Experimental Study on Defoaming of Flotation Concentrate with Different Defoamers and Their Effect on Flotation

-

摘要:

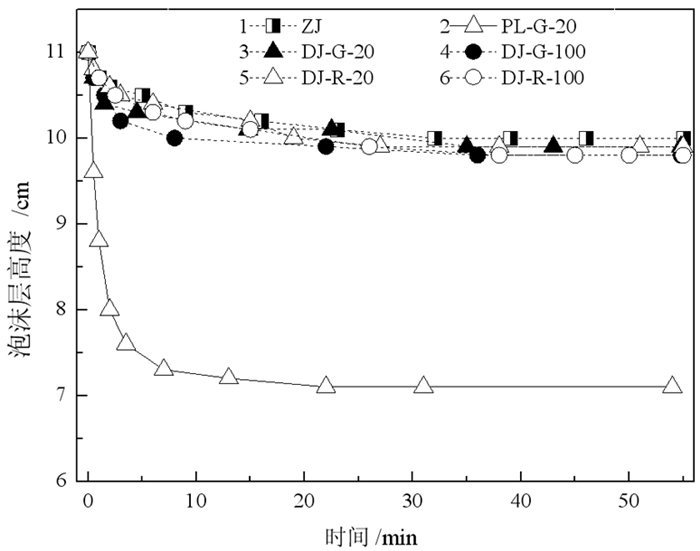

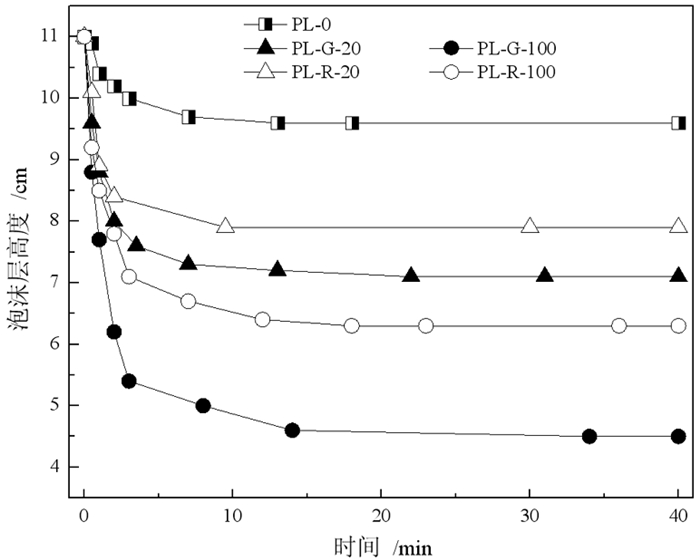

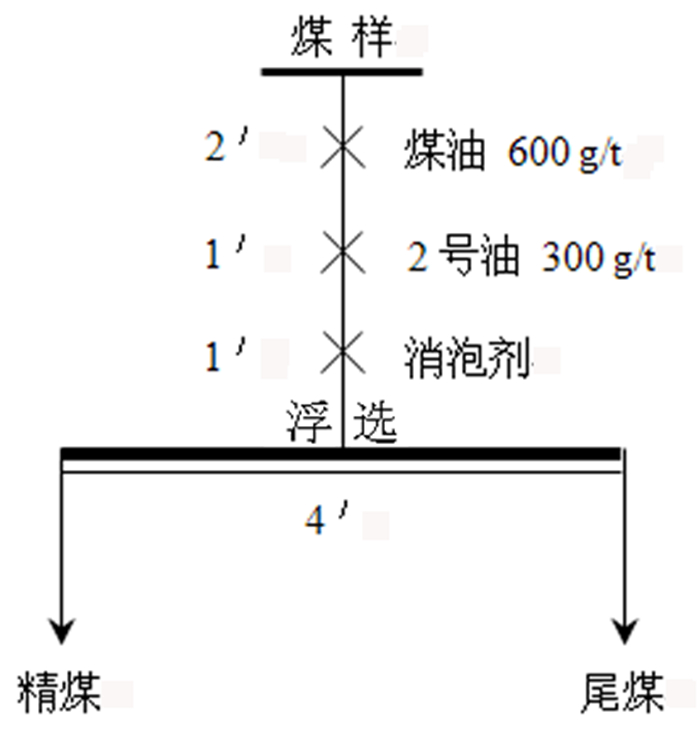

为了解决稳定的浮选精煤泡沫给精煤的储存、转运和脱水带来的系列工业生产问题, 进行了硅油消泡剂(G)和乳化烃类油消泡剂(R)对浮选精煤泡沫的消泡试验, 考察了消泡剂的添加方式和用量对浮选精煤消泡效果的影响, 以及消泡剂残留于循环水对浮选流程的影响。结果表明, 消泡剂以喷淋方式加入更能有效增加消泡速率和消泡程度; 随着消泡剂用量的增加, 消泡效果越好, 且硅油消泡剂优于乳化烃类油消泡剂; 循环水中较低用量消泡剂的残留对浮选影响较小, 当残留量较大时, 硅油消泡剂降低了浮选选择性, 抑制了浮选, 而乳化烃类油消泡剂有利于浮选。综合考虑, 建议使用低用量的乳化烃类油消泡剂, 以喷淋方式对浮选精煤进行消泡。

Abstract:In order to solve a series of industrial production problems of storage, transport and dehydration of coal flotation concentrate caused by the strong stability of their foam, the defoaming experiments of silicone defoamer (G) and emulsified hydrocarbon oil defoamer (R) for flotation concentrate were studied to revel the effect of the adding method and dosage of defoamer on the defoaming results. In addition, the effect of residual defoamer in circulating water on flotation process was revealed by the flotation test. The results showed that the rate and degree of defoaming can be increased more effectively by defoamers added in the way of spraying. The defoaming property is better with the increase of the dosage of defoamers and the silicone defoamer is superior to emulsified hydrocarbon oil defoamer. A low amount of defoamer in circulating water has little effect on flotation. When the residual amount increasing, silicone oil defoaming agent reduces flotation selectivity and inhibits flotation, while emulsified hydrocarbon oil defoamer can promote it. It is suggested that the flotation concentrate should be defoamed with low dosage emulsified hydrocarbon oil by spraying.

-

Key words:

- flotation concentrate of coal /

- defoaming /

- defoamer /

- spray /

- recycled water /

- flotation

-

-

表 1 不同条件下的消泡率

Table 1. Defoaming rate under different conditions

条件 PL-0 PL-G-20 PL-G-100 PL-R-20 PL-R-100 消泡率/% 12.73 35.45 59.09 28.18 42.73 注:条件同图 3;消泡率——被消除泡沫层高度占原泡沫层高度百分比。 表 2 浮选结果

Table 2. Flotation results

消泡剂种类 消泡剂用量/(L·mg-1) 尾煤 精煤 精煤可燃体

回收率/%质量/g 产率/% Aad/% 质量/g 产率/% Aad/% / / 196.1 68.61 73.54 89.7 31.39 14.81 59.56 G 10 194.4 67.90 72.75 91.9 32.10 13.26 60.08 R 10 185.5 64.95 71.54 100.1 35.05 16.45 61.30 G 100 252.0 89.58 57.91 29.3 10.42 18.73 18.33 R 100 160.1 58.13 80.90 115.3 41.87 18.63 75.42 -

[1] CHEN Y, HU S, LI J, et al. Improvement on combustible matter recovery in coal slime flotation with the addition of sodium silicate [J]. Colloids and Surfaces a-Physicochemical and Engineering Aspects, 2020, 603: 125220.

[2] ZHOU W, WU C, LV H, et al. Nanobubbles heterogeneous nucleation induced by temperature rise and its influence on minerals flotation [J]. Applied Surface Science, 2020, 508: 145282. doi: 10.1016/j.apsusc.2020.145282

[3] 徐博, 徐岩, 于刚. 煤泥浮选技术与实践[M]. 北京: 化学工业出版社, 2006.

XU B, XU Y, YU G. Slime flotation technology and practice [M]. Beijing: Chemical Industry Press, 2006.

[4] 吴昌宁, 翁力, 李俊国, 等. 微矿分离: 煤炭清洁化与土壤改良的新契机[J]. 科学通报, 2021, 66(25): 3352-3364. https://www.cnki.com.cn/Article/CJFDTOTAL-KXTB202125015.htm

Wu C N, Weng L, Li J G, et al. A novel mineral separation process: New opportunity for clean coal utilization and soil remediation (in Chinese). Chin. Sci. Bull., 2021, 66: 3352-3364. https://www.cnki.com.cn/Article/CJFDTOTAL-KXTB202125015.htm

[5] 穆枭, 冯其明, 陈建华, 等. 铝土矿浮选三相泡沫稳定性研究[J]. 中国矿业, 2008(1): 81-83+97. doi: 10.3969/j.issn.1004-4051.2008.01.025

MU X, FENG Q M, CHEN J H, et al. Study on stability three phase foam of bauxite flotation [J]. China Mine Magazine, 2008(1): 81-83+97. doi: 10.3969/j.issn.1004-4051.2008.01.025

[6] 郭贞强. 细粒赤铁矿精矿泡沫稳定性与消泡效果的研究[D]. 武汉: 武汉科技大学, 2020.

GUO Z Q. Study on Foam Stability and Defoaming Behavior of Fine Hematite Concentrate [D]. Wuhan: Wuhan University of Science and Technology, 2020.

[7] 柳泉洲, 陶秀祥, 何环, 等. 浮选油泡稳定性试验研究[J]. 煤炭技术, 2016, 35(10): 303-305. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201610121.htm

LIU Q Z, TAO X X, HE H, et al. Experimental study on stability of oil bubbles of flotation [J]. Coal Technology, 2016, 35(10): 303-305. https://www.cnki.com.cn/Article/CJFDTOTAL-MTJS201610121.htm

[8] 韩来兵, 付晓恒, 赵海铭, 等. 捕收剂和起泡剂对浮选精煤三相泡沫稳定性的影响[J]. 选煤技术, 2015(2): 4-7. https://www.cnki.com.cn/Article/CJFDTOTAL-XMJS201502003.htm

HAN L B, FU X H, ZHAO H M, et al. Effect of collecting agent and frothing agent on stability of three-phase clean coal froth in flotation [J]. Coal Preparation Technology, 2015(2): 4-7. https://www.cnki.com.cn/Article/CJFDTOTAL-XMJS201502003.htm

[9] GUO J, ZHANG L, LIU S, et al. Effects of hydrophilic groups of nonionic surfactants on the wettability of lignite surface: Molecular dynamics simulation and experimental study [J]. Fuel, 2018, 231: 449-457. doi: 10.1016/j.fuel.2018.05.106

[10] 任利勤, 郭建伟, 丁光耀, 等. 实验室浮选泡沫真空消泡试验研究[J]. 煤炭科学技术, 2018, 46(S1): 252-255. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ2018S1058.htm

REN L Q, GUO J W, DING G Y, et al. Study on vacuum defoaming test of flotation foam in laboratory [J]. Coal Science and Technology, 2018, 46(S1): 252-255. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ2018S1058.htm

[11] 穆枭. 胶磷矿浮选三相泡沫稳定性研究[J]. 矿产保护与利用, 2012(4): 26-28. doi: 10.3969/j.issn.1001-0076.2012.04.007 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=a71e5500-c43f-41be-ae31-8266f7f87af5

MU X. Study on Stability of Three-phase Foam in Collophanite Flotation [J]. Conservation and Utilization of Mineral Resources, 2012(4): 26-28. doi: 10.3969/j.issn.1001-0076.2012.04.007 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=a71e5500-c43f-41be-ae31-8266f7f87af5

[12] 穆枭. 三相泡沫稳定性与消泡研究[D]. 长沙: 中南大学, 2005.

MU X. Study on Stability and Antifoaming of Three-phase Foam [D]. Changsha: Central South University, 2005.

[13] 张高峰. 采用喷淋装置消除浮选精煤泡沫的试验研究[J]. 内蒙古煤炭经济, 2017(24): 144-145. doi: 10.3969/j.issn.1008-0155.2017.24.085

ZHANG G F. Experimental study on elimination of flotation cleaned coal foam by spraying device [J]. Inner Mongolia Coal Economy, 2017(24): 144-145. doi: 10.3969/j.issn.1008-0155.2017.24.085

[14] 林娟. 关于浮选精煤泡沫消除的系统改造[J]. 煤质技术, 2006(3): 53-54. doi: 10.3969/j.issn.1007-7677.2006.03.023

LIN J. The system improvement in the removal of foam to floation clean coal [J]. Coal Quality Technology, 2006(3): 53-54. doi: 10.3969/j.issn.1007-7677.2006.03.023

[15] 王里, 李秉轩, 师天华. 浮选过程中的消泡研究[J]. 煤炭加工与综合利用, 2010(4): 25-28. doi: 10.3969/j.issn.1005-8397.2010.04.010

WANG L, LI B X, SHI T H. Study on defoaming in flotation process [J]. Coal Processing & Comprehensive Utilization, 2010(4): 25-28. doi: 10.3969/j.issn.1005-8397.2010.04.010

[16] 张利国. 消泡剂消泡机理、应用及评价方法介绍[J]. 日用化学品科学, 2018, 41(2): 40-44. https://www.cnki.com.cn/Article/CJFDTOTAL-RYHX201802015.htm

ZHANG L G. Introduction of mechanism, application and evaluation methods of defoaming agents [J]. Detergent & Cosmetics, 2018(2): 40-44. https://www.cnki.com.cn/Article/CJFDTOTAL-RYHX201802015.htm

[17] 徐胜. 机械搅拌消除浮选精矿泡沫的试验研究[J]. 选煤技术, 2016(1): 19-23. https://www.cnki.com.cn/Article/CJFDTOTAL-XMJS201601006.htm

XU S. Experimental study on defoaming of flotation concentrate by means of mechanical agitation [J]. Coal Preparation Technology, 2016(1): 19-23. https://www.cnki.com.cn/Article/CJFDTOTAL-XMJS201601006.htm

[18] 吴伦, 魏小磊, 桂夏辉, 等. 无烟煤浮选精煤物理消泡试验研究[J]. 煤炭工程, 2015, 47(1): 118-120+123. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ201501040.htm

WU L, WEI X L, GUI X H, et al. Experimental Study on Physical Defoaming of Anthracite Flotation Concentrate [J]. Coal Engineering, 2015, 47(1): 118-120+123. https://www.cnki.com.cn/Article/CJFDTOTAL-MKSJ201501040.htm

[19] 李明, 徐梦迪, 晋伟, 等. 柴油对浮选泡沫稳定性影响的试验研究[J]. 煤炭学报, 2019, 44(6): 1876-1882. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201906027.htm

LI M, XU M D, JIN W, et al. Effect of diesel on flotation foam stability [J]. Journal of China Coal Society, 2019, 44(6): 1876-1882. https://www.cnki.com.cn/Article/CJFDTOTAL-MTXB201906027.htm

[20] 中国国家标准化管理委员. GB/T 4757—2013, 煤粉(泥)实验室单元浮选试验方法[S]. 北京: 中国标准出版社, 2013.

Standardization Administration of China. GB/T 4757—2013, Methods for the batch flotation testing of fine coal [S]. Beijing: China Standards Press, 2013.

[21] WONG W S Y, NAGA A, HAUER L, et al. Super liquid repellent surfaces for anti-foaming and froth management [J]. Nature Communications, 2021, 12(1): 1-11. doi: 10.1038/s41467-020-20314-w

[22] 胡楠, 胡明明, 李雪, 等. 一种高效聚醚酯消泡剂的制备及性能研究[J]. 盐科学与化工, 2021, 50(7): 9-13. doi: 10.3969/j.issn.2096-3408.2021.07.004

HU N, HU M M, LI X, et al. Study on preparation and performance of a highly efficient GPES defoamer [J]. Journal of Salt Science and Chemical Industry, 2021, 50(7): 9-13. doi: 10.3969/j.issn.2096-3408.2021.07.004

[23] FRANK A, SCHOLZ W. Defoamers in the coatings industry [J]. Chimia, 2002, 56(5): 177-183. doi: 10.2533/000942902777680478

[24] 李想. 有机硅消泡剂的消泡机理及其应用[J]. 化学工程师, 2009, 23(1): 47-48. doi: 10.3969/j.issn.1002-1124.2009.01.018

LI X. Defoaming mechanism and application of organic silicon defoamer [J]. Chemical Engineer, 2009, 23(1): 47-48. doi: 10.3969/j.issn.1002-1124.2009.01.018

[25] DENKOV N D. Mechanisms of action of mixed solid-liquid antifoams. 2. Stability of oil bridges in foam films [J]. Langmuir, 1999, 15(24): 8530-8542. doi: 10.1021/la990214y

[26] DENKOV N D, TCHOLAKOVA S, MARINOVA K G, et al. Role of oil spreading for the efficiency of mixed oil-solid antifoams [J]. Langmuir, 2002, 18(15): 5810-5817.

[27] 陈更, 秦俊岭, 徐慧, 等. 延迟焦化消泡剂的室内评选[J]. 全面腐蚀控制, 2020, 34(7): 29-31. https://www.cnki.com.cn/Article/CJFDTOTAL-QMFK202007006.htm

CHEN G, QIN J L, XU H, et al. Indoor Evaluation of delayed coking defoaming agent [J]. Total Corrosion Control, 2020, 34(7): 29-31. https://www.cnki.com.cn/Article/CJFDTOTAL-QMFK202007006.htm

[28] 于国玲, 王学克. 水性涂料中消泡剂的应用及研究进展[J]. 中国涂料, 2019, 34(2): 70-74. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTU201902014.htm

YU G L, WANG X K. Application of defoamer in waterborne coatings and research progress [J]. China Coatings, 2019, 34(2): 70-74. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTU201902014.htm

[29] CHEN Y, ZHANG D, LI J, et al. Using emulsified and pre-dispersed hydrocarbon oil in waste coal reprocessing: A case study [J]. Fuel, 2021, 306: 121628.

[30] ZHAO X, TANG Y, ZHAO B, et al. Collecting behaviors of high internal phase (HIP) emulsion in flotation of ultrafine high-ash content coal slime [J]. International Journal of Coal Preparation and Utilization, 2021: 1-21.

-

下载:

下载: