Preparation and Property of Porous Carbon with Phenolic Polymerization Catalyzed by Hydrated Magnesium Carbonate

-

摘要:

利用水合碳酸镁催化功能及易分解特性,实现间苯二酚-甲醛体系的快速凝胶,通过炭化得到孔隙发达,比表面积大的整体式多孔炭(MCM-Mg)。系统研究了原料浓度、催化剂用量、反应温度、反应时间、炭化温度以及炭化时间工艺等因素对多孔炭性能的影响。结果表明,适宜的制备条件是反应温度85℃、反应时间0.5 h、间苯二酚质量3 g、催化剂用量3 g,炭化温度900℃,炭化时间1.5 h,获得密度为1.23 g/cm3、气孔率为39.71%、收率为29.07%、比表面积为193.475 m2/g,平均孔径为22.696 nm,抗压强度为25.68 Mpa的多孔炭。该工艺具有反应时间短、成本低廉和绿色环保等优点。

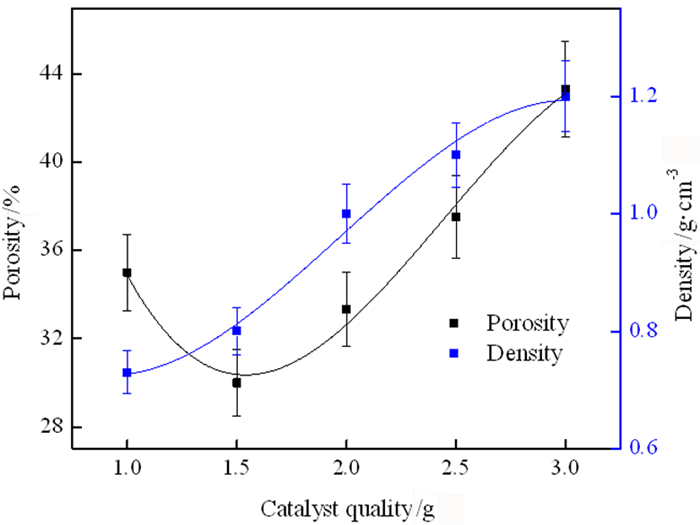

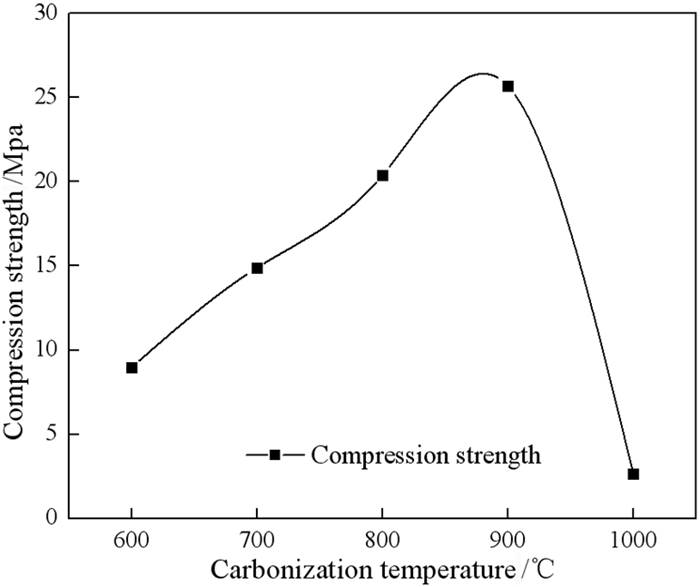

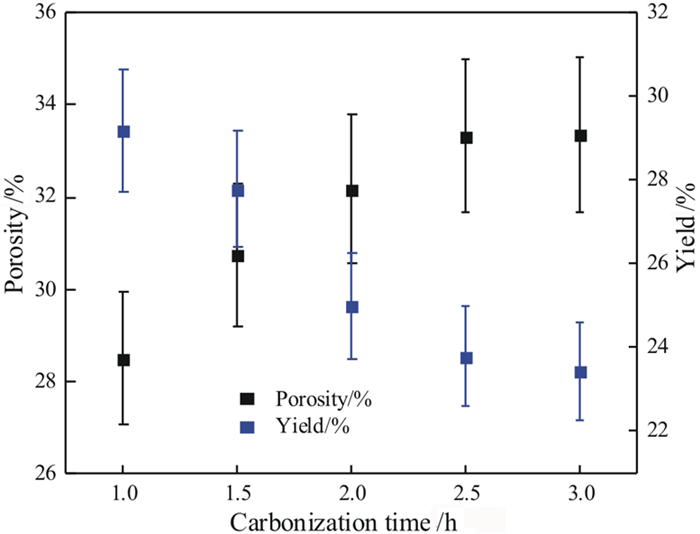

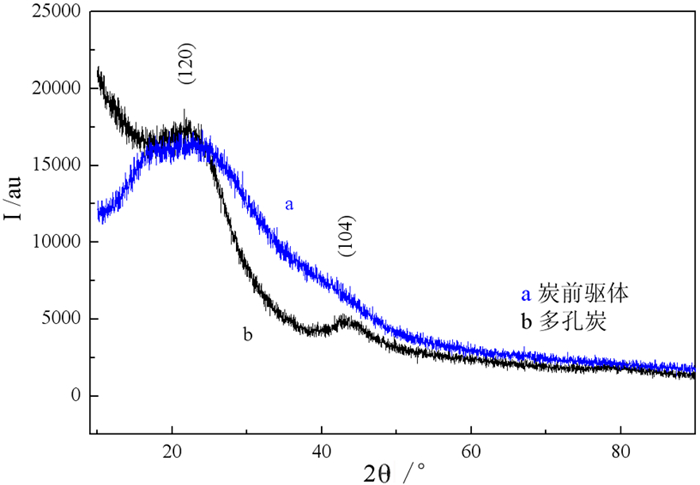

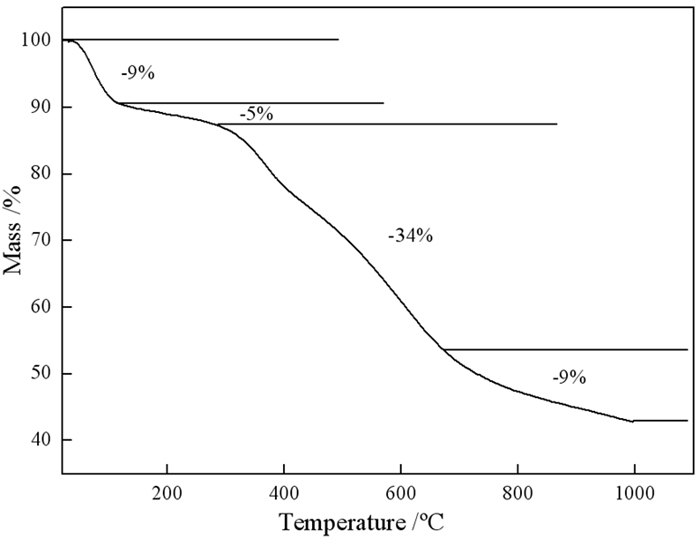

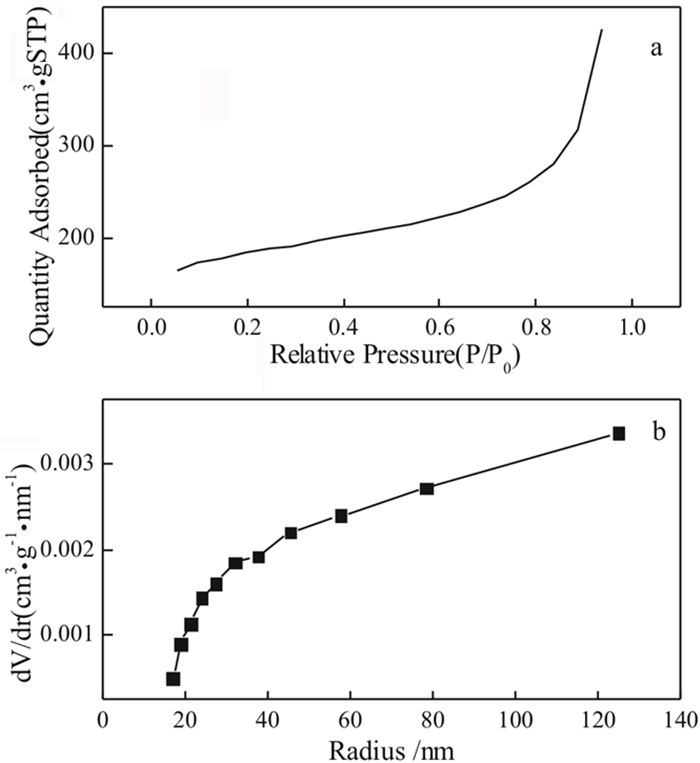

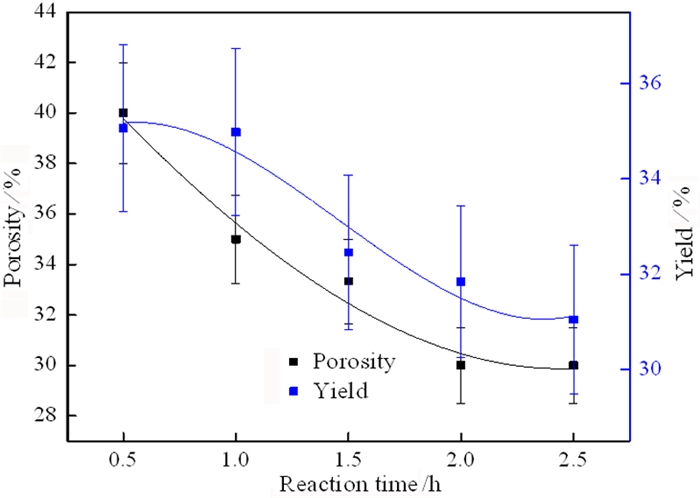

Abstract:The rapid gelation of the resorcinol-formaldehyde system was realized by the catalytic function and easy-decomposability of hydrated magnesium carbonate, and the monolithic porous carbon (MCM-Mg) with developed pores and large specific surface area was obtained by carbonization. The effects of raw material concentration, catalyst dosage, reaction temperature, reaction time, carbonization temperature and carbonization time on the properties of porous carbon were systematically studied. The results showed that the suitable preparation conditions were reaction temperature of 85℃, reaction time of 0.5 h, resorcinol mass of 3 g, catalyst dosage of 3 g, carbonization temperature of 900℃, carbonization time of 1.5 h. Under the optimum conditions, the porous carbon could be obtained with the density of 1.23 g/cm3, the porosity of 39.71%, the yield of 29.07%, the specific surface area of 193.475 m2/g, the average pore size of 22.696 nm, the compressive strength of 25.68 Mpa. The process has the advantages of short reaction time, low cost and environmental protection.

-

Key words:

- porous carbon /

- hydrated magnesium carbonate /

- phenolic resin

-

-

[1] 李浩, 钟文斌.基于双金属有机配位聚合物的氮掺杂多孔炭的制备及电化学性能研究[J].炭素技术:2019, 38(2):31. http://d.old.wanfangdata.com.cn/Periodical/tsjs201806006

[2] Xiong, Y. Experimental determination of solubility constant of hydromagnesite (5424) in NaCl solutions up to 4.4 m at room temperature. Chem.Geol, 2011, 284, 262-269.

[3] 王苗苗, 赵静, 张建安, 等.纳米多孔炭球的制备及应用进展[J].炭素技术, 2018, 37(1):1-3. http://d.old.wanfangdata.com.cn/Periodical/tsjs201801001

[4] Lee J S, Kim S I, Yoon J C, et al. Chemical vapor deposition of mesoporous graphene nanoballs for supercapacitor[J]. ACS Nano, 2013, 7(7):6047-6055. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=367672d6bdec3d0d8fa088498a960724

[5] Mao C, Liu S, Pang L, et al. Ultrathin MnO2 nanosheets grown on fungal conidium-derived hollow carbon spheres as supercapacitor electrodes[J]. RSC Advances, 2016, 6(7):5184-5191. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=1113fde6e018cb1b6ac01ae5610c1148

[6] Xu X, Liu Y, Wang M, et al. Hierarchical hybrids with microporous carbon spheres decorated three-dimensional graphene frameworks for capacitive applications in supercapacitor and deionization[J]. Electrochimica Acta, 2016, 193:88-95. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=bd5407e46d0600c4e2034e97b9007638

[7] Zeng X. Hierarchical nanocomposite of hollow N-doped carbon spheres decorated with ultrathin WS2 nanosheets for high-performance lithium-ion battery anode[J]. ACS Applied Materials and Interfaces, 2016, 8(29):18841-18848. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=9371f0c96158dd78e68d1e1fe2e9ded1

[8] Zheng G, Lee S W, Zheng L, et al. Interconnected hollow carbon nanospheres for stable lithium metal anodes[J]. Nature Nanotechnology, 2014, 9(8):618-623. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=806e56abc37d9ed1bf1ca15c76233b35

[9] Kalantari M, Yu M, Noonan O, et al. Rattle-type magnetic mesoporous hollow carbon as a high-performance and reusable adsorbent for water treatment[J]. Chemosphere, 2017, 166:109-117.

[10] Bing X, Wei Y, Wang M, et al. Template-free synthesis of nitrogen-doped hierarchical porous carbons for CO2 adsorption and supercapacitor electrodes[J]. Journal of Colloid and Interface Science, 2016, 488:207-217. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=4667b913c556e0c14130e32c43e8df42

[11] Xiong H F, Moyo Mahluli, Myriam A, et al. Fischer-Tropsch synthesis:iron catalysts supported on N-doped carbon spheres prepared by chemical vapor deposition and hydrothermal approaches[J]. Journal of Catalysis, 2014, 311(3):80-87.

[12] 黄婧, 文婕, 江成发, 等.酚醛树脂基多孔炭的制备及应用研究进展[J].功能材料, 2015, 46(1):01016-01026. http://d.old.wanfangdata.com.cn/Periodical/gncl201501003

[13] 王梅, 贾献峰, 马成, 等.整体型多孔炭的制备及其对苯和甲苯吸/脱附行为研究[J].新型炭材料, 2017, 32(4):358-364. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xxtcl201704011

[14] 王余莲, 印万忠, 李昂, 等.热分解法制备三水碳酸镁晶须及其结晶动力学研究[J].矿产保护与利用, 2018, 12(6):108-111. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=c1bbc99b-612f-4286-99fe-1f848277f396

[15] 王恩民, 李文翠, 雷成, 等.碱式碳酸镁催化酚醛聚合制备多孔炭及其CO2吸附性能[J].化工学报, 2015, 66(7):2565-2572. http://d.old.wanfangdata.com.cn/Periodical/hgxb201507027

[16] 王余莲, 印万忠, 张夏翔, 等.大长径比三水碳酸镁晶须的制备及晶体生长机理[J].硅酸盐学报, 2018, 46(7):944-951. http://d.old.wanfangdata.com.cn/Periodical/gsyxb201807008

-

下载:

下载: