Study on Process Mineralogy and Separation Technology of Titanium-Zirconium Rough Concentrate with Refractory Hematite in Malawi

-

摘要:

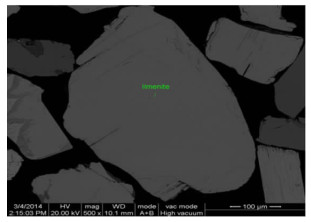

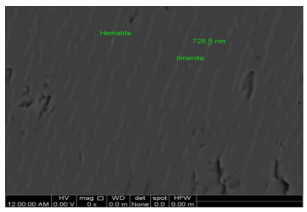

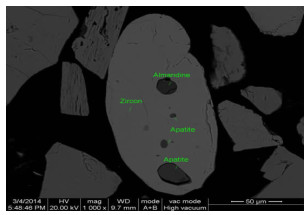

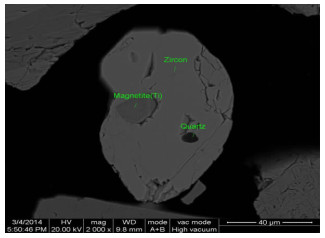

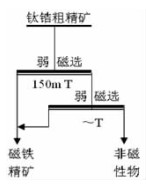

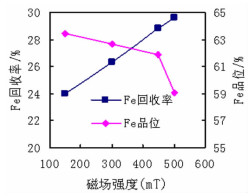

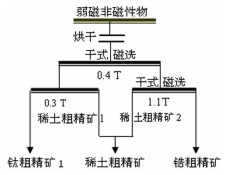

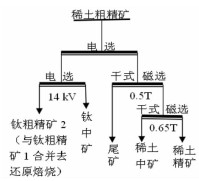

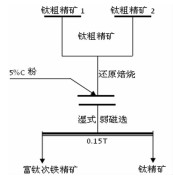

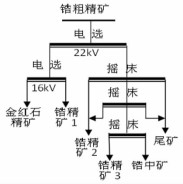

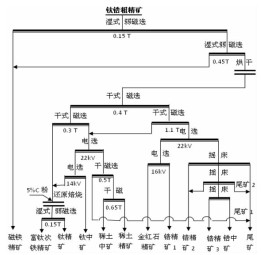

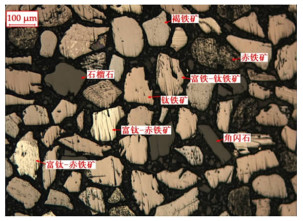

马拉维难选钛锆粗精矿中钛矿物分布率48%左右,但由于铁、钛矿物较复杂,可回收钛矿物种类多,磁性变化大,同时存在磁性、密度与钛铁矿相似的赤铁矿及一些比重较大的磁性脉石如石榴石和角闪石等,磁选时,赤铁矿、石榴石和角闪石均会进入钛精矿中而影响钛精矿品位,因此,采用常规磁选或重选方法很难获得合格钛精矿。基于MLA技术系统工艺矿物学研究基础上,根据矿物组成及各矿物之间的特性差异,针对马拉维某海滨砂钛锆粗精矿,利用赤铁矿还原焙烧后磁性增强、以及磁性脉石与钛矿物之间有电性差的特点,采用湿式弱磁选—干式磁选(—还原焙烧—湿式弱磁选)—电选—重选联合工艺流程,可有效分离易进入钛精矿中的赤铁矿及磁性脉石。最终获得TiO2含量49.17%、回收率66.36%的钛精矿,ZrO2含量分别为65.04%、60.78%和55.79%的三个锆精矿,锆精矿合计回收率89.28%;同时综合回收了金红石、磁铁矿和稀土。本研究解决了钛锆粗精矿中钛铁矿与赤铁矿、磁性脉石矿物难分离的关键技术问题,可为该类钛锆资源的有效利用提供技术途径。

Abstract:The content of titanium minerals in the refractory titanium-zircon rough concentrate in Malawi is about 48%. However, due to the complexity of iron and titanium distribution, there are many types of recyclable titanium minerals and the magnetic changes are large. Meanwhile, there are existing some hematite with similar magnetic and density to titanium and some magnetic gangues with large specific gravity such as garnet and amphibole. When magnetic separation is used, hematite, garnet and amphibole will enter the titanium concentrate affecting the grade of titanium concentrate. Therefore, it is difficult to obtain qualified titanium concentrate by conventional magnetic separation or gravity separation method. For a seashore sand-titanium-zirconium rough concentrate in Malawi, the research basis of process mineralogy by MLA technology system and the mineral composition and the difference of characteristics between minerals were obtained. According to the magnetic enhancement after hematite reduction roasting and the difference in electrical properties between magnetic gangue and titanium mineral, the process of "wet low intensity magnetic separation-dry magnetic separation (reduction roasting-wet low intensity magnetic separation)-electric separation-gravity separation was adopted, which can realize the effective separation of hematite and magnetic gangue which were easy to enter into titanium concentrate. Finally, the titanium concentrate with TiO2 content of 49.17% and recovery of 66.36% was obtained. Three zirconium concentrate with ZrO2 content of 65.04%, 60.78% and 55.79% was obtained, respectively. The total recovery of zirconium concentrate was 89.28%. Meanwhile, rutile, magnetite and rare earth were recovered comprehensively. This study solved the key technical problems of difficult separation of titanium and hematite and magnetic gangue minerals in titanium-zirconium coarse concentrate, and provided a technical way for the effective utilization of such titanium-zirconium resources.

-

Key words:

- ilmenite /

- hematite /

- zircon /

- rutile /

- rare earth /

- reduction roasting /

- combined flowsheet of ore dressing-metallurgy /

- MLA

-

-

表 1 钛锆粗精矿多元素分析结果

Table 1. Analysis results of multi-elements of titanium-zircon rough concentrate

成分 TiO2 Zr(Hf)O2 REO Nb2O5 TFe P2O5 Al2O3 CaO MgO MnO SiO2 K2O Na2O CeO2 Sc / 含量/% 29.43 1.70 0.106 0.036 39.82 0.06 2.73 0.35 2.12 0.39 12.57 0.038 0.067 0.036 0.008 / 表 2 钛锆粗精矿钛物相分析结果

Table 2. Analysis results of titanium phase of titanium-zircon rough concentrate

钛物相 磁性铁中TiO2 钛铁矿中TiO2 金红石/白钛石中TiO2 赤铁矿及硅酸盐中TiO2 总TiO2 含量/% 0.58 24.54 0.69 4.01 29.82 分布率/% 1.95 82.29 2.31 13.45 100.00 表 3 钛锆粗精矿矿物含量分析结果

Table 3. Analysis results of minerals content of titanium-zircon rough concentrate

矿物 含量/% 矿物 含量/% 矿物 含量/% 磁铁矿 13.619 尖晶石 0.052 符山石 0.032 钛磁铁矿 1.048 铬铁矿 0.060 橄榄石 0.001 磁赤铁矿 2.043 钽铌铁矿 0.001 电气石 0.022 富钛赤铁矿 6.686 锆石 2.586 高岭土 0.173 赤铁矿 11.585 斜锆石 0.002 蓝晶石 0.143 富铁钛铁矿 12.990 石英 2.648 刚玉 0.003 钛铁矿 35.039 长石 0.392 方解石 0.006 褐铁矿 0.049 黑云母 0.006 磷灰石 0.158 金红石 0.336 角闪石 4.066 磁黄铁矿 0.000 白钛石 0.529 辉石 0.717 其他 0.010 榍石 0.031 铁铝榴石 4.684 合计 100.000 独居石 0.146 钙铝榴石 0.105 / / 磷钇矿 0.015 锰铝榴石 0.017 / / 表 4 钛锆粗精矿主要矿物粒度分布

Table 4. Grain size distribution of the main valuable minerals of titanium-zircon rough concentrate

粒级/mm 粒度分布/% 钛磁铁矿 磁铁矿/磁赤铁矿 赤铁矿/富钛赤铁矿 钛铁矿/富铁钛铁矿 金红石 白钛石 独居石 磷钇矿 锆石 +0.30 0.95 1.52 0.70 0.58 / / / / 0.93 -0.30+0.15 21.55 22.24 14.30 25.08 16.02 1.56 15.61 69.07 17.94 -0.15+0.075 48.13 59.04 60.49 57.23 55.75 36.54 54.13 20.81 62.48 -0.075+0.045 21.10 15.19 20.96 14.57 16.97 31.03 27.63 3.55 17.01 -0.045+0.02 5.95 1.66 2.69 2.09 7.12 21.03 2.30 5.83 1.42 -0.02+0.01 1.55 0.23 0.58 0.36 3.13 7.49 0.12 0.46 0.22 -0.01 0.77 0.12 0.28 0.09 1.01 2.35 0.21 0.28 0.00 合计 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 表 5 钛锆粗精矿中矿物在不同磁场中分布

Table 5. Minerals distribution of titanium-zircon rough concentrate in different magnetic fields

磁场/mT 产率/% 主要矿物组成 100 16.71 磁铁矿、钛磁铁矿、磁赤铁矿 240 34.57 富铁钛铁矿、钛铁矿,其次钛赤铁矿、赤铁矿 430 33.89 钛铁矿、赤铁矿、石榴石、角闪石 650 6.99 角闪石、石榴石,赤铁矿,少量钛铁矿 1 100 0.59 独居石,辉石、金红石、电气石、石榴石,锆石 非磁 7.25 锆石、石英,金红石 合计 100.00 表 6 全流程试验结果

Table 6. Test results of whole flowsheet

产品 产率/% 品位/% 回收率/% 总回收率/% Fe TiO2 ZrO2 REO Fe TiO2 ZrO2 REO 磁铁精矿 18.61 61.68 6.48 0.09 0.02 28.82 4.10 1.03 3.51 Fe 富钛次铁精矿 23.43 49.32 32.72 / / 29.02 26.05 / / 57.84 钛精矿 39.72 37.21 49.17 0.05 0.06 37.12 66.36 / / TiO2 金红石精矿 0.35 / 77.86 2.34 / / 0.92 0.48 / 67.18 锆精矿1 0.38 / 4.56 55.79 / / 0.06 12.47 / ZrO2 锆精矿2 1.12 / 0.82 65.04 0.04 / 0.03 42.85 / 89.28 锆精矿3 0.95 / 0.79 60.78 / / 0.03 33.96 / REO 稀土精矿 0.10 / 1.43 0.18 63.16 / 0.01 0.01 58.99 58.99 钛中矿 6.84 / 9.28 0.113 0.09 / 2.16 0.45 5.81 / 锆中矿 0.17 / 0.45 40.50 / / 0.00 4.05 / / 稀土中矿 0.49 / 10.89 0.16 0.41 / 0.18 0.05 1.90 / 总尾砂 7.84 / 0.38 0.69 / / 0.10 3.20 / / 钛锆粗精矿 100.00 39.82 29.43 1.70 0.106 100.00 100.00 100.00 100.00 / -

-

下载:

下载: