Analysis of External Influence Factors and Hydration Reaction of Static Crushing Agent

-

摘要:

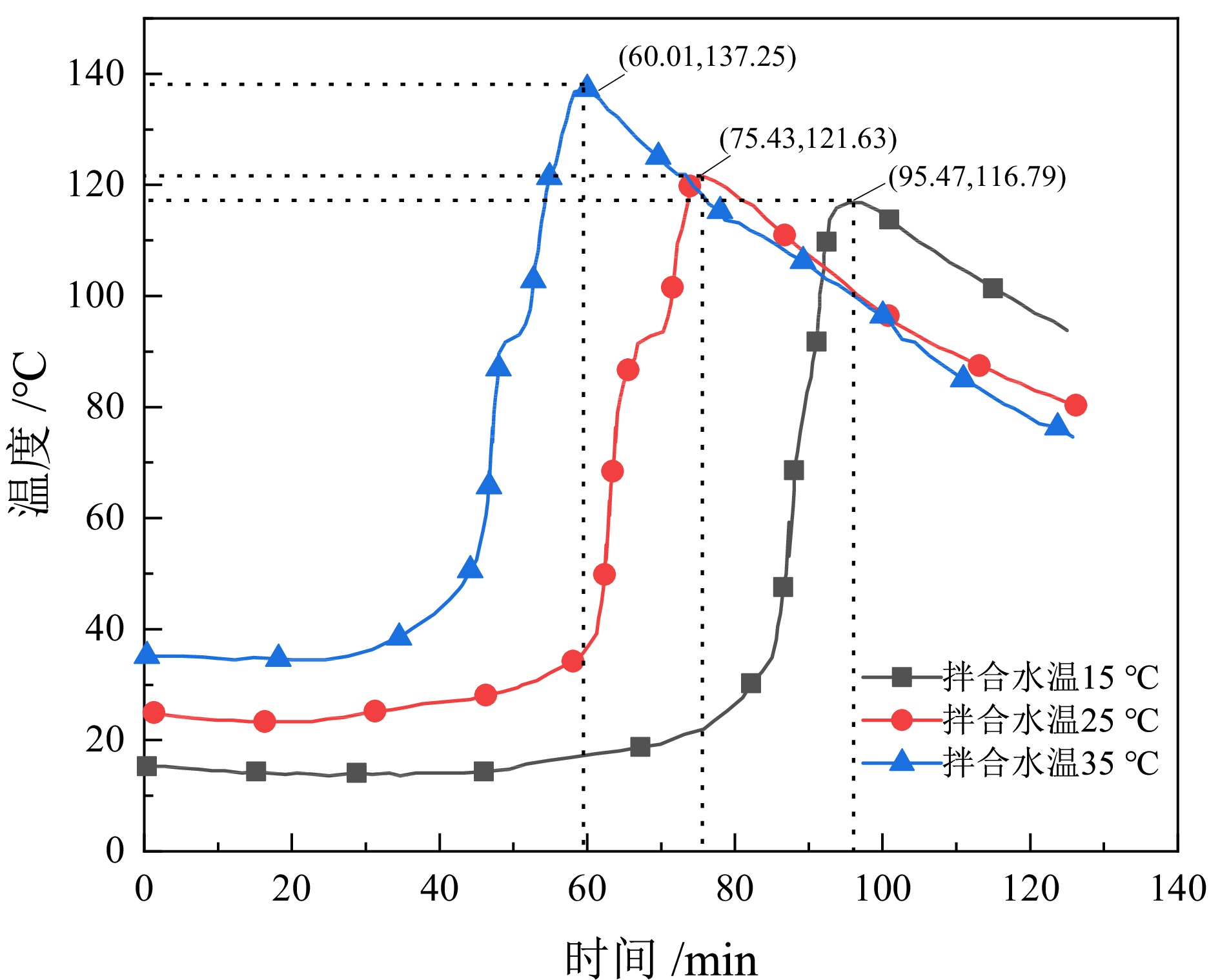

为探究影响爆破用静态破碎剂水化反应过程中膨胀压力与温度变化的外部因素,基于多水平正交实验进行静态破碎剂的配方优化设计,利用“外管法”测试静态破碎剂膨胀压力,使用温度计探针实时监测破碎剂水化反应温度。从不同水灰比、不同环境温度、不同拌合水温三个方面对静态破碎剂进行水化反应分析研究,结果表明:静态破碎剂反应的峰值温度随水灰比的增加而先增加后降低;随环境温度以及拌合水温的升高而升高,整体水化反应温度经历“平缓—急剧升温—快速降温”的过程;静态破碎剂在测试钢管中的峰值压力随水灰比增大而呈现先增大后减小的趋势,随环境温度升高而升高,但温度过高易导致破碎剂喷孔使膨胀压急剧降低直至失去膨胀力。适当提高拌合水温对静态破碎剂水化反应起促进作用,拌合水温不宜高于35 ℃。

Abstract:In order to explore the external factors affecting the expansion pressure and temperature changes during the hydration reaction of static crusher, the formula optimization design of static crusher was carried out based on multi−level orthogonal test, the expansion pressure of static crusher was tested by using the “outer tube method”, and the hydration reaction temperature of crusher was monitored in real time by thermometer probe. The results showed that the peak temperature of the static crusher increased first and then decreased with the increase of the water−cement ratio. With the increase of ambient temperature and mixing water temperature, the overall hydration reaction temperature undergo a process of “gentle−sharp heating−rapid cooling”. The peak pressure of static crusher in the test steel pipe increases first and then decreases with the increase of water−cement ratio, and increases with the increase of ambient temperature, but too high temperature can easily lead to the expansion pressure of the crusher nozzle to decrease sharply until it loses its expansion force. Appropriately increasing the mixing water temperature can promote the hydration reaction of the static crusher, and the mixing water temperature should not be higher than 35 ℃. increase the mixing water temperature on the static crusher hydration reaction to promote the role of mixing water temperature should not be higher than 35 ℃.

-

Key words:

- calcium oxide /

- static crusher /

- expansion pressure /

- hydration reaction

-

-

表 1 正交设计各组分质量分数

Table 1. Percentage of each component in orthogonal experiment

/% 编号 氧化钙 石膏 水泥 膨润土 减水剂 粉煤灰 1 70(Ⅰ) 3(Ⅰ) 8(Ⅰ) 6(Ⅰ) 1 12 2 70(Ⅰ) 4(Ⅱ) 9(Ⅱ) 8(Ⅱ) 1 8 3 70(Ⅰ) 5(Ⅲ) 10(Ⅲ) 10(Ⅲ) 1 4 4 73(Ⅱ) 4(Ⅱ) 8(Ⅰ) 10(Ⅲ) 1 4 5 73(Ⅱ) 5(Ⅲ) 9(Ⅱ) 6(Ⅰ) 1 6 6 73(Ⅱ) 3(Ⅰ) 10(Ⅲ) 8(Ⅱ) 1 5 7 76(Ⅲ) 5(Ⅲ) 8(Ⅰ) 8(Ⅱ) 1 2 8 76(Ⅲ) 3(Ⅰ) 9(Ⅱ) 10(Ⅲ) 1 1 9 76(Ⅲ) 4(Ⅱ) 10(Ⅲ) 6(Ⅰ) 1 3 注:括号内Ⅰ、Ⅱ、Ⅲ表示水平。 表 2 水化反应36 h后破碎剂膨胀压

Table 2. Swelling pressure of static cracking agent at 36 h

编号 1 2 3 4 5 6 7 8 9 膨胀压/MPa 66.15 64.45 67.87 74.34 79.59 77.77 70.32 66.66 68.28 表 3 正交实验数据分析结果

Table 3. Results of the orthogonal experimental data analysis

原料 氧化钙 石膏 水泥 膨润土 ΣⅠ/3 66.49 70.19 70.27 71.34 ΣⅡ/3 77.23 69.36 70.57 71.18 ΣⅢ/3 68.42 72.59 71.30 69.62 平均膨胀压极差 10.74 3.23 1.03 1.72 -

[1] 马芹永, 袁璞, 卢小雨. 静态破碎技术在桥梁临时支撑拆除中的应用[J]. 施工技术, 2013, 42(增刊): 337−340.

MA Q Y, YUAN P, LU X Y. Application of soundlesscracking technology in demolishing bridge temporary sup−port[J]. Construction Technology, 2013, 42(Suppl.): 337−340.

[2] 李元杰, 刘鹏, 樊文明. 静态破碎技术在拆除工程中的应用[J]. 山西建筑, 2010, 36(31): 155−156. doi: 10.3969/j.issn.1009-6825.2010.31.095

LI Y J, LIU P, FAN W M. Application of static breakage technology in demolition engineering[J]. Shanxi Architecture, 2010, 36(31): 155−156. doi: 10.3969/j.issn.1009-6825.2010.31.095

[3] 谭毅. 静态破碎剂在回采工作面端头悬顶处理中的应用与研究[D]. 太原: 太原理工大学, 2012.

TAN Y. Application and research of the soundless cracking agent in mining working face end hanging roof[D]. Taiyuan: Taiyuan University of Technology, 2012.

[4] 孙雪, 龚飞飞, 戴银所, 等. 基于SCA的静态破碎剂性能研究[J]. 土木工程, 2016, 5(5): 181−189. doi: 10.12677/HJCE.2016.55024

SUN X, GONG F F, DAI Y S, et al. Research of static blasting agent based on SCA[J]. Hans Journal of Civil Engineering, 2016, 5(5): 181−189. doi: 10.12677/HJCE.2016.55024

[5] 罗明坤, 李胜, 李宗杰, 等. 煤岩致裂中的静态破碎剂组分及其性能[J]. 工程爆破, 2017, 23(3): 5−9. doi: 10.3969/j.issn.1006-7051.2017.03.002

LUO M K, LI S, LI Z J, et al. Composition and per−formance of static cracking agent in coal and rock fractu−ring[J]. Engineering Blasting, 2017, 23(3): 5−9. doi: 10.3969/j.issn.1006-7051.2017.03.002

[6] 李胜, 李宗杰, 罗明坤. 煤岩静态破碎剂合理组分及配比实验研究[J]. 爆破, 2018, 35(1): 137−141+153.

LI S, LI Z J, LUO M K. Experimental study on rea−sonable composition and ratio of coal rock static crushing agent[J]. Blasting, 2018, 35(1): 137−141+153.

[7] 汪智勇, 陈旭峰. 辅助相对静态破碎剂性能的影响[C]//第七届全国混凝土膨胀剂学术交流会论文集, 2018: 73−78.

WANG Z Y, CHEN X F. Effect of auxiliary relative static breaker performance[C]//Proceedings of the Seventh National Concrete Expansion Agent Academic Exchange Conference, 2018: 73−78.

[8] 刘文, 吴爱军, 王辉, 等. 铅锌尾矿砂掺量对静态破碎剂性能影响的实验研究[J]. 爆破, 2020, 37(2): 121−126+140. doi: 10.3963/j.issn.1001-487X.2020.02.021

LIU W, WU A J, WANG H, et al. Experimental studyon effect of lead−zinc mine tailing on properties of static crushing agent[J]. Blasting, 2020, 37(2): 121−126+140. doi: 10.3963/j.issn.1001-487X.2020.02.021

[9] 张嘉勇, 崔啸, 许慎, 等. 铁尾矿粉对静态破碎剂反应温度影响研究[J]. 矿产综合利用, 2018(2): 121−124. doi: 10.3969/j.issn.1000-6532.2018.02.027

ZHANG J Y, CUI X, XU S, et al. Study on effect of iron tailings powders on reaction temperature of static cracking agent[J]. Multipurpose Utilization of MineralResources, 2018(2): 121−124. doi: 10.3969/j.issn.1000-6532.2018.02.027

[10] 郑文忠, 李瑞森, 徐笠博, 等. 静态破碎技术研究综述与建议[J]. 哈尔滨工业大学学报, 2021, 53(5): 190−200. doi: 10.11918/201907034

ZHENG W Z, LI R S, XU L B, et al. Review and analysis on research and application of static crushing technology[J]. Journal of Harbin Institute of Technology, 2021, 53(5): 190−200. doi: 10.11918/201907034

[11] 杜光钢, 董立哲, 李祥龙, 等. 静态破碎剂的配方优化设计与水化反应分析[J]. 爆破器材, 2022, 51(6): 32−38+44. doi: 10.3969/j.issn.1001-8352.2022.06.006

DU G G, DONG L Z, LI X L, et al. Optimization of the formulation design of the static crushing agent and the hydration reaction analysis[J]. Explosive Blasting, 2022, 51(6): 32−38+44. doi: 10.3969/j.issn.1001-8352.2022.06.006

[12] 王萱, 余超, 董博, 等. 氧化钙材料的性能及优化研究进展[C]//第十八届全国耐火材料青年学术报告会论文集, 2022: 28−34.

WANG X, YU C, DONG B, et al. Research progress on the properties and optimisation of calcium oxide materials[C]//Proceedings of the 18th National Refractories Youth Symposium, 2022: 28−34.

[13] 徐国庆. 静态破碎剂制备及力学性能研究[D]. 哈尔滨: 哈尔滨工程大学, 2020.

XU G Q. Study on the preparation and mechanical properties of static crushing agents [D]. Harbin: Harbin Engineering University, 2020.

[14] 国家发展和改革委员会. JC 506—2008, 无声破碎剂[S]. 北京: 建材工业出版社, 2008.

National Development and Reform Commission. JC 506—2008, Soundless cracking agent[S]. Beijing: Building Materials Industry Press, 2008.

[15] 冯彧雷. 静态破碎剂的膨胀压力测试实验与应用[D]. 淮南: 安徽理工大学, 2010.

FENG Y L. Test and application of static crushing agent[D]. Huainan: Anhui University of Science and Technology, 2010.

[16] 张嘉勇, 关联合, 张新双, 等. 水灰比和粉煤灰对静态破碎剂反应温度影响研究[J]. 矿产综合利用, 2020(1): 173−176+106. doi: 10.3969/j.issn.1000-6532.2020.01.035

ZHANG J Y, GUAN L H, ZHANG X S, et al. Study on the influence of water ash ratio and fly ash on the reaction temperature of static crushing agent[J]. Multipurpose Utilization of Mineral Resources, 2020(1): 173−176+106. doi: 10.3969/j.issn.1000-6532.2020.01.035

[17] 谢益盛, 杨光辉, 黄小朋. 静态破碎剂膨胀力学性能实验研究[J]. 煤矿安全, 2019, 50(3): 9−12+16.

XIE Y S, YANG G H, HUANG X P. Experimental research on mechanical properties of static breaking agents[J]. Safety in Coal Mines, 2019, 50(3): 9−12+16.

[18] 陈卫东, 吴培文, 于会军, 等. 静态破碎剂防喷和破岩的实验与仿真[J]. 哈尔滨工程大学学报, 2021, 42(9): 1295−1302.

CHEN W D, WU P W, YU H J, et al. Spray−prevention trial and rock−breaking simulation of a static cracking agen[J]. Journal of Harbin Engineering University, 2021, 42(9): 1295−1302.

[19] 武世亮, 翟成, 向贤伟, 等. 钻孔内静态破碎剂喷孔实验研究[J]. 煤炭技术, 2015, 34(9): 142−145.

WU S L, ZHAI C, XIANG X W, et al. Experimental study on jet orifice of static cracking agent in drilling hole[J]. Coal Technology, 2015, 34(9): 142−145.

[20] 王作鹏, 杜华善, 张现亭, 等. 一种新型静态破碎剂的研制[J]. 煤矿爆破, 2004(2): 13−15.

WANG Z P, DU H S, ZHANG X T, et al. Development of a new type of static crushing agent[J]. Coal Mine Blasting, 2004(2): 13−15.

[21] 康志鹏, 罗勇, 余国锋, 等. 静态破碎剂性能分析及致裂效果实验研究[J]. 科学技术与工程, 2024, 24(4): 1740−1748. doi: 10.12404/j.issn.1671-1815.2303856

KANG Z P, LUO Y, YU G F, et al. Performance analysis of static crushing agent and experimental study on fracturing effect[J]. Science Technology and Engineering, 2024, 24(4): 1740−1748. doi: 10.12404/j.issn.1671-1815.2303856

[22] 马冬冬, 马芹永, 袁璞. 气温和水温对静态破碎剂膨胀性能影响的实验分析[J]. 爆破, 2014, 31(4): 124−128. doi: 10.3963/j.issn.1001-487X.2014.04.028

MA D D, MA Q Y, YUAN P. Test and analysis on air temperature and water temperature for expansion performance of static cracking agent[J]. Blasting, 2014, 31(4): 124−128. doi: 10.3963/j.issn.1001-487X.2014.04.028

-

下载:

下载: