Development of Room-temperature and Low-temperature Collectors for Hematite Flotation: a Comprehensive Review

-

摘要:

目前我国应用的赤铁矿浮选捕收剂多数因含有较长烃链而水溶性差,在浮选作业时常需要对矿浆进行加热处理,增加了选厂生产能耗和成本。基于“双碳”背景研发赤铁矿常温捕收剂、低温捕收剂是优化赤铁矿浮选药剂制度、增效降耗的关键途径之一。归纳总结了近年来赤铁矿浮选体系的常温/低温新型捕收剂和复配型捕收剂的研究进展,阐述了有利于实现赤铁矿常温/低温浮选过程的药剂特征活性有机基团及其对生产指标的影响,旨在总结并拓宽赤铁矿新型常温/低温浮选捕收剂设计思路,推动赤铁矿常温/低温浮选药剂的研发与应用,进而逐步实现赤铁矿浮选过程的增效降耗。

Abstract:The majority of hematite flotation collectors currently utilized in China exhibit poor water solubility due to their long hydrocarbon chains. Consequently, the slurry frequently necessitates heating during flotation operations, which increases energy consumption and costs in processing plants. Developing hematite collectors that are effective at normal and low temperatures is one of the pivotal approaches to optimizing the hematite flotation reagent system enhancing efficiency, and reducing consumption, especially within the framework of the "dual carbon" goals. By meticulously analyzing the recent research findings on new normal and low-temperature collectors and compound collectors in the hematite flotation system, the characteristics of reagents conducive to normal and low-temperature flotation processes were elucidated, focusing on the active organic groups and their impact on production indicators. The objective is to summarize and expand upon the design ideas for new types of normal and low-temperature hematite flotation collectors, promoting the research, development, and application of these reagents in hematite flotation processes and gradually achieving enhanced efficiency and reduced consumption.

-

Key words:

- hematite ore /

- flotation /

- ambient/low temperature /

- trapping agent /

- combination agent

-

-

表 1 传统捕收剂的浮选效果

Table 1. Flotation effects of conventional traps

表 2 新型阴离子捕收剂的浮选指标

Table 2. Flotation index of the new anionic collector

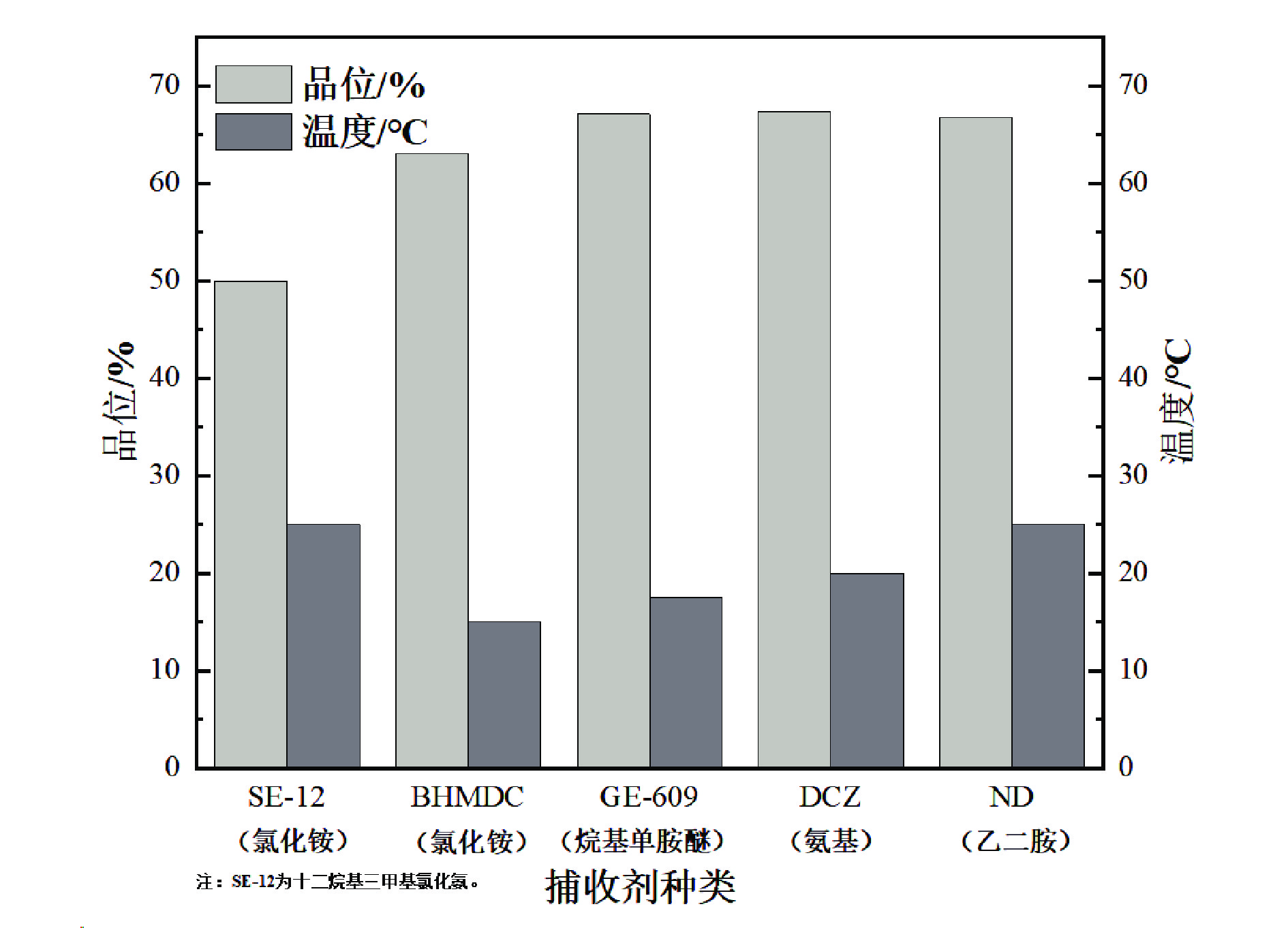

表 3 新型阳离子捕收剂的浮选效果

Table 3. Flotation effects of the new cationic traps

表 4 组合捕收剂的浮选效果

Table 4. Flotation effects of the combined traps

-

[1] 宋仁峰, 李维兵, 刘华艳, 等. 我国铁矿石反浮选技术发展综合评述[J]. 金属矿山, 2009(9): 13−18.

SONG R F, LI W B, LIU H Y, et al. Comprehensive review on the development of reverse flotation technology of iron ore in China[J]. Metal Mine, 2009(9): 13−18.

[2] 刘军, 靳淑韵. 中国铁矿资源的现状与对策[J]. 中国矿业, 2009, 18(12): 1−2+19.

LIU J, JIN S Y. Current situation and countermeasures of iron ore resources in China[J]. China Mining, 2009, 18(12): 1−2+19.

[3] ALINE PEREIRA LEITE NUNES, CLÁUDIO LÚCIO LOPES PINTO, GEORGE EDUARDO SALES VALADO, et al. Floatability studies of wavellite and preliminary results on phosphorus removal from a Brazilian iron ore by froth flotation[J]. Minerals Engineering, 2012(39): 206−212.

[4] 余永富, 陈雯, 麦笑宇. 提高铁精矿质量实现高炉节能减排增效[J]. 矿产保护与利用, 2009(1): 13−16.

YU Y F, CHEN W, MAI X Y. Improve the quality of iron concentrate to achieve blast furnace energy conservation and emission reduction efficiency[J]. Conservation and Utilization of Mineral Resources, 2009(1): 13−16.

[5] 吴文红, 吴承优, 王秋林, 等. 高效低温捕收剂选别关宝山铁矿实验[J]. 现代矿业, 2018, 34(1): 136−138+144.

WU W H, WU C Y, WANG Q L, et al. High−efficiency low−temperature collector selection test of Guanbaoshan Iron Mine[J]. Modern Mining, 2018, 34(1): 136−138+144.

[6] 孟晓光. 捕收剂和起泡剂作用机理分析[J]. 煤炭加工与综合利用, 2017(5): 44−46.

MENG X G. Mechanism analysis of collector and foaming agent[J]. Coal Processing and Comprehensive Utilization, 2017(5): 44−46.

[7] 贺寒冰, 何廷树, 王鑫, 等. 矿浆温度对方铅矿浮选效果的影响及机理研究[J]. 矿产保护与利用, 2020, 40(6): 88−94.

HE H B, HE T S, WANG X, et al. Study on the effect and mechanism of pulp temperature on galena flotation[J]. Conservation and Utilization of Mineral Resources, 2020, 40(6): 88−94.

[8] 杨茂麟, 邓朝勇, 徐本军. 铁矿石浮选药剂的研究现状[J]. 钢铁研究学报, 2011, 23(11): 1−3+46.

YANG M L, DENG C Y, XU B J. Research status of iron ore flotation reagents[J]. Journal of Iron and Steel Research, 2011, 23(11): 1−3+46.

[9] 王涛. 安徽李楼铁矿常温浮选药剂应用之路[J]. 现代矿业, 2020, 36(7): 107−110.

WANG T. Application of flotation reagent at normal temperature in Lilou Iron Mine, Anhui Province[J]. Modern Mining, 20, 36(7): 107−110.

[10] 肖玮, 邵延海, 尉佳怡, 等. 钛铁矿浮选药剂研究现状及展望[J]. 矿产保护与利用, 2021, 41(5): 160−167.

XIAO W, SHAO Y H, WEI J Y, et al. Research status and prospect of flotation reagents for ilmenite[J]. Conservation and Utilization of Mineral Resources, 2021, 41(5): 160−167.

[11] 余攀, 丁湛, 李春龙, 柏少军, 等. 我国钛铁矿矿石浮选药剂研究进展[J]. 矿产保护与利用, 2020, 40(2): 82−87.

YU P, DING Z, LI C L, BAI S J, et al. Research progress on flotation reagents for ilmenite ore in China[J]. Conservation and Utilization of Mineral Resources, 2020, 40(2): 82−87.

[12] 张朝宏, 戴惠新. 铁矿石反浮选捕收剂现状及未来发展趋势[J]. 矿产综合利用, 2012(2): 3−6.

ZHANG C H, DAI H X. Present situation and future development trend of iron ore reverse flotation collector[J]. Multipurpose Utilization of Mineral Resources, 2012(2): 3−6.

[13] 任爱军, 孙传尧. 油酸钠作捕收剂时变性淀粉对赤铁矿及石英可浮性的影响[J]. 矿冶, 2018, 27(3): 1−6+12.

REN A J, SUN C Y. Effect of modified starch on floatability of hematite and quartz when sodium oleate is used as collector[J]. Mining and Metallurgy, 2018, 27(3): 1−6+12.

[14] 李志彬, 马洪显. M203捕收剂浮选东鞍山高亚铁难选贫赤铁矿工业实验[J]. 金属矿山, 1994(1): 37−40.

LI Z B, MA H X. Industrial test on flotation of high ferrous refractory lean hematite in Donganshan by M203 collector[J]. Metal Mine, 1994(1): 37−40.

[15] 郑贵山, 刘炯天. 十二烷基磺酸钠浮选赤铁矿的研究[J]. 金属矿山, 2009(9): 70−73.

ZHENG G S, LIU J T. Study on flotation of hematite with sodium dodecyl sulfonate[J]. Metal Mine, 2009(9): 70−73.

[16] 许洪刚, 刘桂云. HD202捕收剂在鞍山式贫赤铁矿酸性正浮选工艺中的实验研究[J]. 金属矿山, 2009(1): 74−77.

XU H G, LIU G Y. Experimental study on acidic positive flotation process of Anshan−type lean hematite with HD202 collector[J]. Metal Mine, 2009(1): 74−77.

[17] 于慧梅, 王化军, 孙传尧. 餐饮废油制备JZQ−F捕收剂反浮选赤铁矿石实验研究[J]. 金属矿山, 2017(11): 64−69.

YU H M, WANG H J, SUN C Y. Experimental study on reverse flotation of hematite ore by JZQ−F collector from waste cooking oil[J]. Metal Mine, 2017(11): 64−69.

[18] 吴中贤, 杨晓, 于晓兵, 等. 响应曲面法优化赤铁矿纳米气泡反浮选实验研究[J]. 黄金, 2023, 44(2): 38−45.

WU Z X, YANG X, YU X B, et al. Optimization of reverse flotation of hematite nanobubbles by response surface methodology[J]. Gold, 2023, 44(2): 38−45.

[19] 任建伟, 王毓华. 铁矿反浮选脱硅的实验研究[J]. 矿产保护与利用, 2004(1): 31−34.

REN J W, WANG Y H. Experimental study on reverse flotation desilication of iron ore[J]. Conservation and Utilization of Mineral Resources, 2004(1): 31−34.

[20] 邹春林, 张范春, 朱一民, 等. 用新型捕收剂DA−1反浮选齐大山选厂混磁精[J]. 金属矿山, 2012(3): 63−65.

ZOU C L, ZHANG F C, ZHU Y M, et al. Reverse flotation of mixed magnetic concentrate from Qidashan Concentrator with a new collector DA−1[J]. Metal Mine, 2012(3): 63−65.

[21] 宋仁峰, 郭客, 张长奎, 等. 新型LKD阴离子反浮选捕收剂的研究[J]. 金属矿山, 2010(3): 57−61.

SONG R F, GUO K, ZHANG C K, et al. Study on a new LKD anionic reverse flotation collector[J]. Metal Mines, 2010(3): 57−61.

[22] 马艺闻, 徐冬林. 赤铁矿常温浮选的阴离子捕收剂研制与实验[J]. 矿冶工程, 2014, 34(6): 53−55.

MA Y W, XU D L. Development and test of anionic collector for hematite flotation at room temperature[J]. Mining and Metallurgy Engineering, 2014, 34(6): 53−55.

[23] 徐冬林, 王长艳, 张玲. 赤铁矿常温浮选的阴离子捕收剂研制与实验[C]//中国矿业科技文汇—2014, 2014: 670−672.

XU D L, WANG C Y, ZHANG L. Development and test of anionic collector for hematite flotation at room temperature[C]//China Mining Science and Technology Wenhui−2014, 2014: 670−672.

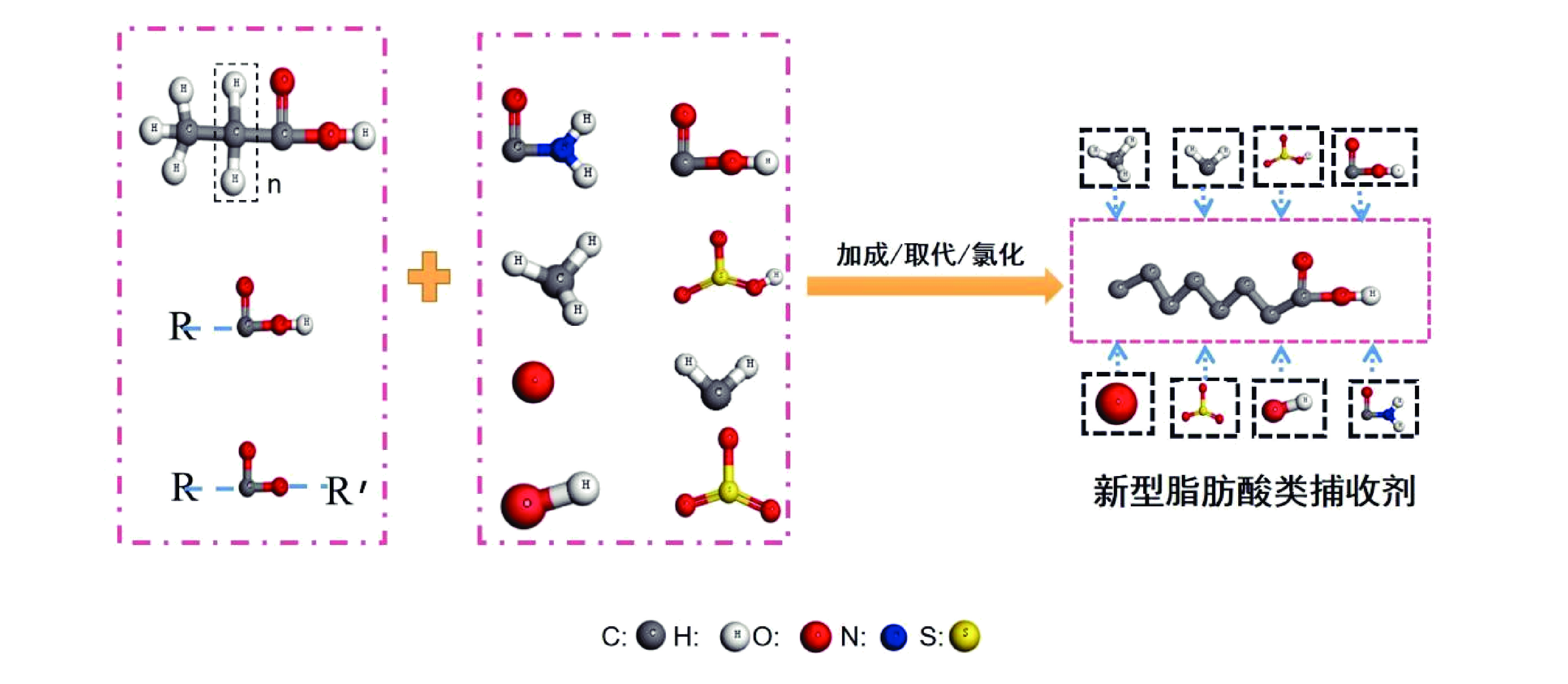

[24] 张月. 几种新型脂肪酸类捕收剂改性药剂介绍[J]. 盐湖研究, 2007(2): 34−37.

ZHANG Y. Introduction of several new fatty acid collectors[J]. Journal of Salt Lake Research, 2007(2): 34−37.

[25] 王福良.铜铅锌铁主要硫化氧化矿物浮选的基础理论研究[D].沈阳:东北大学,2011.

WANG F L. Basic theoretical study on flotation of main sulfide oxide minerals of copper, lead, zinc and iron[D]. Shenyang: Northeast University, 2011.

[26] 张行荣, 刘崇峻, 艾晶, 等. 新型耐低温捕收剂BK427在赤铁矿反浮选脱硅中的应用[J]. 中国矿业, 2014, 23(S2): 270−272.

ZHANG X R, LIU C J, AI J, et al. Application of a novel low−temperature tolerant collector BK427 in reverse flotation desilication of hematite[J]. China Mining Magzine, 2014, 23(S2): 270−272.

[27] 朱顺伟, 李孝龙, 李永利, 等. 新型捕收剂在尾矿中赤铁矿回收的应用实验[J]. 烧结球团, 2022, 47(4): 71−76+98.

ZHU S W, LI X L, LI Y L, et al. Application test of new collector in hematite recovery from tailings[J]. Sintered Pellets, 2022, 47(4): 71−76+98.

[28] 夏夕雯, 梁广泉, 朱一民. 新型常温捕收剂DX−1对赤铁矿的浮选性能研究[J]. 金属矿 山, 2018(6): 75−79.

XIA X W, LIANG G Q, ZHU Y M. Study on the flotation performance of a new normal temperature collector DX−1 for hematite[J]. Metal Mines, 2018(6): 75−79.

[29] 闵程, 胡向梅, 张汉泉. 复配阴离子捕收剂在高磷鲕状赤铁矿反浮选中的应用[J]. 矿冶工程, 2017, 37(2): 49−53.

MIN C, HU X M, ZHANG H Q. Application of compound anionic collector in reverse flotation of high phosphorus oolitic hematite[J]. Mining and Metallurgical Engineering, 2017, 37(2): 49−53.

[30] 董怡斌, 强敏, 段正义, 等. QD捕收剂对鄂西高磷鲕状赤铁矿的反浮选效果[J]. 金属矿 山, 2010(2): 62−65.

DONG Y B, QIANG M, DUAN Z Y, et al. Reverse flotation effect of QD collector on high phosphorus oolitic hematite in western Hubei[J]. Metal Mine, 2010(2): 62−65.

[31] 王涛, 龚豪, 武利朔, 等. 安徽李楼镜铁矿低温捕收剂反浮选实验研究[J]. 矿产保护与利用, 2015(3): 34−37.

WANG T, GONG H, WU L S, et al. Experimental study on low temperature collector reverse flotation of Anhui Lilou specularite[J]. Conservation and Utilization of Mineral Resources, 2015(3): 34−37.

[32] 罗光明. 耐低温捕收剂TA−19在李楼铁矿的研究及应用[J]. 矿业工程, 2020, 18(5): 41−44.

LUO G M. Research and application of low temperature resistant collector TA−19 in Lilou Iron Mine[J]. Mining Engineering, 2020, 18(5): 41−44.

[33] 李文风, 刘旭. 铁矿低温捕收剂CY−411的研制与应用实验研究[J]. 金属材料与冶金工程, 2014, 42(4): 42−44+54.

LI W F, LIU X. Development and application of low temperature collector CY−411 for iron ore[J]. Metallic Materials and Metallurgical Engineering, 2014, 42(4): 42−44+54.

[34] 高野, 张亚辉, 周南, 等. 新型捕收剂在宣龙鲕状赤铁矿反浮选中的实验研究[J]. 矿产保护与利 用, 2017(5): 34−37+43.

GAO Y, ZHANG Y H, ZHOU N, et al. Experimental study of new collectors in reverse flotation of Xuanlong oolitic hematite[J]. Conservation and Utilization of Mineral Resources, 2017(5): 34−37+43.

[35] 朱一民, 刘杰, 李艳军. 非硫化矿浮选药剂作用原理[M]. 北京: 冶金工业出版社, 2021

ZHU Y M, LIU J, LI Y J. Action principle of non−sulfide ore flotation reagent[M]. Beijing: Metallurgical Industry Press, 2021.

[36] 刘文宝. 赤铁矿反浮选高选择性阳离子捕收剂的合成及浮选性能研究[D]. 沈阳: 东北大学, 2020.

LIU W B. Synthesis and flotation performance of highly selective cationic collector for reverse flotation of hematite[D]. Shenyang: Northeast University, 2020.

[37] Weidi Z, Shuang L, Qilong R, et al. Proposing a novel factor influencing flotation collector abilities to collect minerals by comparing two cationic collectors N, N−bis(2−hydroxy−3−chloropropyl) dodecylamine and dodecylamine[J]. Applied Surface Science, 2023, 640.

[38] Weichao L, Wenbao L, Kelin T, et al. Synthesis and flotation performance of a novel low−foam viscous cationic collector based on hematite reverse flotation desilication system[J]. Minerals Engineering, 2023, 201.

[39] Zhongxian W, Dongping T, Youjun T, et al. A novel cationic collector for silicon removal from collophane using reverse flotation under acidic conditions[J]. International Journal of Minerals, Metallurgy and Materials, 2023, 30(6):1038-1047.

[40] 刘文宝, 刘文刚, 段浩, 等. 阳离子捕收剂及其分子结构设计理论研究进展[J]. 金属矿山, 2019(9): 15−21.

LIU W B, LIU W G, DUAN H, et al. Research progress of cationic collector and its molecular structure design theory[J]. Metal Mine, 2019(9): 15−21.

[41] 余新阳, 钟宏, 刘广义. 阳离子反浮选脱硅捕收剂研究现状[J]. 轻金属, 2008(6): 6−10.

YU X Y, ZHONG H, LIU G Y. Research status of cationic reverse flotation desilication collector[J]. Light Metals, 2008(6): 6−10.

[42] 张永, 钟宏, 谭鑫, 等. 阳离子捕收剂研究进展[J]. 矿产保护与利用, 2011(3): 44−49.

ZHANG Y, ZHONG H, TAN X, et al. Research progress of cationic collectors[J]. Conservation and Utilization of Mineral Resources, 2011(3): 44−49.

[43] PANXING Z, WENGANG L, WENBAO L, et al. Novel low−foam viscous cationic collector 2−[2−(Tetradecylamino)ethoxy]ethanol: Design, synthesis, and flotation performance study to quartz[J]. Separation and Purification Technology, 2023, 307. DOI.org/10.1016/j.seppur.2022.122633

[44] 王伟之, 刘泽伟, 王立宇, 等. 司家营铁矿阳离子反浮选降硅正交实验[J]. 矿产综合利用, 2016(6): 35−38.

WANG W Z, LIU Z W, WANG L Y, et al. Sijiaying iron ore cationic reverse flotation orthogonal test[J]. Multipurpose Utilization of Mineral Resources, 2016(6): 35−38.

[45] 杨雪. 新型捕收剂在尖山铁精矿反浮选中的实验探讨[J]. 华北国土资源, 2012(3): 127−129.

YANG X. Experimental study of new collectors in reverse flotation of Jianshan iron concentrate[J]. North China Land Resources, 2012(3): 127−129.

[46] 王春梅, 葛英勇, 王凯金, 等. GE−609捕收剂对齐大山赤铁矿反浮选的初探[J]. 有色金属(选矿部分), 2006(4): 41−43.

WANG C M, GE Y Y, WANG K J, et al. Preliminary study on reverse flotation of Qidashan hematite with GE−609 collector[J]. Nonferrous Metals(Mineral Processing Section), 2006(4): 41−43.

[47] 葛英勇. 新型捕收剂烷基多胺醚(GE−609)的合成及浮选性能研究[D]. 武汉: 武汉理工大学, 2010.

GE Y Y. Synthesis and flotation performance of a new collector alkyl polyamine ether ( GE−609 )[D]. Wuhan: Wuhan University of Technology, 2010.

[48] 朱一民, 乘舟越洋, 骆斌斌. 一种新型阳离子捕收剂DCZ浮选性能研究[J]. 矿产综合利用, 2017(1): 32−36.

ZHU Y M, CHENG Z Y Y, LUO B B. Study on flotation performance of a new cationic collector DCZ[J]. Multipurpose Utilization of Mineral Resources, 2017(1): 32−36.

[49] 佟柯霖, 刘文宝, 刘文刚, 等. 季铵化对阳离子捕收剂N, N−十二烷基二乙醇胺性能的影响研究[J]. 金属矿山, 2021(12): 28−33.

TONG K L, LIU W B, LIU W G, et al. Effect of quaternization on the performance of cationic collector N, N−dodecyldiethanolamine[J]. Metal Mine, 2021(12): 28−33.

[50] 周永锋, 罗溪梅, 宋水祥, 等. 四种阳离子捕收剂对赤铁矿和石英浮选行为的影响[J]. 矿产保护与利用, 2020, 40(2): 56−61.

ZHOU Y F, LUO X M, SONG S X, et al. Effects of four cationic collectors on flotation behavior of hematite and quartz[J]. Conservation and Utilization of Mineral Resources, 2020, 40(2): 56−61.

[51] 刘文刚, 魏德洲, 崔宝玉, 等. 新型捕收剂在赤铁矿反浮选中的应用[J]. 东北大学学报(自然科学版), 2011, 32(4): 575−578.

LIU W G, WEI D Z, CUI B Y, et al. Application of new collectors in reverse flotation of hematite[J]. Journal of Northeastern University (Natural Science Edition), 2011, 32(4): 575−578.

[52] 王本英, 徐新阳, 陈熙, 等. 十二烷基胺类捕收剂的取代基基因特性对其浮选性能的影响研究[J]. 金属矿山, 2020(6): 31−35.

WANG B Y, XU X Y, CHEN X, et al. Study on the effect of substituent gene characteristics of dodecylamine collectors on their flotation performance[J]. Metal Mines, 2020(6): 31−35.

[53] 王纪镇, 印万忠, 刘明宝, 等. 浮选组合药剂协同效应定量研究[J]. 金属矿山, 2013(5): 62−66.

WANG J Z, YIN W Z, LIU M B, et al. Quantitative study on synergistic effect of flotation combined reagents[J]. Metal Mines, 2013(5): 62−66.

[54] 刘文宝, 甘琦强, 刘文刚, 等. 新型组合捕收剂对锂云母、钠长石和石英的浮选性能研究[J]. 矿产保护与利用, 2023, 43(3): 34−42.

LIU W B, GAN Q Q, LIU W G, et al. Study on the flotation performance of new combined collectors for lepidolite, albite and quartz[J]. Conservation and Utilization of Mineral Resources, 2023, 43(3): 34−42.

[55] 卢颖. 关于组合药剂在浮选工艺应用的探讨[J]. 中国矿业, 2000(S1): 269−271.

LU Y. Discussion on the application of combined reagents in flotation process[J]. China Mining Magazine, 2000(S1): 269−271.

[56] 卢颖, 孙胜义. 组合药剂的发展及规律[J]. 矿业工程, 2007(6): 42−44. doi: 10.3969/j.issn.1671-8550.2007.06.017

LU Y, SUN S Y. The Development and Law of Combined Reagents[J]. Mining Engineering, 2007(6): 42−44. doi: 10.3969/j.issn.1671-8550.2007.06.017

[57] Qiang L, Yating L, Jiyan S, et al. Synergistic detoxification by combined reagents and safe filling utilization of cyanide tailings[J]. Chemosphere, 2022, 312(P1).

[58] 刘述忠, 李晓阳, 徐晓军, 等. 捕收剂组合使用的研究概况[J]. 云南冶金, 2002(4): 17−20.

LIU S Z, LI X Y, XU X J, et al. Research on the combination of collectors[J]. Yunnan Metallurgy, 2002(4): 17−20.

[59] MAITI, K, BHATTACHARYA, SC, MOULIK, SP, et al. Physicochemistry of the binary interacting mixtures of cetylpyridinium chloride (CPC) and sodium dodecylsulfate (SDS) with special reference to the catanionic ion−pair (coacervate) behavior[J]. Colloids and Surfaces, A. Physicochemical and Engineering Aspects, 2010, 355(1/3): 88−98.

[60] Qian Y, Ding W, Wang Z, et al. New combined depressant/collectors system for the separation of powellite from dolomite and the interaction mechanism[J]. Minerals, 2020, 10(3): 291.

[61] QIONGYIN M, HANYU Z, LEMING O. Flotation separation of chalcopyrite and talc using calcium ions and calcium lignosulfonate as a combined depressant[J]. Metals, 2021, 11(4): 651.

[62] 姜永良, 付泳贺, 姜效军, 等. 组合阴离子捕收剂对石英的吸附机理研究[J]. 金属矿山, 2020(11): 118−123.

JIANG Y L, FU Y H, JIANG X J, et al. Adsorption mechanism of quartz by combined anionic collectors[J]. Metal Mines, 2020(11): 118−123.

[63] 仝丽娟, 朱一民, 李艳军, 等. 组合药剂TL−5对东鞍山赤铁矿的捕收性能研究[J]. 现代矿业, 2010, 26(8): 34−37.

TONG L J, ZHU Y M, LI Y J, et al. Study on the collecting performance of combined reagent TL−5 for Donganshan hematite[J]. Modern Mining, 2010, 26(8): 34−37.

[64] 曹少航, 印万忠, 姚金, 等. 组合捕收剂在赤铁矿常温反浮选中的应用[J]. 金属矿山, 2016(12): 77−81. doi: 10.3969/j.issn.1001-1250.2016.12.017

CAO S H, YIN W Z, YAO J, et al. Application of combined collectors in reverse flotation of hematite at room temperature[J]. Metal Mine, 2016(12): 77−81. doi: 10.3969/j.issn.1001-1250.2016.12.017

[65] 徐小革, 乘舟越洋, 朱一民, 等. 复合捕收剂在铁矿石反浮选中的协同作用[J]. 金属矿山, 2019(2): 92−96.

XU X G, CHENG Z Y Y, ZHU Y M, et al. Synergistic effect of composite collectors in reverse flotation of iron ore[J]. Metal Mine, 2019(2): 92−96.

[66] 王小飞, 米金月, 陈先龙, 等. 组合捕收剂WM−1对东鞍山赤铁矿的捕收性能[J]. 金属矿山, 2010(8): 51−54.

WANG X F, MI J Y, CHEN X L, et al. Collection performance of combined collector WM−1 for Donganshan hematite[J]. Metal Mine, 2010(8): 51−54.

[67] 祁忠旭, 韩远燕, 孙大勇, 等. 提高云南某超贫微细赤铁矿选矿回收率的研究[J]. 烧结球团, 2020, 45(5): 59−62.

QI Z X, HAN Y Y, SUN D Y, et al. Study on improving the recovery rate of an ultra−low fine hematite in Yunnan[J]. Sintered pellets, 2020, 45(5): 59−62.

[68] 纪振明. 云南某难选赤铁矿选矿实验[J]. 现代矿业, 2018, 34(11): 103−105+123. doi: 10.3969/j.issn.1674-6082.2018.11.024

JI Z M. Mineral processing test of a refractory hematite in Yunnan[J]. Modern Mining, 2018, 34(11): 103−105+123. doi: 10.3969/j.issn.1674-6082.2018.11.024

-

下载:

下载: