve the aluminum dross hazardous waste. In the future, it is suggested to further improve the toxicity testing standards and environmental risk assessment of aluminum ash, strengthen the monitoring and harmless management of fluorine, nitrogen and other elements in aluminum ash, and realize the commercial industrialization promotion of the harmless technology.

-

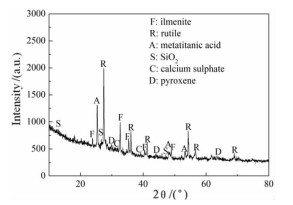

Key words:

- titanium white /

- acid solution waste residue /

- aluminum dross /

- hazardous solid waste /

- recycling /

- harmless treatment

-

-

表 1 烘干处理的酸解泥渣的化学组成 /%

Table 1. The chemical composition of dry tionite

Composition TiO2 Fe2O3 SiO2 SO3 CaO Al2O3 MgO MnO NiO AsO PbO Cr2O3 Content 35~45 8~16 21~28 7~15 3~5 2~4 1~3 0.3~1 <0.2 <0.1 <0.1 <0.1 -

[1] 宋曦韡.钛白粉酸解泥渣的危害特性及无害化处置研究[D].成都: 西南交通大学, 2016.

http://cdmd.cnki.com.cn/Article/CDMD-10613-1017059547.htm [2] 唐振宁.硫酸法钛白粉废副产物综合利用的最新进展[C].济南: 国家化工行业生产力促进中心钛白分中心会员大会, 2016.

http://www.wanfangdata.com.cn/details/detail.do?_type=conference&id=7701074 [3] 唐文骞, 宋冬宝.硫酸法钛白"三废"治理与效益[J].化工设计, 2016, 26(2):3-6. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgsj201602001

[4] 鲍善词, 李素芹, 张昌泉, 等.二次铝灰中氟、氯的浸出与回收分析[J].中国冶金, 2018, 28(10):24-28. http://d.old.wanfangdata.com.cn/Periodical/zgyj201810007

[5] 郭冉, 刘雄章, 李青达, 等.铝灰高值化回收利用技术现状[J].无机盐工业, 2017, 49(11):12-15. http://d.old.wanfangdata.com.cn/Periodical/wjygy201711003

[6] 李宗云, 许妍霞, 汪瑾, 等.硫酸法钛白酸解尾渣工艺矿物学特性分析[J].化工学报, 2015, 66(5):1947-1954. http://d.old.wanfangdata.com.cn/Periodical/hgxb201505043

[7] 王晓峰.钛铁矿酸浸废渣制备高效絮凝剂及应用研究[D].广州: 广东工业大学, 2012.

http://cdmd.cnki.com.cn/Article/CDMD-11911-1012362368.htm [8] 孟凡成.难处理金红石型钛资源碱法分解方法研究[D].北京: 中国科学院大学, 2016.

http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y3169093 [9] 李景胜.从钛白酸解废渣中回收钛矿的工艺研究[D].长沙: 中南大学, 2007.

http://cdmd.cnki.com.cn/Article/CDMD-10533-2007172106.htm [10] 张玉林.硫酸法铁白粉生产中三废的综合治理[J].化工环保, 1992(4):244-245. http://www.cnki.com.cn/Article/CJFDTotal-HGHB199204014.htm

[11] 吴永宝.钛白粉生产中酸性废渣的利用[J].上海有色金属, 1980(2):21-23. http://www.cnki.com.cn/Article/CJFDTotal-SHHA198002008.htm

[12] 李景胜, 陈晓青, 薛晓娟, 等.浮选法从钛白酸解废渣中回收TiO2的研究[J].稀有金属与硬质合金, 2006(1):14-17. doi: 10.3969/j.issn.1004-0536.2006.01.004

[13] Xu HF, Zhong H, Tang Q. A novel collector 2-ethyl-2-hexenoic hydroxamic acid:Flotation performance and adsorption mechanism to ilmenite[J]. Applied surface science, 2015, 353:882-889. doi: 10.1016/j.apsusc.2015.06.072

[14] 杜鑫.磁选技术在硫酸法钛白酸解泥渣中的应用初探[J].四川冶金, 2014, 36(1):71-74. doi: 10.3969/j.issn.1001-5108.2014.01.016

[15] 刘之远.矿物通论[M].北京:商务印书馆, 1956:159.

[16] 唐波, 许妍霞, 宋兴福, 等.钛白酸解尾渣旋流分级数值模拟与实验研究[J].华东理工大学学报(自然科学版), 2016, 42(4):454-459. http://d.old.wanfangdata.com.cn/Periodical/hdlgdxxb201604003

[17] 杨谦.钛白粉工业酸解废渣回收利用的研究[D].湘潭: 湘潭大学, 2007.

http://cdmd.cnki.com.cn/Article/CDMD-10530-2008180381.htm [18] 郭焦星.萃取分离法从钛白粉酸解废渣中回收钛铁矿[J].有色金属(冶炼部分), 2012(8):21-24. doi: 10.3969/j.issn.1007-7545.2012.08.007

[19] 初景龙, 刘亚辉, 李晓霞, 齐涛.一种综合利用硫酸法钛白黑泥的方法: 201210237410.9[P].2012-07-09.

[20] Meng F C, Xue T Y, Liu Y H, et al. Treatment of tionite residue from titanium oxide industry for recovery of TiO2 and removal of silica[J]. Hydrometallurgy, 2016, 161:112-116. doi: 10.1016/j.hydromet.2016.02.001

[21] Meng F C, Xue T Y, Liu Y H, et al. Recovery of titanium from undissolved residue (tionite) in titanium oxide industry via NaOH hydrothermal conversion and H2SO4 leaching[J]. Transactions of nonferrous metals society of China, 2016, 26(6):1696-1705. doi: 10.1016/S1003-6326(16)64247-4

[22] Dondi M, Guarini G, Raimond M, et al. Recycling the insoluble residue from titania slag dissolution (tionite) in clay bricks[J]. Ceramics international, 2010, 36(8):2461-2467. doi: 10.1016/j.ceramint.2010.08.007

[23] Contreras M, Martín M I, Gázquez M J, et al. Valorisation of ilmenite mud waste in the manufacture of commercial ceramic[J]. Construction and building materials, 2014, 72(15):31-40. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=e82e743b142e984fda53e36f0c2a9d89

[24] Contreras M, Garcia-Diaz I, Gázquez M J, et al. Valorisation of waste ilmenite mud in the manufacture of sulphur polymer cement[J]. Journal of environmental management, 2013, 128:625-630. doi: 10.1016/j.jenvman.2013.06.015

[25] 王晓峰.钛铁矿酸浸废渣制备高效絮凝剂及应用研究[D].广州: 广东工业大学, 2012.

http://cdmd.cnki.com.cn/Article/CDMD-11911-1012362368.htm [26] 何林, 蒲灵.钛白粉酸解泥渣危险特性及处置研究[J].无机盐工业, 2015, 47(8):69-72. http://d.old.wanfangdata.com.cn/Periodical/wjygy201508018

[27] 周立志.利用二次固废制备硫铝酸盐水泥的试验研究与理论分析[D].济南: 山东大学, 2016.

http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y3036125 [28] 郑磊.铝灰髙效分离提取及循环利用研究[D].长沙: 中南大学, 2010.

http://cdmd.cnki.com.cn/Article/CDMD-10533-2010190244.htm [29] Manfredi O, Wuth W, Bohlinger I. Characterizing the physical and chemical properties of aluminum dross[J]. JOM, 1997, 49(11):48-51. doi: 10.1007/s11837-997-0012-9

[30] 李帅, 刘万超, 刘中凯, 等.铝灰处理技术现状及展望[J].有色金属(冶炼部分), 2018(10):29-34. http://d.old.wanfangdata.com.cn/Periodical/ysjs-yl201810007

[31] Jafari NH, Stark TD, Roper R. Classification and reactivity of secondary aluminum production waste[J]. Journal of hazardous, toxic, and radioactive waste, 2013, 18(4):1-11. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=2f8e9cec4975e5149f56433b44bea80b

[32] Schlesinger ME. Aluminum recycling[M]. 2nd edition. Boca Raton:CRC Press, 2013:228-229.

[33] 李远兵, 孙莉, 赵雷, 等.铝灰的综合利用[J].中国有色冶金, 2008, 37(6):63-67. doi: 10.3969/j.issn.1672-6103.2008.06.014

[34] Zhou B, Yang Y, Reuter M, et al. Modelling of aluminium scrap melting in a rotary furnace[J]. Minerals engineering, 2006, 19(3):299-308. doi: 10.1016/j.mineng.2005.07.017

[35] Zholnin A, Zakharov A, Novichkov S, et al. Peculiarities of aluminum dross melting in a laboratory tilting rotary furnace[C]//Light metals 2004. Chichester: John Wiley and Sons Ltd. 2010: 943-956.

[36] 李艳, 夏毅敏.热铝炉渣处理及高效冷却压滤机研制[J].湖南有色金属, 2004, 20(5):46-47. doi: 10.3969/j.issn.1003-5540.2004.05.015

[37] 钟华萍, 李坊平.从热铝灰中回收铝[J].铝加工, 2001, 24(1):54-55. doi: 10.3969/j.issn.1005-4898.2001.01.017

[38] Hwang J Y, Huang X, Xu Z. Recovery of metals from aluminum dross and salt cake aluminum dross and salt cake[J]. Journal of minerals & materials characterization & engineering, 2006, 5(1):47-62.

[39] 蔡艳秀.铝灰的回收利用现状及发展趋势[J].资源再生, 2007, 6(10):7-29. http://d.old.wanfangdata.com.cn/Periodical/ysjszsyly200710010

[40] Das B R, Dash B, Tripathy B C, et al. Production of η-alumina from waste aluminum dross[J]. Minerals Engineering, 2007, 20(3):252-258. doi: 10.1016/j.mineng.2006.09.002

[41] Mostafa M, Allahverdi A. Enhanced alumina recovery from secondary aluminum dross for high purity nanostructured γ-alumina powder production:Kinetic study[J]. Journal of environmental management, 2018, 212(15):78-291. http://cn.bing.com/academic/profile?id=551396db72c52bcd2ba7915a316e09af&encoded=0&v=paper_preview&mkt=zh-cn

[42] 谢刚, 于站良, 田林, 等.一种铝灰的资源化利用方法: 103555955A[P].2014-02-05.

[43] 李菲, 郭学益, 田庆华.二次铝灰制备α-Al2O3工艺[J].北京科技大学学报, 2012, 34(4):383-389. http://d.old.wanfangdata.com.cn/Periodical/bjkjdxxb201204005

[44] 周扬民, 谢刚, 姚云, 等.碱烧结法处理铝灰制备氢氧化铝[J].轻金属, 2015(9):12-14. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=qjs201509003

[45] 康文通, 李建军, 李小云, 等.低铁硫酸铝生产新工艺研究[J].河北科技大学学报, 2001, 22(1):68-70. http://d.old.wanfangdata.com.cn/Periodical/hbkjdx200101015

[46] 胡保国, 蒋晨, 赵海侠, 等.铝灰酸溶法制备聚合氯化铝[J].化工环保, 2013, 33(4):325-329. doi: 10.3969/j.issn.1006-1878.2013.04.010

[47] 韩文爱, 陈亚鹏, 张雪梅, 等.铝灰和电镀酸洗液制备聚合氯化铝铁[J].石家庄职业技术学院学报, 2014, 26(2):11-12. doi: 10.3969/j.issn.1009-4873.2014.02.003

[48] 赵斌南, 唐剑, 敬叶灵.一种从铝灰中回收氧化铝和氯盐、氟盐的方法: 103060566A[P].2013-04-24.

[49] Bruckard W J, Woodcock J T. Characterization and treatment of Australian salt cakes by aqueous leaching[J]. Minerals engineering, 2007, 20(15):1376-1390. doi: 10.1016/j.mineng.2007.08.020

[50] 崔维, 易武平, 蔡安.超声波强化浸出铝灰中氯的机理[J].过程工程学报, 2017, 17(4):757-762. http://d.old.wanfangdata.com.cn/Periodical/hgyj201704015

[51] 李家镜.利用铝灰制备Sialon材料的研究[D].上海: 上海交通大学, 2012.

http://cdmd.cnki.com.cn/Article/CDMD-10248-1013020687.htm [52] 刘瑞琼, 智利彪, 智国彪.利用铝灰低温冶炼制备棕刚玉[J].耐火材料, 2014, 48(2):145-146. doi: 10.3969/j.issn.1001-1935.2014.02.018

[53] 徐晓虹, 熊碧玲, 吴建锋, 等.废铝灰制备陶瓷清水砖的研究[J].武汉理工大学学报, 2006, 28(5):14-16, 23. doi: 10.3321/j.issn:1671-4431.2006.05.005

[54] 王文龙, 田伟, 段广彬, 等.完全以工业固废为原料制备硫铝酸盐水泥的研究与应用[J].水泥工程, 2015, 28(6):12-15. http://d.old.wanfangdata.com.cn/Periodical/sngc201506004

[55] 袁向红, 许晓路.炼铝废渣的综合利用试验[J].环境污染与防治, 2000, 22(1):37-39. doi: 10.3969/j.issn.1001-3865.2000.01.015

[56] 徐强强.二次铝灰渣免烧砖的研制[D].金华: 浙江师范大学, 2016.

http://cdmd.cnki.com.cn/Article/CDMD-10345-1016291274.htm [57] Ewais E M M, Khalil N M, Amin M S, et al. Utilization of aluminum sludge and aluminum slag (dross)for the manufacture of calcium aluminate cement[J]. Ceramics international, 2009, 35:3381-3388. doi: 10.1016/j.ceramint.2009.06.008

[58] Mailar G, Sujay R N, Sreedhara B M, et al. Investigation of concrete produced using recycled aluminium dross for hot weather concreting conditions[J]. Resource efficient technologies, 2016, 2(2):68-80. doi: 10.1016/j.reffit.2016.06.006

[59] Gupta VK, Ali I, Saini VK. Removal of chlorophenols from waste-water using red mud:An aluminum industry waste[J]. Environmental science & technology, 2004, 38(14):4012-4018. http://med.wanfangdata.com.cn/Paper/Detail/PeriodicalPaper_PM15298213

[60] 董文亮, 季晨曦, 张宏艳, 等.铝渣复合脱硫剂在KR铁水脱硫过程中的应用[J].钢铁研究学报, 2017, 29(1):44-49. http://d.old.wanfangdata.com.cn/Periodical/scyj201703006

[61] 李燕龙, 张立峰, 杨文, 等.铝灰用于钢包渣改质剂试验[J].钢铁, 2014, 49(3):17-23. doi: 10.3969/j.issn.1672-4224.2014.03.005

[62] 张洪, 王明勇, 丘关南, 等.用工业废铝渣和废酸制备聚合硫酸铝的研究[J].轻工科技, 2017(3):93-94. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QKC20172017041000085298

[63] Murayama N, Arimura K, Okajima N, et al. Effect of structure-directing agent on AlPO4-n synthesis from aluminum dross[J]. International journal of mineral processing, 2009, 93(2):110-114. doi: 10.1016/j.minpro.2009.07.002

[64] Kim J, Biswas K, Jhon KW, et al. Synthesis of AlPO4-5 and CrAPO-5 using aluminum dross[J]. Journal of Hazardous Materials, 2009, 169(1):919-925. https://www.sciencedirect.com/science/article/pii/S0304389409006062

[65] Li P, Guo M, Zhang M, et al. Leaching process investigation of secondary aluminum dross:The effect of CO2 on leaching process of salt cake from aluminum remelting process[J]. Metallurgical and materials transactions B, 2012, 43(5):1220-1230. doi: 10.1007/s11663-012-9678-7

[66] 刘吉.铝灰渣性质及其中的AlN在焙烧和水解过程中的行为研[D].沈阳: 东北大学, 2008.

http://cdmd.cnki.com.cn/Article/CDMD-10145-2010259167.htm [67] 周长祥, 王卿, 张文娟, 等.铝渣灰中氨氮的回收[J].矿产保护与利用, 2012(3):38-41. doi: 10.3969/j.issn.1001-0076.2012.03.010 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=779b6b92-609f-4d57-b279-9e2e45ff7c2c

[68] 张勇, 郭朝晖, 王硕, 等.响应曲面法对铝灰中AlN的水解行为[J].中国有色金属学报, 2016(4):919-927. http://d.old.wanfangdata.com.cn/Periodical/zgysjsxb201604025

[69] Li Q, Yang Q, Zhang G, et al. Investigations on the hydrolysis behavior of AlN in the leaching process of secondary aluminum dross[J]. Hydrometallurgy, 2018, 182:121-127. doi: 10.1016/j.hydromet.2018.10.015

[70] Fukumoto S, Hookabe T, Tsubakino H. Hydrolysis behavior of aluminum nitride in various solutions[J]. Journal of materials science, 2000, 35(11):2743-2748. doi: 10.1023/A:1004718329003

[71] Li P, Guo M, Zhang M, et al. Seetharaman, leaching process investigation of secondary aluminium dross:investigation of AlN hydrolysis behaviour in NaCl solution[J]. Mineral processing and extractive metallurgy, 2012, 21(3):140-146.

[72] Tenorio JAS, Espinosa DCR. Effect of salt/oxide interaction on the process of aluminum recycling[J]. Journal of Light Metals, 2002, 2(2):89-93. doi: 10.1016/S1471-5317(02)00027-5

[73] 戴翔, 焦少俊, 郑洋, 等.利用含氟盐熔剂产生的二次铝灰的危险特性分析[J].无机盐工业, 2018, 50(11):42-44. http://d.old.wanfangdata.com.cn/Periodical/wjygy201811011

[74] 周扬民.铝灰的无害化处理及综合利用研究[D].昆明: 昆明理工大学, 2014.

http://cdmd.cnki.com.cn/Article/CDMD-10674-1015539788.htm -

下载:

下载: