Preparation and Performance of Montmorillonite Nanosheet/PVDF−Polypropylene Composite Separator

-

摘要:

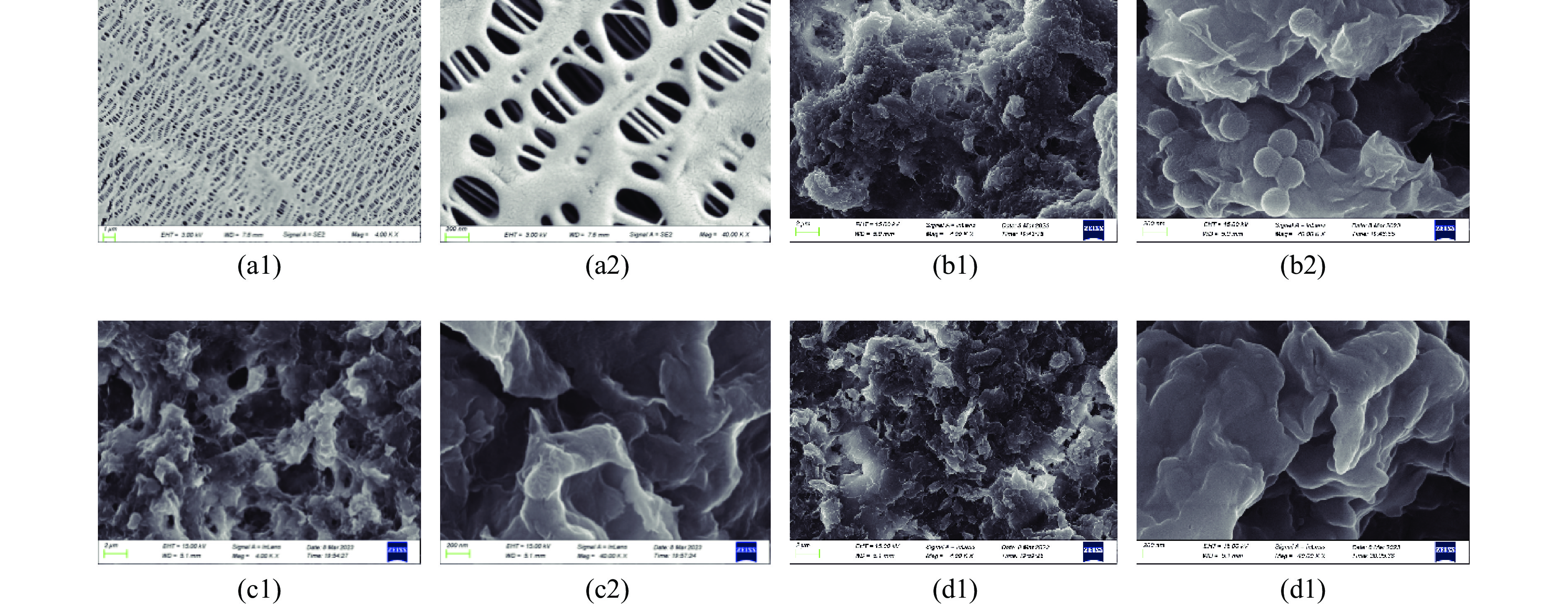

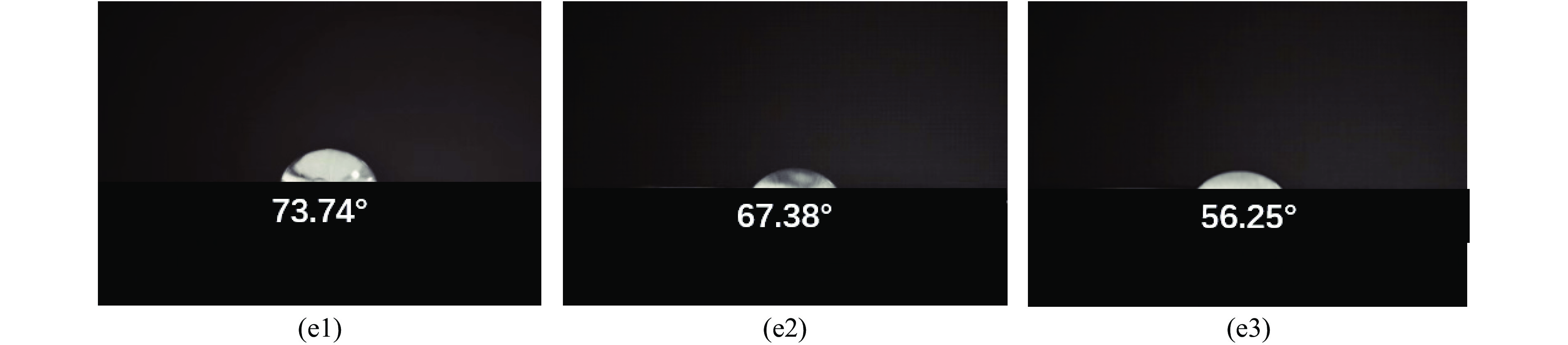

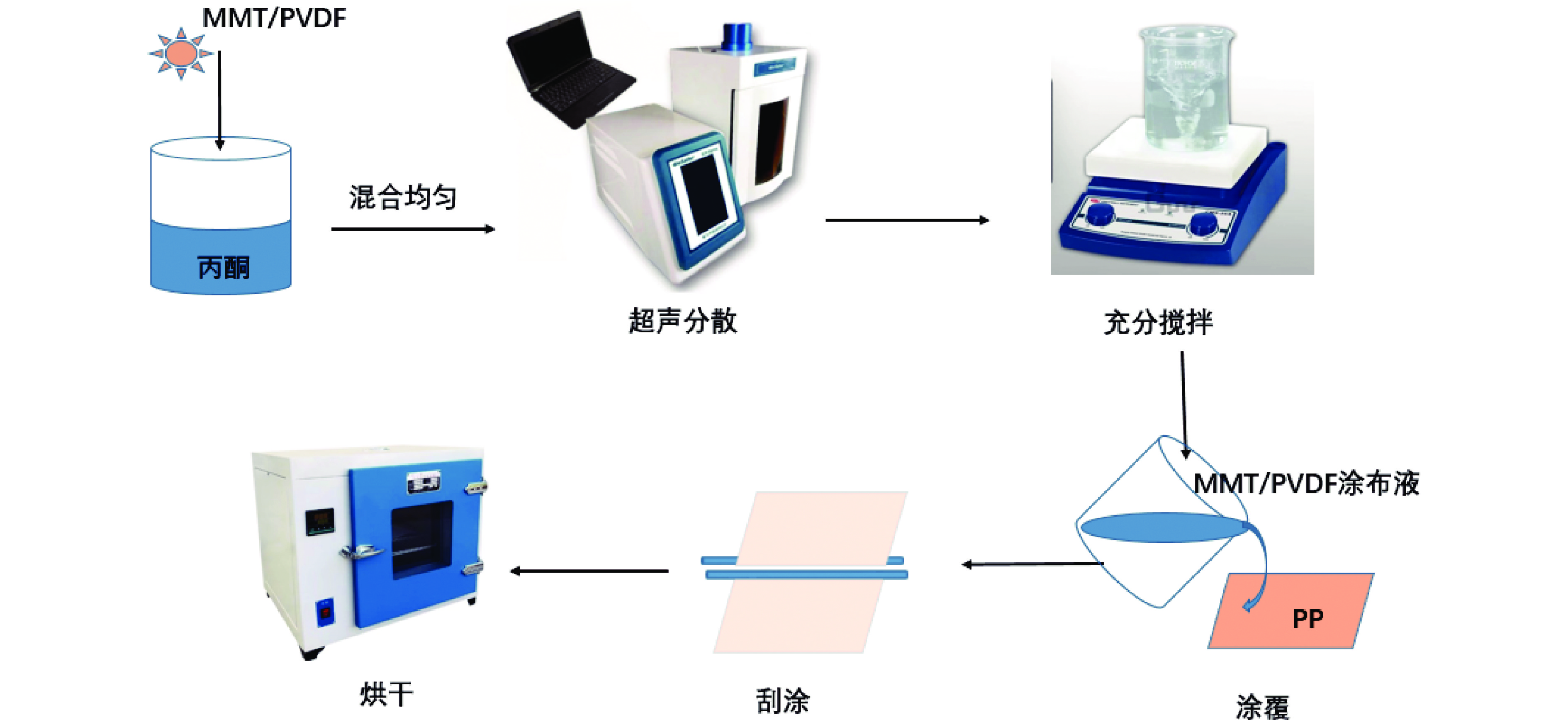

商用聚烯烃隔膜表现出较差的电解液浸润性和大幅的热收缩性,不利于锂离子电池的安全高效运行。利用天然矿物独特的晶体结构、良好的润湿性、优异的热稳定性和机械稳定性,在聚烯烃隔膜表面涂覆天然矿物材料是增强隔膜性能的方法之一。采用刮涂法制备了复合隔膜(MMT−PVDF/PP),对复合隔膜的机械性能、润湿性能、热稳定性等性能进行了研究。结果表明:当涂布液中蒙脱石纳米片和黏结剂的质量比为5∶5时,复合隔膜表面形成了MMT−PVDF三维稳定结构,相比聚丙烯隔膜(PP),MMT−PVDF/PP复合隔膜的拉伸强度提升了6倍,吸液率和保液率分别提升了24.93百分点和96.7百分点。复合隔膜在150℃环境下1 h后仍能维持较好的尺寸形态,收缩率不到10%。

Abstract:Commercial polyolefin separators exhibit poor electrolyte wettability and severe thermal shrinkage, which are not conducive to the safe and efficient operation of lithium−ion batteries. Using the unique crystal structure, good wettability, excellent thermal and mechanical stability of natural minerals, coating raw mineral materials on the surface of polyolefin separators is one of the methods to enhance the performance of the separators. The composite separator (MMT−PVDF/PP) was prepared by scraping coating method, and the mechanical properties, wettability, thermal stability of the composite separator were investigated. The results showed that when the mass ratio of montmorillonite nanosheets and binder in the coating solution was 5∶5, a three−dimensional stabilized structure of MMT−PVDF was formed on the surface of the composite separator. Compared with polypropylene separators (PP), the tensile strength of the MMT−PVDF/PP composite separator was increased by 6 times, and the electrolyte uptake and retention rate were increased by 24.93% and 96.7%, respectively. The composite separator can maintain a good dimensional morphology at 150 ℃ for 1h with less than 10% shrinkage.

-

Key words:

- lithium−ion battery /

- polyolefin separator /

- electrolyte wettability /

- thermal shrinkage

-

-

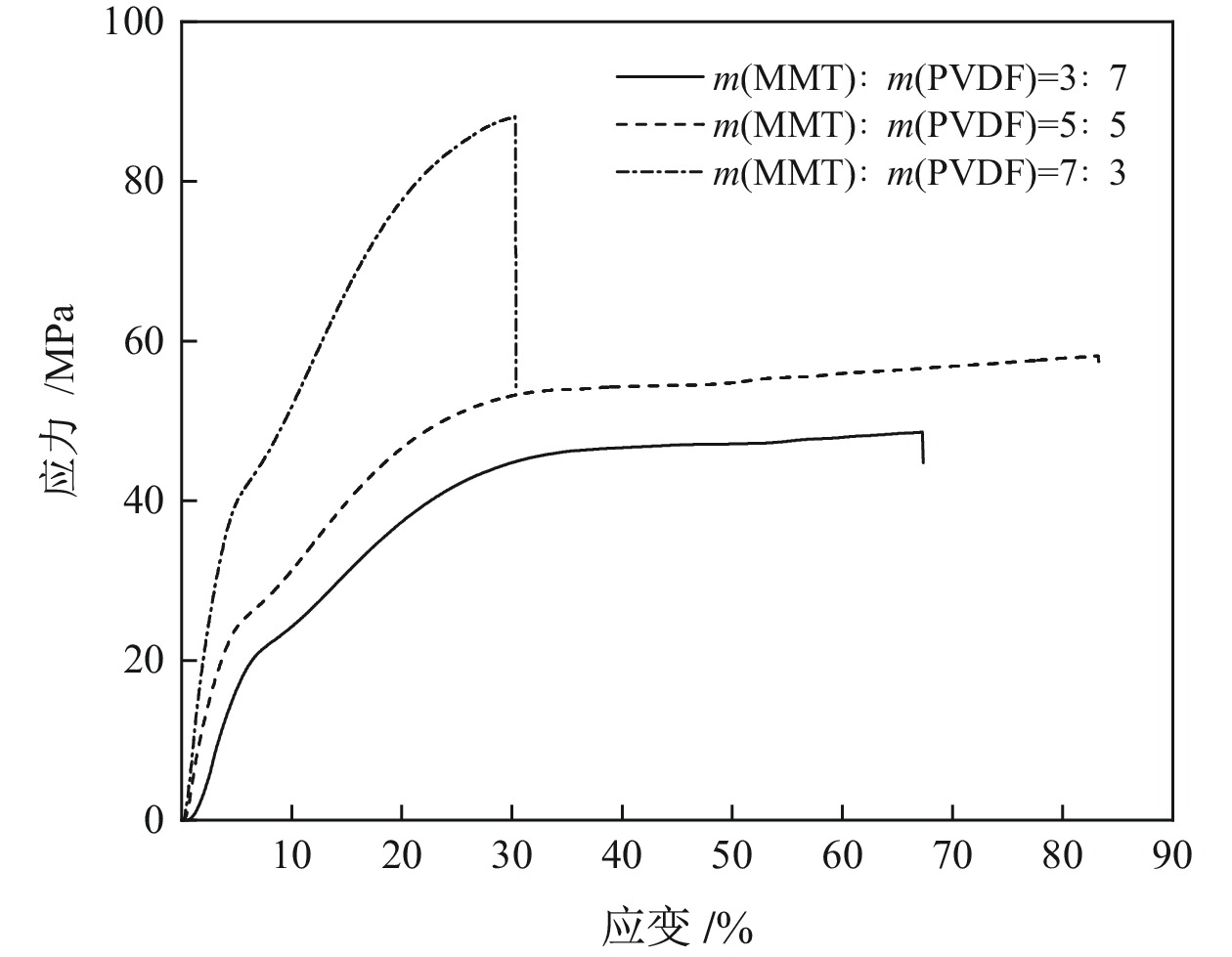

表 1 不同比例MMT−PVDF涂覆改性隔膜的其他性能

Table 1. Other propertis of modified separator coated with different ratios of MMT−PVDF

项目 m(MMT)∶m(PVDF)=3∶7 m(MMT)∶m(PVDF)=5∶5 m(MMT)∶m(PVDF)=7∶3 厚度/μm 39 32 35 面密度/(g·m−2) 14.03 15.34 10.37 孔隙率/% 93.39 95.39 93.83 拉伸强度(MD)/MPa 48.6 58.12 88.11 断裂伸长率(TD)/% 67.34 83.28 30.39 最大力/N 97.2 101.72 88.11 -

[1] 隋谨伊, 吕晓东. 锂离子电池隔膜行业发展现状及趋势展望[J]. 石油石化绿色低碳, 2023, 8(1): 17−21.

SUI J Y, LV X D. Status and prospect of lithium−ion battery separator[J]. Green Petroleum& Petrochemicals, 2023, 8(1): 17−21.

[2] WANG Y, SHI L, ZHOU H, et al. Polyethylene separators modified by ultrathin hybrid films enhancing lithium ion transport performance and Li−metal anode stability[J]. Electrochimica Acta, 2018(8): 259.

[3] SU M, HUANG G, WANG S, et al. High safety separators for rechargeable lithium batteries[J]. Science China(Chemistry), 2021, 64(7): 1131−1156.

[4] 袁玉玲. 锂离子电池聚烯烃隔膜的改性研究[J]. 化工管理, 2021(20): 83−84.

YUAN Y L. Study on modification of polyolefin diaphragm in lithium−ion battery[J]. Chemical Enterprise Management, 2021(20): 83−84.

[5] 王惠亚, 赵立敏, 张芳, 等. 高性能锂离子二次电池隔膜[J]. 化学进展, 2019, 31(9): 1251−1262.

WANG H Y, ZHAO L M, ZHANG F, et al. High−performance lithium−ion secondary battery membranes[J]. Progress in Chemistry. 2019, 31(9): 1251−1262.

[6] 李嘉兴, 李锋. 聚烯烃锂电隔膜表面改性技术研究进展[J]. 信息记录材料, 2021, 22(4): 3−8.

LI J X, LI F. Research progress on surface modification of polyolefin membrane for lithium−ion batteries[J]. Information Recording Materials, 2021, 22(4): 3−8.

[7] 孙明辉, 马小楷, 阚婷, 等. 锂电用聚烯烃基涂覆隔膜研究进展[J]. 电池工业, 2021, 25(3): 143−147.

SUN M H, MA X K, HAN T, et al. Research progress of polyolefin−based surface coating separator for lithium−ion batteries[J]. Chinese Battery Industry, 2021, 25(3): 143−147.

[8] 孙国华, 崔佳齐, 汪杨, 等. 耐热型聚合物锂离子电池隔膜的研究进展[J]. 中国塑料, 2022, 36(10): 190−194.

SUN G H, CUI J Q, WANG Y, et al. Research progress in heat−resistant polymer lithium−ion battery separators[J]. China Plastics, 2022, 36(10): 190−194.

[9] LIANG X, YANG Y, JIN X, et al. The high performances of SiO2/Al2O3−coated electrospun polyimide fibrous separator for lithium−ion battery[J]. Journal of Membrane Science, 2015, 493(3): 1−7.

[10] 郑怡磊, 吴于松, 许远远, 等. 高性能锂离子电池隔膜的研究进展[J]. 有机氟工业, 2018(4): 21−26.

ZHENG Y L, WU Y S, XU Y Y, et al. Research progress on high performance separator for lithium−ion batteries[J]. Organo−Flurine Indystry, 2018(4): 21−26.

[11] YAN H, ZHANG Z. Effect and mechanism of cation species on the gel properties of montmorillonite[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2020, 611(3): 0927−7757.

[12] 谢潇琪, 范鹏凯, 刘超. 蒙脱石基复合光催化材料处理有机废水研究进展[J]. 复旦学报(自然科学版), 2022, 61(2): 238−248.

XIE X Q, FAN P K, LIU C. Research progress on montmorillonite−based composite photocatalysts[J]. Journal of Fudan University(Natural Science), 2022, 61(2): 238−248.

[13] 侯磊, 韩学锋, 邢宝林, 等. 天然矿物为模板制备功能炭材料的研究进展[J]. 材料导报, 2022, 36(12): 32−42.

HOU L, HAN X F, XING B L, et al. Research progress on the preparation of functional carbon materials using natural minerals as templates[J]. Materials Reports, 2022, 36(12): 32−42.

[14] SONG Q, LI A, SHI L, et al. Thermally stable, nano−porous and eco−friendly sodium alginate/attapulgite separator for lithium−ion batteries[J]. Energy Storage Materials, 2019, 22(5): 48−56.

[15] KUMAR S, JOG J P, NATARAJAN U. Preparation and characterization of poly (methyl methacrylate)−clay nanocomposites via melt intercalation: The effect of organoclay on the structure and thermal properties[J]. Journal of Applied Polymer Science, 2003, 89(5): 1186−1194. doi: 10.1002/app.12050

[16] LIU F, CHUAN X. Recent developments in natural mineral−based separators for lithium−ion batteries[J]. RSC Advances, 2021, 11(27): 16633−16644.

[17] LI J, YU J R, WANG Y, et al. Intercalated montmorillonite reinforced polyimide separator prepared by solution blow spinning for lithium−ion batteries[J]. Industrial & Engineering Chemistry Research, 2020, 59(28): 12879−12888.

[18] ZHANG X, CHEN Y, YU B, et al. Lithiophilic 3D VN@N−rGO as a multifunctional interlayer for dendrite−free and ultrastable lithium−metal batteries[J]. ACS Applied Materials & Interfaces, 2021, 13(17): 20125−20136.

[19] HUANG C, JI H, GUO B, et al. Composite nanofiber membranes of bacterial cellulose/halloysite nanotubes as lithium ion battery separators[J]. Cellulose, 2019, 26(11): 6669−6681. doi: 10.1007/s10570-019-02558-y

[20] 李晓哲. 浸涂−刮涂法改性聚对苯二甲酸乙二醇酯隔膜[D]. 秦皇岛: 燕山大学, 2016.

LI X Z. Poly (ethylene terphthalate) separators were modified by dip−blade coating method[D]. Qinhuangdao: Yanshan University, 2016.

[21] 马平川, 刘杲珺, 杜敬然, 等. 锂离子电池用溶剂型PVDF混涂隔膜制备及性能[J]. 工程塑料应用, 2022, 50(1): 38−42.

MA P C, LIU G J, DU J R, et al. Preparation and properties of hybrid coated separator of solvent type PVDF for lithium battery[J]. Engineering Plastics Application, 2022, 50(1): 38−42.

[22] 梁志扬, 郭亮亮, 朱梦媛, 等. 浅谈锂电池隔膜拉伸强度试样的制备[J]. 制造业自动化, 2020, 42(6): 150−152.

LIANG Z Y, GUO L L, ZHU M Y, et al. Preparation of tensile strength sample of lithium battery separator[J]. Manufacturing Automation, 2020, 42(6): 150−152.

[23] MAO Y, JUE N, WEI C, et al. Interfacial engineering of polypropylene separator with outstanding high−temperature stability for highly safe and stable lithium−sulfur batteries[J]. Electrochemistry Communications, 2021, 125(3): 1388−2481.

[24] 张红涛, 尚华, 顾波, 等. 沸石基锂离子电池隔膜的制备及性能[J]. 材料工程, 2017, 45(12): 83−87.

ZHANG H T, SHANG H, GU B, et al. Preparation and performances of zeolite−based separator for lithium−ion batteries[J]. Journal of Materials Engineering, 2017, 45(12): 83−87.

-

下载:

下载: