Research Progress of Comprehensive Recovery Rechnology of Secondary Resources Containing Cobalt

-

摘要:

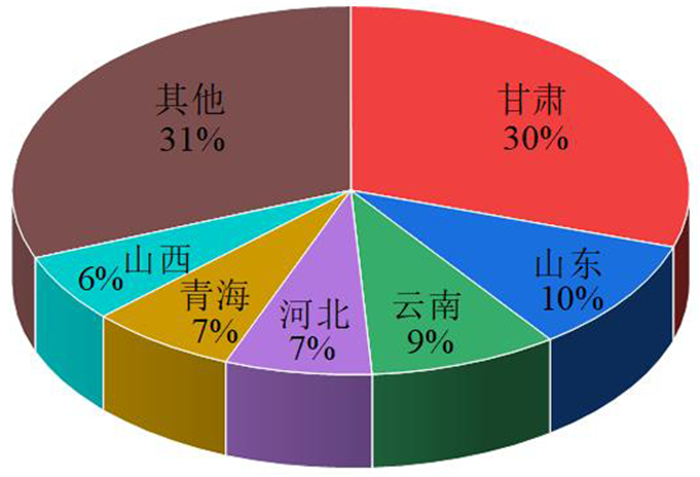

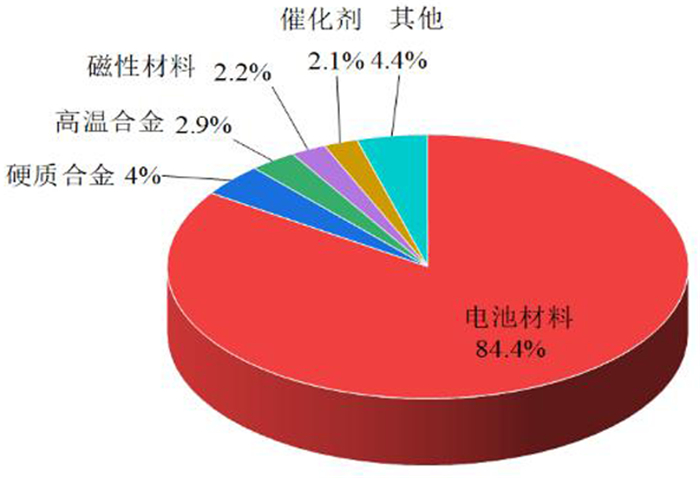

我国钴资源极度匮乏,严重依赖进口,突出的供需矛盾已成为制约我国钴行业发展的关键。开发含钴二次资源的回收利用技术对于缓解供需矛盾具有重要意义。论文概述了钴矿产资源的分布和储量,介绍了钴二次资源来源及种类,并以含钴冶金渣、废合金、加氢催化剂和废电池等二次资源为主要对象,详细阐述了含钴二次资源中钴的回收利用潜力和相关技术。结果表明,目前含钴二次资源通常采用湿法浸出技术进行回收再利用,其中含钴浸出液中钴与杂质元素的高效分离是回收钴的关键环节。因此,选择性溶出提钴体系和工艺的开发是提高含钴二次资源利用率的核心。

Abstract:China's cobalt resources are extremely scarce and rely heavily on imports. The prominent contradiction between supply and demand has become the key to restrict the development of China's cobalt industry. The development of recovery and utilization technology of cobalt-containing secondary resources is of great significance to alleviate the contradiction between supply and demand. This paper summarizes the distribution and reserves of cobalt mineral resources, introduces the sources and types of cobalt secondary resources, and focuses on the secondary resources such as cobalt-bearing metallurgical slag, waste alloy, hydrogenation catalyst and waste battery as the main object. the recovery and utilization potential and related technologies of cobalt in cobalt-containing secondary resources are described in detail. The results show that at present, the secondary resources containing cobalt are usually recovered and reused by wet leaching technology, in which the efficient separation of cobalt from impurity elements in the leaching solution containing cobalt is the key link for the recovery of cobalt. Therefore, the development of the system and process of selective leaching and extraction of cobalt is the core to improve the utilization rate of secondary resources containing cobalt.

-

Key words:

- cobalt /

- secondary resources /

- cobalt recovery /

- hydrometallurgy /

- efficient separation

-

-

图 8 [69]回收钴、锌的工艺流程

Figure 8.

表 1 钴资源分类[1]

Table 1. Classification of cobalt resources

主要一次资源 主要二次资源 镍(铜钴)硫化物矿石、红土镍(钴)矿、铜(钴)硫化物矿石、钴(砷)硫化物矿石、深海锰结核 铜冶炼产生的炉渣、锌冶炼产生的净化渣、电解锰净化渣、使用过的高温合金、硬质合金、磁性合金、催化剂、二次电池 -

[1] SAFARZADEH M S, DHAWAN N, BIRINCI M, et al. Reductive leaching of cobalt from zinc plant purification residues [J]. Hydrometallurgy, 2011, 106(1/2): 51-57.

[2] SCHMIDT T, BUCHERT M, SCHEBEK L. Investigation of the primary production routes of nickel and cobalt products used for Li-ion batteries [J]. Resources Conservation and Recycling, 2016, 112: 107-122. doi: 10.1016/j.resconrec.2016.04.017

[3] 王海北, 蒋开喜, 林江顺, 等. 废旧锂离子电池钴综合回收技术研究[J]. 日用电器, 2010(9): 15-17. doi: 10.3969/j.issn.1673-6079.2010.09.002

[4] WANG S. Cobalt - Its recovery, recycling, and application [J]. Jom, 2006, 58(10): 47-50. doi: 10.1007/s11837-006-0201-y

[5] U.S. Depertment Of Energy, Critical materials strategy summary 2010 [M]. U.S. Depertment Of, Energy, 2010.

[6] U.S. Geological Survey, 2019, Mineral commodity summaries 2019 [M]. U.S. Geological Survey, 2019.

[7] 黄晓兵. 中国钴资源安全评估[D]. 北京: 中国地质大学(北京), 2018.

[8] SMITH C G. Always the bridesmaid, never the bride: cobalt geology and resources [J]. Applied Earth Science, 2001, 110(2): 75-80. doi: 10.1179/aes.2001.110.2.75

[9] U.S. Geological Survey. Mineral commodity summaries 2021 [M]. U.S. Geological Survey, 2021.

[10] 刘永刚, 何高文, 姚会强, 等. 世界海底富钴结壳资源分布特征[J]. 矿床地质, 2013, 32(6): 1275-1284. doi: 10.3969/j.issn.0258-7106.2013.06.013

[11] 张福良, 崔笛, 胡永达, 等. 钴矿资源形势分析及管理对策建议[J]. 中国矿业, 2014, 23(7): 6-10. doi: 10.3969/j.issn.1004-4051.2014.07.002

[12] 张富元, 章伟艳, 任向文, 等. 全球三大洋海山钴结壳资源量估算[J]. 海洋学报, 2015, 37(1): 88-105. doi: 10.3969/j.issn.0253-4193.2015.01.010

[13] 张伟波, 叶锦华, 陈秀法, 等. 全球钴矿资源分布与找矿潜力[J]. 资源与产业, 2018, 20(4): 56-61. https://www.cnki.com.cn/Article/CJFDTOTAL-ZIYU201804015.htm

[14] KAPUSTA J P T. Cobalt production and markets: A brief overview [J]. Jom, 2006, 58(10): 33-36. doi: 10.1007/s11837-006-0198-2

[15] HUANG Y, ZHANG Z, CAO Y, et al. Overview of cobalt resources and comprehensive analysis of cobalt recovery from zinc plant purification residue- a review [J]. Hydrometallurgy, 2020, 193: 105327. doi: 10.1016/j.hydromet.2020.105327

[16] GOLMOHAMMADZADEH R, FARAJI F, RASHCHI F. Recovery of lithium and cobalt from spent lithium ion batteries (LIBs) using organic acids as leaching reagents: A review [J]. Resources Conservation and Recycling, 2018, 136: 418-435. doi: 10.1016/j.resconrec.2018.04.024

[17] WANG Y, ZHOU C S. Hydrometallurgical process for recovery of cobalt from zinc plant residue [J]. Hydrometallurgy, 2002, 63(3): 225-234. doi: 10.1016/S0304-386X(01)00213-4

[18] 刘晓剑. 镍钴二次资源回收过程溶液深度净化及材料制备研究[D]. 长沙: 中南大学, 2007.

[19] 唐娜娜, 马少健. 废弃物料中钴、镍的回收[J]. 有色矿冶, 2005(S1): 113-114. https://www.cnki.com.cn/Article/CJFDTOTAL-YSKY2005S1044.htm

[20] 张建军, 陈为亮, 李照刚. 从钴渣中回收钴的研究进展[J]. 矿产综合利用, 2017(4): 11-15. doi: 10.3969/j.issn.1000-6532.2017.04.003

[21] FAN X, TAN C, LI Y, et al. A green, efficient, closed-loop direct regeneration technology for reconstructing of the LiNi0.5CoO. 2MnO. 3O2 cathode material from spent lithium-ion batteries [J]. J Hazard Mater, 2021, 410: 124610. doi: 10.1016/j.jhazmat.2020.124610

[22] JUNG J CY, SUI PC, ZHANG J. A review of recycling spent lithium-ion battery cathode materials using hydrometallurgical treatments [J]. Journal of Energy Storage, 2021, 35: 102217. doi: 10.1016/j.est.2020.102217

[23] 孟晗琪, 马光, 吴贤, 等. 镍钴高温合金废料湿法冶金回收[J]. 广州化工, 2012, 40(17): 29-30+43. doi: 10.3969/j.issn.1001-9677.2012.17.012

[24] 谭世雄, 申勇峰. 从废高温合金中回收镍钴的工艺[J]. 化工冶金, 2000(3): 294-297. doi: 10.3321/j.issn:1009-606X.2000.03.014

[25] RABAH M A, HEWAIDY I F, FARGHALY F E. Recovery of molybdenum and cobalt powders from spent hydrogenation catalyst [J]. Powder Metallurgy, 1997, 40(4): 283-288. doi: 10.1179/pom.1997.40.4.283

[26] GHOLAMI R M, BORGHEI S M, MOUSAVI S M. Bacterial leaching of a spent Mo-Co-Ni refinery catalyst using acidithiobacillus ferrooxidans and acidithiobacillus thiooxidans [J]. Hydrometallurgy, 2011, 106(1/2): 26-31.

[27] MARAFI M, STANISLAUS A. Spent hydroprocessing catalyst management: A review Part Ⅱ. Advances in metal recovery and safe disposal methods [J]. Resources Conservation and Recycling, 2008, 53(1/2): 1-26.

[28] LE M N, LEE M S. A review on hydrometallurgical processes for the recovery of valuable metals from spent catalysts and life cycle analysis perspective [J]. Mineral Processing and Extractive Metallurgy Review, 2020, 42(5): 335-354.

[29] MESHRAM P, MISHRA A, ABHILASH, et al. Environmental impact of spent lithium ion batteries and green recycling perspectives by organic acids - A review [J]. Chemosphere, 2020, 242: 12591.

[30] 李平, 邓攀, 刘宜强, 等. 从硬质合金磨削废料中综合回收钴试验研究[J]. 湿法冶金, 2017, 36(4): 271-274. https://www.cnki.com.cn/Article/CJFDTOTAL-SFYJ201704005.htm

[31] 黄炳光, 谢克难, 解然, 等. 盐酸法处理硬质合金粉双回收Co和WC新工艺研究[J]. 四川有色金属, 2009(2): 30-33. doi: 10.3969/j.issn.1006-4079.2009.02.007

[32] 汤青云, 段冬平. 硝酸法处理废硬质合金回收金属钴和碳化钨[J]. 城市学刊, 1996(6): 64-70. https://www.cnki.com.cn/Article/CJFDTOTAL-YYSZ199606013.htm

[33] 李强, 李奇勇, 徐叶, 等. 湿法炼锌净化钴渣选择性浸出回收锌与钴[J]. 有色金属(冶炼部分), 2019(4): 6-10. doi: 10.3969/j.issn.1007-7545.2019.04.002

[34] MORADKHANI D, SEDAGHAT B, KHODAKARAMI M, et al. Recovery of valuable metals from zinc plant residue through separation between manganese and cobalt with n-n reagent[J]. Physicochemical Problems of Mineral Processing, 2014, 50(2): 735-746.

[35] 刘红斌, 蒋伟, 蒋训雄, 等. 铜转炉渣湿法回收钴[J]. 有色金属(冶炼部分), 2012(2): 19-22. doi: 10.3969/j.issn.1007-7545.2012.02.005

[36] 喻正军. 从镍转炉渣中回收钴镍铜的理论与技术研究[D]. 长沙: 中南大学, 2006.

[37] KOJIMA T, SHIMIZU T, SASAI R, et al. Recycling process of WC-Co cermets by hydrothermal treatment [J]. Journal of Materials Science, 2005, 40(19): 5167-5172. doi: 10.1007/s10853-005-4407-0

[38] SINHA M K, PRAMANIK S, KUMARI A, et al. Recovery of value added products of Sm and Co from waste SmCo magnet by hydrometallurgical route [J]. Sep Purif Technol, 2017, 179: 1-12. doi: 10.1016/j.seppur.2017.01.056

[39] 柳松, 古国榜. 镍基高温合金废料的回收[J]. 无机盐工业, 1997(2): 38-39. https://www.cnki.com.cn/Article/CJFDTOTAL-WJYG702.013.htm

[40] 魏国侠, 孙挺. 电解法回收废镍基高温合金的研究[C]//中国工程院化工、冶金与材料工学部第七届学术会议论文集. 北京: 2009.

[41] CHEN W S, HO H J. Leaching behavior analysis of valuable metals from lithium-ion batteries cathode material [J]. Key Engineering Materials, 2018, 775: 419-426. doi: 10.4028/www.scientific.net/KEM.775.419

[42] GUZOLU J S, GHARABAGHI M, MOBIN M, et al. Extraction of Li and Co from Li-ion Batteries by Chemical Methods [J]. Journal of The Institution of Engineers (India): Series D, 2017, 98(1): 43-48. doi: 10.1007/s40033-016-0114-z

[43] LEE C K, RHEE K I. Reductive leaching of cathodic active materials from lithium ion battery wastes [J]. Hydrometallurgy, 2003, 68(1-3): 5-10. doi: 10.1016/S0304-386X(02)00167-6

[44] VALVERDE I M, Jr., PAULINO J F, AFONSO J C. Hydrometallurgical route to recover molybdenum, nickel, cobalt and aluminum from spent hydrotreating catalysts in sulphuric acid medium [J]. J Hazard Mater, 2008, 160(2/3): 310-317.

[45] BANDA R, NGUYEN T H, SOHN S H, et al. Recovery of valuable metals and regeneration of acid from the leaching solution of spent HDS catalysts by solvent extraction [J]. Hydrometallurgy, 2013, 133: 161-167. doi: 10.1016/j.hydromet.2013.01.006

[46] HAMZA M F, ROUX JC, GUIBAL E. Metal valorization from the waste produced in the manufacturing of Co/Mo catalysts: leaching and selective precipitation [J]. Journal of Material Cycles and Waste Management, 2019, 21(3): 525-538. doi: 10.1007/s10163-018-0811-9

[47] LEE J C, KIM E Y, KIM J H, et al. Recycling of WC-Co hardmetal sludge by a new hydrometallurgical route [J]. International Journal of Refractory Metals & amp; Hard Materials, 2011, 29(3): 365-371.

[48] 岳松. 废高磁合金钢中钴、镍的分离和利用[J]. 四川环境, 2000, 19(4): 29-31. doi: 10.3969/j.issn.1001-3644.2000.04.009

[49] A. R M. Recovery of molybdenum and cobalt powders from spent catalysts [J]. Metal Powder Report, 1998, 53(11): 37.

[50] LI L, GE J, WU F, et al. Recovery of cobalt and lithium from spent lithium ion batteries using organic citric acid as leachant [J]. J Hazard Mater, 2010, 176(1): 288-293.

[51] HE LP, SUN SY, MU YY, et al. Recovery of lithium, nickel, cobalt, and manganese from spent lithium-ion batteries using l-tartaric acid as a leachant [J]. ACS Sustainable Chemistry & amp; Engineering, 2017, 5(1): 714-721.

[52] SUN L, QIU K. Organic oxalate as leachant and precipitant for the recovery of valuable metals from spent lithium-ion batteries [J]. Waste Management, 2012, 32(8): 1575-1582. doi: 10.1016/j.wasman.2012.03.027

[53] HUANG Y, GUO H, ZHANG C, et al. A novel method for the separation of zinc and cobalt from hazardous zinc & amp; ndash; cobalt slag via an alkaline glycine solution [J]. Sep Purif Technol, 2021, 273: 119009. doi: 10.1016/j.seppur.2021.119009

[54] 王俊杰, 谈定生, 丁家杰, 等. 湿法炼锌渣柠檬酸浸出回收钴、锌和镍[J]. 矿产保护与利用, 2021, 41(2): 137-143. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=786784f1-b390-4864-931a-d03e5c20a162

[55] LI L, LU J, REN Y, et al. Ascorbic-acid-assisted recovery of cobalt and lithium from spent Li-ion batteries [J]. Journal of Power Sources, 2012, 218: 21-27. doi: 10.1016/j.jpowsour.2012.06.068

[56] CHEN X P, LUO C B, ZHANG J X, et al. Sustainable recovery of metals from spent lithium-ion batteries: a green process [J]. Acs Sustainable Chemistry & amp; Engineering, 2015, 3(12): 3104-3113.

[57] NAYAKA G P, MANJANNA J, PAI K V, et al. Recovery of valuable metal ions from the spent lithium-ion battery using aqueous mixture of mild organic acids as alternative to mineral acids [J]. Hydrometallurgy, 2015, 151: 73-77. doi: 10.1016/j.hydromet.2014.11.006

[58] ZENG X, LI J, SHEN B. Novel approach to recover cobalt and lithium from spent lithium-ion battery using oxalic acid [J]. J Hazard Mater, 2015, 295: 112-118. doi: 10.1016/j.jhazmat.2015.02.064

[59] BEUTHER H, FLINN R A. Technique for removing metal contaminants from catalysts [J]. I & amp; EC Product Research and Development, 1963, 2(1): 53-57.

[60] WU C, LI B, YUAN C, et al. Recycling valuable metals from spent lithium-ion batteries by ammonium sulfite-reduction ammonia leaching [J]. Waste Management, 2019, 93: 153-161. doi: 10.1016/j.wasman.2019.04.039

[61] MARCANTONIO P J. Leaching cobalt from metal-containing particles, Google Patents [P]. 1991

[62] CHEN L, TANG X, ZHANG Y, et al. Process for the recovery of cobalt oxalate from spent lithium-ion batteries [J]. Hydrometallurgy, 2011, 108(1): 80-86.

[63] ANGELIDIS T N, TOURASANIDIS E, MARINOU E, et al. Selective dissolution of critical metals from diesel and naptha spent hydrodesulphurization catalysts [J]. Resources, Conservation and Recycling, 1995, 13(3/4): 269-282.

[64] PRANOLO Y, ZHANG W, CHENG C Y. Recovery of metals from spent lithium-ion battery leach solutions with a mixed solvent extractant system [J]. Hydrometallurgy, 2010, 102(1/2/3/4): 37-42.

[65] 叶有明, 谢雪珍, 农永萍. 用常压酸浸—溶剂萃取法从硫锰废渣中回收锰钴镍试验研究[J]. 湿法冶金, 2020, 39(4): 298-303. https://www.cnki.com.cn/Article/CJFDTOTAL-SFYJ202004007.htm

[66] 陈亮, 唐新村, 张阳, 等. 从废旧锂离子电池中分离回收钴镍锰[J]. 中国有色金属学报, 2011, 21(5): 1192-1198. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201105039.htm

[67] 刘三平, 王海北, 蒋开喜, 等. 钴提取分离技术分析与应用[J]. 有色金属, 2004(2): 73-76. doi: 10.3969/j.issn.2095-1744.2004.02.018

[68] 孙明生, 沙涛, 苏凤来. 湿法炼锌净化渣综合回收的生产实践[J]. 矿冶, 2010, 19(1): 73-76. https://www.cnki.com.cn/Article/CJFDTOTAL-KYZZ201001019.htm

[69] SONG S L, SUN W, WANG L, et al. Recovery of cobalt and zinc from the leaching solution of zinc smelting slag [J]. J Environ Chem Eng, 2019, 7(1): 102777. doi: 10.1016/j.jece.2018.11.022

[70] YANG Y, LEI S, SONG S, et al. Stepwise recycling of valuable metals from Ni-rich cathode material of spent lithium-ion batteries [J]. Waste Management, 2020, 102: 131-138. doi: 10.1016/j.wasman.2019.09.044

[71] 郭丽萍, 杜小弟, 方伟, 等. Na2S2O3还原溶解LiCoO2及钴、锂分离回收[J]. 应用化学, 2006(10): 1182-1184. doi: 10.3969/j.issn.1000-0518.2006.10.026

[72] 黎华玲, 陈永珍, 宋文吉, 等. 湿法回收退役三元锂离子电池有价金属的研究进展[J]. 化工进展, 2019, 38(2): 921-932. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201902026.htm

[73] 李冰洁, 廖亚龙, 胡亮, 等. 溶液中钴与镍的深度分离研究进展[J]. 化学工程, 2015, 43(8): 33-37. doi: 10.3969/j.issn.1005-9954.2015.08.008

[74] BANZA A N, GOCK E, KONGOLO K. Base metals recovery from copper smelter slag by oxidising leaching and solvent extraction [J]. Hydrometallurgy, 2002, 67(1/2/3): 63-69.

[75] 蔡传算, 刘荣义. 含钴高温合金废料的综合利用[J]. 中国有色金属学报, 1996, 6(1): 49-52. doi: 10.3321/j.issn:1004-0609.1996.01.011

[76] 陈奇志, 高锋, 史磊. 全湿法从锰钴镍渣中回收钴、镍的试验研究[J]. 企业技术开发(学术版), 2014(2): 20-22. https://www.cnki.com.cn/Article/CJFDTOTAL-QYJK201404009.htm

[77] 周炳珍. 用P204和P507脱除含钴废料中的杂质生产高纯度氯化钴[J]. 有色金属(冶炼部分), 2002(6): 16-17+44. doi: 10.3969/j.issn.1007-7545.2002.06.005

[78] 刘富强, 朱兆华, 邓华利. 废镍催化剂中有价金属回收试验研究[J]. 三峡环境与生态, 2008(2): 21-23+62. doi: 10.3969/j.issn.1674-2842.2008.02.006

[79] 张阳, 满瑞林, 王辉, 等. 用P507萃取分离钴及草酸反萃制备草酸钴[J]. 中南大学学报(自然科学版), 2011, 42(2): 317-322. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201102008.htm

[80] KANG J, SENANAYAKE G, SOHN J, et al. Recovery of cobalt sulfate from spent lithium ion batteries by reductive leaching and solvent extraction with Cyanex 272 [J]. Hydrometallurgy, 2010, 100(3/4): 168-171.

[81] GRANATA G, MOSCARDINI E, PAGNANELLI F, et al. Product recovery from Li-ion battery wastes coming from an industrial pre-treatment plant: Lab scale tests and process simulations [J]. Journal of Power Sources, 2012, 206: 393-401. doi: 10.1016/j.jpowsour.2012.01.115

[82] 侯晓川, 肖连生, 高从堦, 等. 从废高温镍钴合金中浸出镍和钴的试验研究[J]. 湿法冶金, 2009, 28(3): 164-169. doi: 10.3969/j.issn.1009-2617.2009.03.008

[83] 侯晓川, 肖连生, 高从堦, 等. 废高温镍钴合金浸出液净化试验研究[J]. 有色金属(冶炼部分), 2010(4): 9-11, 21. doi: 10.3969/j.issn.1007-7545.2010.04.003

-

下载:

下载: