Study on Composite Modification of Natural Barite of Stearic Acid Titanate Coupling Agent

-

摘要:

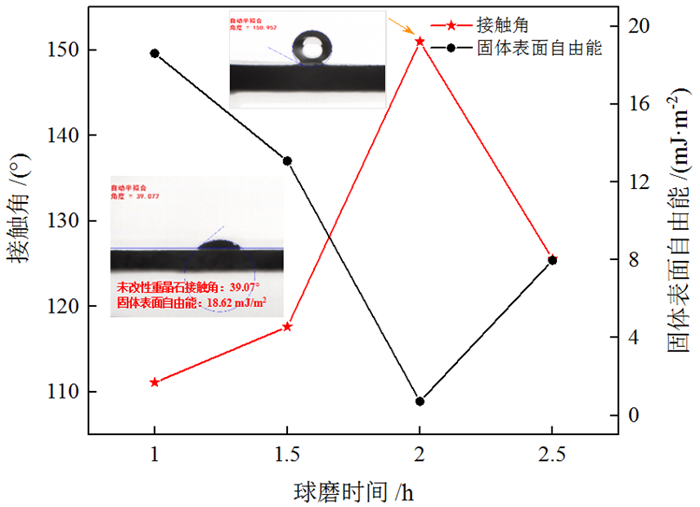

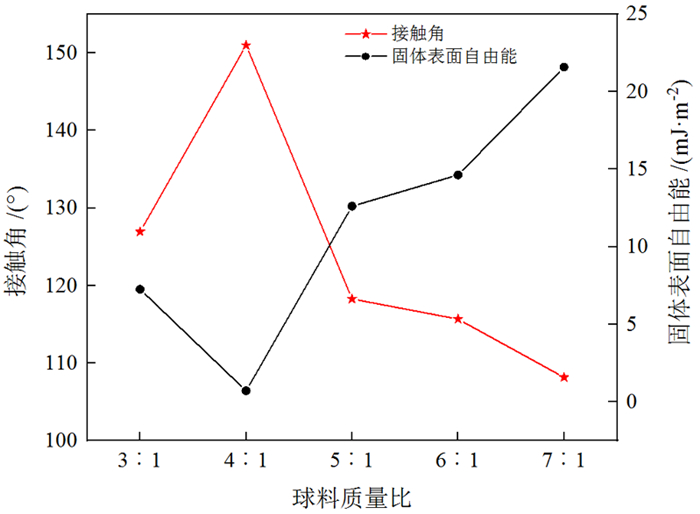

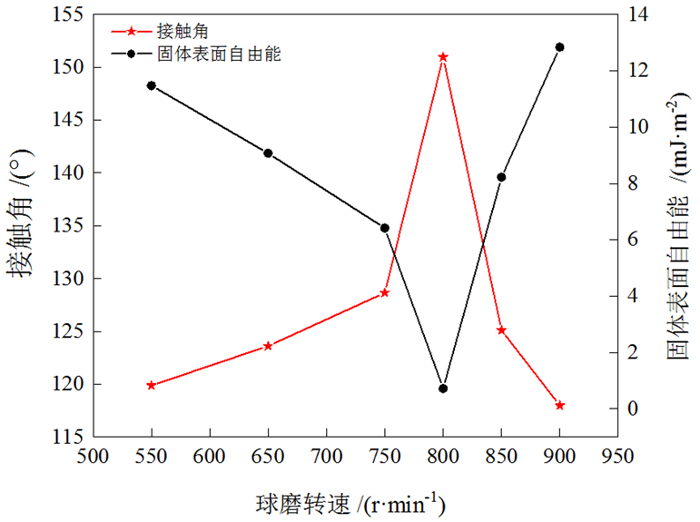

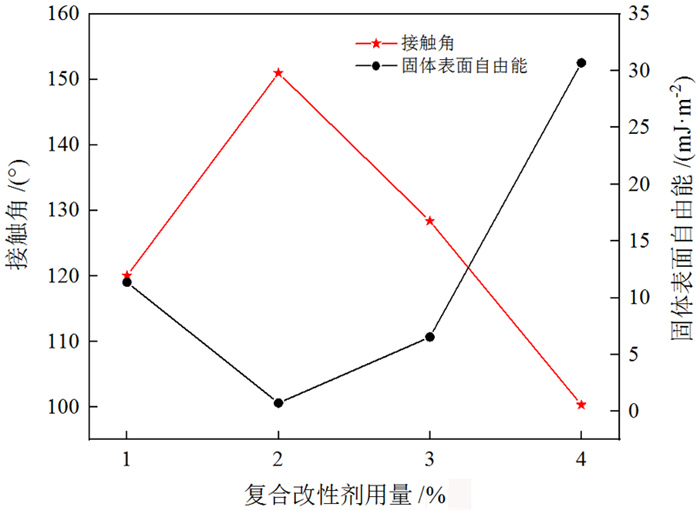

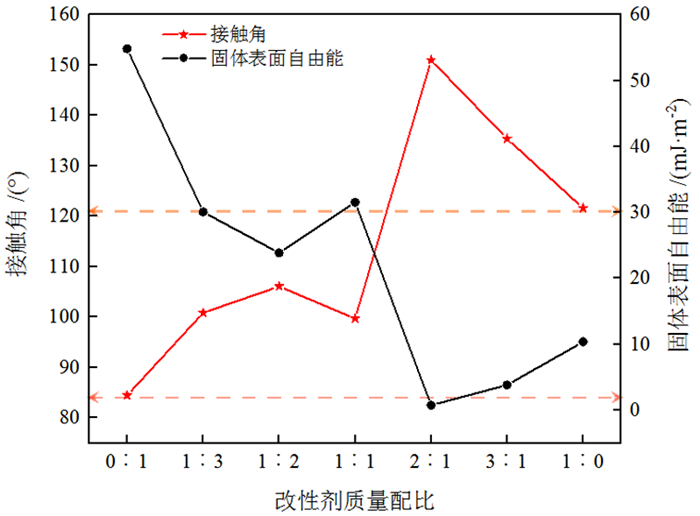

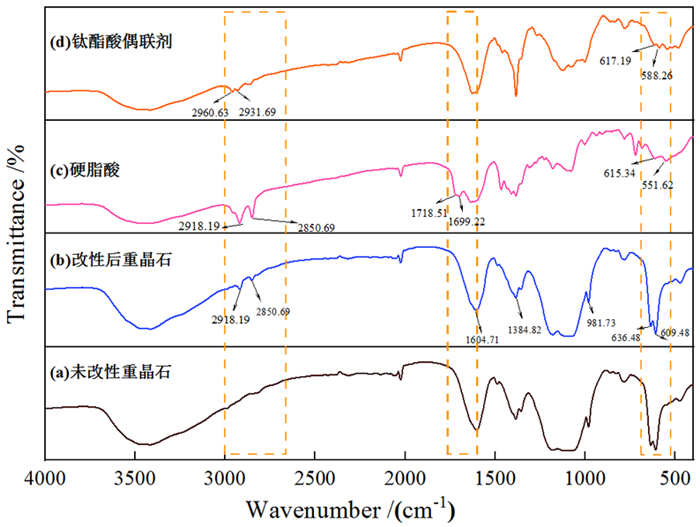

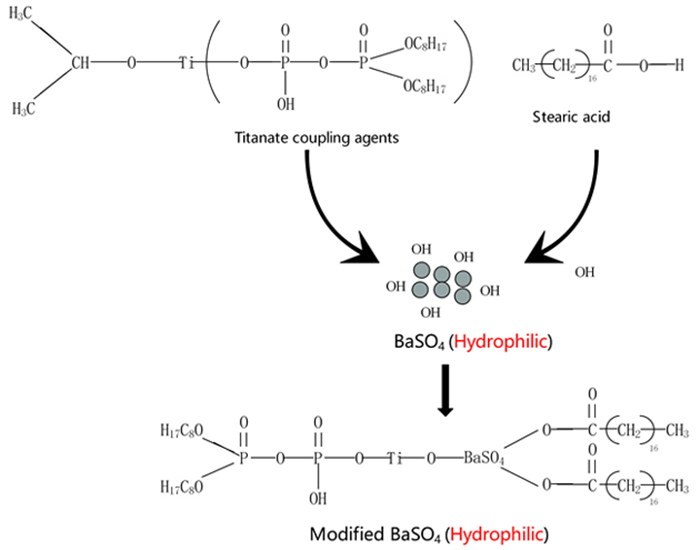

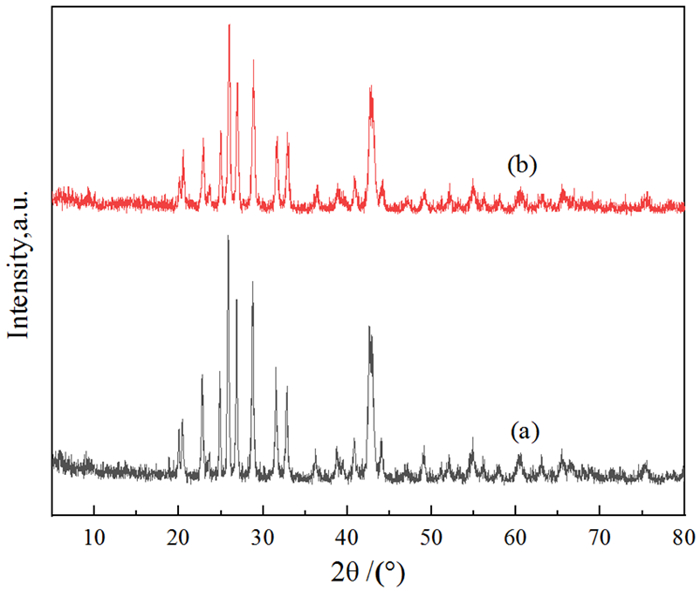

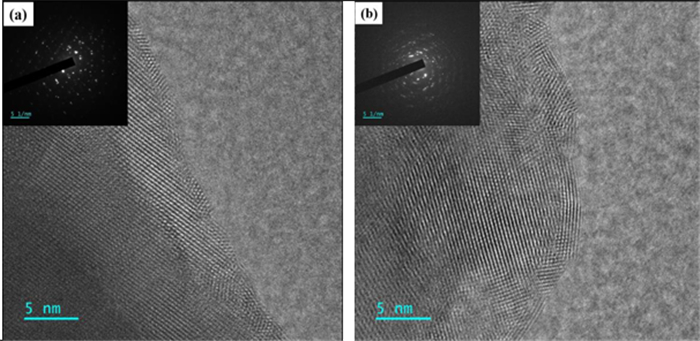

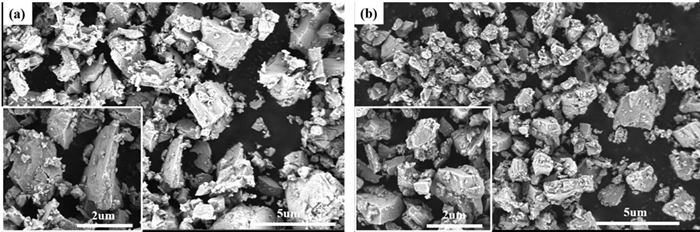

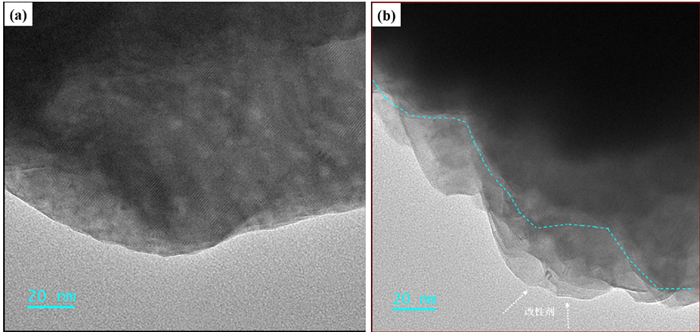

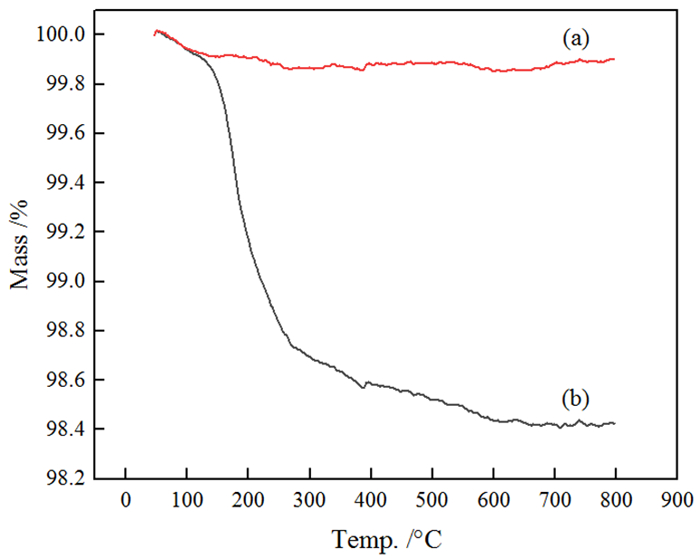

采用湿式机械力化学法,以硬脂酸和钛酸酯偶联剂为复合改性剂对贵州产天然重晶石进行改性。考察了球磨时间、球磨转速、球料质量比、复合改性剂用量及改性剂质量配比对重晶石改性效果的影响。通过FTIR、XRD、SEM、TEM、TG对改性前后重晶石的物相结构、形貌特征和包覆情况进行了研究。结果表明,经过单因素试验得到最佳工艺条件为:球磨时间为2 h、球磨转速为800 r/min、球料质量比(介质球/重晶石)为4 GA6FA 1、复合改性剂用量为2%、改性剂质量配比(硬脂酸/钛酸酯偶联剂)为2 GA6FA 1。改性后改性剂成功地化学键合在重晶石表面。与未改性重晶石相比,改性重晶石的平均粒径减小,分散性增强,晶体结构未发生明显的变化。改性后重晶石的接触角从39.07°增大到150.95°,固体表面自由能从18.62 mJ/m2变化到0.72 mJ/m2,改性后重晶石具有较好的超疏水性,可作为制备超疏水涂层材料的原料。

Abstract:Using stearic acid and titanate coupling agent as composite modifier, the natural barite powder produced in Guizhou was modified by wet mechanochemical method. The effects of process conditions such as ball milling time, ball milling speed, mass ratio of ball to material, dosage of compound modifier, and mass ratio of modifier on the properties of modified barite were studied. The phase structure, morphological characteristics and coating of barite before and after modification were characterized by FT-IR、XRD、SEM、TEM and TG. The results show that the optimal process conditions are obtained through single factor experiments: the ball milling time is 2 h, the ball milling speed is 800 r/min, the mass ratio of ball to material (ball/barite) is 4 GA6FA 1, the dosage of compound modifier is 2.0% (modifier/barite), and the mass ratio of modifier (stearic acid/titanate coupling agent) is 2 GA6FA 1. After modification, the modifier was successfully chemically bonded to the barite surface. Compared with the unmodified barite, the average particle size of the modified barite is reduced, the dispersibility is enhanced, and the crystal structure does not change significantly. The modified barite's contact angle changes from 39.07° to 150.95°, and the solid surface free energy changes from 18.62 mJ/m2 to 0.72 mJ/m2. The modified barite has better superhydrophobicity and can be used as a raw material for preparing superhydrophobic coating materials.

-

Key words:

- barite /

- stearic acid /

- titanate coupling agent /

- composite modification /

- wet mechanochemical method

-

-

[1] CELEN Y Y, EVCIN A, AKKURT I, et al. Evaluation of boron waste and barite against radiation[J]. International Journal of Environmental Science and Technology, 2019, 16(9): 5267-5274. doi: 10.1007/s13762-019-02333-3

[2] BAHL S, LOCHAB S P, PANDEY A, et al. Characterization and luminescence studies of Eu doped barite nanophosphor[J]. Journal of Luminescence, 2014, 149: 176-184.

[3] 王洋, 黄聪, 李珍. 重晶石资源现状及材料化应用[J]. 矿产保护与利用, 2020, 40(6): 26-32. doi: 10.13779/j.cnki.issn1001-0076.2020.06.004 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=1b94b52d-0ba6-484c-9641-4f4a6f4c8c8d

WANG Y, HUANG C, LI Z. Status quo and materialized application of barite resources[J]. Conservation and Utilization of Mineral Resources, 2020, 40(6): 26-32. doi: 10.13779/j.cnki.issn1001-0076.2020.06.004 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=1b94b52d-0ba6-484c-9641-4f4a6f4c8c8d

[4] ELKAWASH H, TIRKES S, HACIOGLU F, et al. Physical and mechanical performance of bentonite and barite loaded low density polyethylene composites: influence of surface silanization of minerals[J]. Journal of Composite Materials, 2020, 54(28): 4359-4368.

[5] GE C H, DING P, SHI L Y, et al. Isothermal crystallization kinetics and melting behavior of poly(ethylene terephthalate)/barite nanocomposites[J]. Journal of Polymer Science(Part B. Polymer Physics), 2009, 47(7): 655-668. doi: 10.1002/polb.21669

[6] 陈有双, 王继虎, 唐忠锋, 等. 改性重晶石补强天然橡胶的研究[J]. 非金属矿, 2010, 33(3): 59-61. https://www.cnki.com.cn/Article/CJFDTOTAL-FJSK201003020.htm

CHEN Y S, WANG H, TANG Z F, et al. Study on reinforcement of natural rubber with modified barite[J]. Non-Metallic Mines, 2010, 33(3): 59-61. https://www.cnki.com.cn/Article/CJFDTOTAL-FJSK201003020.htm

[7] 陈思雨, 刘四清, 陈章鸿. 我国重晶石选矿与提纯研究现状及展望[J]. 矿产保护与利用, 2020, 40(6): 33-40. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=d6e4dc42-db5b-448d-94ba-2a51fefa3726

CHEN S Y, LIU S Q, CHEN Z H, et al. Present situation and outlook of barite flotation and purification in china[J]. Conservation and Utilization of Mineral Resources, 2020, 40(6): 33-40. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=d6e4dc42-db5b-448d-94ba-2a51fefa3726

[8] HUANG R Z, ZHANG X, ZHOU C J. Mechanical, flammable, and thermal performances of co-extruded wood polymer composites with core-shell structure containing barite-filled shells[J]. Wood Science and Technology, 2020, 54(5): 1299-1318.

[9] 王威, 欧阳兆辉. 重晶石矿粉表面改性研究与应用[J]. 中国非金属矿工业导刊, 2005(6): 37-39. https://www.cnki.com.cn/Article/CJFDTOTAL-LGFK200506011.htm

WANG W, OUYANG Z H. Study and application on surface modification of barite powder[J]. China Non-metallic Mining Industry Herald, 2005(6): 37-39. https://www.cnki.com.cn/Article/CJFDTOTAL-LGFK200506011.htm

[10] 肖琴, 满瑞林, 杨萍, 等. 十二烷基硫酸钠改性重晶石的研究[J]. 非金属矿, 2013, 36(2): 5-7+47. https://www.cnki.com.cn/Article/CJFDTOTAL-FJSK201302003.htm

XIAO Q, MAN R L, YANG P, et al. Surface modification of barite using sodium dedocyl sulfate[J]. Non-Metallic Mines, 2013, 36(2): 5-7+47. https://www.cnki.com.cn/Article/CJFDTOTAL-FJSK201302003.htm

[11] DING H, ZHOU H, ZHENG Y X, et al. Effect of sodium stearate on grinding behaviour of calcium carbonate in wet stirred mill[J]. Materials Research Innovations, 2013, 17(sup1): 292-296.

[12] 杭建忠. 纳米天然重晶石制备及其在卷材涂料中应用研究[D]. 上海: 上海大学, 2008.

HANG J Z. The preparation of nanometer nature barite and its application research in coil coating[D]. Shanghai: Shanghai University, 2008.

[13] 黄向阳, 彭国煌. 一种高分散重晶石的制备方法: CN111362291A[P]. 2020-07-03.

HUANG X Y, PENG G H. A method for the preparation of a highly dispersed barite: CN111362291A[P]. 2020-07-03.

[14] LEI T T, XU Y, WANG LT, et al. Surface modification of barite powder by coupling agent and characterization[J]. Open Journal of Nature Science, 2015, 3(4): 113-120.

[15] 陈焕章, 孙朝利, 张洁. 硅烷偶联剂对超细硫酸钡的改性研究[J]. 现代化工, 2020, 40(5): 181-185+189. https://www.cnki.com.cn/Article/CJFDTOTAL-XDHG202005041.htm

CHEN H Z, SUN C L, ZHANG J. Study on modification of ultrafine barium sulfate by silane coupling agent[J]. Modern Chemical Industry, 2020, 40(5): 181-185+189. https://www.cnki.com.cn/Article/CJFDTOTAL-XDHG202005041.htm

[16] 陈有双, 王继虎, 唐忠锋, 等. 重晶石/橡胶复合材料的力学性能研究[J]. 化工新型材料, 2010, 38(12): 108-110. https://www.cnki.com.cn/Article/CJFDTOTAL-HGXC201012038.htm

CHEN Y S, WANG J H, TANG Z F, et al. Mechanical properties of natural rubber/barite composite materials[J]. New Chemical Materials, 2010, 38(12): 108-110. https://www.cnki.com.cn/Article/CJFDTOTAL-HGXC201012038.htm

[17] 王健, 丁浩, 周红. 重晶石表面改性工艺[J]. 中国粉体技术, 2017, 23(2): 62-64+98. https://www.cnki.com.cn/Article/CJFDTOTAL-FTJS201702014.htm

WANG J, DING H, ZHOU H. Study on surface modification of barite[J]. China Powder Science and Technology, 2017, 23(2): 62-64+98. https://www.cnki.com.cn/Article/CJFDTOTAL-FTJS201702014.htm

[18] 周红, 丁浩, 沈凯. 重晶石表面疏水改性对表面能与颗粒分散性的影响[J]. 化工矿物与加工, 2015, 44(5): 11-12+40. https://www.cnki.com.cn/Article/CJFDTOTAL-HGKJ201505004.htm

ZHOU H, DING H, SHEN K. Impacts of hydrophobic modification of barite surface on surface energy and particle dispersion[J]. Industrial Minerals & Processing, 2015, 44(5): 11-12+40. https://www.cnki.com.cn/Article/CJFDTOTAL-HGKJ201505004.htm

[19] ZHAO G Z, SHI L Y, ZHANG D S, et al. Synergistic effect of nanobarite and carbon black fillers in natural rubber matrix[J]. Materials & Design, 2012, 35: 847-853.

[20] 王友, 曾一文, 覃康玉, 等. 硬脂酸-钛酸酯偶联剂改性重质碳酸钙粉体研究[J]. 无机盐工业, 2016, 48(6): 38-40. https://www.cnki.com.cn/Article/CJFDTOTAL-WJYG201606013.htm

WANG Y, ZENG Y W, QIN K Y, et al. Study on modification of ground calcium carbonate by stearic acid and titanate coupling agent[J]. Inorganic Chemicals Industry, 2016, 48(6): 38-40. https://www.cnki.com.cn/Article/CJFDTOTAL-WJYG201606013.htm

[21] ZHU Y M, WANG Y, SHA L, et al. Design of antibacterial polyethylene terephthalate masterbatch functionalized by modified nano-Mg(OH)2[J]. Journal of Applied Polymer Science, 2018, 135: 46755.

[22] 刘春琦, 马天, 李钊, 等. 天然矿物的机械力化学活化改性研究进展[J]. 金属矿山, 2021(10): 75-81. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202110012.htm

LIU C Q, MA T, LI Z, et al. Research progress in the mechanochemical activation and modification of natural minerals[J]. Metal Mine, 2021(10): 75-81. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202110012.htm

[23] 徐波, 王树林, 李来强, 等. 固体颗粒的结构演化与机械力化学效应[J]. 物理学报, 2012, 61(9): 1-5. https://www.cnki.com.cn/Article/CJFDTOTAL-WLXB201209004.htm

XU B, WANG S L, LI L Q, et al. Structure evolvement of solid particles and mechano-chemical effect[J]. Acta Physica Sinica, 2012, 61(9): 1-5. https://www.cnki.com.cn/Article/CJFDTOTAL-WLXB201209004.htm

[24] 方伟, 屠宇迪, 严俊, 等. 机械力化学法超疏水改性叶蜡石的研究[J]. 非金属矿, 2011, 34(4): 23-25. https://www.cnki.com.cn/Article/CJFDTOTAL-FJSK201104008.htm

FANG W, TU Y D, YAN J, et al. Study on ultra-hydrophobic modification of pyrophyllite by mechanochemical method[J]. Non-Metallic Mines, 2011, 34(4): 23-25. https://www.cnki.com.cn/Article/CJFDTOTAL-FJSK201104008.htm

[25] LI L L, HANG J Z, SHI L Y. Surface modification of barite nanoparticles using stearate[J]. Journal of Shanghai University (English Edition), 2009, 13(4): 296-300.

[26] 武靖轩, 李解, 林嘉威, 等. 红外拟合光谱分析微波对重晶石浮选的影响机理[J]. 光谱学与光谱分析, 2021, 41(10): 3083-3091. https://www.cnki.com.cn/Article/CJFDTOTAL-GUAN202110016.htm

WU J X, LI X, LIN J W, et al. Influence mechanism of microwave on barite flotation based on infrared fitting spectrum analysis[J]. Spectroscopy and Spectral Analysis, 2021, 41(10): 3083-3091. https://www.cnki.com.cn/Article/CJFDTOTAL-GUAN202110016.htm

[27] YING W, YEH J T, YUE T J, et al. Surface modification of superfine tourmaline powder with titanate coupling agent[J]. Colloid and Polymer Science, 2006, 284(12): 1465-1470.

[28] 胡春艳, 周志明, 刘兴隆. 硬脂酸系列对天然重晶石粉末的表面改性[J]. 应用化工, 2010, 39(2): 237-239. https://www.cnki.com.cn/Article/CJFDTOTAL-SXHG201002023.htm

HU C Y, ZHOU Z M, LIU X L. Series of stearic acid surface-modified natural barite powder[J]. Applied Chemical Industry, 2010, 39(2): 237-239. https://www.cnki.com.cn/Article/CJFDTOTAL-SXHG201002023.htm

[29] ACAR I, ACISLI O. Mechano-chemical surface modification of calcite by wet-stirred ball milling[J]. Applied Surface Science, 2018, 457: 208-213.

[30] 邓丽荣, 王晓刚, 华小虎, 等. 机械粉碎法制备β-SiC纳米粉体及其特性分析[J]. 中国粉体技术, 2022, 28(1): 62-67. https://www.cnki.com.cn/Article/CJFDTOTAL-FTJS202201007.htm

DENG L R, WANG X G, HUA X H, et al. Preparation and characterization of β-SiC nano-powders by mechanical crushing method[J]. China Powder Science and Technology, 2022, 28(1): 62-67. https://www.cnki.com.cn/Article/CJFDTOTAL-FTJS202201007.htm

[31] XU J L, REN S B, KANG C H, et al. Study on the ball milling modification of attapulgite[J]. Materials Research Express, 2020, 7(11): 115006.

[32] 谢安建, 朱雪梅, 沈玉华, 等. 硬脂酸修饰的纳米硫酸钡的制备[J]. 安徽大学学报(自然科学版), 2006, 30(4): 70-74. https://www.cnki.com.cn/Article/CJFDTOTAL-AHDX200604018.htm

XIE A J, ZHU X M, SHEN Y H, et al. The preparation of nanosized BaSO4 particles modified with stearic acid[J]. Journal of Anhui University (Natural Science Edition), 2006, 30(4): 70-74. https://www.cnki.com.cn/Article/CJFDTOTAL-AHDX200604018.htm

-

下载:

下载: