Macroscopic and microscopic shear failure characteristics of anchored penetrating jointed rock mass

-

摘要:

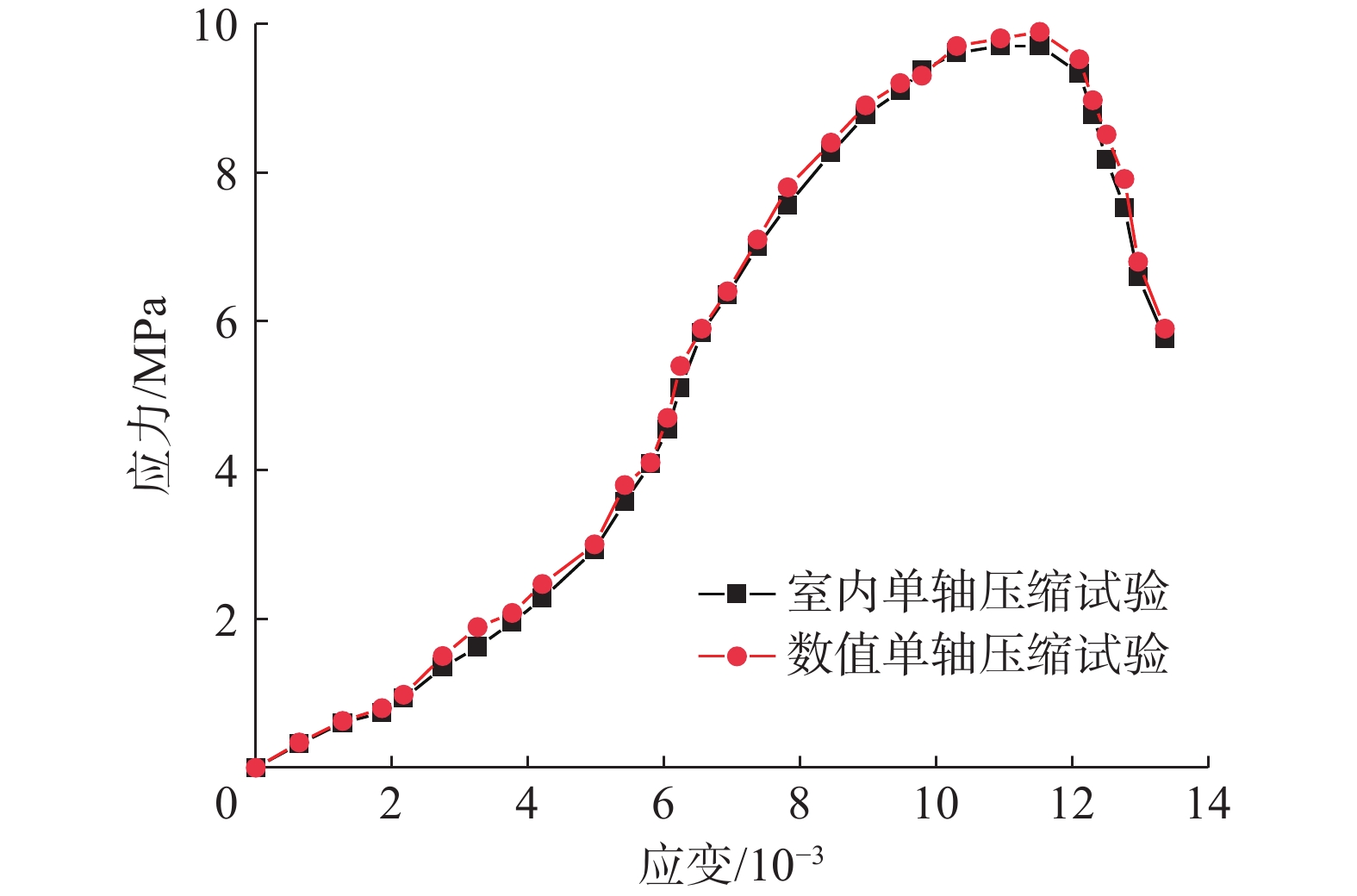

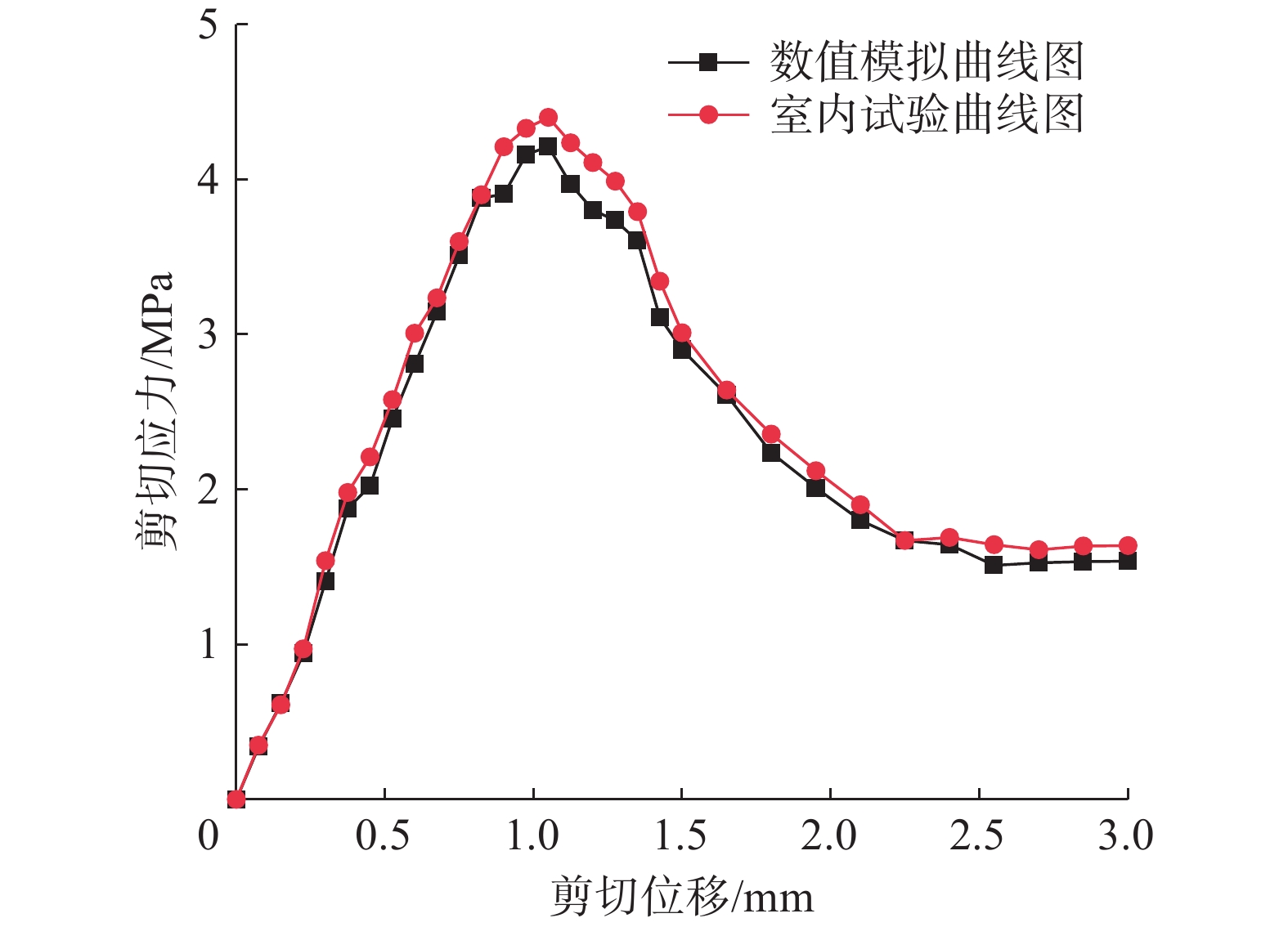

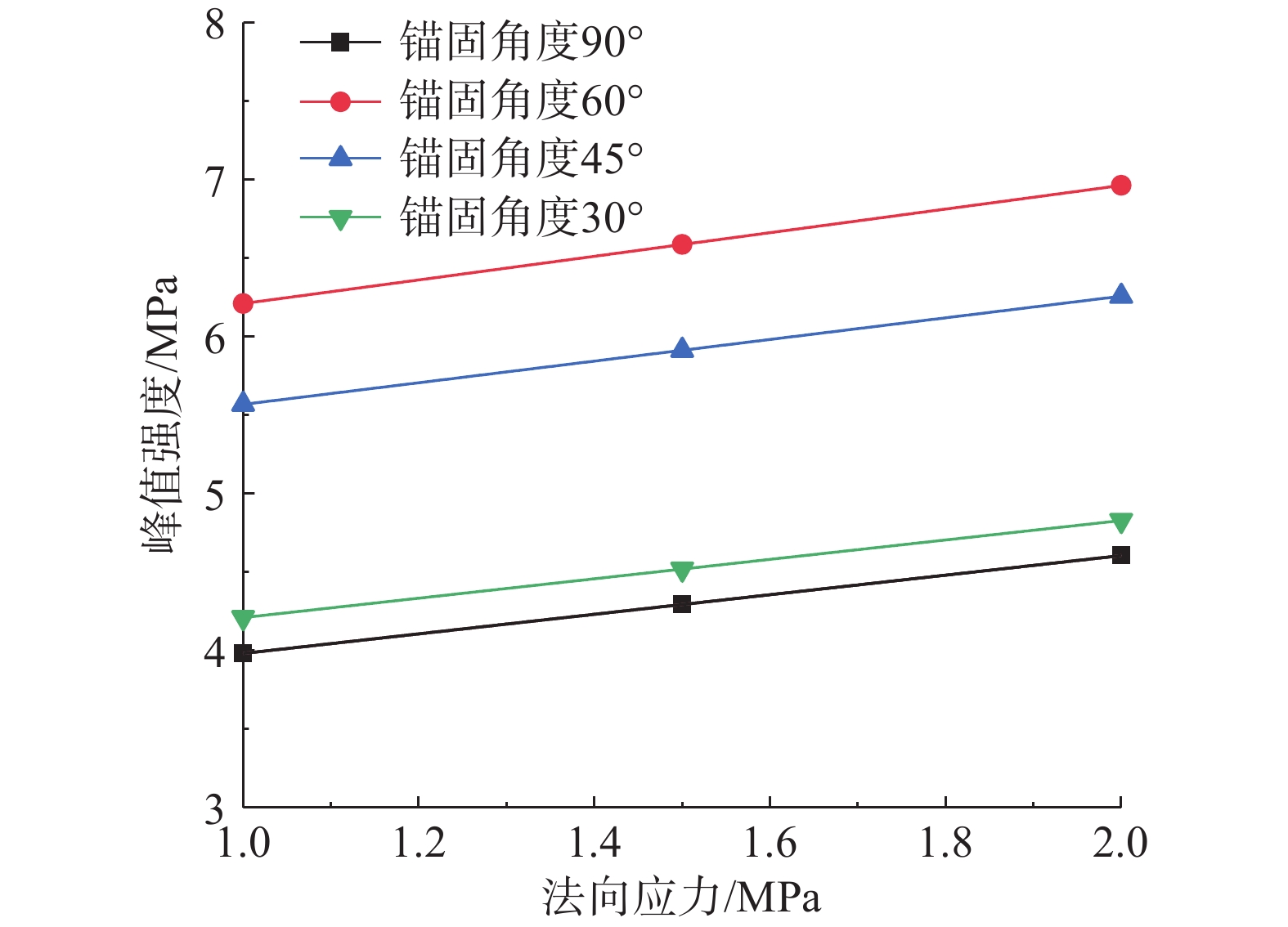

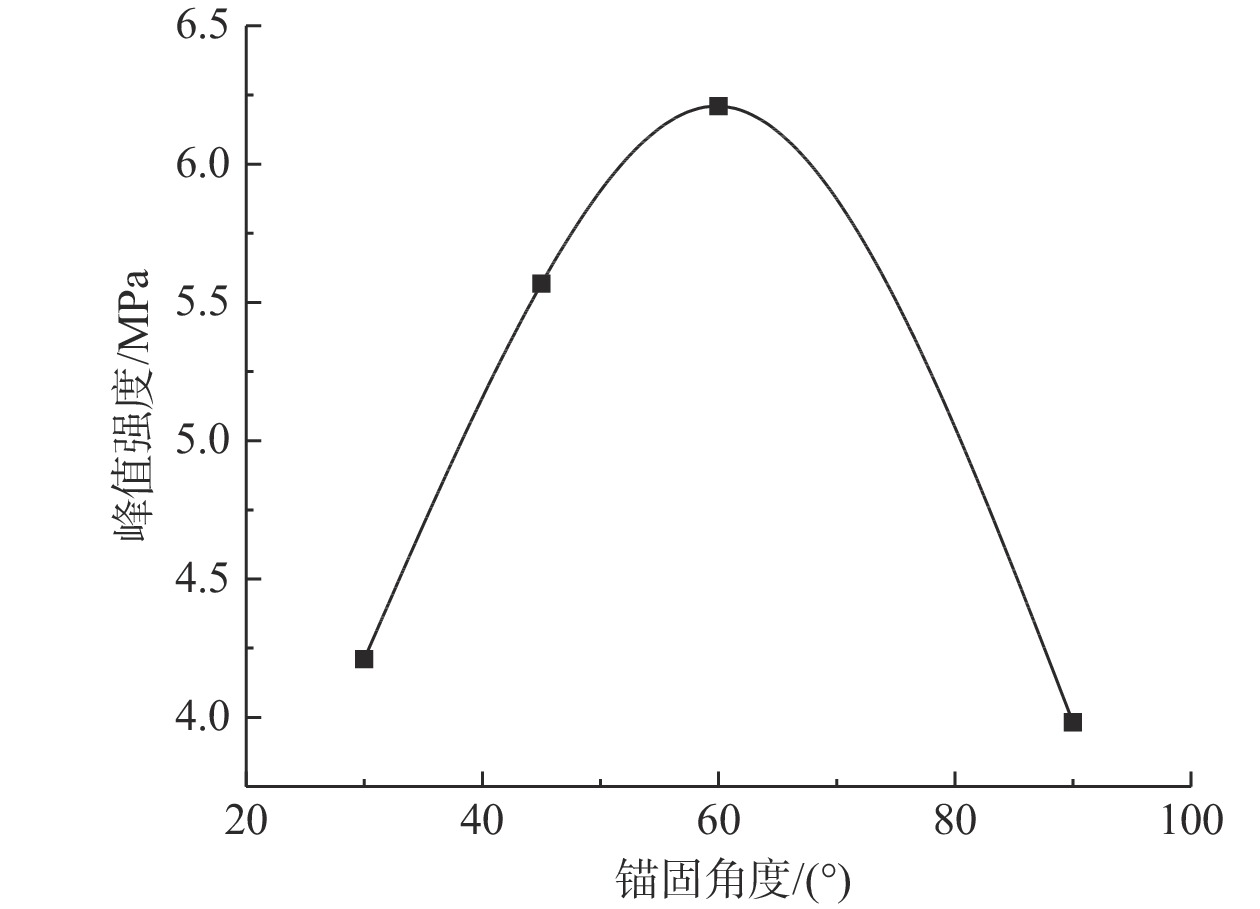

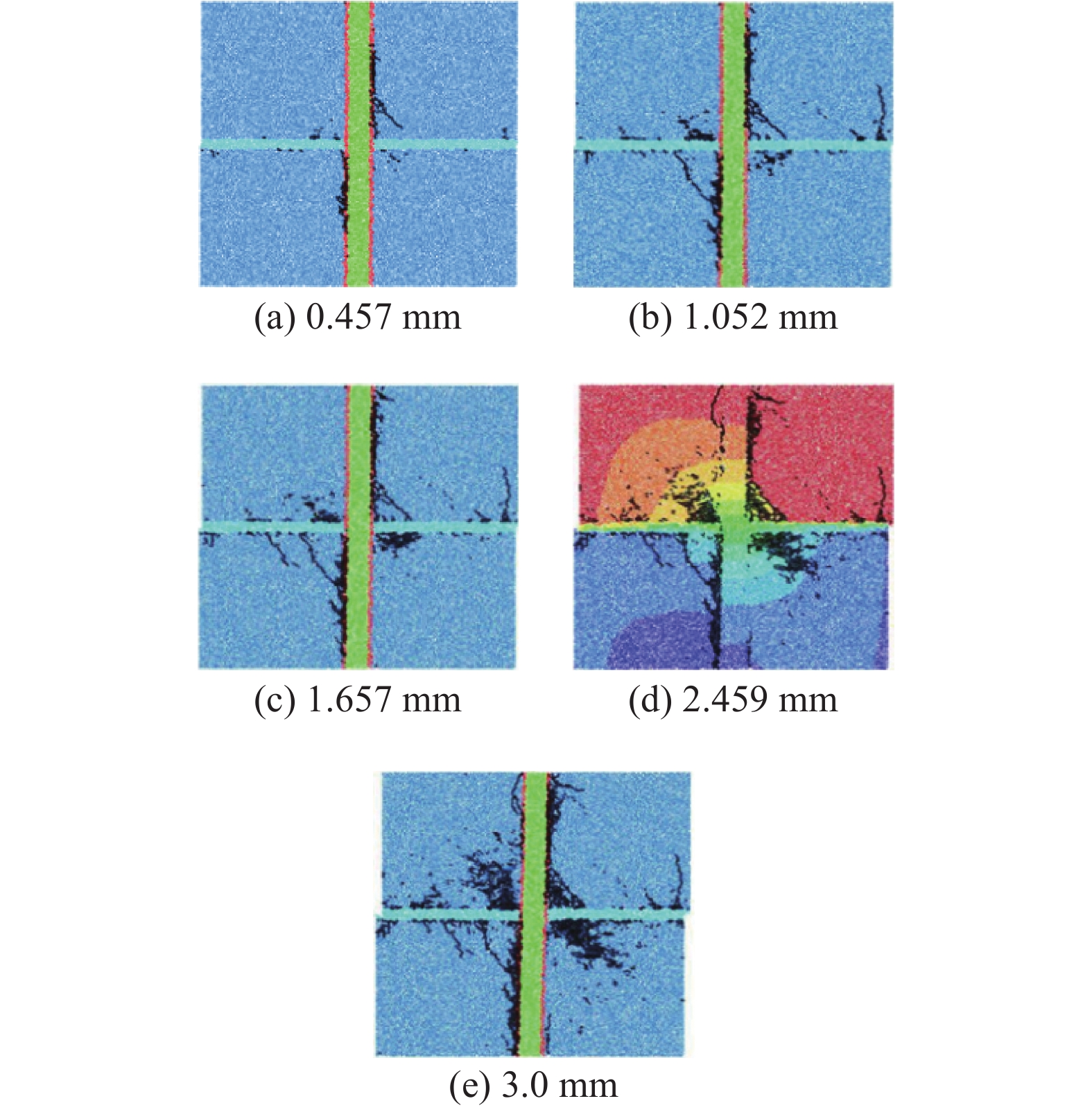

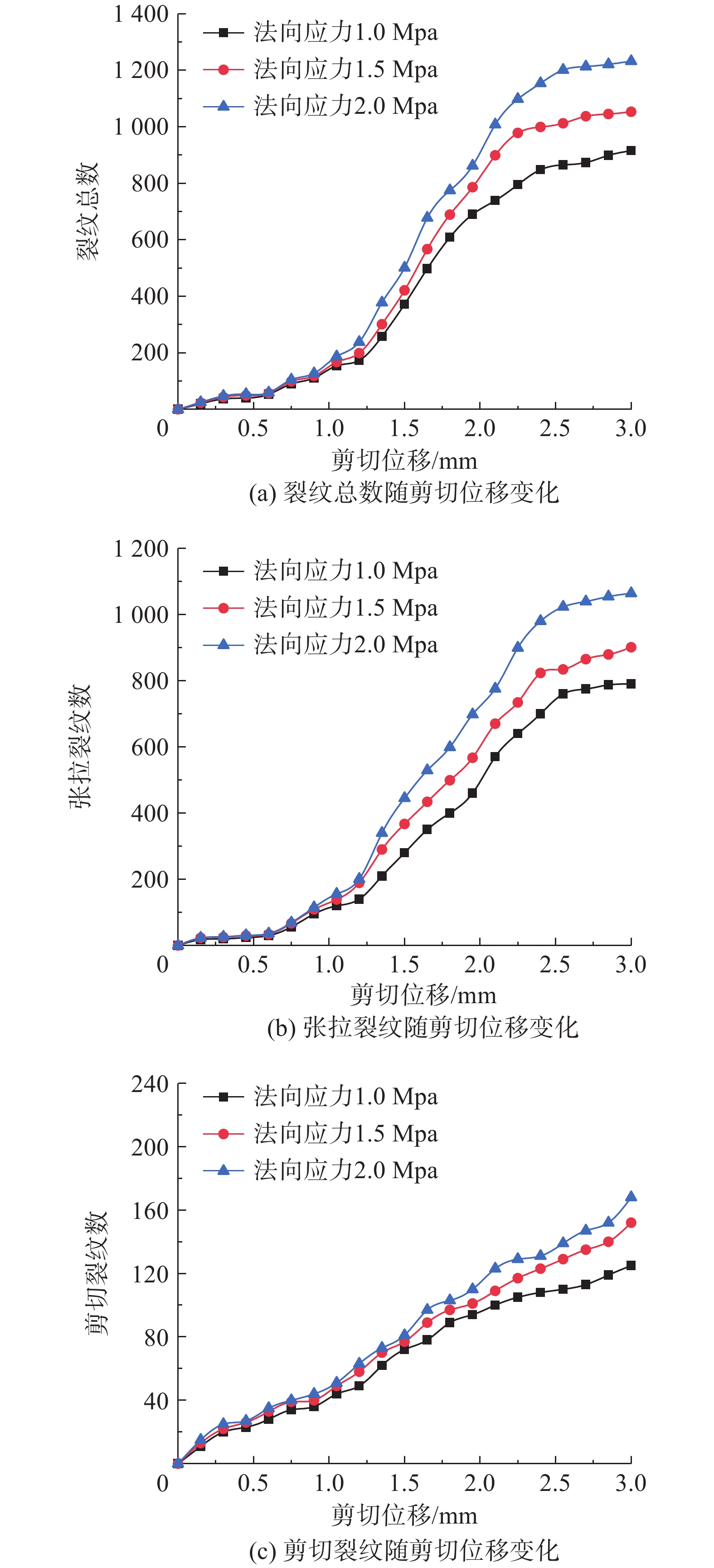

为了研究加锚贯通节理岩体的剪切破坏特性,根据室内实验及数值模拟软件PFC2D,分析了不同法向应力及不同锚固角度作用下,加锚贯通节理岩体的抗剪性能及内部细观裂纹的演变过程。研究表明:(1)随着锚固倾角的增加,加锚节理岩体抗剪强度呈现先增大后减小的趋势,且在锚固角度为60°时,其抗剪强度最大,锚固效果最好。随着法向应力越大,加锚节理岩体抗剪强度越高,其抗剪性能越好。(2)随着剪切位移的不断增加,由初期阶段在锚杆和节理附近产生的少量裂纹通过不断的向外扩展,最终在锚杆和节理交界处聚集了大量的裂纹,其中裂纹以张拉裂纹为主。(3)锚固角度及法向应力对裂纹扩展影响显著,随着法向应力的增加,裂纹数也呈现了增加的趋势,且岩体破坏越严重。随着锚固角度的变化,加锚节理岩体破坏时形成的裂纹数量有先减小后增大的趋势,且在锚固角度为60°时,产生的裂纹最少。

Abstract:In order to study the shear failure characteristics of anchored jointed rock mass, according to the indoor test and particle flow software PFC2D, the shear behavior and internal meso-crack evolution of the anchored rock mass under different normal stresses and different anchoring angles are analyzed. The researches show that: (1) With the increasing of the anchoring angle, the shear strength of the anchored rock mass increases first and then decreases, and when the anchoring angle is 60°, the shear strength is the largest and the anchoring effect is the best. With the higher the normal stress, the higher the shear strength of the anchored jointed rock mass, the better the shear resistance. (2) As the shear displacement increasing, a small number of cracks generated in the early stage near the anchor and joints, through continuous outward expansion, eventually gather a large number of cracks at the joint between the anchor and the joint, where in the crack, the tensile crack is dominant. (3) The anchoring angle and normal stress have a significant influence on crack propagation. With the increasing of normal stress, the number of cracks also shows an increasing trend, and the rock mass damage is more serious. With the change of the anchoring angle, the number of cracks formed when the anchored rock mass is destroyed firstly decreases and then increases, and when the anchoring angle is 60°, the cracks are the least.

-

Key words:

- anchored jointed rock mass /

- particle flow /

- anchoring angle /

- normal stress /

- mesoscopic crack

-

-

表 1 宏观物理力学参数

Table 1. Macrophysical and mechanical parameters

抗压强度/MPa 泊松比 弹性模量/GPa 内摩擦角/(°) 黏聚力/MPa 10.1 0.3 1.24 36 4.56 表 2 加锚岩体数值模型细观参数表

Table 2. Mesoscopic parameter table of numerical model of anchored rock mass

名称 数值 名称 数值 最小粒径 0.5 摩擦因数 1.0 颗粒粒径比 1.4 黏结抗拉强度 30.2 体积密度 1890 黏结抗剪强度 30.2 颗粒模量 5.0 平行黏结模量 4.86 颗粒刚度比 1.8 平行黏结半径因子 1.0 表 3 不同法向应力的作用下及四种不同锚固角度的加锚节理岩体模型进行直剪试验表

Table 3. Direct shear test results of anchored rock mass models under different normal stresses and four different anchoring angles

试验号 法向应力/MPa 锚固角度/(°) 峰值强度/MPa A1 1 30° 4.210 A2 1 45° 5.568 A3 1 60° 6.210 A4 1 90° 3.982 B1 1.5 30° 4.519 B2 1.5 45° 5.912 B3 1.5 60° 6.586 B4 1.5 90° 4.293 C1 2 30° 4.828 C2 2 45° 6.257 C3 2 60° 6.962 C4 2 90° 4.605 表 4 不同剪切位移处剪切裂纹数、张拉裂纹数及裂纹总数表

Table 4. Number of shear cracks, number of tensile cracks and total number of cracks at different shear displacements

剪切位移/mm 剪切裂纹数 张拉裂纹数 裂纹总数 0.457 23 24 47 1.052 46 181 227 1.657 78 330 408 2.459 108 530 638 3.000 125 790 915 -

[1] 刘泉声, 雷广峰, 彭星新, 等. 白砂岩、大理岩及花岗岩加锚剪切力学特性研究[J]. 岩石力学与工程学报,2018,37(增刊2):4007 − 4015. [LIU Quansheng, LEI Guangfeng, PENG Xingxin, et al. Study on shear mechanical properties of sandstone, marble and granite after anchoring[J]. Chinese Journal of Rock Mechanics and Engineering,2018,37(Sup2):4007 − 4015. (in Chinese with English abstract)

[2] 张伟, 刘泉声. 基于剪切试验的预应力锚杆变形性能分析[J]. 岩土力学,2014,35(8):2231 − 2240. [ZHANG Wei, LIU Quansheng. Analysis of deformation characteristics of prestressed anchor bolt based on shear test[J]. Rock and Soil Mechanics,2014,35(8):2231 − 2240. (in Chinese with English abstract)

[3] 王传兵, 雷广峰. 锚杆锚固对裂隙岩体力学特性影响试验研究[J]. 建井技术, 2017, 38(2): 23 − 29.

WANG Chuanbing, LEI Guangfeng. Experiment study on bolt anchorage affected to mechanics features of fractured rock mass[J]. Mine Construction Technology, 2017, 38(2): 23 − 29. (in Chinese with English abstract)

[4] 刘泉声, 雷广峰, 彭星新, 等. 锚杆锚固对节理岩体剪切性能影响试验研究及机制分析[J]. 岩土力学,2017,38(增刊1):27 − 35. [LIU Quansheng, LEI Guangfeng, PENG Xingxin, et al. Experimental study and mechanism analysis of influence of bolt anchoring on shear properties of jointed rock mass[J]. Rock and Soil Mechanics,2017,38(Sup1):27 − 35. (in Chinese with English abstract)

[5] 夏才初, 宋英龙, 唐志成, 等. 粗糙节理剪切性质的颗粒流数值模拟[J]. 岩石力学与工程学报,2012,31(8):1545 − 1552. [XIA Caichu, SONG Yinglong, TANG Zhicheng, et al. Particle flow numerical simulation for shear behavior of rough joints[J]. Chinese Journal of Rock Mechanics and Engineering,2012,31(8):1545 − 1552. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-6915.2012.08.007

[6] 王刚, 袁康, 蒋宇静, 等. 基于颗粒离散元法的锚固节理剪切行为宏细观研究[J]. 煤炭学报,2014,39(12):2381 − 2389. [WANG Gang, YUAN Kang, JIANG Yujing, et al. Macro-micro mechanical study on bolted joint subjected to shear loading based on DEM[J]. Journal of China Coal Society,2014,39(12):2381 − 2389. (in Chinese with English abstract)

[7] FERRERO A M. The shear strength of reinforced rock joints[J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts,1995,32(6):595 − 605.

[8] 周喻, 张怀静, 吴顺川, 等. 节理连通率对岩体力学特性影响的细观研究[J]. 岩土力学,2015,36(增刊2):29 − 36. [ZHOU Yu, ZHANG Huaijing, WU Shunchuan, et al. Meso-research on mechanical properties of rock mass affected by joint connectivity rate[J]. Rock and Soil Mechanics,2015,36(Sup2):29 − 36. (in Chinese with English abstract)

[9] 杨庆, 刘元俊. 岩石类材料裂纹扩展贯通的颗粒流模拟[J]. 岩石力学与工程学报,2012,31(增刊1):3123 − 3129. [YANG Qing, LIU Yuanjun. Simulations of crack propagation in rock-like materials using particle flow code[J]. Chinese Journal of Rock Mechanics and Engineering,2012,31(Sup1):3123 − 3129. (in Chinese with English abstract)

[10] 刘宁, 张春生, 褚卫江. 深埋大理岩破裂扩展时间效应的颗粒流模拟[J]. 岩石力学与工程学报,2011,30(10):1989 − 1996. [LIU Ning, ZHANG Chunsheng, CHU Weijiang. Simulating time-dependent failure of deep marble with particle flow code[J]. Chinese Journal of Rock Mechanics and Engineering,2011,30(10):1989 − 1996. (in Chinese with English abstract)

-

下载:

下载: