Separation of Rare Earth and Aluminium by Long-chain Polymeric Phosphate Complexation Precipitation

-

摘要:

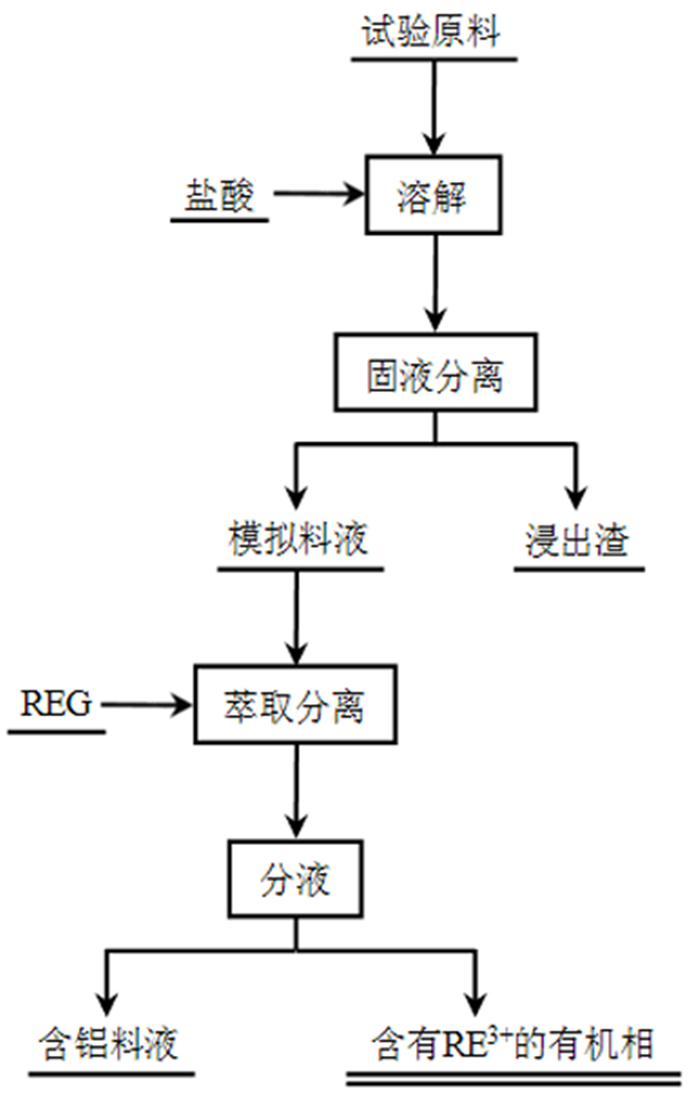

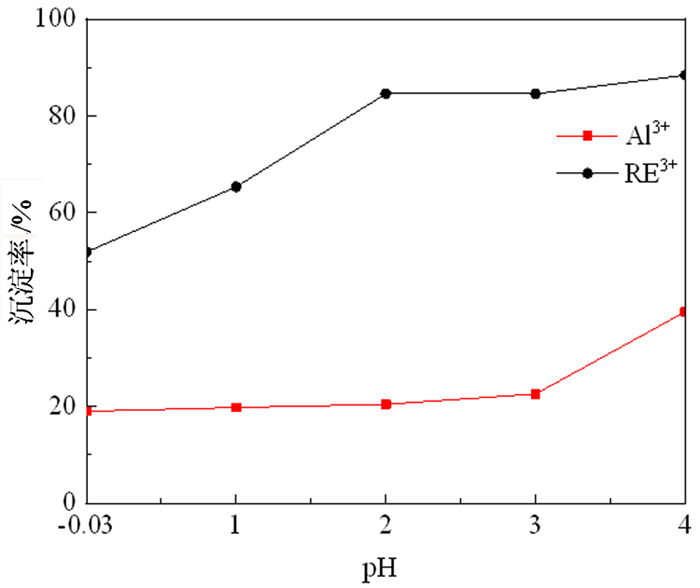

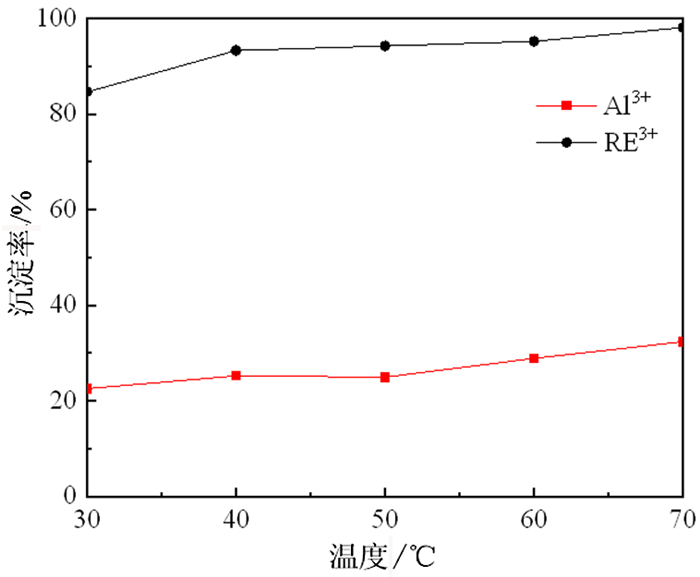

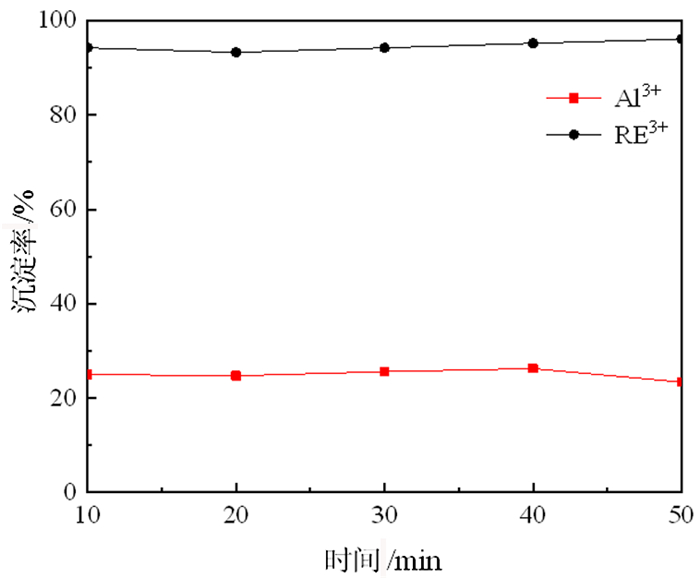

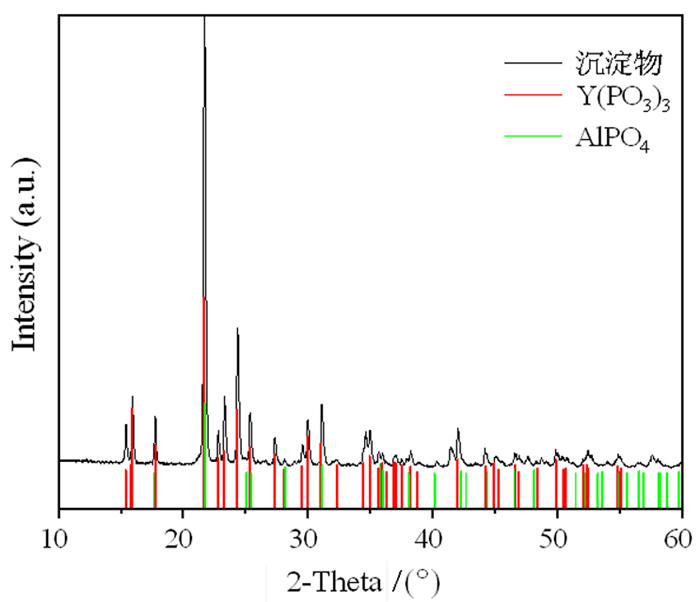

在离子型稀土矿浸出过程中,稀土浸出的同时大量的非稀土杂质如铝离子也会进入稀土浸出液中。本文针对稀土浸出液中杂质铝离子的去除问题展开研究,采用聚磷酸丁二酯选择性络合沉淀料液中的稀土元素,分别考察了溶液pH、聚磷酸丁二酯的量、反应时间、反应温度对除铝效果的影响,结果表明:以聚磷酸丁二酯作为络合沉淀剂,控制模拟料液的pH值为2.5、加入m(聚磷酸丁二酯单体):m(RE3+)=12:1当量的聚磷酸丁二酯、反应时间为10 min、反应温度为50℃时,稀土的沉淀率为91.35%,铝的共沉淀率为11.22%,有效地实现了稀土与铝的分离。

Abstract:In the leaching process of ionic rare earth ore, a large number of non-rare earth impurities such as aluminum ions will also enter the leaching solution. In this paper, the removal of impurity aluminum ions in the rare earth leaching solution was studied. The rare earth elements in the feed solution were selectively precipitated by polybutylene phosphate. The effects of solution pH, amount of polybutylene phosphate, reaction time and reaction temperature on the removal effect of aluminum were investigated respectively. The results show that: polybutylene phosphate is used as a complex precipitation agent, the pH value of the simulated feed liquid is controlled to 2.5, the polybutylene phosphate dosages is m(REG monomer): m(RE3+)= 12:1 equivalent is added, the reaction time is 10 min, the reaction temperature At 50 ℃, the precipitation rate of rare earth is 91.35%, and the precipitation rate of aluminum is 11.22%, which effectively separates rare earth from aluminum.

-

Key words:

- rare earth /

- aluminum removal /

- polybutylene phosphate /

- complex precipitation /

- separation

-

-

[1] 张苏江, 张立伟, 张彦文, 等. 国内外稀土矿产资源及其分布概述[J]. 无机盐工业, 2020, 52(1): 9-16. https://www.cnki.com.cn/Article/CJFDTOTAL-WJYG202001004.htm

[2] 胡轶文, 王丽明, 曹钊, 等. 我国稀土资源冶炼分离技术研究进展[J]. 矿产保护与利用, 2020, 40(2): 151-161. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=fe087d92-1945-4a99-9e1e-fe2a004eb330

[3] 张博, 宁阳坤, 曹飞, 等. 世界稀土资源现状[J]. 矿产综合利用, 2018(4): 7-12. doi: 10.3969/j.issn.1000-6532.2018.04.002

[4] 何耀, 程柳, 李毅, 等. 离子吸附型稀土矿的成矿机理及找矿标志[J]. 稀土, 2015, 36(4): 98-103. https://www.cnki.com.cn/Article/CJFDTOTAL-XTZZ201504018.htm

[5] 范飞鹏, 肖惠良, 陈乐柱, 等. 赣南陂头一带风化壳淋积型稀土矿成矿地质特征[J]. 中国稀土学报, 2014, 32(1): 101-107. doi: 10.11785/S1000-4343.20140110

[6] 池汝安, 刘雪梅. 风化壳淋积型稀土矿开发的现状及展望[J]. 中国稀土学报, 2019, 37(2): 129-140. https://www.cnki.com.cn/Article/CJFDTOTAL-XTXB201902001.htm

[7] 邱廷省, 伍红强, 方夕辉, 等. 风化壳淋积型稀土矿提取除杂技术现状及进展[J]. 稀土, 2012, 33(4): 81-85. doi: 10.3969/j.issn.1004-0277.2012.04.017

[8] 池汝安, 李隆峰, 王淀佐. 吸附稀土的粘土矿离子交换平衡研究[J]. 中南矿冶学院学报, 1991(2): 142-148. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD199102005.htm

[9] WANG L, LIAO C F, YANG Y M, et al. Effects of organic acids on the leaching process of ion-adsorption type rare earth ore[J]. Journal of Rare Earths, 2017, 35(12): 1233-1238. doi: 10.1016/j.jre.2017.07.001

[10] 欧阳克氙, 饶国华, 姚慧琴, 等. 南方稀土矿抑铝浸出研究[J]. 稀有金属与硬质合金, 2003, 31(4): 1-3. doi: 10.3969/j.issn.1004-0536.2003.04.001

[11] 任继鹏, 张逸, 钱诚, 等. 南方酸性森林土壤中铝的形态分布与活化机理[J]. 环境化学, 2011, 30(6): 1131-1135. https://www.cnki.com.cn/Article/CJFDTOTAL-HJHX201106016.htm

[12] 田君, 池汝安, 朱国才, 等. 我国南方某类稀土矿中铝的赋存状态[J]. 有色金属, 2000(3): 58-60+65. https://www.cnki.com.cn/Article/CJFDTOTAL-YOUS200003014.htm

[13] 陈志峰, 李金辉, 申邦坡, 等. 离子吸附型稀土矿除铝技术研究进展[J]. 有色金属科学与工程, 2017, 8(2): 112-118. https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS201702019.htm

[14] 潜美丽. 铝对P507体系萃取稀土元素的影响[D]. 沈阳: 东北大学, 2010.

[15] LI H F, GUO F Q, ZHANG Z F, et al. A new hydrometallurgical process for extracting rare earths from apatite using solvent extraction with P350[J]. Journal of Alloys & amp; Compounds, 2006, 408: 995-998. http://ir.ciac.jl.cn/bitstream/322003/16561/1/374.pdf

[16] BELOVA V V, VOSHKIN A A, EGOROVA N S, et al. Solvent extraction of rare earth metals from nitrate solutions with di(2, 4, 4-trimethylpentyl)phosphinate of methyltrioctylammonium[J]. Journal of Molecular Liquids, 2012, 172: 144-146. doi: 10.1016/j.molliq.2012.04.012

[17] 杨子超, 王秀山, 张安运, 等. 三正辛基氧化膦萃取钯的研究[J]. 应用化学, 1990(5): 72-76. https://www.cnki.com.cn/Article/CJFDTOTAL-YYHX199005011.htm

[18] LIAO C F, JIAO Y F, LIANG Y, et al. Adsorption-extraction mechanism of heavy rare earth by Cyanex272-P507 impregnated resin[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(8): 1511-1516. doi: 10.1016/S1003-6326(09)60330-7

[19] YIN S H, LI S W, WU W Y, et al. Extraction and separation of Ce(Ⅲ) and Pr(Ⅲ) in the system containing two complexing agents with di-(2-ethylhexyl) phosphoric acid[J]. Rsc Advances, 2014, 4(104): 59997-60001. doi: 10.1039/C4RA10143J

[20] 张章, 李林艳, 徐盛明, 等. 有机磷萃取剂的合成研究进展[J]. 湿法冶金, 2010, 29(4): 233-237. doi: 10.3969/j.issn.1009-2617.2010.04.006

[21] 尹敬群, 付桂明, 万茵, 等. 从风化壳淋积型稀土矿浸取液提取稀土技术与发展[J]. 江西科学, 2012, 30(5): 574-578+616. doi: 10.3969/j.issn.1001-3679.2012.05.007

[22] 池汝安, 王博, 李隆峰, 等. 用碳酸氢铵分离铝和稀土的新工艺研究[J]. 精细化工中间体, 1991(3): 35-39. https://www.cnki.com.cn/Article/CJFDTOTAL-HNHG199103009.htm

[23] 谢跃生. 铝盐水解、聚合行为分析[J]. 广西师院学报: 自然科学版, 1994(1): 32-37. https://www.cnki.com.cn/Article/CJFDTOTAL-GXSZ401.006.htm

[24] 刘文新, 栾兆坤. 水体中铝(Ⅲ)的化学形态及其生态效应的研究进展[J]. 生态学报, 1996, 16(2): 212-220. https://www.cnki.com.cn/Article/CJFDTOTAL-STXB602.015.htm

[25] PHILLIPS B L, CASEY W H, KARLSSON M. Bonding and reactivity at oxide mineral surfaces from model aqueous complexes[J]. Nature, 2000, 404(6776): 379. doi: 10.1038/35006036

[26] PERRY C C, SHAFRAN K L. The systematic study of aluminium speciation in medium concentrated aqueous solutions[J]. Journal Of Inorganic Biochemistry, 2001, 87(1/2): 115-124. http://www.sciencedirect.com/science?_ob=ShoppingCartURL&_method=add&_eid=1-s2.0-S0162013401003269&originContentFamily=serial&_origin=article&_ts=1483817720&md5=cd305ec2adbeca75ea8a6ff32f351345

[27] 陈志峰. 高铝稀土料液除铝工艺研究[D]. 赣州: 江西理工大学, 2018.

[28] 康天飞. 聚合磷酸酯阻燃剂的合成及应用研究[D]. 苏州: 苏州科技大学, 2012.

-

下载:

下载: