Research on the Flotation Reagent Regime of Jinchuan Copper-Nickel Sulfide Ore in Acidic Medium

-

摘要:

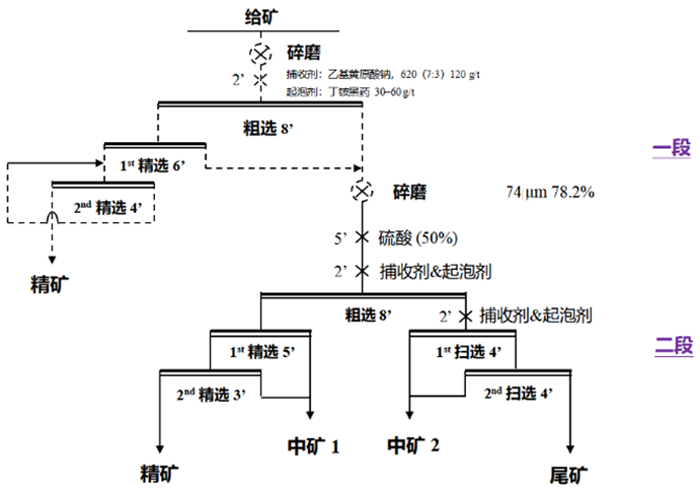

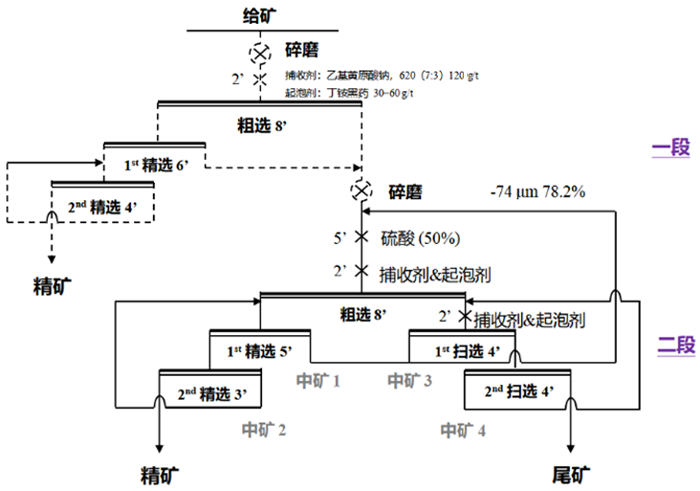

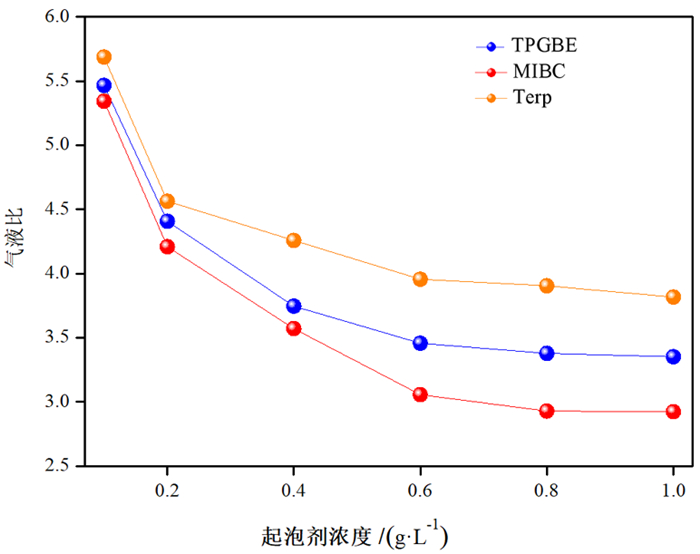

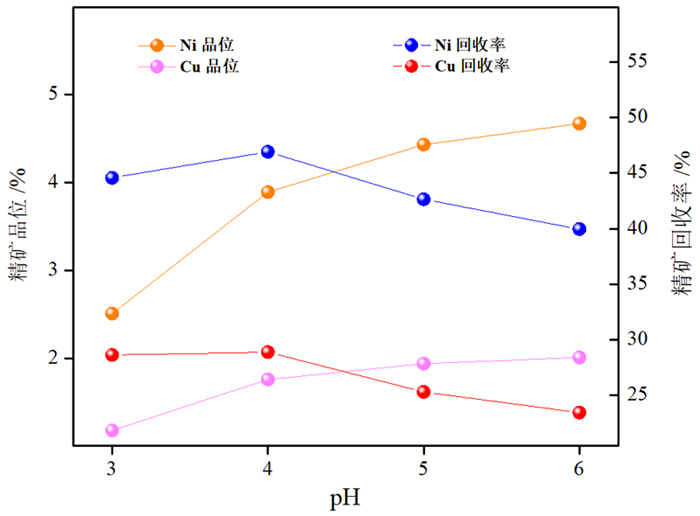

金川硫化铜镍矿含镁硅酸盐脉石含量高,泥化后通过异相凝聚和机械夹带影响精矿镍、铜金属的富集。相关研究与国外的工业实践证明,酸性介质浮选能促进含镁硅酸盐脉石的分解,显著提升硫化铜镍矿中有用矿物的回收,降低精矿氧化镁含量。但目前国内相关研究较少,缺乏与酸性介质浮选匹配的药剂体系。对此,以Ni品位0.42%、Cu品位0.32%的金川某生产车间二段浮选给矿为研究对象,研究了酸性介质中适合的新型药剂体系,并利用起泡剂测试装置对比分析了不同起泡剂的性能。试验结果表明,在pH值为4的酸性浮选条件下,以异丁基黄原酸钠为捕收剂、Z-200为辅助捕收剂和松油醇为起泡剂,经过一次粗选两次精选和两次扫选,可获得Ni回收率58.92%、Cu回收率45.60%、Ni品位3.54%和Cu品位2.03%的精矿产品。与现场药剂体系相比,精矿Ni、Cu回收率分别提高了7.54、24.40百分点,MgO含量降低了0.94百分点。新药剂体系全面提升了金川硫化铜镍矿资源综合利用率。

Abstract:The content of magnesium silicate gangue minerals in Jinchuan sulfide copper-nickel ore is high. It affects the enrichment of nickel and copper in concentrates through heterogeneous condensation and mechanical entrainment after grinding. Related researches and foreign industrial practices have proved that acidic medium flotation can promote the decomposition of magnesium silicate gangue minerals, which significantly improved the recovery of useful minerals in copper-nickel sulfide ore and reduced the content of magnesium oxide in concentrates. At present, however, there are few researches on the suitable reagent system for the acidic medium flotation of sulfide minerals in China. To solve this issue, feed of the second stage processing production line of the third flotation plant of Jinchuan Group Co. (Ni and Cu grade of ore was 0.42% and 0.32% respectively) was regarded as the research object. The open circuit flotation tests studied the new reagent system suitable for the acid medium, and compared and analyzed the performance of different frothers by using the foam tester. Under acid flotation condition (pH value = 4), with sodium isobutyl xanthanate (NaIBX) as the collector, O-isopropyl-N-ethylthiocarbamate (Z-200) as the co-collector and terpineol as the frother, after one roughing, two cleaning and two scavenging, the recovery of Ni and Cu are 58.92%, 45.60% and the grade of Ni and Cu are 3.54%, 2.03% respectively. Compared with comparative system (according with industrial process), the recovery of Ni and Cu are increased by 7.54%, 24.40% and the grade of Cu is increased by 0.70%. The new reagent system significantly improved the comprehensive utilization rate of copper-nickel sulfide resources in Jinchuan.

-

-

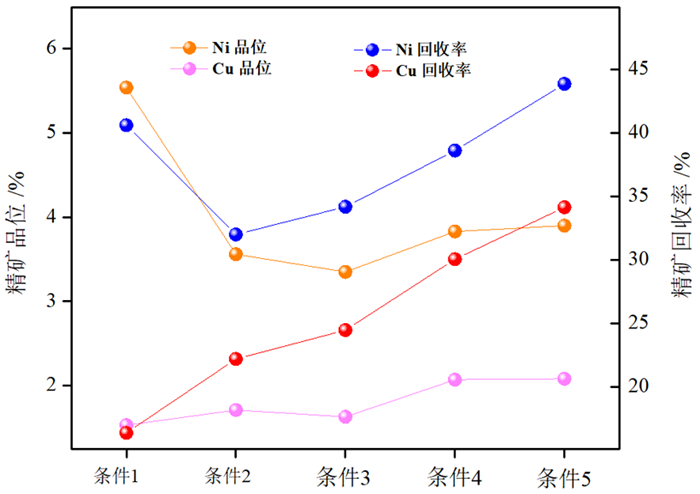

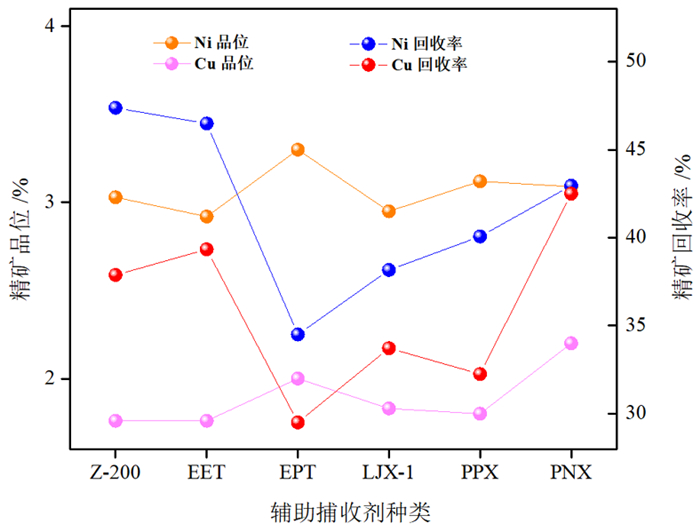

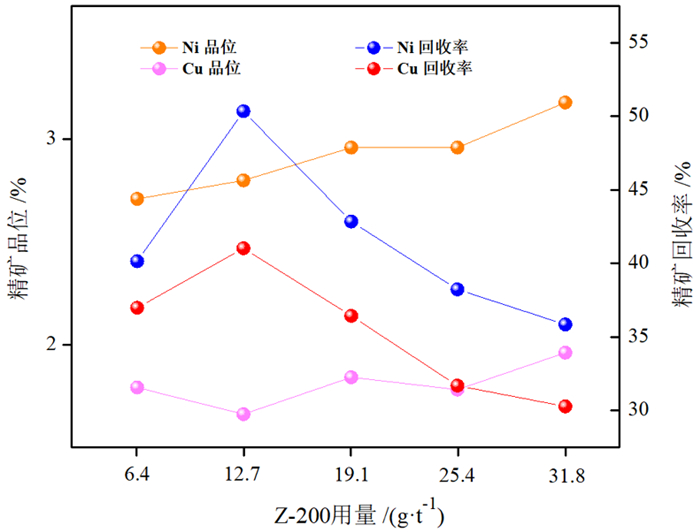

图 7 不同条件下捕收剂对金属品位和回收率的影响(浮选条件1:pH值为9.8,粗选NaEX/AT 620 80 g/t,ADD 42 g/t,扫选补加捕收剂32 g/t;浮选条件2:pH值为4,粗选NaEX/AT 620 80 g/t,ADD 42 g/t;扫选补加捕收剂32 g/t;浮选条件3:pH值为4,粗选NaIBX 100 g/t,ADD 42 g/t,扫选补加捕收剂40 g/t;浮选条件4:pH值为4,粗选NaIBX 100 g/t,MIBC 15.1 g/t;扫选补加捕收剂40 g/t;浮选条件5:pH值为4,粗选NaIBX 100 g/t,MIBC 15.1 g/t,PNX 12.7 g/t;扫选补加捕收剂40 g/t)

Figure 7.

表 1 矿浆干矿样的主要化学成分

/% Table 1. Chemical composition of dry ore contained in the slurry sample

元素 Ni Cu Fe Co MgO CaO Al2O3 S SiO2 含量 0.42 0.32 14.20 0.02 28.05 1.45 1.63 3.40 27.74 表 2 开路浮选试验结果

/% Table 2. The results of bench-scale open circuit tests

浮选体系 产品名称 产率 品位 回收率 Ni Cu MgO Ni Cu MgO 起始pH约等于4;粗选丁黄药75 g/t,2 d松油醇(10 g/t),2d Z-200(12.7 g/t); 扫选补加黄药30 g/t,1 d松油醇,1 d Z-200 精矿 5.90 3.58 1.70 4.30 43.33 27.76 0.94 1号中矿 11.78 1.27 1.12 19.83 30.70 36.52 8.63 2号中矿 6.12 0.45 0.49 28.89 5.65 8.30 6.53 尾矿 76.20 0.13 0.13 29.81 20.32 27.42 83.91 现场(起始pH约等于9.8,粗选捕收剂NaEX/AT620=7:3 80 g/t,黑药40 g/t); 扫选补加捕收剂32 g/t 精矿 4.54 4.02 1.22 5.50 37.96 15.33 0.92 1号中矿 8.65 1.25 0.71 19.40 22.48 16.99 6.18 2号中矿 4.31 0.97 0.70 21.99 8.68 8.34 3.49 尾矿 82.51 0.18 0.26 29.39 30.88 59.35 89.40 表 3 闭路循环浮选试验结果

/% Table 3. The results of bench-scale close circuit tests

浮选体系 产品名称 产率 品位 回收率 Ni Cu MgO Ni Cu MgO 起始pH约等于4;第一次循环:粗选NaIBX 75 g/t, Z-200 12.7 g/t,Terp 6.7 g/t; 扫选补加NaIBX 30 g/t。其余四次循环:粗选NaIBX 75 g/t, Z-200 12.7 g/t,Terp 1.6 g/t; 扫选补加NaIBX 30 g/t 精矿 6.08 3.54 2.03 5.84 58.92 45.60 1.28 尾矿 93.92 0.16 0.16 29.25 41.08 54.40 98.72 合计 100.00 0.37 0.37 27.83 100.00 100.00 100.00 现场起始pH约等于9.8;第一次循环:粗选捕收剂NaEX/AT620=7:3 80 g/t,ADD 42 g/t; 扫选补加捕收剂32 g/t。其余四次循环:粗选捕收剂80 g/t, ADD 10.5 g/t; 扫选补加捕收剂32 g/t 精矿 5.13 4.17 1.33 6.78 51.38 21.20 1.24 尾矿 94.87 0.21 0.27 29.16 48.62 78.80 98.76 合计 100.00 0.42 0.32 28.01 100.00 100.00 100.00 -

[1] 朱凌霄. 镍资源及利用[J]. 新疆有色金属, 2011, 34(5): 27-29. https://www.cnki.com.cn/Article/CJFDTOTAL-XJYS201105011.htm

ZHU L X. Nickel resources and utilization[J]. Xinjiang nonferrous metals, 2011, 34(5): 27-29. https://www.cnki.com.cn/Article/CJFDTOTAL-XJYS201105011.htm

[2] 杨志强, 王永前, 高谦, 等. 金川镍钴铂族金属资源开发与可持续发展研究[J]. 中国矿山工程, 2016, 45(5): 1-6. doi: 10.3969/j.issn.1672-609X.2016.05.001

YANG Z Q, WANG Y Q, GAO Q, et al. Study on the exploitation of nickel and cobalt resources and sustainable development in Jinchuan mine[J]. China Mine Engineering, 2016, 45(5): 1-6. doi: 10.3969/j.issn.1672-609X.2016.05.001

[3] 杨学善, 郭远生, 陈百友, 等. 世界红土型镍矿的资源分布及勘查、开发利用现状[C]//云南省有色地质局建局60周年学术论文集, 2013, 6(1): 200-208.

YANG X S, GUO Y S, CHEN B Y, et al. The distribution and the exploration, development and utilization situation of the lateritic nickel ore resource in the world[C]//Collection of academic papers on the 60th anniversary of the establishment of Yunnan Nonferrous Geological Bureau, 2013, 6(1): 200-208.

[4] WATLING H R. The bioleaching of nickel-copper sulphides[J]. Hydrometallurgy, 2008, 91(1): 70-88.

[5] 官旭晖, 黄晓辉. 我国矿山环境治理与环保投资战略探析[J]. 有色金属(矿山部分), 2021, 73(5): 132-137. doi: 10.3969/j.issn.1671-4172.2021.05.022

GUAN X H, HUANG X H. Analysis of mine environmental governance and environmental protection investment strategy in China[J]. Nonferrous Metals(Mining Section), 2021, 73(5): 132-137. doi: 10.3969/j.issn.1671-4172.2021.05.022

[6] TANG Q Y, LI C S, ZHANG M J, et al. Detrital zircon constraint on the timing of amalgamation between Alxa and Ordos, with exploration implications for Jinchuan-type Ni-Cu ore deposit in China[J]. Precambrian Research, 2014, 255(2): 748-755.

[7] BASILE A, HUGHES J, MCFARLANE A J. Development of a model for serpentine quantification in nickel laterite minerals by infrared spectroscopy[J]. Minerals Engineering, 2010, 23(5): 407-412. doi: 10.1016/j.mineng.2009.11.018

[8] YANG S T, PELTON R, ABARCA C. Towards nanoparticle flotation collectors for pentlandite separation[J]. International Journal of Mineral Processing, 2013, 123: 137-144. doi: 10.1016/j.minpro.2013.05.007

[9] PIETROBON M C, GRANO S R. Recovery mechanisms for pentlandite and MgO-bearing gangue minerals in nickel ores from Western Australia[J]. Minerals Engineering, 1997, 10(8): 775-786. doi: 10.1016/S0892-6875(97)00056-3

[10] 耿志强, 刘润清, 孙伟. 河北某泥化黄铜矿浮选脱泥-微泡浮选试验研究[J]. 矿冶工程, 2017, 37(5): 56-63. doi: 10.3969/j.issn.0253-6099.2017.05.013

GE Z Q, LIU R Q, SUN W. Flotation desliming-microfroth flotation approach applied in processing of slimed chalcopyrite ore from Hebei[J]. Mining and Metallurgical Engineering, 2017, 37(5): 56-63. doi: 10.3969/j.issn.0253-6099.2017.05.013

[11] 刘谷山, 冯其明, 张国范, 等. 某铜镍硫化矿浮选脱除滑石的研究[J]. 金属矿山, 2005, 51(9): 35-37. doi: 10.3321/j.issn:1001-1250.2005.09.010

LIU G S, FENG Q M, ZHANG G F, et al. Research on talc removal from a copper-nickel sulfide ore by flotation[J]. Metal Mine, 2005, 51(9): 35-37. doi: 10.3321/j.issn:1001-1250.2005.09.010

[12] 王毓华, 周瑜林, 邓海波, 等. 提高某铜镍混合精矿中墨铜矿浮选回收率的试验研究[J]. 有色金属(选矿部分), 2010, 3(3): 29-32. doi: 10.3969/j.issn.1671-9492.2010.03.008

WANG Y H, ZHOU Y L, DENG H B, et al. Flotation experiments the improving of recovery of valleriite in copper-nickel concentrate. Nonferrous Metals(Mineral Processing Section), 2010, 3(3): 29-32. doi: 10.3969/j.issn.1671-9492.2010.03.008

[13] 张其东, 温建康, 李文娟, 等. 一种用于抑制含镁硅酸盐脉石矿物的组合浮选药剂: CN111359782A[P]. 2020-07-03.

ZHANG Q D, WEN J K, LI W J, et al. A combined flotation reagent for inhibiting magnesium silicate gangue minerals: CN111359782A[P]. 2020-07-03.

[14] CAO J, LUO Y C, XU G Q, et al. Utilization of starch graft copolymers as selective depressants for lizardite in the flotation of pentlandite[J]. Applied Surface Science, 2015, 337(3): 58-64.

[15] G·别拉尔迪斯科, 李长根, 林森. 在酸性介质中从含橄榄石和蛇纹石矿石中浮选铬铁矿[J]. 国外金属矿选矿, 2004, 41(10): 12-18. G· https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK200410001.htm

BIELALDISCO, LI C G, LIN S. Flotation of chromite containing olivine and serpentine in acidic medium[J]. Metallic Ore Dressing Abroad, 2004, 41(10): 12-18. https://www.cnki.com.cn/Article/CJFDTOTAL-JSXK200410001.htm

[16] 冯其明, 张国范, 卢毅屏. 蛇纹石对镍黄铁矿浮选的影响及其抑制剂研究现状[J]. 矿产保护与利用, 1997, 4(5): 21-24. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=469b2d95-36cd-48c5-b86a-f7e0af6ad6ff

FENG Q M, ZHANG G F, LU Y P. The effects of serpentine on blucite flotation and present status for studies of its depressant[J]. Conservation and Utilization of Mineral Resources, 1997, 4(5): 21-24. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=469b2d95-36cd-48c5-b86a-f7e0af6ad6ff

[17] 胡显智, 张文彬. 金川镍铜矿精矿降镁研究与实践进展[J]. 矿产保护与利用, 2003(1): 34-37. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=d2a51f9d-dca1-4964-85a6-f90fb1dfd936

HU Q Z, ZHANG W B. Research progresses on removal of MgO from the flotation concentrate of Jinchan copper-nickel sulfide[J]. Conservation and Utilization of Mineral Resources, 2003(1): 21-24. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=d2a51f9d-dca1-4964-85a6-f90fb1dfd936

[18] UDDIN S, RAO S R, MIRNEZAMI M. Processing an ultramafic ore using fiber disintegration by acid attack[J]. International Journal of Mineral Processing, 2012, 102(1): 38-44.

[19] KIRJAVAINEN V, HEISKANEN K. Some factors that affect beneficiation of sulphide nickel-copper ores[J]. Minerals Engineering, 2007, 20(7): 629-633. doi: 10.1016/j.mineng.2007.01.001

[20] 许鹏飞, 徐国强, 罗永春, 等. 一种用于硫化铜镍矿的浮选药剂: CN103433147B[P]. 2015-04-29.

XU P F, XU G Q, LUO Y C, et al. A flotation reagent for copper nickel sulfide ore: CN103433147B[P]. 2015-04-29.

[21] FINCH J A, GELINAS S, MOYO P. Frother-related research at McGill University[J]. Minerals Engineering, 2006, 19(6): 726-733.

[22] GU Y L, FENG Q M, OU L M, et al. A new method of testing frother performance[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(9): 2776-2780. doi: 10.1016/S1003-6326(13)62796-X

[23] XIA Y K, PENG F F. Selection of frothers from residual organic reagents for copper-molybdenite sulfide flotation[J]. International Journal of Mineral Processing, 2007, 83(1): 68-75. http://www.onacademic.com/detail/journal_1000034024521410_026c.html

[24] PIETROBON M C, GRANO S R. Recovery mechanisms for pentlandite and MgO-bearing gangue minerals in nickel ores from Western Australia[J]. Minerals Engineering, 1997, 10(8): 775-786. doi: 10.1016/S0892-6875(97)00056-3

[25] 周旭日, 魏宗武. 不同碳链长度的黄药对大厂多金属硫化矿混合浮选指标的影响[J]. 中国矿业, 2011, 20(4): 82-84. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA201104024.htm

ZHOU X R, WEI Z W. Effection of the xanthate with different length to the bulk flotation index of polymentallic sulfide in Dachang[J]. China Mining Magazine, 2011, 20(4): 82-84. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA201104024.htm

[26] 王纪镇, 印万忠, 刘明宝, 等. 浮选组合药剂协同效应定量研究[J]. 金属矿山, 2013(5): 62-66. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201305019.htm

WANG J Z, YIN W Z, LIU M B, et al. Quantitative research of synergistic effects of combined flotation reagents[J]. Metal Mine, 2013(5): 62-66. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201305019.htm

[27] WALTER A N, GREGORY H. The effect of using sodium di-methyl-dithiocarbamate as a co-collector with xanthates in the froth flotation of pentlandite containing ore from Nkomati mine in South Africa[J]. Minerals Engineering, 2013, 54(1): 94-99.

[28] DAVID A B, LE H Y, GILLIAN B N. The effect of polysaccharides and polyacrylamides on the depression of talc and the flotation of sulphide minerals[J]. Minerals Engineering, 2006, 19(6): 598-608.

-

下载:

下载: