Physicochemical Properties and Humidity Control and Formaldehyde Adsorption of De-nickel Silicon Slag

-

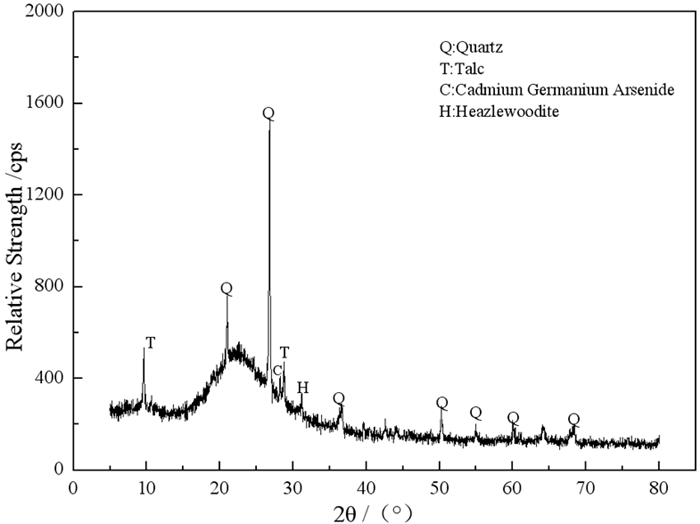

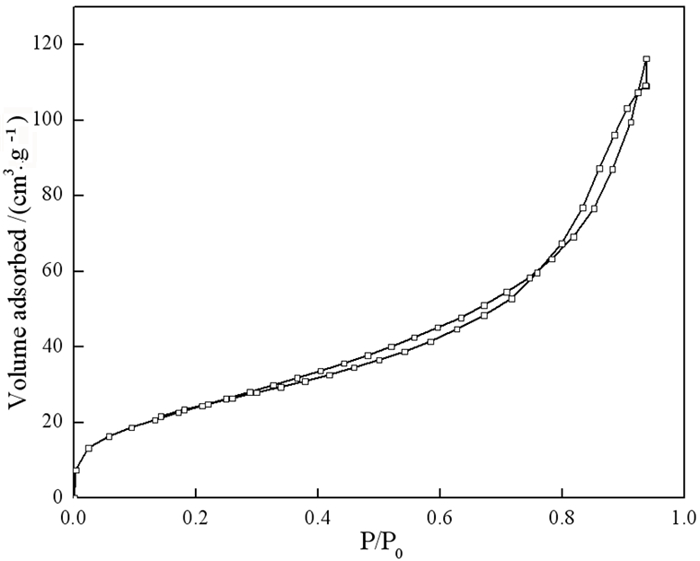

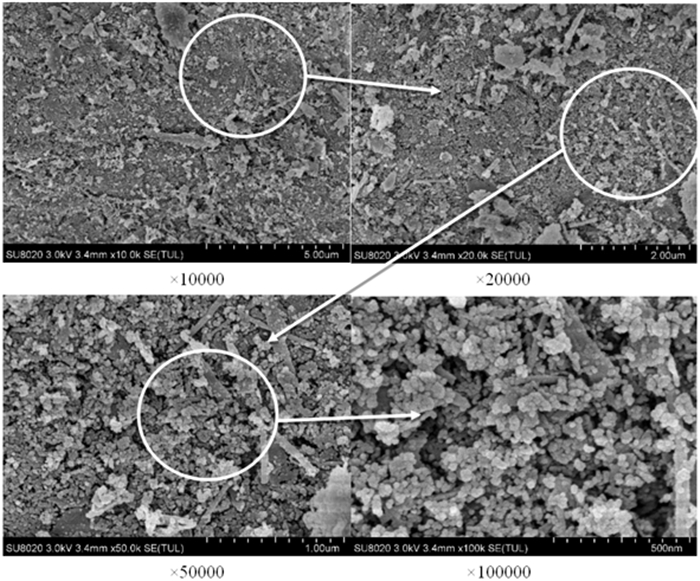

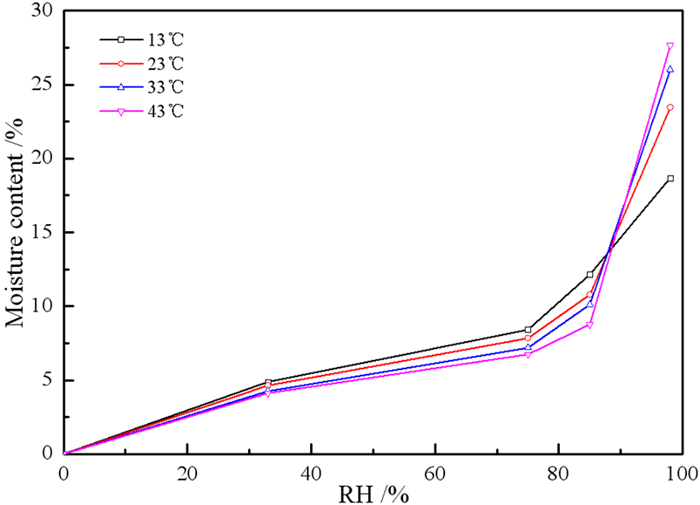

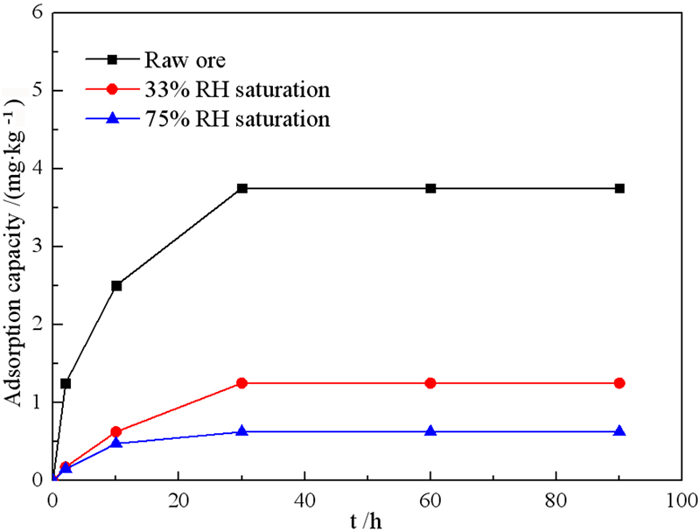

摘要: 脱镍硅渣是红土镍矿经酸浸法提取镍及其它金属后剩余的固体废弃物。本文研究了国内进口的印尼红土镍矿脱镍硅渣的理化特性及调湿与甲醛吸附性能。结果表明,红土镍矿脱镍硅渣的主要矿物成分为非晶质二氧化硅,化学成分除氧化硅、氧化铝、氧化钙、氧化镁、氧化铁等外,还含有少量的重金属;多孔结构,孔径主要为介孔,平均孔径7.661 nm,孔体积0.18 cm3/g,比表面积84.196 m2/g;具有良好吸/放湿性能和甲醛吸附性能;可以用于开发高性能调湿和空气净化材料。Abstract: De-nickel silicon slag is the solid waste remaining after nickel and other metals are extracted from laterite nickel ore by acid leaching. In this paper, the physicochemical properties, humidity control and formaldehyde adsorption properties of De-nickel silicon slag from laterite nickel ore in Indonesia were studied. The results showed that the main mineral component of the De-nickel silicon slag from laterite nickel ore was amorphous silica. The chemical components contain a small amount of heavy metals in addition to silicon oxide, aluminum oxide, calcium oxide, magnesium oxide, and iron oxide. The pore size was mainly mesopores, the average pore size was 7.661 nm, the pore volume was 0.18 cm3/g, the specific surface area was 84.196 m2/g. It had good absorption/desorption performance and formaldehyde adsorption performance. Therefore, it can be used to develop high-performance humidity control and air purification materials.

-

-

表 1 脱镍硅渣的粒度分布

Table 1. The granularity distribution of De-nickel silicon slag

Grand total D3 D6 D10 D16 D25 D50 D75 D84 D90 D97 Size /μm 1.51 2.14 2.79 3.76 5.35 10.47 18.34 24.74 31.93 53.09 表 2 脱镍硅渣主要化学成分

/% Table 2. The main chemical composition of De-nickel silicon slag

Composition SiO2 Al2O3 Fe2O3 CaO MgO TiO2 K2O Na2O LOI Content 78.95 0.67 0.92 0.18 0.24 0.06 0.085 0.54 11.15 表 3 脱镍硅渣的比表面积、孔径和孔体积分析结果

Table 3. Specific surface area, pore diameter and pore volume analysis results of De-nickel silicon slag

Specific surface area

/(m2·g-1)Average pore size

/nmPore volume

/(cm3·g-1)84.196 7.661 0.180 表 4 脱镍硅渣重金属含量

Table 4. The heavy metal content of De-nickel silicon slag

Composition Pb Cr Ba As Sb Cd Hg Content/(g·t-1) 58 4 245 8 842 125 91 2 0 表 5 脱镍硅渣的48 h最大吸放湿量

Table 5. 48 h maximum moisture absorption and release capacity of De-nickel silicon slag

Humidity control performance Maximum moisture absorption /% Maximum moisture release /% Environment humidity or temperature/℃ 33% 75% 85% 98% 75% 85% 98% 13 4.89 8.42 12.16 18.69 3.64 7.09 13.91 23 4.65 7.84 10.79 23.46 3.22 6.21 18.87 33 4.25 7.19 10.11 26.01 2.94 5.72 21.80 43 4.12 6.75 8.77 27.67 2.71 4.68 23.56 -

[1] 姜荣, 郭效东.从红土镍矿酸浸渣中回收铁矿物的试验研究[J].甘肃冶金, 2008(4):15-18. doi: 10.3969/j.issn.1672-4461.2008.04.006

[2] 李艳军, 于海臣, 王德全, 等.红土镍矿资源现状及加工工艺综述[J].金属矿山, 2010(11):5-9. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jsks201011002

[3] 王虹, 邓海波, 路秀峰.重要有色金属资源——红土镍矿的现状与开发[J].甘肃冶金, 2009, 31(1):20-24. doi: 10.3969/j.issn.1672-4461.2009.01.006

[4] 李国洲, 张燕云, 马泳波, 等.镍冶金渣综合利用现状[J].中国冶金, 2017, 27(8):1-5. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgyj201708001

[5] 李静.红土酸浸镍渣蒸压制品的制备参数及性能研究[D].南宁: 广西大学, 2016.

http://cdmd.cnki.com.cn/Article/CDMD-10593-1016218616.htm [6] 王宁, 施捍东.有色金属工业冶炼废渣-镍渣的综合利用[J].环境工程, 1994(1):16-17. http://www.cnki.com.cn/Article/CJFDTotal-HJGC401.019.htm

[7] 唐天佼.镍渣在混凝土中的应用研究[J].商品混凝土, 2014(2):49-50. http://www.cqvip.com/QK/90627X/201205/43629960.html

[8] 鲁逢霖, 郭玉华, 张颖异, 等.镍渣直接还原磁选提铁试验[J].钢铁, 2014, 49(2):19-23. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gt201402004

[9] 卢学峰, 南雪丽, 郭鑫.利用镍渣冶炼回收硅钙合金的研究[J].矿产保护与利用, 2009(2):55-58. doi: 10.3969/j.issn.1001-0076.2009.02.014 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=ea08d1e3-f67b-4ac4-92d0-c1cc0fb15072

[10] 张超.红土镍矿的选冶提取工艺研究[D].长沙: 中南大学, 2012.

http://d.wanfangdata.com.cn/thesis/Y2197702 [11] 吕文强, 狄永浩, 李兴东, 等.红土镍矿酸浸渣与硅藻土的吸放湿性能比较[J].矿产保护与利用, 2018(4):89-92, 96. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=5ed0a81f-703b-4be0-9654-e2d152f05fd3

[12] 李小明, 谢庚, 赵俊学, 等.镍渣直接还原提铁及同时制备胶凝材料的研究[J].有色金属(冶炼部分), 2015(12):51-55. doi: 10.3969/j.issn.1007-7545.2015.12.014

[13] 郭学益, 公琪琪, 石文堂, 等.镍红土矿加压浸出渣磁化焙烧-弱磁选铁精矿的研究[J].中南大学学报(自然科学版), 2012, 43(6):2048-2053. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zngydxxb201206005

[14] 李克庆, 冯琳, 高术杰.镍渣基矿井充填用胶凝材料的制备[J].北京科技大学学报, 2015(1):1-6. doi: 10.3969/j.issn.1008-2689.2015.01.001

[15] 史伟莉, 袁怀雨, 马明生, 等.镍渣制备建筑用微晶玻璃的初步研究[J].安全与环境学报, 2006, 6(1):128-130. doi: 10.3969/j.issn.1009-6094.2006.01.035

[16] 周琦, 南雪丽, 易育强, 等.镍渣微晶玻璃制备及铁的回收利用[J].兰州理工大学学报, 2010, 36(5):14-18. doi: 10.3969/j.issn.1673-5196.2010.05.004

[17] 吴阳, 吴其胜, 顾红霞, 等.镍渣替代铁粉制备道路硅酸盐水泥[J].硅酸盐通报, 2018, 37(4):1315-1319. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gsytb201804032

[18] 王顺祥, 吴其胜, 诸华军, 等.富硅镁镍渣粉磨细度和掺量对硅酸盐水泥水化特性的影响[J].材料科学与工程学报, 2018, 36(2):229-235. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=clkxygc201802011

[19] 刘甜甜, 郭伟, 蒋金海.镍渣制备多孔堇青石陶瓷的研究[J].中国陶瓷, 2017, 53(2):72-76. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgtc201702013

[20] 申莹莹, 张燕云, 黄仔牛, 等.镍渣熔融氧化过程中磁铁矿相生成热力学研究[J].材料与冶金学报, 2018, 17(3):175-181. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=clyyjxb201803004

[21] 张立敏, 谷丹.红土镍矿冶炼废渣在公路工程中的应用研究[J].北方交通, 2017(12):33-38. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lnjtkj201712009

[22] 孔令军, 赵祥麟, 刘广龙.红土镍矿冶炼镍铁废渣综合利用研究综述[J].铜业工程, 2014(4):42-44. doi: 10.3969/j.issn.1009-3842.2014.04.014

[23] European Committee for Standardization, Technical Committee ISO/TC 163. ygrothermal performance of building materials and products-Determination of hygroscopic sorption properties: ISO 12571: 2013[S]. Brussels, Belgium: 2013.

[24] 胡志波.硅藻土及复合材料孔结构和表面特性与调湿性能研究[D].北京: 中国矿业大学(北京), 2017.

http://cdmd.cnki.com.cn/Article/CDMD-11413-1017237808.htm [25] 吕文强, 郑水林, 孙志明, 等.红土镍矿酸浸渣硫酸铵焙烧-超声分散-离心分离提纯增白效果与机理[J].矿业科学学报, 2019, 4(6):564-572. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=kykxxb201906012

[26] YANG H, PENG Z, ZHOU Y, et al. Preparation and performances of a novel intelligent humidity control composite material[J]. Energy and Buildings, 2011, 43(2-3):386-392. doi: 10.1016/j.enbuild.2010.10.001

[27] 王吉会, 任曙凭, 韩彩.沸石/聚丙烯酸(钠)复合材料的制备与调湿性能[J].化学工业与工程, 2011(1):1-6. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hxgyygc201101001

[28] 曹丽云, 黄剑锋.配位插层聚合制备膨润土/聚丙烯酰胺调湿材料(英文)[J].陕西科技大学学报, 2004(1):1-5. doi: 10.3969/j.issn.1000-5811.2004.01.001

-

下载:

下载: