Study on Technology Optimization of Heavy Medium Separation - Flotation for a Spodumene Ore

-

摘要:

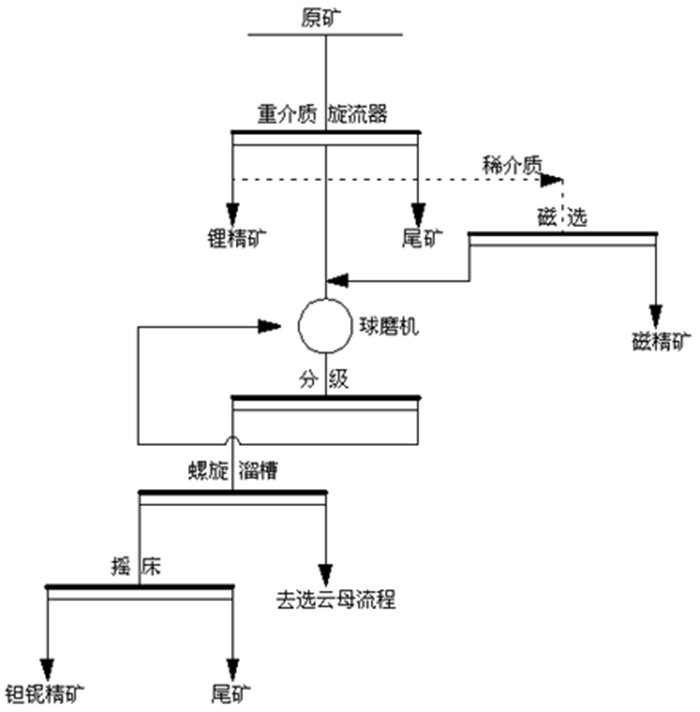

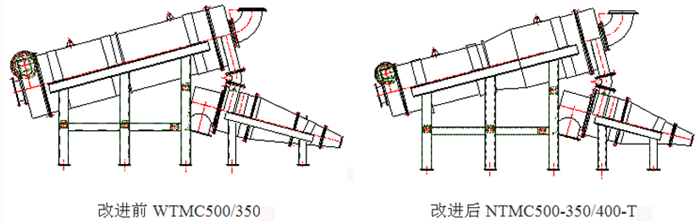

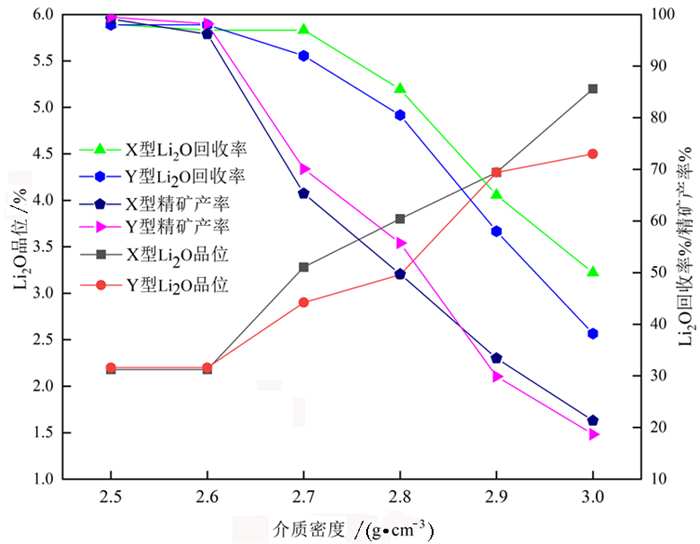

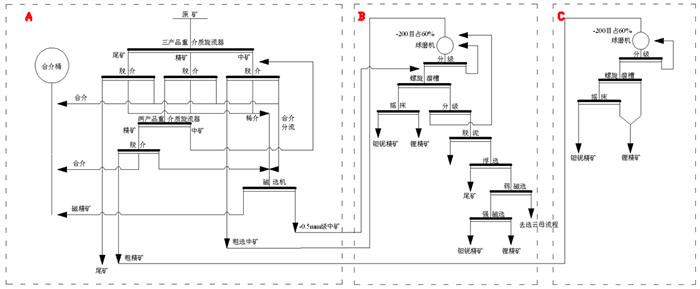

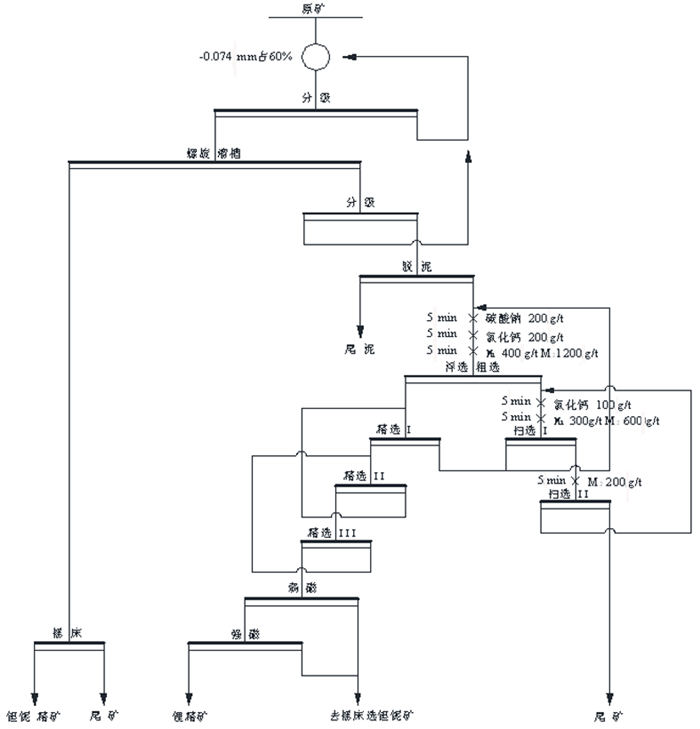

为了优化山东某锂辉石矿石选矿厂1 200 t/d重介质分选流程,以原浮选和重介分选数据为基础,结合破碎后的原矿浮沉试验结果,对重介质分选—浮选联合分选工艺进行了优化试验研究。试验结果表明,该锂辉石矿石采用重介质分选是可行的;原矿中主要有价矿物为锂辉石和钽铌锰矿,脉石矿物主要是石英、长石和云母等;新型NTMC500-350/400-T三产品重介质旋流器分选效果明显提升,在分选密度2.90 g/cm3、精矿Li2O品位4.30%时,改进后的X型旋流器的精矿Li2O回收率比Y型的约高7.00%;改进后的重介质分选工艺在第一段分选密度2.80 t/m3、第二段分选密度3.15 t/m3时,得到Li2O品位5.20%的化工级锂精矿;将重介质中矿给入浮选流程再处理,重介质分选—浮选联合工艺最终得到精矿产率35.46%、Li2O品位5.20%、Li2O回收率83.43%的分选指标。该工艺减少了浮选工艺入磨矿量,降低了运行成本高和原矿损失率。

Abstract:In order to improve the 1 200 t/d heavy medium separation process of a spodumene concentrator in Shandong province, based on the original flotation and heavy medium separation data and combined with the flotation test of broken ore, the combined heavy medium flotation separation process was used to carry out the beneficiation experiment. The results show that heavy medium separation is feasible for spodumene ore. The main valuable ore is spodumene and tantalum niobite, gangue is quartz, feldspar, mica, etc. The new NTMC500-350/400-T cyclone separation effect is obviously improved. When the separation density is 2.90 g/cm3 and Li2O grade is 4.30%, the recovery rate of type X Li2O is about 7.00% higher than that of type Y. After the improved heavy medium process, chemical grade lithium concentrate with Li2O grade of 5.20% was obtained when the separation density of one stage was 2.80 g/cm3 and that of the second stage was 3.15 g/cm3. The combined separation process will input the heavy medium ore into the flotation process, respectively, to maximize the utilization of resources, and obtain the separation index of Li2O grade of 5.20%, Li2O recovery of 83.43%, the fine mineral rate of 35.46%, to solve the problems of heavy medium separation medium ore where about, the flotation process into grinding, high operation cost, high raw ore loss rate.

-

Key words:

- spodumene /

- heavy medium separation /

- flotation /

- spiral chute /

- joint separation

-

-

表 1 原矿化学多元素分析结果

Table 1. Results of chemical multi-element analysis of raw ore

元素 Li2O Ta2O5 Nb2O5 Rb2O Cs2O BeO Sn F MnO Ti 含量/% 2.23 0.03 0.01 0.41 0.02 0.05 0.04 0.21 0.21 0.02 元素 CaO MgO Al2O3 SiO2 Na2O K2O Fe S P 含量/% 0.70 0.68 15.06 73.20 2.91 2.39 2.91 0.16 0.14 表 2 原矿XRD矿物组成测定结果

Table 2. XRD results of mineral composition of raw ore

矿物种类 铌钽锰矿 锡锰钽矿 锂辉石 石英 锂云母 铁锂云母 磁铁矿 含量/% 0.028 0.023 14.308 25.857 4.007 0.521 0.552 矿物种类 钠长石 钾长石 直闪石 角闪石 白云母 黑云母 其他 含量/% 28.528 9.342 3.912 1.607 7.133 0.615 3.563 表 3 原矿浮沉试验结果

Table 3. Float-sink test results of raw ore

密度

(g·cm-3)产率

/%Li2O

品位/%金属分布率/% 浮物(轻产品) 沉物(重产品) 品位% 产率% 品位% 产率% -2.50 3.24 0.00 0.00 0.00 3.24 2.24 100.00 2.50~2.60 1.26 0.15 0.08 0.04 4.50 2.31 96.76 2.60~2.70 11.87 0.65 3.44 0.48 16.37 2.34 95.50 2.70~2.80 17.62 0.70 5.51 0.59 33.99 2.58 83.63 2.80~2.90 18.72 1.30 10.86 0.84 52.71 3.08 66.01 2.90~3.00 9.33 1.50 6.25 0.94 62.04 3.78 47.29 3.00~3.10 6.81 3.30 10.03 1.17 68.85 4.35 37.96 3.10~3.20 10.73 3.20 15.33 1.45 79.58 4.57 31.15 +3.20 20.42 5.30 48.32 2.24 100.00 5.30 20.42 表 4 原工艺流程锂精矿指标

Table 4. Lithium concentrate index of the original process

分选工艺 产率/% Li2O品位/% Li2O回收率/% 浮选工艺 28.66 5.20 66.50 重介分选工艺 30.42 4.30 58.42 注:浮选指标是一次强磁选化工级精矿指标。 表 5 螺旋溜槽提质结果

Table 5. Quality improvement results of spiral chute

/% 产品名称 产率(对原矿) 品位

Li2O回收率(对原矿)

Li2O提质前锂精矿指标 35.05 4.89 77.46 提质后锂精矿指标 32.31 5.20 75.94 表 6 三种工艺获得的锂精矿指标对比

Table 6. Comparison of three process concentrates

/% 产品名称 产率

(对原矿)品位

Li2O回收率(对原矿)

Li2O重介质分选—浮选联合工艺 35.46 5.20 83.43 重介质分选工艺 32.31 5.20 75.94 浮选工艺 28.66 5.20 66.50 -

[1] 张亮, 杨卉芃, 柳林, 等. 全球提锂技术进展[J]. 矿产保护与利用, 2020(5): 24-31. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=5ece33dc-2002-467d-98b9-bad5df90669f

[2] 尚玺, 孟宇航, 张乾, 等. 富锂矿物的锂提取与战略性应用[J]. 矿产保护与利用, 2019(6): 152-157. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=aa61359c-cf07-4fd6-967c-910b3d3e71d6

[3] 董栋, 程宏伟, 郭保万, 等. 锂辉石选矿技术现状及展望[J]. 矿产保护与利用, 2018(4): 130-134. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=e4589445-9f36-4131-b79b-2c19f2305e4a

[4] 吴西顺, 孙艳, 王登红, 等. 国际锂矿开发的技术现状、革新及展望[J]. 矿产综合利用, 2020(6): 110-120. doi: 10.3969/j.issn.1000-6532.2020.06.019

[5] 陈少学. 某锂辉石矿选矿工艺流程改造[J]. 金属矿山, 2015(S1): 59-61. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS2015S1017.htm

[6] 于福顺, 蒋曼, 王建磊, 等. 澳大利亚某锂辉石矿预先脱泥—浮选试验研究[J]. 有色金属(选矿部分), 2019(6): 69-72. doi: 10.3969/j.issn.1671-9492.2019.06.013

[7] 钱志博, 于洋, 周少珍. 基于强化预处理工艺的某锂矿浮选试验研究[J]. 矿冶工程, 2021(1): 59-62. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC202101015.htm

[8] 刘星, 李成秀, 程仁举, 等. 国外某锂多金属矿选矿试验研究[J]. 矿产综合利用, 2019(2): 65-69. https://www.cnki.com.cn/Article/CJFDTOTAL-KCZL201902013.htm

[9] 陶家荣. 锂辉石矿重介质选矿工业试验与研究[J]. 有色金属(选矿部分), 2002(2): 13-16. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK200202003.htm

[10] 梁雪峰, 黄杰, 吴国富, 等. 某地锂辉石矿重介质选矿扩大连续试验[J]. 现代矿业. 2017(11): 132-134. https://www.cnki.com.cn/Article/CJFDTOTAL-KYKB201711036.htm

[11] 中国国家标准化管理委员会. 煤炭浮沉试验方法: GB/T 478—2008[S]. 北京: 中国标准出版社, 2008.

-

下载:

下载: