Preparation and Properties of Heat-Collecting Coating from Vanadium Extraction Slag under Double Carbon Background

-

摘要:

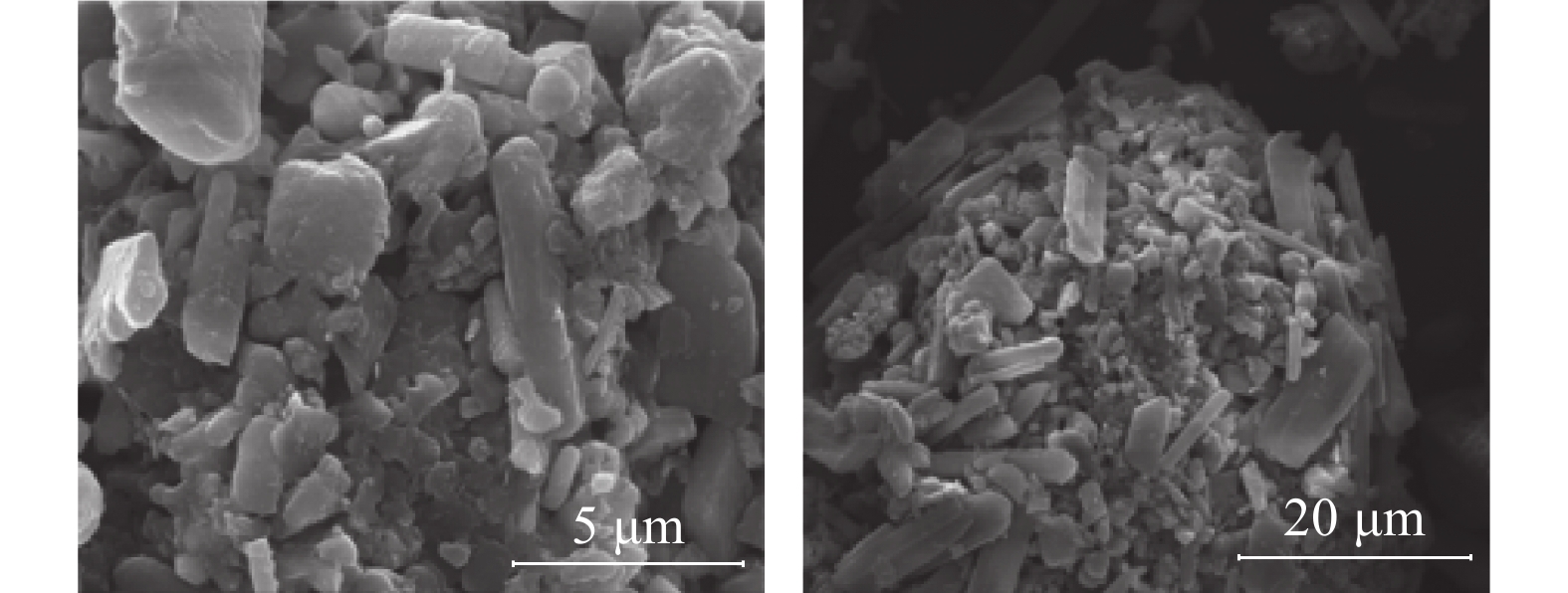

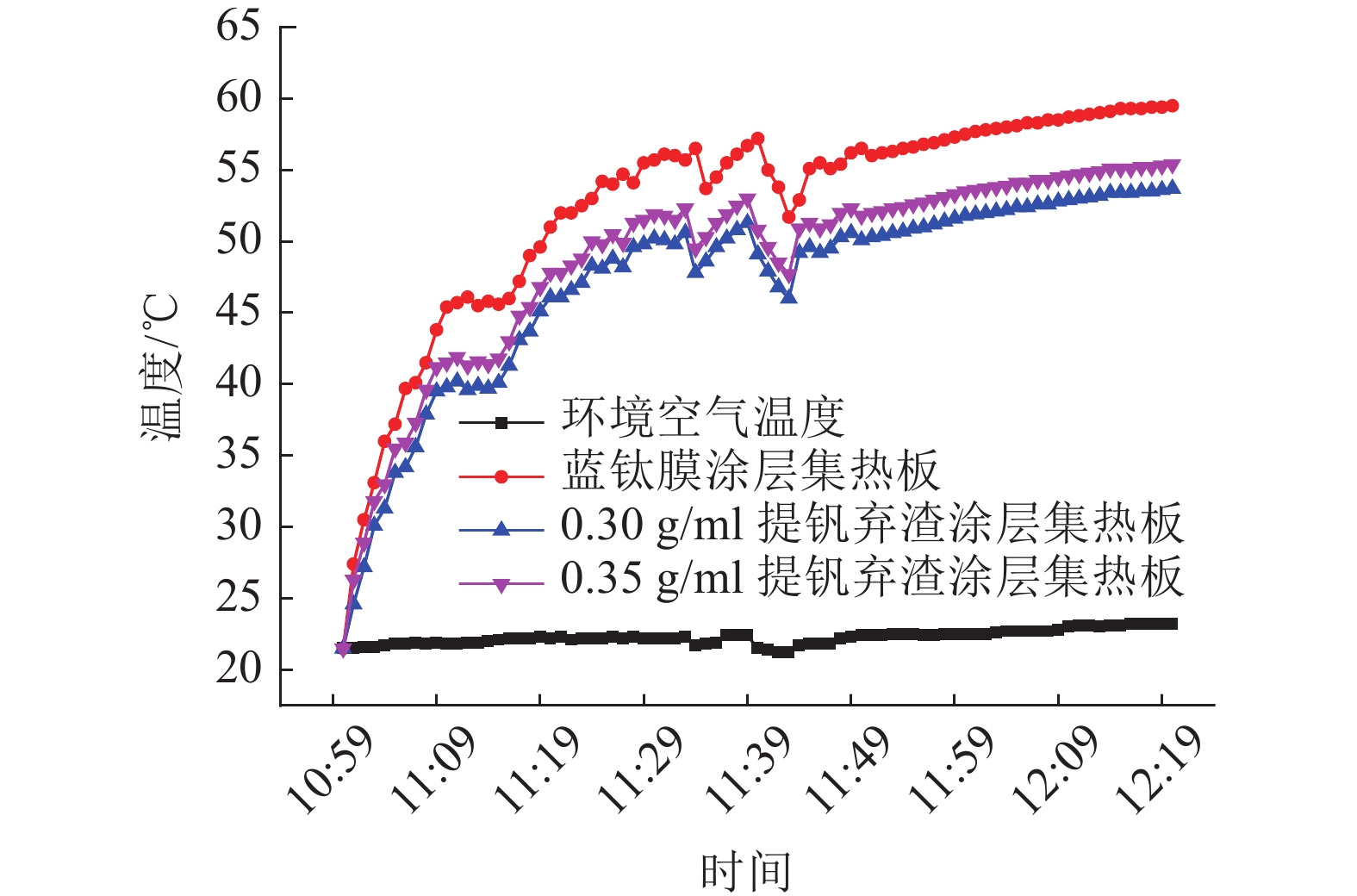

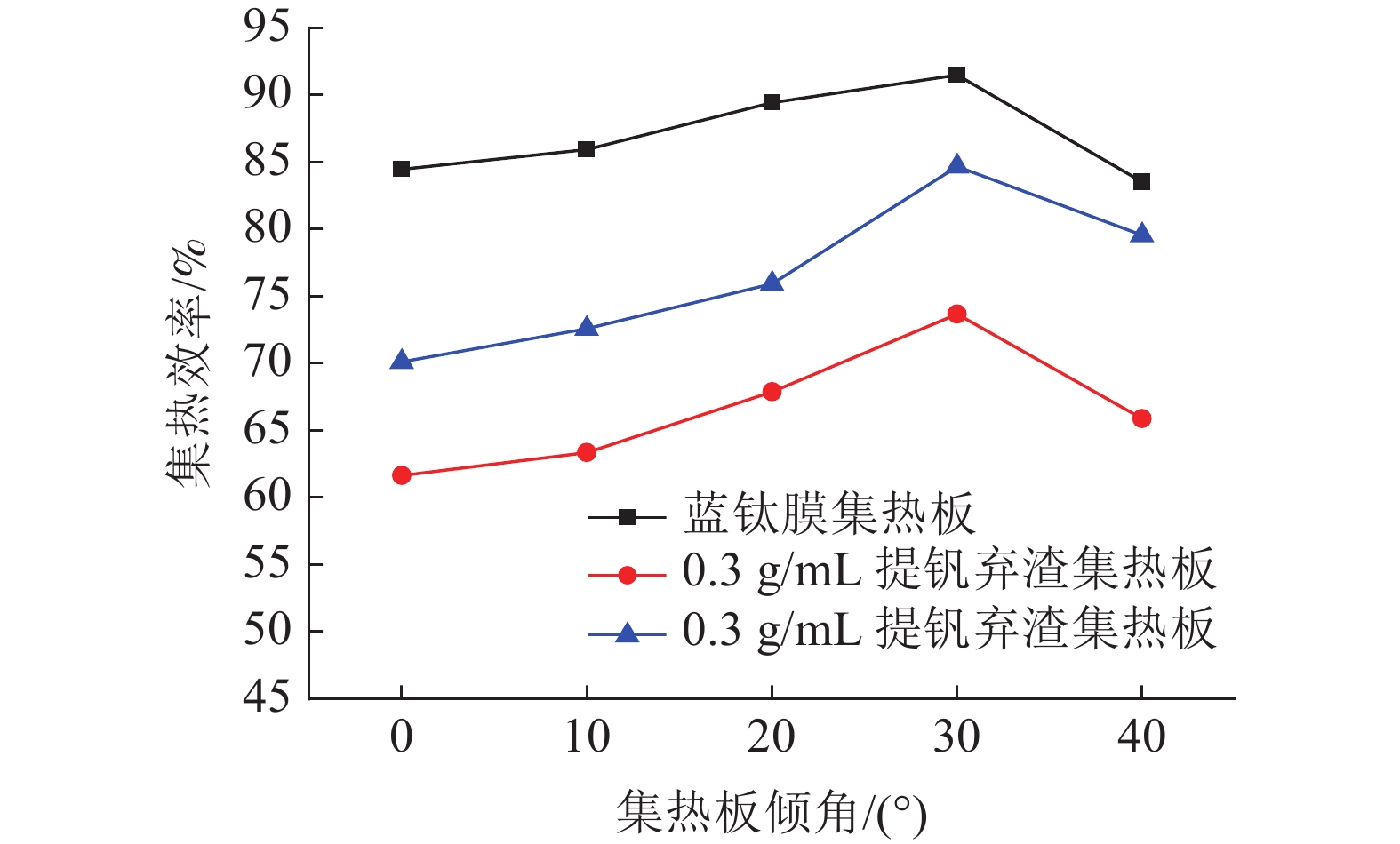

冶金矿产固废综合利用是构建绿色低碳循环经济体系的重要组成部分,本文以提钒弃渣为原料,经除铁、球磨、打浆、喷涂制备提钒弃渣太阳集热涂层,以水为介质,研究了不同倾角下的集热板的集热性能,结果表明在倾角为30°时,提钒弃渣涂层集热板的集热效率最好,可达到84.69%,同条件下仅比蓝钛膜涂层集热板集热效率低6.81%。

Abstract:The comprehensive utilization of metallurgical mineral solid waste is an important part of building a green and low-carbon circular economy system. In this paper, the vanadium-extracted and discarded slag is used as raw material, and the vanadium-extracted and discarded slag solar thermal collector coating is prepared by iron removal, ball milling, beating, and spraying. As the medium, the heat collection performance at different inclination angles was studied. The results show that when the inclination angle is 30°, the heat collection efficiency of the vanadium-extracted spoil coated heat collector plate is the best, which can reach 84.69%. The heat collection efficiency of the titanium film-coated collector plate is 6.81% lower. It shows that the vanadium-extracted waste slag used as a solar collector coating has a feasible technology, low price and important significance for solid waste reuse.

-

-

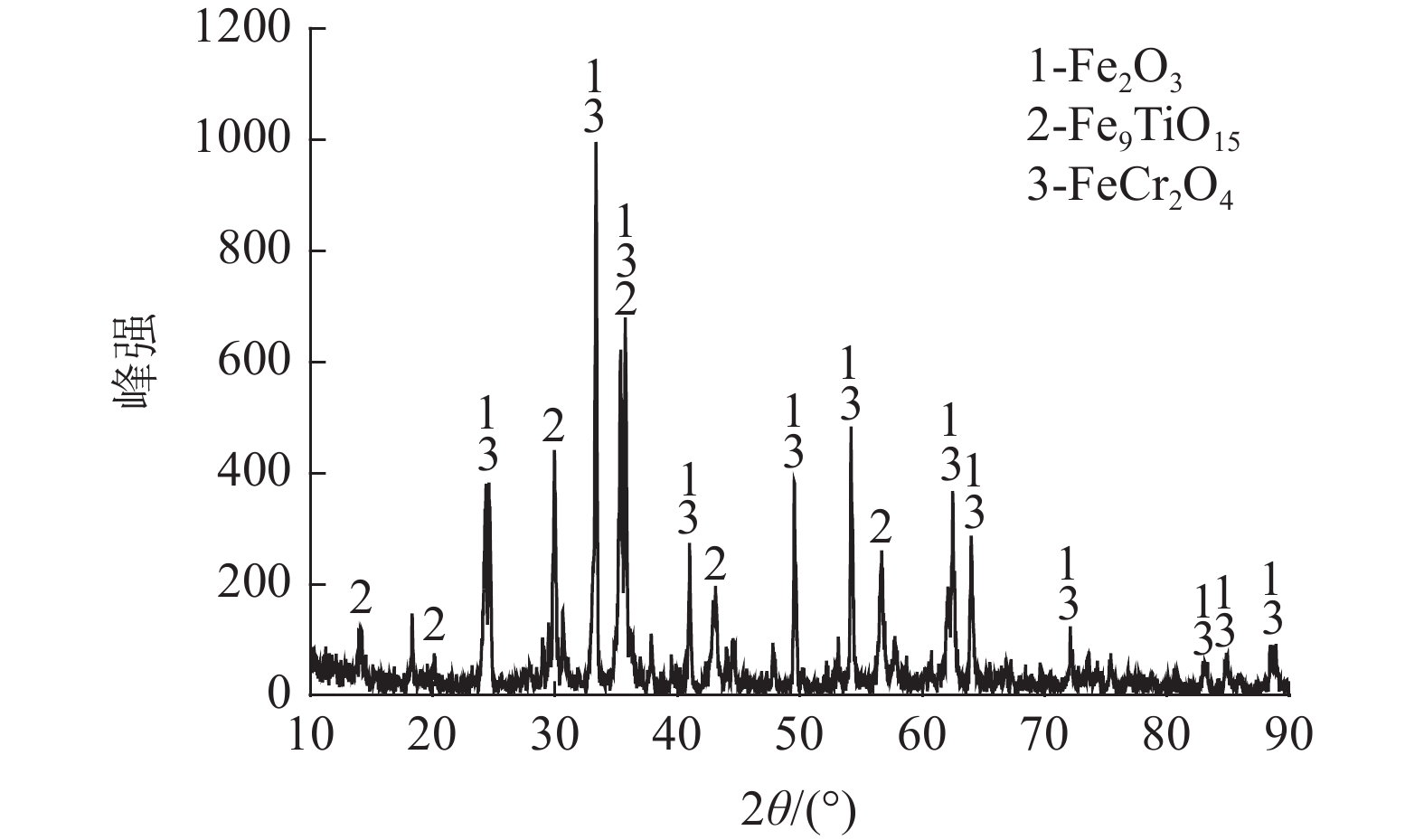

表 1 提钒弃渣主要化学成分/%

Table 1. Main Chemical Components of vanadium extraction tailings

Fe2O3 TiO2 SiO2 MgO Al2O3 CaO MnO Cr2O3 Na2O V2O5 其他 41.84 12.90 14.40 3.57 3.20 2.50 7.84 2.24 8.12 2.08 1.31 表 2 提钒弃渣的粒度组成/%

Table 2. Particle size composition of vanadium extraction tailings

粒径范围/mm +0.154 -0.154+0.074 -0.074+0.038 -0.038+0.023 -0.023 比例/% 1.34 5.12 10.39 18.74 64.41 表 3 除铁后的提钒弃渣主要化学成分/%

Table 3. Main chemical composition of vanadium extraction tailings after removing iron

Fe2O3 TiO2 SiO2 MgO Al2O3 CaO MnO Cr2O3 Na2O V2O5 其他 3.29 21.43 22.46 5.85 5.24 4.10 12.84 3.67 13.30 3.51 4.31 表 4 提钒弃渣中氧化物的吸收率

Table 4. Absorption rate of oxide in vanadium extraction tailings

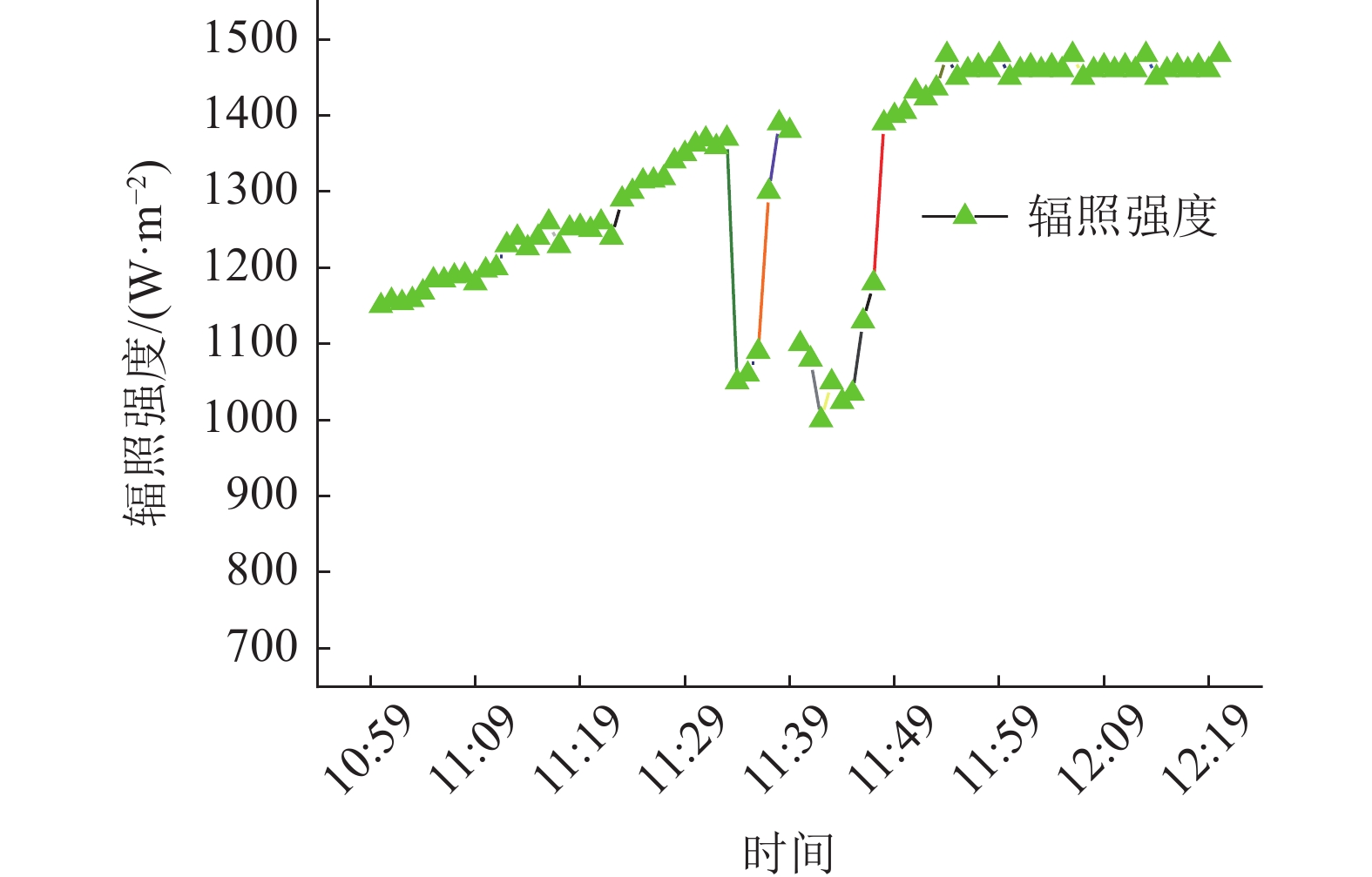

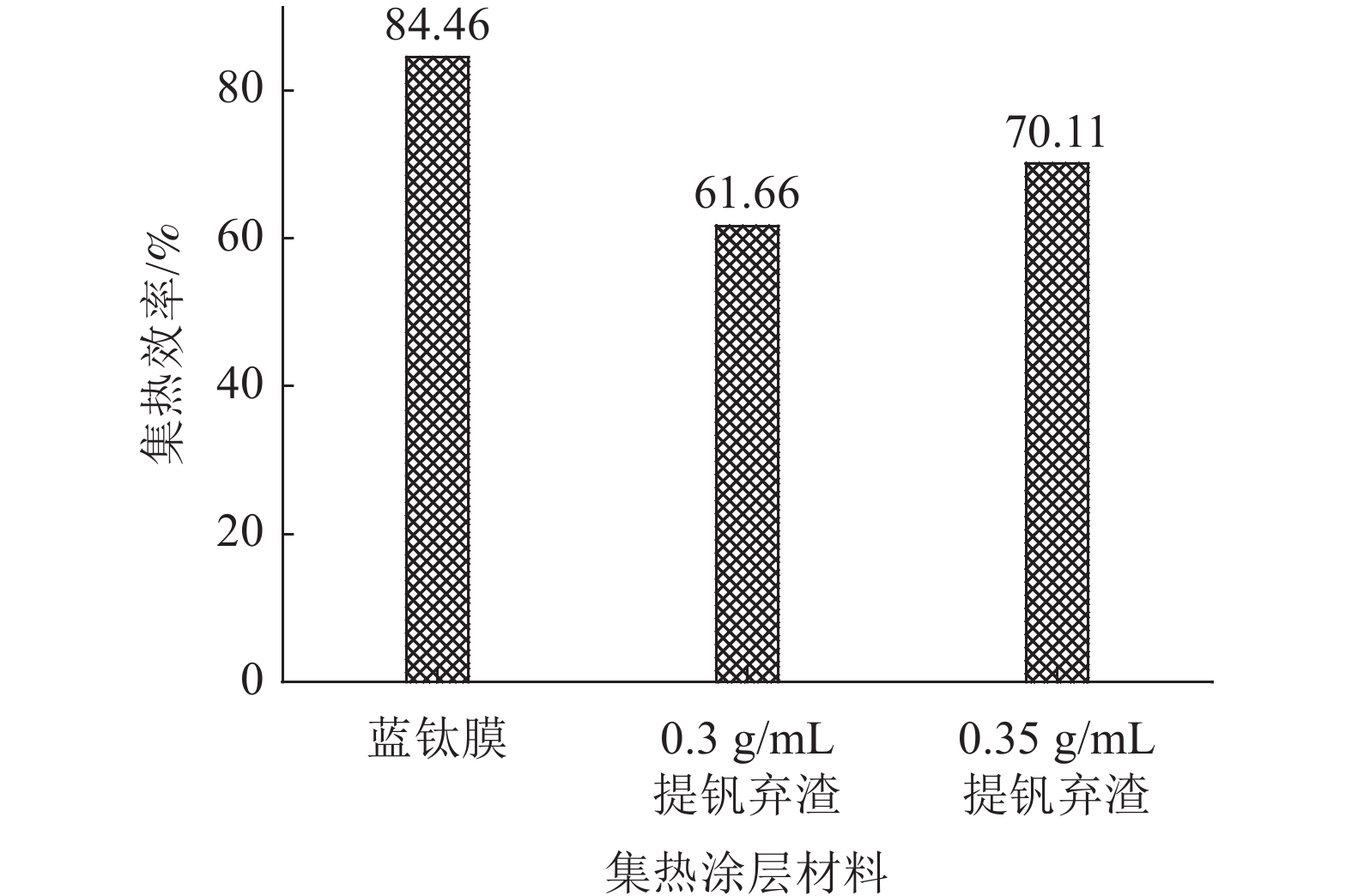

成分 Fe2O3 TiO2 V2O5 MnO SiO2 Al2O3 CaO MgO Cr2O3 Na2O 吸收率 0.88 0.83 0.85 0.90 0.89 0.86 0.87 0.92 0.82 0.87 表 5 实验数据结果计算

Table 5. Calculation of experimental data results

集热板 水减少量/kg 水升温的热量W1/kJ 汽化的水的热量W2/kJ 集热器吸收的太阳辐射能Qn/W 集热器集热效率/% 蓝钛膜 0.86 42.75 2136.24 2178.99 84.46 0.3 g/mL提钒弃渣 0.59 125.19 1465.56 1590.75 61.66 0.35 g/mL提钒弃渣 0.69 94.66 1713.96 1808.62 70.11 表 6 不同倾角下提钒弃渣涂层集热板的集热性能

Table 6. Heat collection performance of vanadium extraction slag discarding coating heat collector plate at different dip angles

倾角

度数蓝钛膜 0.3 g/mL

提钒弃渣0.35 g/mL

提钒弃渣辐照

强度0° 84.46 61.66 70.11 1289.9 w/m2 10° 85.95 63.35 72.58 1217.5 w/m2 20° 89.45 67.87 75.94 1257.4 w/m2 30° 91.50 73.68 84.69 1189.5 w/m2 40° 83.54 65.89 79.56 1276.8 w/m2 -

[1] 吕晓冯. 加快推动产业园区绿色低碳循环发展, 助力“双碳”目标早日实现[J]. 资源再生, 2021(11):1. doi: 10.3969/j.issn.1673-7776.2021.11.001

LV X F. Accelerate the promotion of the green and low-carbon circular development of industrial parks to help achieve the "dual-carbon" goal as soon as possible[J]. Resource Recycling, 2021(11):1. doi: 10.3969/j.issn.1673-7776.2021.11.001

[2] 丁满堂. 含钒钢渣提钒利用研究[J]. 矿产综合利用, 2020(6):69-72.

DING M T. Research on utilization of vanadium extraction from vanadium-bearing steel slag[J]. Multipurpose Utilization of Mineral Resources, 2020(6):69-72.

[3] 徐正震, 梁精龙, 李慧, 等. 含钒废弃物中钒的回收研究现状及展望[J]. 矿产综合利用, 2020(0):8-13.

XU Z Z, LIANG J L, LI H, et al. Research status and prospects of vanadium recovery in vanadium containing wastes[J]. Multipurpose Utilization of Mineral Resources, 2020(0):8-13.

[4] 时亮, 魏昶, 樊刚, 等. 石煤提钒浸出渣制取建筑用砖的研究[J]. 矿产综合利用, 2009(6):35-37. doi: 10.3969/j.issn.1000-6532.2009.06.011

SHI L, WEI C, FAN G, et al. Prepartion of building brick using the leaching residue of extracting vanadium from stone coal[J]. Multipurpose Utilization of Mineral Resources, 2009(6):35-37. doi: 10.3969/j.issn.1000-6532.2009.06.011

[5] 刘金生, 丁学勇, 薛向欣, 等. 提钒尾渣资源化综合利用的研究进展[J]. 钢铁, 2021, 56(7):152-160.

LIU J S, DING X Y, XUE X X, et al. Research progress of comprehensive utilization of vanadium extraction tailings[J]. Iron and Steel, 2021, 56(7):152-160.

[6] 徐众, 侯静, 李军, 等. 提钒尾渣对膨胀石墨/石蜡复合相变材料导热性能的影响[J]. 化工新型材料, 2021, 49(5):115-119.

XU Z, HOU J, LI J, et al. Influence of vanadium tailing on the thermal conductivity performance of EG/PW phase change composite material[J]. New Chemical Materials, 2021, 49(5):115-119.

[7] 修大鹏, 曹树梁, 许建华, 等. 黑瓷复合陶瓷太阳板集热系统的应用研究[J]. 山东科学, 2013, 26(2):72-77.

XIU D P, CAO S L, XU J H, et al. Application of ceramic solar plate heating system[J]. Shandong Science, 2013, 26(2):72-77.

[8] 朴荣勋, 李轩, 李国伟, 等. 利用提钒尾渣和石墨制备高温显热蓄热材料的研究[J]. 钢铁钒钛, 2020, 41(6):52-59. doi: 10.7513/j.issn.1004-7638.2020.06.011

PU R X, LI X, LI G W, et al. Preparation of high temperature sensible heat storage material from vanadium extraction tailings and graphite[J]. Iron Steel Vanadium Titanium, 2020, 41(6):52-59. doi: 10.7513/j.issn.1004-7638.2020.06.011

[9] 戴松元, 古丽米娜, 王景甫, 等. 太阳能转换原理与技术[M]. 北京: 中国水利水电出版社, 2018.

DAI S Y, GU L M N, WANG J F, et al. The principle and technology of solar energy conversion [M]. Beijing: China Water Resources and Hydropower Press, 2018.

[10] 柴诚敬, 贾绍义. 化工原理(第三版)上册[M]. 天津: 高等教育出版社, 2017.

CHAI C J, JIA S Y. Principles of chemical engineering (third edition) volume 1 [M]. Tianjin: Higher Education Press, 2017.

[11] 杨先亮, 刘新雨, 田胜楠, 等. 平板型太阳能集热器性能影响因素模拟分析[J]. 煤气与热力, 2016, 8(12):10-14.

YANG X L, LIU X Y, TIAN S N, et al. Simulation and analysis of performance influence factors of flat plate solar collector[J]. Gas & Heat, 2016, 8(12):10-14.

[12] 陈洁. 平板型太阳能集热器热性能影响因素分析[J]. 中国农机化学报, 2014, 35(6):226-229.

CHEN J. Influencing factors analysis of the thermal performance of flat plate solar collector[J]. Journal of Chinese Agricultural Mechanization, 2014, 35(6):226-229.

-

下载:

下载: