Study on Comprehensive Recovery Technology of Hua Yangchuan Low Grade U-Nb-Pb Polymetallic Ore

-

摘要:

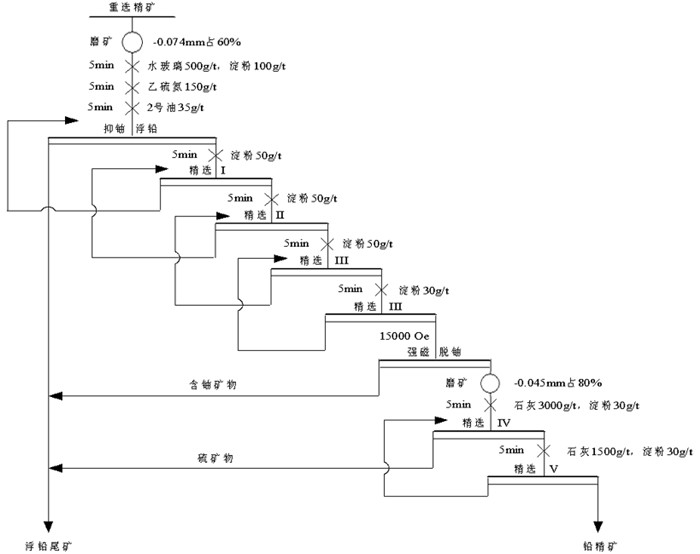

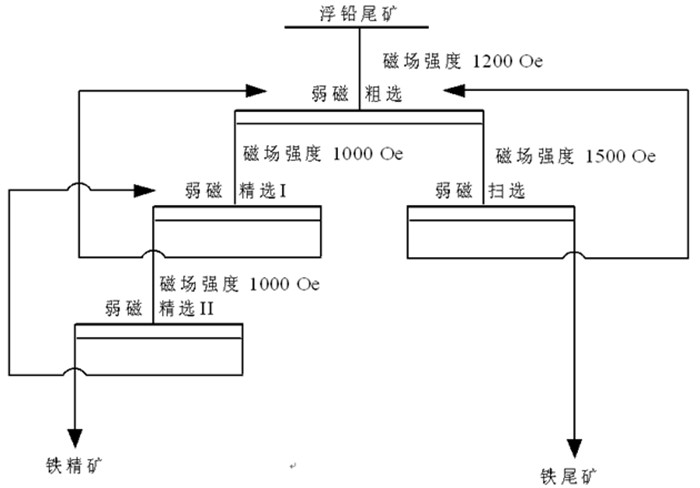

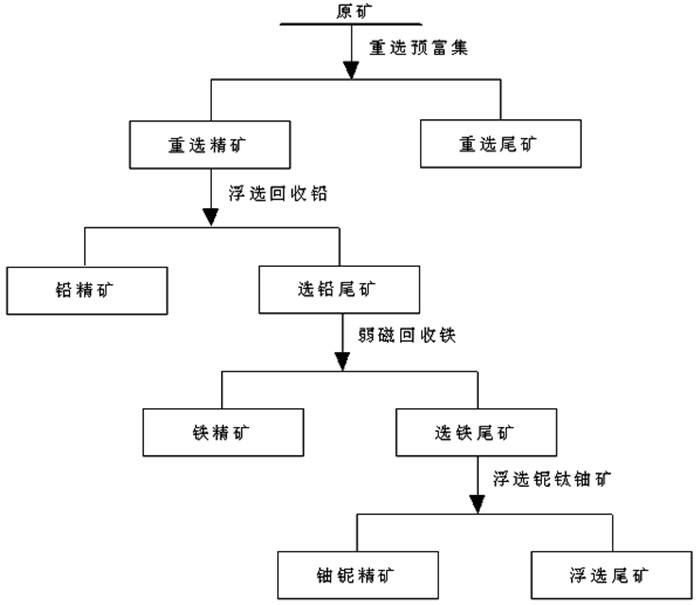

针对华阳川低品位铀铌铅多金属矿,首先利用重选将矿石中的铀铌铅有价金属进行预富集,通过预先筛分、阶段磨矿等方式减少矿石泥化,提高了有价金属的重选回收率;然后从重选精矿中回收伴生的方铅矿和磁铁矿,得到了放射性和品位均合格的铅精矿和铁精矿,实现了伴生金属的综合回收;最后采用苯甲羟肟酸作为捕收剂直接浮选铌钛铀矿,获得了高回收率和高品位的铀铌精矿。最终指标为:铅精矿产率0.67%,铅品位57.85%,回收率69.48%;铁精矿产率3.05%,铁品位64.50%,回收率65.87%;铀铌精矿产率1.76%,铀品位0.702%,回收率77.89%,铌品位0.695%,回收率72.55%。

Abstract:For the Hua Yangchuan low-grade uranium niobium lead polymetallic ore, the valuable metals in the ore were preconcentrated by gravity separation, and the slime of ore was reduced by prescreening and stage grinding, which could improve the gravity separation recovery rate of valuable metals. Then the associated galena and magnetite were recovered from the gravity concentrate, and the lead concentrate and iron concentrate with qualified radioactivity and grade were obtained, which realized the comprehensive recovery of associated metals. Finally, benzohydroxamic acid was used as a collector to directly flotation betafite, and the uranium-niobium concentrate with high recovery and high grade was obtained. The final indicators were obtained with the lead concentrate yield of 0.67%, lead grade of 57.85%, lead recovery of 69.48%; iron concentrate yield of 3.05%, iron grade of 64.50%, iron recovery of 65.87%; uranium niobium concentrate yield of 1.76%, uranium grade of 0.702%, uranium recovery of 77.89%, niobium grade of 0.695%, niobium recovery of 72.55%.

-

Key words:

- betafite /

- polymetallic ore /

- preconcentration /

- comprehensive recovery /

- benzohydroxamic acid /

- flotation

-

-

表 1 原矿X荧光分析结果

Table 1. XRF analysis results of raw ore

元素 U Si Ca Mg Al Fe K Na S 含量/% 0.014 24.18 7.61 0.66 5.88 2.4 4.63 1.22 1.09 元素 P Sr Ba Mn F Pb Ti Nb La 含量/% 0.11 1.13 0.94 0.20 0.11 0.60 0.16 0.016 0.015 表 2 原矿主要元素化学分析结果

Table 2. Chemical analysis results of main elements in raw ore

元素 U Nb Pb Fe S Sr Al Ca 含量/% 0.016 0.017 0.56 2.99 0.93 1.24 4.63 7.39 元素 Mg Mn P Ba K Si Na Ti 含量/% 0.64 0.46 0.08 1.69 3.46 28.47 1.41 0.18 表 3 重选预富集试验结果

Table 3. Test results of gravity separation and preconcentration

重选产品 产率/% 品位/% 回收率/% U Nb Pb Fe U Nb Pb Fe 重选精矿 19.38 0.070 0.071 2.41 11.64 84.88 81.03 84.04 75.46 重选尾矿 80.62 0.003 0.004 0.11 0.91 15.12 18.97 15.96 24.54 原矿 100.00 0.016 0.017 0.56 2.99 100.00 100.00 100.00 100.00 表 4 铅回收试验结果

Table 4. Test results of lead recovery

选矿产品 产率/% 品位/% 回收率/% Pb U Nb Fe Pb U Nb Fe 铅精矿 3.45 57.85 0.003 0.004 0.53 82.78 0.15 0.19 0.16 浮铅尾矿 96.55 0.43 0.072 0.073 12.04 17.22 99.85 99.81 99.84 重选精矿 100.00 2.41 0.070 0.071 11.64 100.00 100.00 100.00 100.00 表 5 铁回收试验结果

Table 5. Test results of iron recovery

选矿产品 产率/% 品位/% 回收率/% Fe U Nb Pb Fe U Nb Pb 铁精矿 16.32 64.5 0.003 0.004 0.08 87.43 0.65 0.83 3.04 铁尾矿 83.68 1.81 0.085 0.086 0.50 12.57 99.35 99.17 96.96 浮铅尾矿 100 12.04 0.072 0.073 0.43 100.00 100.00 100.00 100.00 表 6 放射性检测结果

Table 6. Radioactivity test results

检测项目 238U/(Bq·kg-1) 226Ra/(Bq·kg-1) 232Th/(Bq·kg-1) 40K/(Bq·kg-1) 国家标准 1 000 1 000 1 000 10 000 铅精矿 242 400 139 1 978 铁精矿 255 411 122 1 609 表 7 铌钛铀矿直接浮选试验结果

Table 7. Test results of direct flotation of betafite

选矿产品 产率/% 品位/% 回收率/% U Nb Fe Pb U Nb Fe Pb 铀铌精矿 11.23 0.702 0.695 1.96 0.45 93.02 91.50 12.16 10.11 浮选尾矿 88.77 0.007 0.009 1.79 0.51 5.98 8.50 87.84 89.89 铁尾矿 100.00 0.085 0.086 1.81 0.50 100.00 100.00 100.00 100.00 表 8 全流程选矿综合回收试验结果

Table 8. Test results of the comprehensive recovery of the whole process

选矿产品 产率/% 品位/% 回收率/% U Nb Pb Fe U Nb Pb Fe 铀铌精矿 1.76 0.702 0.695 0.45 1.96 77.89 72.55 1.42 1.15 铅精矿 0.67 0.003 0.004 57.85 0.53 0.13 0.16 69.48 0.12 铁精矿 3.05 0.003 0.004 0.08 64.50 0.58 0.73 0.44 65.87 浮选尾矿 13.90 0.007 0.009 0.51 1.79 6.14 7.43 12.73 8.32 重选尾矿 80.62 0.003 0.004 0.11 0.91 15.26 19.14 15.93 24.54 原矿 100.00 0.016 0.017 0.56 2.99 100.00 100.00 100.00 100.00 -

[1] 洪斌跃, 彭瑞强, 魏星星, 等. 华阳川铀多金属矿床铀成矿地质特征[J]. 四川地质学报, 2018(1): 97-100. doi: 10.3969/j.issn.1006-0995.2018.01.021

[2] 高成, 康清清, 江宏君, 等. 秦岭造山带发现新型铀多金属矿: 华阳川与伟晶岩脉和碳酸岩脉有关的超大型铀-铌-铅-稀土矿床[J]. 地球化学, 2017(5): 446-455. doi: 10.3969/j.issn.0379-1726.2017.05.004

[3] 孟广寿, 赵满常, 李文霞, 等. 低品位含铀铌钛矿选矿和综合利用的工艺研究[J]. 铀矿冶, 1982(3): 11-17. https://www.cnki.com.cn/Article/CJFDTOTAL-YKYI198203003.htm

[4] 黄美媛. 某低品位铀铌铅矿综合利用试验[J]. 矿产保护与利用, 2006(4): 34-36. doi: 10.3969/j.issn.1001-0076.2006.04.008 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=e12cbc80-3e55-46c2-bac7-147e892b26c4

[5] 惠小朝, 何升. 陕西华阳川铀、铌、铅多金属矿石工艺矿物学研究[J]. 金属矿山, 2016(5): 85-90. doi: 10.3969/j.issn.1001-1250.2016.05.019

[6] 康清清, 江宏君, 李鹏, 等. 陕西华阳川铀铌铅矿床矿石矿物学特征[J]. 东华理工大学学报: 自然科学版, 2018(2): 111-123. doi: 10.3969/j.issn.1674-3504.2018.02.002

[7] 武翠莲, 刘志超, 马嘉, 等. 华阳川多金属矿床中铀的赋存状态研究[J]. 铀矿冶, 2015(1): 30-34. https://www.cnki.com.cn/Article/CJFDTOTAL-YKYI201501010.htm

[8] 王守敬. 华阳川铀多金属矿工艺矿物学研究[J]. 金属矿山, 2019(4): 116-120. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201904024.htm

[9] 高玉德, 邱显扬, 冯其明. 钽铌矿捕收剂的研究[J]. 广东有色金属学报, 2003(2): 79-82. https://www.cnki.com.cn/Article/CJFDTOTAL-GDYS200302000.htm

[10] 王介良, 曹钊, 王建英, 等. 辛基羟肟酸在氟碳铈矿表面的吸附机理[J]. 中南大学学报: 自然科学版, 2019(4): 762-770. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201904002.htm

[11] 胡岳华, 韩海生, 田孟杰, 等. 苯甲羟肟酸铅金属有机配合物在氧化矿浮选中的作用机理及其应用[J]. 矿产保护与利用, 2018(1): 42-47. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=850ab651-3250-4e85-8821-25be50b3d064

[12] SONG C, ZHOU YY, LIU QJ, et al. Effects of BaCl2 on K-feldspar flotation using dodecyl amine chloride under natural pH[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(11): 2335-2340. doi: 10.1016/S1003-6326(18)64878-2

[13] 邱显扬, 高玉德. 苯甲羟肟酸与铌钽锰矿作用机理的研究[J]. 有色金属: 选矿部分. 2005(6): 37-40. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK200506011.htm

-

下载:

下载: