Research on Thermal Activation Pretreatment and Sulfuric Acid Leaching of Cobalt-Copper Sulfide Concentrates from Congo (Kinshasa)

-

摘要:

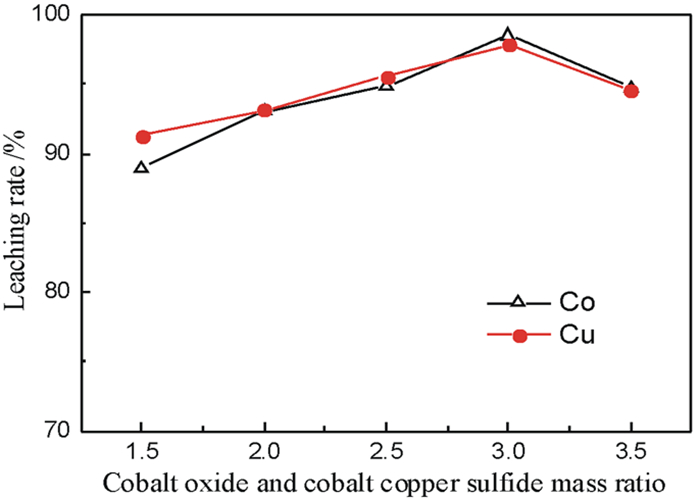

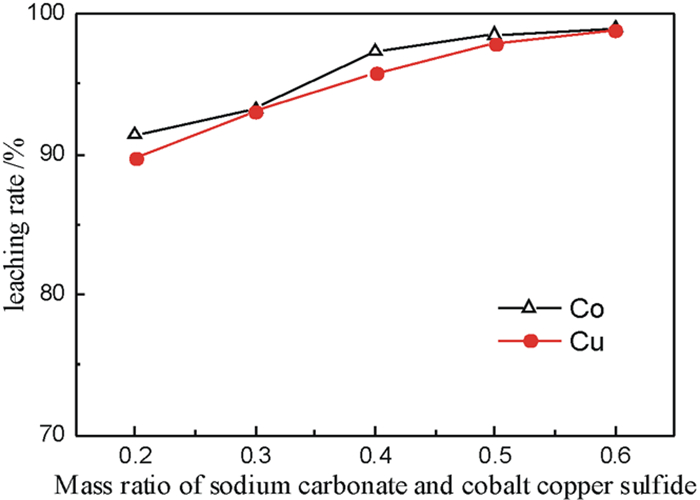

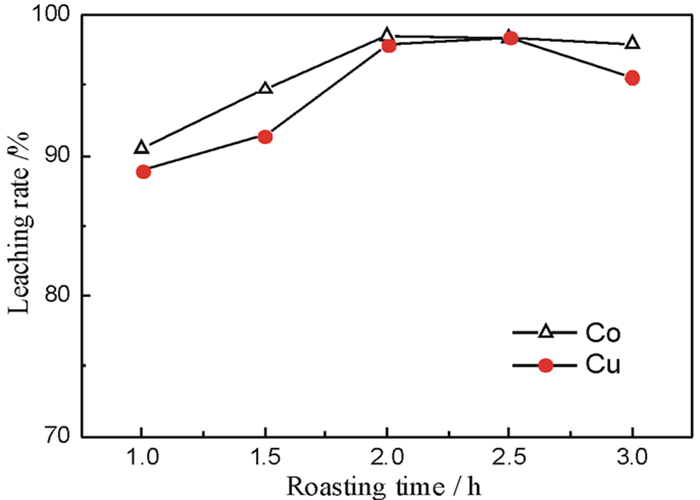

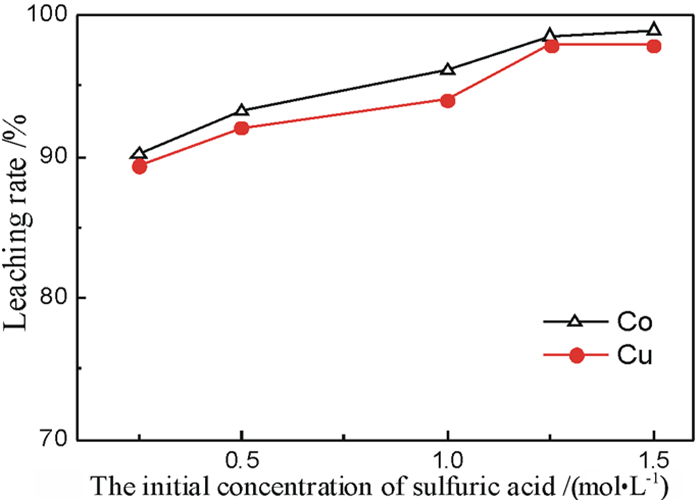

针对刚果(金)硫化钴铜精矿矿物组成复杂、直接酸浸效果较差等物料特性,研究了热活化-硫酸浸出工艺来强化有价金属铜、钴的回收,取得了理想的浸出效果。试验结果表明,当硫化钴铜精矿、氧化钴矿和无水碳酸钠质量配比为1 GA6FA 3 GA6FA 0.4,于500℃温度下热活化2 h,所得焙砂在初始硫酸浓度为1.25 mol/L,液固比为5 GA6FA 1 mL/g,浸出为温度80℃,搅拌转速为300 r/min的条件下反应时间5 h,钴的浸出率为98.51%、铜的浸出率为97.80%,试验采用的工艺可实现硫化钴铜精矿中钴和铜的高效回收利用。

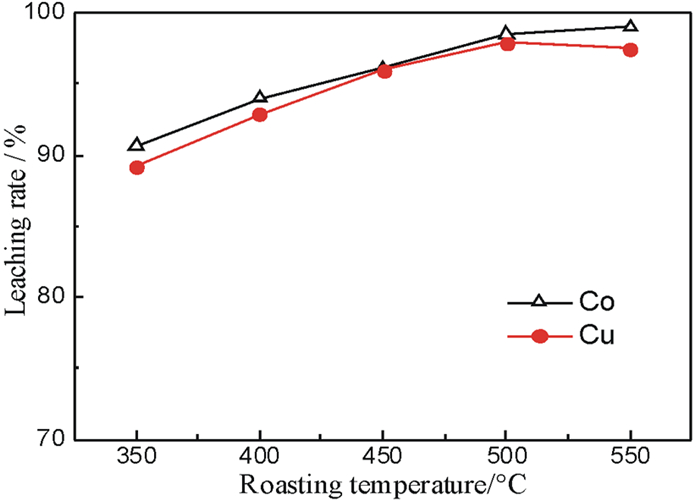

Abstract:Due to the complex mineral composition of Congo cobalt sulphide copper concentrate and the poor effect of direct acid leaching, the thermal activation pretreatment and sulfuric acid leaching process was investigated to strengthen the recovery of copper and cobalt. The test results showed that the leaching rate of cobalt and copper was 98.51% and 97.80% respectively obtained by the calcine generated from thermal activation at 500℃ for 2 h with the mass ratio of cobalt sulfide copper concentrate, cobalt oxide ore and anhydrous sodium carbonate of 1 GA6FA 3 GA6FA 0.4 reacting for 5 hours under the conditions of the initial concentration of sulfuric acid of 1.25 mol/L, liquid-solid ratio of 5 to 1 mL/g, leaching temperature of 80℃, and the stirring speed of 300 r/min. The process adopted in the experiment can realize the efficient recovery and utilization of cobalt and copper in the cobalt-copper sulfide concentrates.

-

Key words:

- copper-cobalt sulfide concentrates /

- cobalt oxide mine /

- thermal activation /

- sulfuric acid /

- leaching

-

-

表 1 硫化钴铜矿中主要元素含量 /%

Table 1. Main chemical composition of copper-cobalt sulfide concentrates

Co Cu Fe Ca Ni Mn Mg Zn S 8.45 20.94 15.65 0.36 0.47 0.09 1.84 0.01 16.74 表 2 氧化钴矿中主要元素含量/%

Table 2. Main chemical composition of cobalt oxide mine

Co Cu Fe Ca Ni Mn Mg Zn S 12.15 1.08 1.70 0.20 0.05 0.96 0.75 0.01 0.11 表 3 平行试验结果

Table 3. Results of parallel experiments

Leaching rate Co/% Cu/% 1 98.49 98.38 2 98.38 97.53 3 98.65 97.48 Average 98.51 97.80 -

[1] 刘全文, 沙景华, 闫晶晶, 等.中国钴资源供应风险评价与治理研究[J].中国矿业, 2018(1):50-56. http://d.old.wanfangdata.com.cn/Periodical/zgky201801011

[2] 孔令强.刚果(金)某难选铜钴矿浮选试验研究[J].矿冶工程, 2013, 33(3):58-61. doi: 10.3969/j.issn.0253-6099.2013.03.016

[3] 月日辉.复杂高硅钴白合金碱焙烧脱硅预处理[J].中国有色金属学报, 2012(10):2916-2923. http://d.old.wanfangdata.com.cn/Periodical/zgysjsxb201210033

[4] 孙留根, 王云, 袁朝新, 等.铜钴精矿焙烧浸出试验研究[J].有色金属(冶炼部分), 2012(8):14-16. doi: 10.3969/j.issn.1007-7545.2012.08.005

[5] 李鑫, 周韫, 王含渊.刚果(金)某硫化铜钴精矿沸腾焙烧试验研究[J].矿冶工程, 2015, 35(2):129-131. doi: 10.3969/j.issn.0253-6099.2015.02.032

[6] 黄胜, 张磊, 王海北, 等.复杂硫化钴矿加压浸出工艺研究[J].有色金属(冶炼部分), 2010(1):2-4. doi: 10.3969/j.issn.1007-7545.2010.01.001

[7] 邓永贵.硫化钴铜精矿加压氧浸研究[J].世界有色金属, 2017(6):199-202.

[8] Liu W, Yang H Y, Song Y, et al. Catalytic effects of activated carbon and surfactants on bioleaching of cobalt ore[J]. Hydrometallurgy, 2015, 152:69-75. doi: 10.1016/j.hydromet.2014.12.010

[9] Yang C, Qin W, Lai S, et al. Bioleaching of a low grade nickel-copper-cobalt sulfide ore[J]. Hydrometallurgy, 2011, 106(1):32-37. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=b1422c3ffa092a643ff8db685e56aa54

[10] 余群波, 韦其晋, 郭持皓.非洲某铜钴精矿焙烧试验研究[J].中国资源综合利用, 2017(1):19-22. doi: 10.3969/j.issn.1008-9500.2017.01.009

[11] 兰玮锋, 米玺学.从氧化钴矿石中提取钴的试验研究[J].湿法冶金, 2008, 27(4):230-233. doi: 10.3969/j.issn.1009-2617.2008.04.010

[12] 张泽强, 罗鸣锐, 张汉泉, 等.硫化铜精矿的硫酸铵焙烧浸出[J].有色金属(冶炼部分), 2015(12):1-4. doi: 10.3969/j.issn.1007-7545.2015.12.001

[13] 赵洁婷, 郭兴敏.CuS氧化焙烧过程的实验研究[C]//第八届(2011)中国钢铁年会论文集. 2011.

-

下载:

下载: