Research Progress on Immobilization Mechanism and Technology of Arsenic-Bearing Solid Waste by Slag Cementation

-

摘要: 有色行业为主要的砷污染源,含砷固废的产生不仅影响了生态文明建设,而且严重制约了有色行业的发展。传统水泥固化含砷固废技术存在着成本高、处置率低等问题。相比而言,矿渣胶凝固砷技术具有固砷效率高、适用性广等优点。该文介绍了矿渣胶凝固砷技术的研究现状,并重点阐述了矿渣胶凝固砷机理,为矿渣胶凝固砷技术的推广和应用提供技术支持和理论支撑。Abstract: The non-ferrous industry is the main source of arsenic pollution. The generation of arsenic-bearing solid wastes is detrimental to the environment and seriously restricts the development of this industry. Arsenic can be immobilized by traditional cement-solidification technology, but problems such as high cost and low disposal rate are usually encountered. By contrast, immobilization technology of arsenic by slag cementation have the advantages of high arsenic-immobilization efficiency and extensive applicability. This paper introduces the research progress on immobilization technology of arsenic by slag cementation, and the immobilization mechanism of arsenic by slag cementation was emphatically described. The results provide technical support and theoretical support for the promotion and application of arsenic immobilization technology of slag cementation.

-

Key words:

- slag /

- arsenic-bearing solid waste /

- immobilization mechanism

-

-

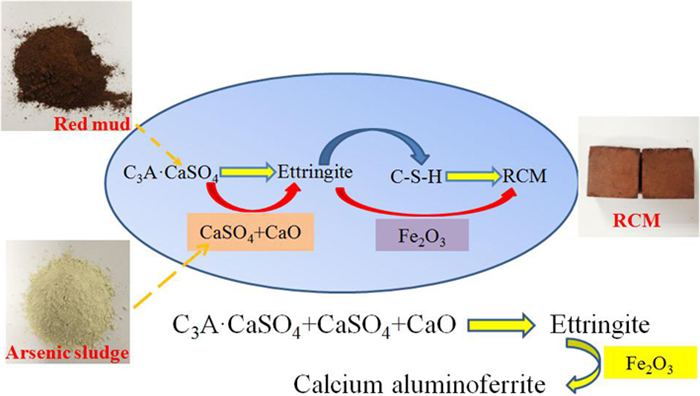

图 1 固化技术处置重金属固废的文章数量[14]

Figure 1.

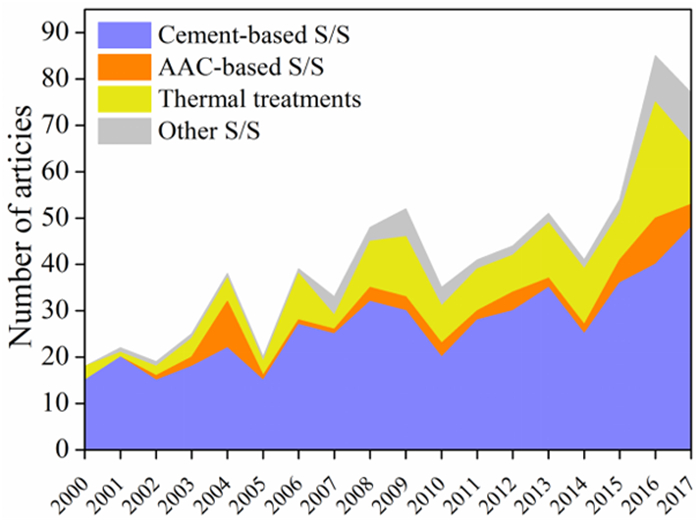

图 2 氧化钙、赤泥和含砷固废胶凝固化的水化过程[31]

Figure 2.

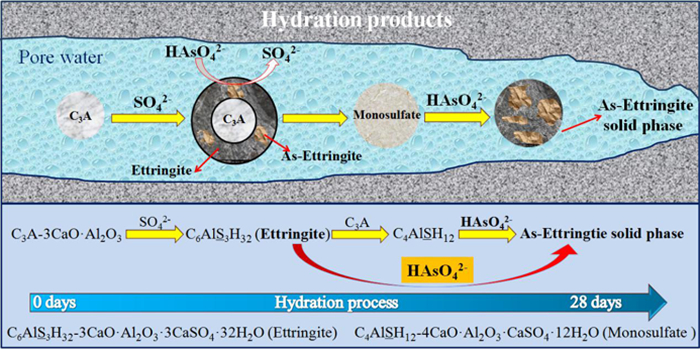

图 3 矿渣胶凝固砷机理[14]

Figure 3.

-

[1] OBEROI S, DEVLEESSCHAUWER B, GIBB H J, et al. Global burden of cancer and coronary heart disease resulting from dietary exposure to arsenic, 2015[J]. Environmental Research, 2019, 171:185-192. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=684a6e0d9f80dea728e736eea4df6acb

[2] 王长印, 李旻廷, 魏昶, 等.有色金属工业含砷污染物处理研究进展[J].矿冶, 2020, 29(1):86-93. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ky202001017

[3] ZHANG L, QIN X, TANG J, et al. Review of arsenic geochemical characteristics and its significance on arsenic pollution studies in karst groundwater, Southwest China[J]. Applied Geochemistry, 2017, 77:80-88. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=e35de4f145683253d9df5e22c8bc1e35

[4] LI Z, YANG Q, YANG Y, et al. Hydrogeochemical controls on arsenic contamination potential and health threat in an intensive agricultural area, northern China[J]. Environmental Pollution, 2020, 256:113455. http://cn.bing.com/academic/profile?id=00ea52987928cc2f57dbae53cd457435&encoded=0&v=paper_preview&mkt=zh-cn

[5] JI Z, PEI Y. Immobilization efficiency and mechanism of metal cations (Cd2+, Pb2+ and Zn2+) and anions (AsO43- and Cr2O72-) in wastes-based geopolymer[J]. Journal of Hazardous Materials, 2020, 384:121290.

[6] CHEN H, YUAN H, MAO L, et al. Stabilization/solidification of chromium-bearing electroplating sludge with alkali-activated slag binders[J]. Chemosphere, 2020, 240:124885. http://cn.bing.com/academic/profile?id=85d34a8687ba63f527fcf19b367b04f5&encoded=0&v=paper_preview&mkt=zh-cn

[7] 郭朝晖, 柴立元.砷污染防治技术政策[R].北京: 国家环境保护部, 2015.

[8] HULING J R, HULING S G, LUDWIG R. Enhanced adsorption of arsenic through the oxidative treatment of reduced aquifer solids[J]. Water Research, 2017, 123:183-191. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=27593a04a710f10828a6158613dc8d54

[9] ZHANG Y, ZHANG S, NI W, et al. Immobilisation of high-arsenic-containing tailings by using metallurgical slag-cementing materials[J]. Chemosphere, 2019, 223:117-123. http://cn.bing.com/academic/profile?id=5528c015139d3fbaa2f48640f9df956a&encoded=0&v=paper_preview&mkt=zh-cn

[10] LIU D G, MIN X B, KE Y, et al. Co-treatment of flotation waste, neutralization sludge, and arsenic-containing gypsum sludge from copper smelting:solidification/stabilization of arsenic and heavy metals with minimal cement clinker[J]. Environmental Science and Pollution Research, 2018, 25(8):7600-7607. http://cn.bing.com/academic/profile?id=321638be690ae90ad236e9475ae7ad4a&encoded=0&v=paper_preview&mkt=zh-cn

[11] 汪海涛.含砷废渣的稳定化/固化处理研究[D].武汉: 武汉理工大学, 2007.

[12] 陈晓飞.有色冶金污泥的稳定化/固化处理研究[D].武汉: 武汉理工大学, 2005.

[13] CHEN Q Y, TYRER M, HILLS C D, et al. Immobilisation of heavy metal in cement-based solidification/stabilisation:A review[J]. Waste Management, 2009, 29(1):390-403. http://cn.bing.com/academic/profile?id=c4e6db1d43da6d61c836f9fb64d490fc&encoded=0&v=paper_preview&mkt=zh-cn

[14] LI Y C, MIN X B, KE Y, et al. Immobilization potential and immobilization mechanism of arsenic in cemented paste backfill[J]. Minerals Engineering, 2019, 138:101-107. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=d64ddbd130af207d1957a400cb341bf8

[15] YOON I H, MOON D H, KIM K W, et al. Mechanism for the stabilization/solidification of arsenic-contaminated soils with Portland cement and cement kiln dust[J]. Journal of Environmental Managment, 2010, 91(11):2322-2328. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=04e6318f724a8cfc7bf74e2e394261c2

[16] 赵萌, 郑发鸿, 王平艳.含砷污泥的粉煤灰固化研究[J].环境工程学报, 2007(10):112-115. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjwrzljsysb200710026

[17] 杨远强, 王翔, 郭丽莉, 等.高浓度含砷污泥的药剂稳定化和水泥固化研究[J].环境科学与管理, 2013, 38(5):94-99. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=bfhj201305021

[18] PALFY P, VIRCIKOVA E, MOLNAR L. Processing of arsenic waste by precipitation and solidification[J]. Waste Management, 1999, 19(1):55-59. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=86acce821c8ac0b2da4022713524413d

[19] 李辕成, 祝星, 祁先进, 等.铜冶炼污泥固化剂优选试验研究[J].安全与环境学报.2013, 13(6):85-90. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=aqyhjxb201306019

[20] JENNI K, KATRI P, VISA I, et al. Solidification/stabilization of gold mine tailings using calcium sulfoaluminate-belite cement[J]. Journal of Cleaner Production, 2019, 239:118008. http://cn.bing.com/academic/profile?id=2dc15b28f286918f83062a7680fde7b6&encoded=0&v=paper_preview&mkt=zh-cn

[21] 刘英, 倪文, 黄晓燕, 等.拜耳法低铁赤泥在电石渣-脱硫石膏体系中的水化硬化特性[J].材料导报, 2016, 30(14):120-124. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cldb201614027

[22] LIU X, ZHANG N. Utilization of red mud in cement production:a review[J]. Waste Management & Research, 2011, 29(10):1053-1063. http://cn.bing.com/academic/profile?id=74eedc0c2ebb7141b8e8c1d8e5dd8ba5&encoded=0&v=paper_preview&mkt=zh-cn

[23] 肖劲光, 刘喜, 肖武, 等.高浓度砷渣土稳定化/固化效果及其影响因素研究[J].节能与环保, 2018(12):74-75. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=bjjn201812025

[24] FELEKOĜLU B, TVRKEL S, KALYONCU H. Optimization of fineness to maximize the strength activity of high-calcium ground fly ash-Portland cement composites[J]. Construction and Building Materials, 2009, 23(5):2053-2061. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f94ca5afee75e6304907cae1d4eae146

[25] KUMAR S, KUMAR R, BANDOPADHYAY A, et al. Mechanical activation of granulated blast furnace slag and its effect on the properties and structure of portland slag cement[J]. Cement and Concrete Composites, 2008, 30(8):679-685. http://cn.bing.com/academic/profile?id=b821e0deabcff08cbe6472417386d68e&encoded=0&v=paper_preview&mkt=zh-cn

[26] HOUNSI A D, LECOMTE-NANA G L, DJÉTÉLI G, et al. Kaolin-based geopolymers:Effect of mechanical activation and curing process[J]. Construction and Building Materials, 2013, 42:105-113. http://cn.bing.com/academic/profile?id=22d9ac73b9e1900b6963414d0e4e491a&encoded=0&v=paper_preview&mkt=zh-cn

[27] LI Y C, MIN X B, KE Y, et al. Preparation of red mud-based geopolymer materials from MSWI fly ash and red mud by mechanical activation[J]. Waste Management, 2019, 83:202-208. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f97d844af409706f556a7139e85dfb39

[28] RICHARDSON I G, BROUGH A R, GROVES G W, et al. The characterization of hardened alkali-activated blast-furnace slag pastes and the nature of the calcium silicate hydrate (C-S-H) phase[J]. Cement and Concrete Research, 1994, 24(5):813-829. http://cn.bing.com/academic/profile?id=e292c38bfa3e59a16214b29e23ef0646&encoded=0&v=paper_preview&mkt=zh-cn

[29] 邵雁.矿渣基胶凝材料固化稳定化垃圾焚烧飞灰机理研究[D].武汉: 武汉大学, 2014.

http://cdmd.cnki.com.cn/Article/CDMD-10486-1015550299.htm [30] PALOMO A, GRUTZECK M W, BLANCO M T. Alkali-activated fly ashes:A cement for the future[J]. Cement and Concrete Research. 1999, 29(8):1323-1329. http://cn.bing.com/academic/profile?id=d262911eec60b0dfae19bacef51659e6&encoded=0&v=paper_preview&mkt=zh-cn

[31] LI Y C, MIN X B, KE Y, et al. Utilization of red mud and Pb/Zn smelter waste for the synthesis of a red mud-based cementitious material[J]. Journal of Hazardous Materials, 2018, 344:343-349. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dad65e66b79ce37f0f3fdb5da0a23e51

[32] KIM J W, JUNG M C. Solidification of arsenic and heavy metal containing tailings using cement and blast furnace slag[J]. Environmental Geochemistry and Health, 2011, 33(1):151-158. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=182da393a2e263982d9032ce016b1079

[33] 王敬冬, 罗中秋, 周新涛, 等.地聚物材料固化含砷废渣抗冻融性能研究[J].硅酸盐通报, 2018, 37(2):602-606. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gsytb201802037

[34] COUSSY S, BENZAAZOUA M, BLANC D, et al. Arsenic stability in arsenopyrite-rich cemented paste backfills:A leaching test-based assessment[J]. Journal of Hazardous Materials, 2011, 185(2):1467-1476. http://cn.bing.com/academic/profile?id=cfc634d60f21abf91a07f30149e2d10c&encoded=0&v=paper_preview&mkt=zh-cn

[35] COUSSY S, PAKTUNC D, ROSE J, et al. Arsenic speciation in cemented paste backfills and synthetic calcium-silicate-hydrates[J]. Minerals Engineering, 2012, 39:51-61. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dcb5c7bfc8f6cc048f2836eedd4d4388

[36] LI Y C, MIN X B, CHAI L Y, et al. Co-treatment of gypsum sludge and Pb/Zn smelting slag for the solidification of sludge containing arsenic and heavy metals[J]. Journal of Environmental Management, 2016, 181:756-761. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=5839ebfa435c6c1e931dc3d0e57a8cea

[37] CHEN W, BROUWERS H J H. The hydration of slag, part 1:reaction models for alkali-activated slag[J]. Journal of Materials Science, 2007, 42(2):428-443. http://cn.bing.com/academic/profile?id=7c1f178b89771b4e08f951bcdf97dcc7&encoded=0&v=paper_preview&mkt=zh-cn

[38] ZHANG M, REARDON E J. Removal of B, Cr, Mo, and Se from wastewater by incorporation into hydrocalumite and ettringite[J]. Environmental Science & Technology, 2003, 37(13):2947-2952. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=5fe380f2134b4c40ba6c9fb1a68b93d7

[39] XU Z, VIEHLAND D. Observation of a Mesostructure in Calcium Silicate Hydrate Gels of Portland Cement[J]. Physical Review Letters, 1996, 77(5):952-955. http://cn.bing.com/academic/profile?id=7ffacb50e9b0400a7a88444da5ac668f&encoded=0&v=paper_preview&mkt=zh-cn

[40] LIN C K, CHEN J N, LIN C C. An NMR, XRD and EDS study of solidification/stabilization of chromium with Portland cement and C3S[J]. Journal of Hazardous Materials, 1997, 56(1):21-34. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=76f3559dbfc7be349f183d0be64b5b8d

[41] OMOTOSO O E, IVEY D G, MIKULA R. Hexavalent chromium in tricalcium silicate:Part Ⅱ Effects of CrVI on the hydration of tricalcium silicate[J]. Journal of Materials Science, 1998, 33(2):515-522.

[42] RICHARDSON I G. The nature of the hydration products in hardened cement pastes[J]. Cement and Concrete Composites, 2000, 22(2):97-113. http://cn.bing.com/academic/profile?id=f5e3930ce152de882ebccc1f0b7b1885&encoded=0&v=paper_preview&mkt=zh-cn

-

下载:

下载: