Electrochemical Pretreatment to Improve the Inhibition Effect of Citric Acid on Muscovite

-

摘要:

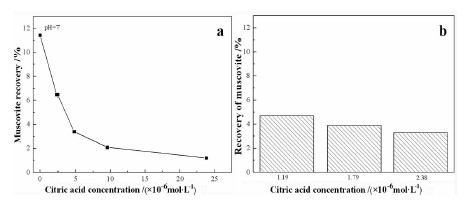

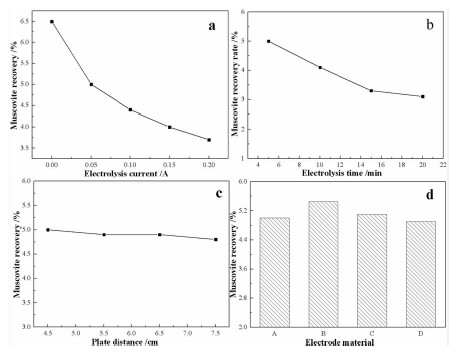

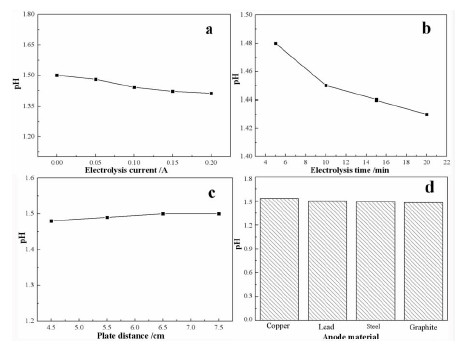

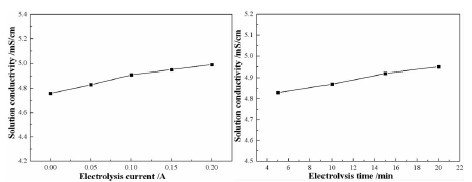

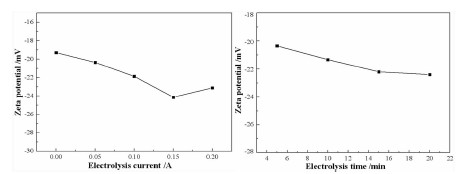

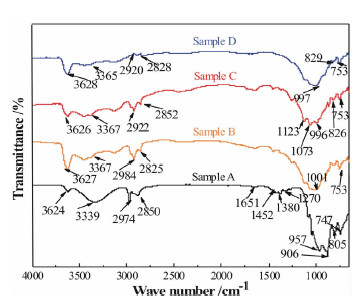

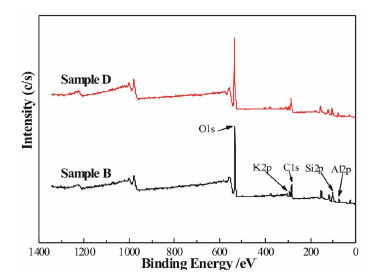

利用电化学预处理前后的柠檬酸进行白云母纯矿物浮选试验,采用XPS、Zeta电位和FITR等方法对白云母样品进行表征,在此基础上研究了油酸钠体系下电化学预处理的柠檬酸与白云母浮选行为的作用机理。结果表明,电化学预处理可明显改善柠檬酸对白云母选别效果,且在矿浆pH值为7、油酸钠浓度为9.20×10-4 mol/L的条件下,对浓度为2.38×10-6 mol/L的柠檬酸溶液进行电化学预处理,白云母回收率仅为3.4%。柠檬酸强化白云母抑制能力的原因在于:电化学预处理增大了柠檬酸的水解及电离程度,使溶液中有效抑制成分C6H7O7-和C6H6O72-的含量升高,强化其在白云母表面的吸附,削弱油酸根在云母表面的静电吸附,导致白云母可浮性下降。研究可为改善提高白云母的分选效率提供一种新思路,也为电化学预处理药剂在浮选中的应用提供一定的参考。

Abstract:The pure mineral flotation experiment of muscovite was carried out by using citric acid before and after electrochemical pretreatment, and the samples were characterized by XPS, Zeta potential and FITR. On this basis, the mechanism of electrochemical pretreatment of citric acid and muscovite flotation behavior under the sodium oleate system was investigated. The results indicated that electrochemical pretreatment could improve the separation effect of citric acid on muscovite. The muscovite recovery of only 3.4% was obtained by the electrochemical pretreatment of the citric acid solution with the concentration of 2.38×10-6 mol/L under the pulp condition of pH value of 7 and sodium oleate concentration of 9.20×10-4 mol/L. The phenomenon that the citric acid can enhance the floatability of muscovite can be explained as follow:the electrochemical pretreatment can increase the degree of hydrolysis and ionization of citric acid. The adsorption of the C6H7O7- and C6H6O72- on the surface of muscovite was enhanced, which correspondingly weakened the electrostatic adsorption of oleate on the surface of mica, resulting in the decrease in the floatability of muscovite. The study can provide a new idea to improve the separation efficiency of muscovite, and also provide a reference for the application of electrochemical pretreatment reagent in flotation.

-

Key words:

- electrochemical pretreatment /

- citric acid /

- muscovite /

- action mechanism

-

-

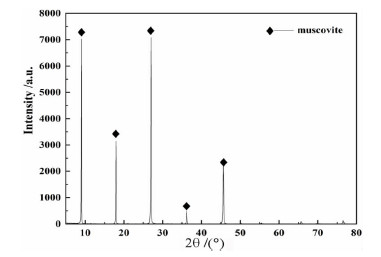

表 1 试样化学成分分析结果

Table 1. Results of chemical composition analysis of samples

Chemical Constituents SiO2 Na2O Al2O3 K2O Other Composition content (%) 48.16 0.72 32.50 10.62 8.00 表 2 不同白云母样品的作用条件

Table 2. Action conditions of different muscovite samples

Sample Numbers Reagent Concentration /(mol·L-1) Electrochemical Pretreatment Conditions Sodium Oleate Citric acid Electrolysis Current /A Electrolysis Time /min Plate Distance/cm Electrode Material Types(Anode-Cathodic) A 9.20×10-4 — — — — — B 9.20×10-4 2.38×10-5 — — — — C 9.20×10-4 2.38×10-5 0.05 5 4.5 graphite plate-graphite plate D 9.20×10-4 2.38×10-5 0.05 15 4.5 graphite plate-graphite plate 表 3 样品表面主要元素的电子结合能及相对含量

Table 3. Electron binding energy and relative content of major elements on the sample surface

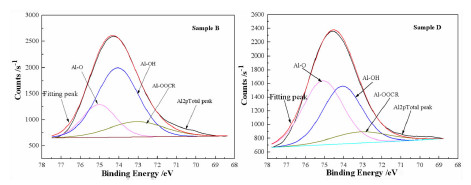

Sample number Al/% Si/% C1s/eV B 12.11 18.16 284.06 D 11.58 16.10 285.10 表 4 白云母表面Al的存在价键及比例

Table 4. Existing valence bond and proportion of Al on muscovite surface

Sample Number Al-OOCR Relative Content/% Al-OH Relative Content/% Al-O Relative Content/% B 17.50 59.71 22.79 D 11.18 41.57 47.25 -

[1] 赵军伟,姚卫红,王虎.硫化矿浮选电化学研究现状[J].矿产保护与利用,2003(4):32-36. doi: 10.3969/j.issn.1001-0076.2003.04.010 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=f103112b-a4ce-446f-bea0-da586810a9c1

[2] 李宁钧.硫化矿浮选电化学的理论研究状况[J].中国有色金属,2011(S1):68-70.

[3] 赵敏捷,方建军,李国栋.硫化铜矿电化学调控浮选应用与研究进展[J].矿冶,2016(5):15-18. doi: 10.3969/j.issn.1005-7854.2016.05.004

[4] Zhou G Y, Li W J, Chen Y, et al. Study on recovery of lead-zinc tailing ore by electrochemical flotation[J]. Applied Mechanics and Materials 2014, 675-677:1451-1454. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=10.4028/www.scientific.net/AMM.675-677.1451

[5] 张威,王宇斌,余乐,等.用电化学调控浮选方法提高某难选镍矿选矿指标[J].金属矿山,2015(5):93-96. doi: 10.3969/j.issn.1001-1250.2015.05.021

[6] Smith, L.K., Bruckard, W.J. These parathion of arsenic from copperina North parkes copper-gold ore using controlled-potential flotation[J]. International Journal of Mineral Processing. 2007(84):15-24. https://www.sciencedirect.com/science/article/abs/pii/S0301751607001020

[7] 张剑锋.电化学调控浮选在梅山选矿厂的应用研究[J].金属矿山,2008(7):46-48,60. doi: 10.3321/j.issn:1001-1250.2008.07.014

[8] 王宇斌,王妍,朱新峰,等.基于电化学浮选的钨铋粗精矿分离研究[J].有色金属(选矿部分),2020(1):48-54. doi: 10.3969/j.issn.1671-9492.2020.01.009

[9] 安士杰.电化学控制浮选在乌拉嘎金矿生产中的应用[J].黄金,2001(11):36-39. doi: 10.3969/j.issn.1001-1277.2001.11.010

[10] 欧阳坚,陈洁.电化学预处理水玻璃的作用探讨[J].矿产综合利用,1989(5):46-50. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000001939747

[11] 方霖,郭珍旭,刘长淼,等.云母矿物浮选研究进展[J].中国矿业,2015(3):131-136. doi: 10.3969/j.issn.1004-4051.2015.03.029

[12] 王宇斌,文堪,张鲁.利用铜离子改善油酸钠体系下白云母的可浮性[J].矿产保护与利用,2017(6):45-51. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=1d95c149-f87c-4bfa-9caf-38279fe2cd18

[13] 王宇斌,文堪,王望泊.DL-苹果酸对白云母可浮性的抑制机理[J].矿产保护与利用,2018(3):117-123. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=71df8ac1-996f-4380-ad20-5aa1db34ce6e

[14] 王宇斌,余乐,张威.酸性条件下十二胺体系中Fe3+对白云母可浮性的影响[J].矿产保护与利用,2015(6):40-45. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=b49fbfc0-b564-4c56-8263-94bedb681848

[15] 王宇斌,文堪,王望泊.柠檬酸对白云母可浮性的抑制机理[J].过程工程学报,2019,19(2):338-344. http://d.old.wanfangdata.com.cn/Periodical/hgyj201902014

[16] LiuWei-jun, Zhang Jie, Wang Wei-qing, et al. Flotation behaviors of ilmenite, titanaugite, and forsterite using sodium oleate as the collector[J]. Minerals Engineering, 2015(72):1-9. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=bb41b9285836299d6a6d5784930e72db

[17] NáJERA J J. Phase transition behavior of sodium oleate aerosol particles[J]. Atmospheric Environment, 2007(5):1041-1052. https://www.sciencedirect.com/science/article/abs/pii/S1352231006009502

[18] Meng Qing-you, Feng Qi-ming, Ou Le-ming. Effect of temperature on floatability and adsorption behavior of fine wolf ramite with sodium oleate[J]. Journal of Central South University, 2018(7):1582-1589. https://www.researchgate.net/publication/326669817_Effect_of_temperature_on_floatability_and_adsorption_behavior_of_fine_wolframite_with_sodium_oleate

-

下载:

下载: