Pilot-scale Study on Direct Reduction of High Phosphorus Oolitic Hematite by Rotary Hearth Furnace

-

摘要:

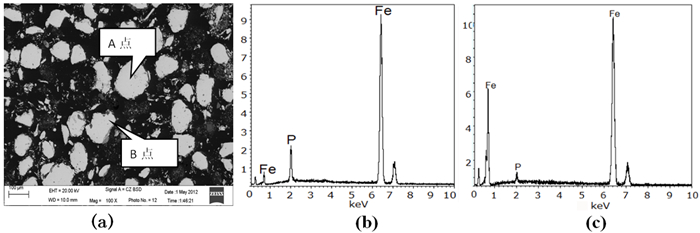

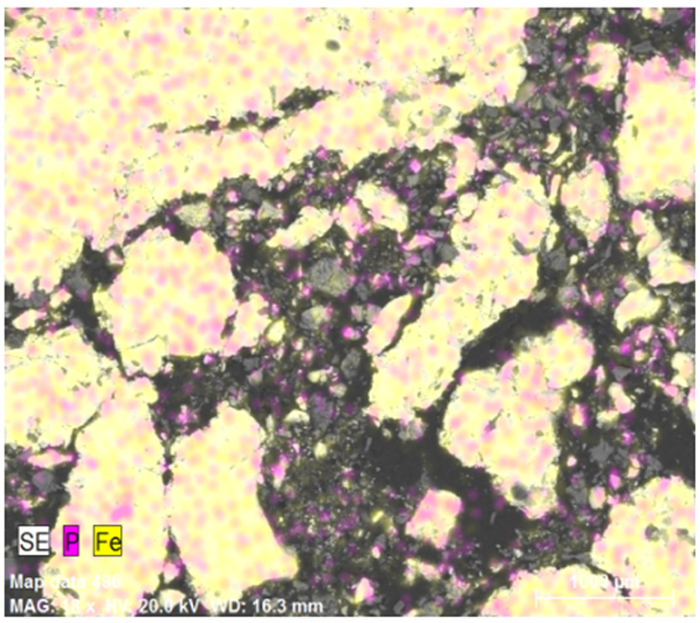

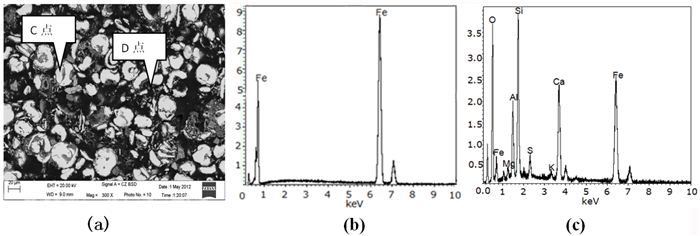

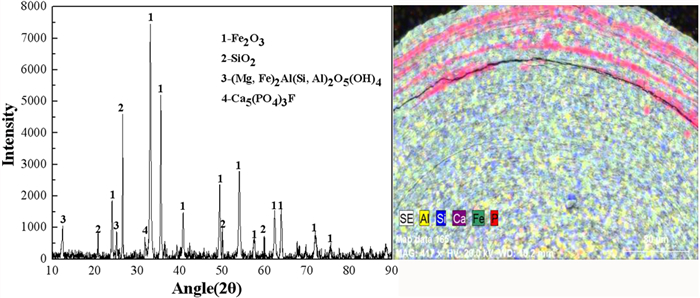

首次采用转底炉直接还原焙烧-磁选方法,对高磷鲕状赤铁矿进行了转底炉中试试验研究。在混合物料配比为m(原矿)GA6FA m(还原煤)GA6FA m(石灰石)GA6FA m(脱磷剂)=100 GA6FA 20 GA6FA 15 GA6FA 1,转底炉焙烧温度1 150℃~1 250℃,还原时间为70 min,含碳球团厚度2~3层(约55~65 mm)的条件下,最终获得的球团平均金属化率88.97%,两段磨矿磁选所得金属铁粉产率42.35%,TFe品位92.56%,铁回收率84.26%,P含量0.04%。金属铁粉压块密度为5.02 t/m3,可以作为优质的电炉炼钢原料。用扫描电镜(SEM)对焙烧温度1 250℃和1 300℃的金属化球团磨选所得金属铁粉进行分析,焙烧温度1 300℃的球团磨选金属铁粉中有单质磷的存在,说明对高磷鲕状赤铁矿而言,必须控制还原温度,选择性还原铁,避免还原磷。

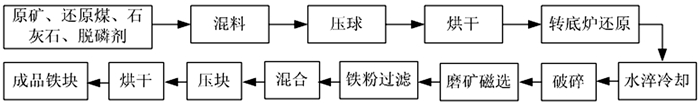

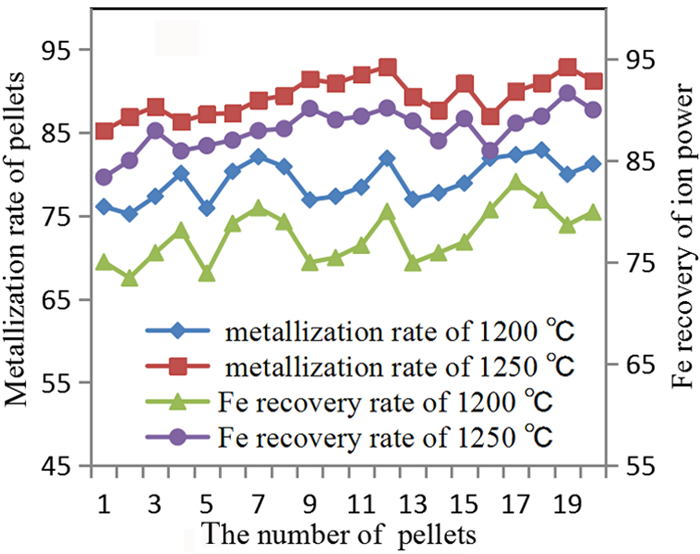

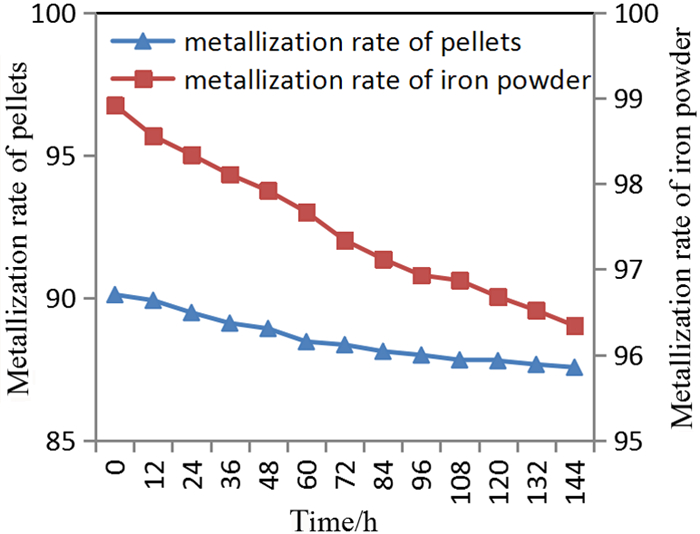

Abstract:With a pilot-scale test, high phosphorus oolitic hematite was firstly carried out in a rotary hearth furnace by direct reduction roasting and magnetic separation. Under the conditions of the mixed material mass ratio of raw ores, reduction coal, limestone and dephosphorization agent at the ratio of 100 GA6FA 20 GA6FA 15 GA6FA 1, the rotary hearth furnace roasting temperature from 1 150℃ to 1 250℃, the reduction time of 70 minutes, the thickness of containing coal pellets from 2 to 3 layers (55 to 65 mm), the metallized pellets could be obtained with an average metallization rate of 88.97%, the yield of iron powder treated with two stages grinding-magnetic separation of 42.35%, the TFe grade of 92.56%, the iron recovery of 84.26% and the P grade of 0.04%. The metal iron powder with a compact density of 5.02 t/m3 could be used as the high-quality steelmaking material in the electric furnace. The metal iron powder obtained by grinding separation of the metallized pellets with the roasting temperature of 1 250℃ and 1 300℃were analyzed by the scanning electron microscope (SEM). The result showed that phosphorus could be found in the metal iron powder with the roasting temperature of 1 300℃. It illustrates that the reduction temperature should be regulated to restore the iron selectively, rather than phosphorus with the high phosphorus oolitic hematite.

-

-

表 1 原矿化学多元素分析 /%

Table 1. Multi-elements analysis results of raw ores

元素 TFe FeO SiO2 Al2O3 CaO MgO K2O Na2O S P 含量 46.03 1.36 18.97 6.78 3.54 1.52 0.25 0.068 0.033 0.91 表 2 转底炉中试试验主要设备

Table 2. Main equipments for pilot-scale test of the rotary hearth furnace

序号 设备名称 设备型号、参数 设备用途 台数 1 XLH型混料机 Y180L-4V1,22kW,380V 原料混合 1 2 对辊压球机 GY650-220C, 最大线压比11 t/h 含碳球团制备 1 3 网带烘干机 三层网带烘干机传动功率:2.2kW 湿球团烘干 1 4 中试转底炉 转底炉外径10 m,炉底宽2 m 转底炉直接还原 1 5 球磨机 MQG1224 金属化球团磨矿 2 6 磁选机 DCIB600*600 铁粉磁选 2 7 浓密机 NZSG3 尾矿脱水 1 8 1#真空过滤机 GW-13 尾矿脱水 1 9 2#真空过滤机 GW-5 磁选铁粉脱水 1 表 3 转底炉还原各区工艺参数

Table 3. Parameters of each zone in the rotary hearth furnace

参数 预热区 中温区 高温一区 高温二区 冷却区 各区温度(℃) 1 150-1 230 1 250±20 1 250±20 1 250±20 <800 CO含量(10-6) >10 000 >30 000 >40 000 >40 000 压力(Pa) 正压 正压 正压 正压 正压 转底炉每圈时间(min/r) 60~70 布料厚度(mm) 55-65 mm(2~3层) -

-

下载:

下载: