Industrial Application of Rhenium Comprehensive Recovery from Spraying Water by Ion Exchange Resin Method in Jinduicheng Molybdenum Company

-

摘要:

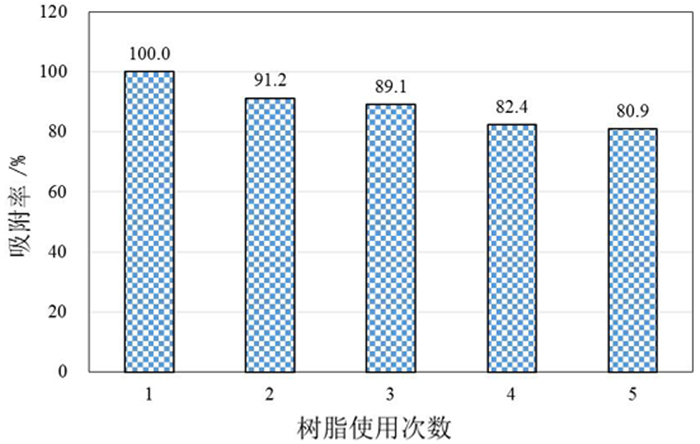

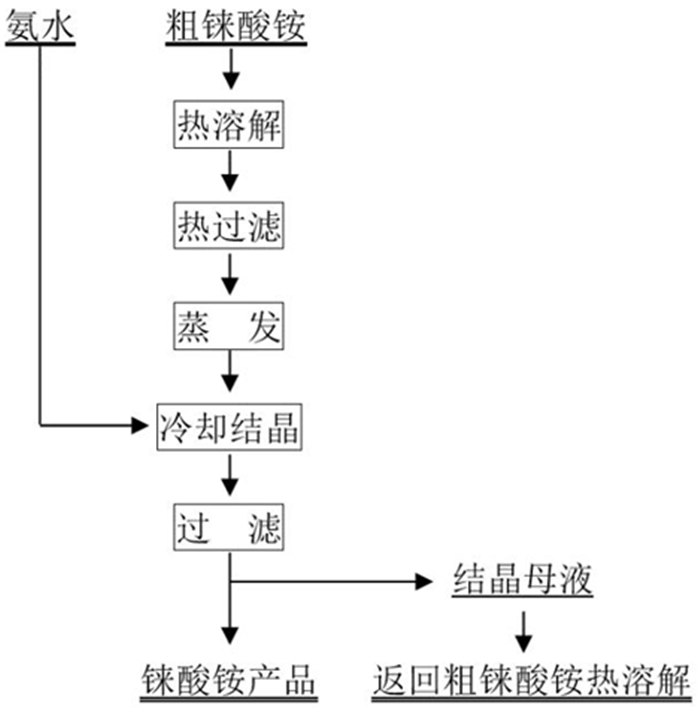

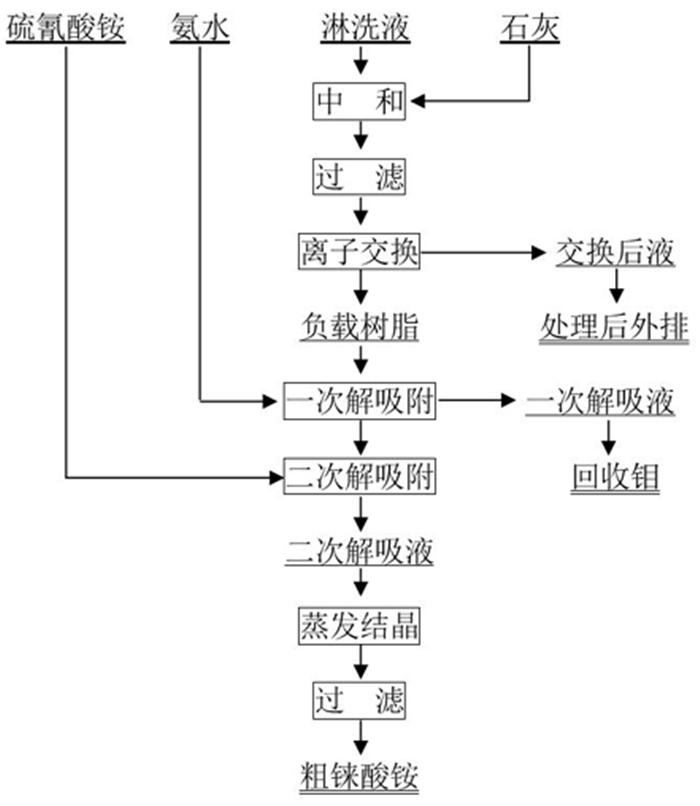

从钼冶炼废酸中高效回收铼一直是研究的热点,本文结合金堆城钼矿中铼回收相关研究,分析了用强碱性阴离子交换树脂和弱碱性阴离子交换树脂吸附回收铼的工艺流程、技术指标和优缺点。目前采用弱碱性阴离子交换树脂直接吸附法,从钼精矿焙烧废酸中回收铼,粗铼酸铵产品经2~3次溶解结晶,制备出合格铼酸铵产品,废酸中铼含量平均为17.86 mg/L,离子交换过程铼吸附率为97.5%,解吸附率为99.7%,总回收率为91.6%,高铼酸铵产品纯度可达99.99%。该生产工艺具有流程简单、生产稳定、技术指标好的特点,具有较好的推广应用前景。

Abstract:The efficient recovery of rhenium had always been a research hotspot. Combined with the related research results of Jinduicheng Molybdenum Company, the differences in technological process, index and technological features of strong basicity resin process and weak basicity resin process are compared and analyzed in this article. At present the direct ion exchange process using weak base resin was adopted for rhenium recovery from molybdenum roasting spraying water. The ammonium perrhenate product was obtained by 2-3 times heat dissolution and cooling crystallization process using crude ammonium perrhenate. The rhenium recovery process was characterized by its simplicity, stabilization and efficiency. According to production statistics the average content of rhenium in spraying water was 17.86 mg/L, the adsorption rate of rhenium was 97.5% in ion exchange process, the elution rate of rhenium was 99.7% and the overall recovery of rhenium was 91.6%. The product purity of ammonium perrhenate reached 99.99%.

-

Key words:

- rhenium /

- ion exchange /

- spraying water /

- molybdenum concentrates /

- evaporative crystallization /

- ammonium perrhenate

-

-

表 1 金堆城钼业钼炉料产品部钼冶炼废酸铼含量

Table 1. Rhenium content in waste acid from molybdenum smelting in sulphuric acid plant

编号 1 2 3 4 5 铼含量/(mg·L-1) 16.75 17.47 15.90 17.00 13.97 编号 6 7 8 9 均值 铼含量/(mg·L-1) 18.70 20.93 21.40 18.65 17.86 表 2 金堆城钼业钼炉料产品部钼冶炼废酸主要杂质元素含量

Table 2. Content of main impurity elements in waste acid from molybdenum smelting in sulphuric acid plant

成分 Mo S Cl Si Na Al Fe Mg Se* 含量/(g·L-1) 1.13 105 0.20 1.24 0.11 0.06 0.10 0.03 4.2 备注:标记“*”的单位为mg/L。 表 3 中和-离子交换法主要技术指标

Table 3. Main technical indexes of neutralization - ion exchange method

工序 中和铼损失率 铼吸附率 解吸率 铼总收率 回收率/% 10 92.5 92.5 77.0 表 4 铼回收过程主要技术指标

Table 4. Main technical indexes of rhenium recovery process

编号 不同物料中铼金属量/kg 吸附率/% 解吸率/% 总收率/% 废酸 离子交换柱 解吸液 铼酸铵 1 27.2 26.8 27.1 25.3 98.5 101.1 93.0 2 21.7 20.9 20.7 19.8 96.3 99.0 91.2 3 22.5 22.0 21.8 20.4 97.8 99.1 90.7 平均值 97.5 99.7 91.6 表 5 粗铼酸铵和滤渣主要化学组成

Table 5. Main chemical composition of crude ammonium perrhenate and filter residue

主要成分 Mo S Si Se K Pb 粗铼酸铵/% 0.33 1.08 0.35 1.77 0.037 0.15 一次过滤渣/% 0.76 5.04 4.73 84.16 0.023 0.048 二次过滤渣/% 0.39 12.08 3.77 91.54 0.021 0.41 主要成分 Ca Fe Na Cu Mg F 粗铼酸铵/% 0.21 0.037 0.076 0.0065 0.045 0.32 一次过滤渣/% 6.22 0.46 0.047 0.023 0.62 6.11 二次过滤渣/% 6.60 0.37 0.036 0.026 0.35 5.73 表 6 高铼酸铵产品的化学分析结果

Table 6. Chemical analysis results of ammonium perrhenate products

成分 Na Mg Al Ti Fe Si Ba Mn Sb W Pb Mo Cu Ta 含量/(g·L-1) < 20 < 1 < 1 < 1 < 5 0 < 1 < 1 < 2 < 5 < 1 < 5 < 1 < 1 成分 Pt P Sn Zn Ca Cr K Be V As Co Zr Cd Ni 含量/(g·L-1) < 5 < 5 < 1 < 2 0 < 1 0 < 1 < 1 < 1 < 1 < 1 < 2 < 1 -

[1] LIU EZ, GUAN XR, ZHENG Z. Effect of rhenium on solidification and segregation of nickel-based superalloy[J]. Rare Metals. 2011, 30(1): 320-322. http://cpfd.cnki.com.cn/Article/CPFDTOTAL-XYJS201009001069.htm

[2] GIAMEI AF, ANTON DL. Rhenium additions to a Ni-base superalloy: Effects on microstructure[J]. Metallurgical Transactions A. 1985, 16(11): 1997-2005. doi: 10.1007/BF02662400

[3] HUANG M, ZHU J. An overview of rhenium effect in single-crystal superalloys[J]. Rare Metals. 2016, 35(2): 127-139. doi: 10.1007/s12598-015-0597-z

[4] HU H, SUN LL, JIANG BQ, et al. Low concentration Re(Ⅶ) recovery from acidic solution by Cu-biochar composite prepared from bamboo (Acidosasa longiligula) shoot shell[J]. Minerals Engineering, 2018, 124: 123-136. doi: 10.1016/j.mineng.2018.05.021

[5] LI YH, YANG LJ, LIU XY, et al. Highly enhanced selectivity for the separation of rhenium and molybdenum using amino-functionalized magnetic Cu-ferrites[J]. Journal of Materials Science, 2015, 50(18): 5960-5969. doi: 10.1007/s10853-015-9140-8

[6] 吴继烈. 江西铜业公司贵金属及铼、钼生产评述[J]. 贵金属, 2003, 23(1): 57-59. https://www.cnki.com.cn/Article/CJFDTOTAL-GJSZ200201012.htm

[7] 龚益彬. 新技术公司钼精矿加工生产综述及发展对策[J]. 铜业工程, 2008(4): 18-20. doi: 10.3969/j.issn.1009-3842.2008.04.006

[8] 张燕红, 崔延遂. 三道庄多金属共生矿综合利用浅析[J]. 矿产保护与利用, 2003(6): 27-31. https://www.cnki.com.cn/Article/CJFDTOTAL-KCBH200303009.htm

[9] 王志诚, 杜小晖. 金堆城钼精矿焙烧烟气中回收铼的生产实践探讨[J]. 中国钼业, 2016, 40(2): 7-9, 25. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMY201602005.htm

[10] 廖秋玲, 高竹青. 离子交换法从烟道灰中提取铼的工艺研究[J]. 中国资源综合利用, 2011, 29(12): 18-21. doi: 10.3969/j.issn.1008-9500.2011.12.005

[11] 符新科, 尹孝刚. 金堆城精矿提取铼金属方法探讨[J]. 中国钼业, 2004(4): 36-38. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMY200404010.htm

[12] 符新科, 董文裕. 反射炉焙烧含铼烟尘的挥发率测定试验[J]. 中国钼业, 2003(5): 22-23, 29. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMY200305006.htm

[13] 杜小晖, 王寒飞, 李卫昌, 等. 钼精矿焙烧烟气淋洗液中回收铼的试验研究[J]. 中国钼业, 2021, 45(1): 39-42. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGMY202101016.htm

[14] 徐元博, 王萍, 周永星, 等. 烟气洗涤液铼回收系统氨氮废水处理及利用[J]. 硫酸工业, 2020(11): 38-40. https://www.cnki.com.cn/Article/CJFDTOTAL-LSGY202011015.htm

[15] 于志伟. 金堆城钼精矿焙烧烟气中铼回收技术研究及工业试验项目设计[J]. 有色矿冶, 2017, 33(2): 35-37. https://www.cnki.com.cn/Article/CJFDTOTAL-YSKY201702011.htm

[16] 刘红召. 铼在辉钼矿焙烧过程中的逸出及淋洗液吸附机理研究[D]. 北京: 北京有色金属研究总院, 2019.

-

下载:

下载: