Flotation Test of a Gneiss Scale Graphite Ore

-

摘要:

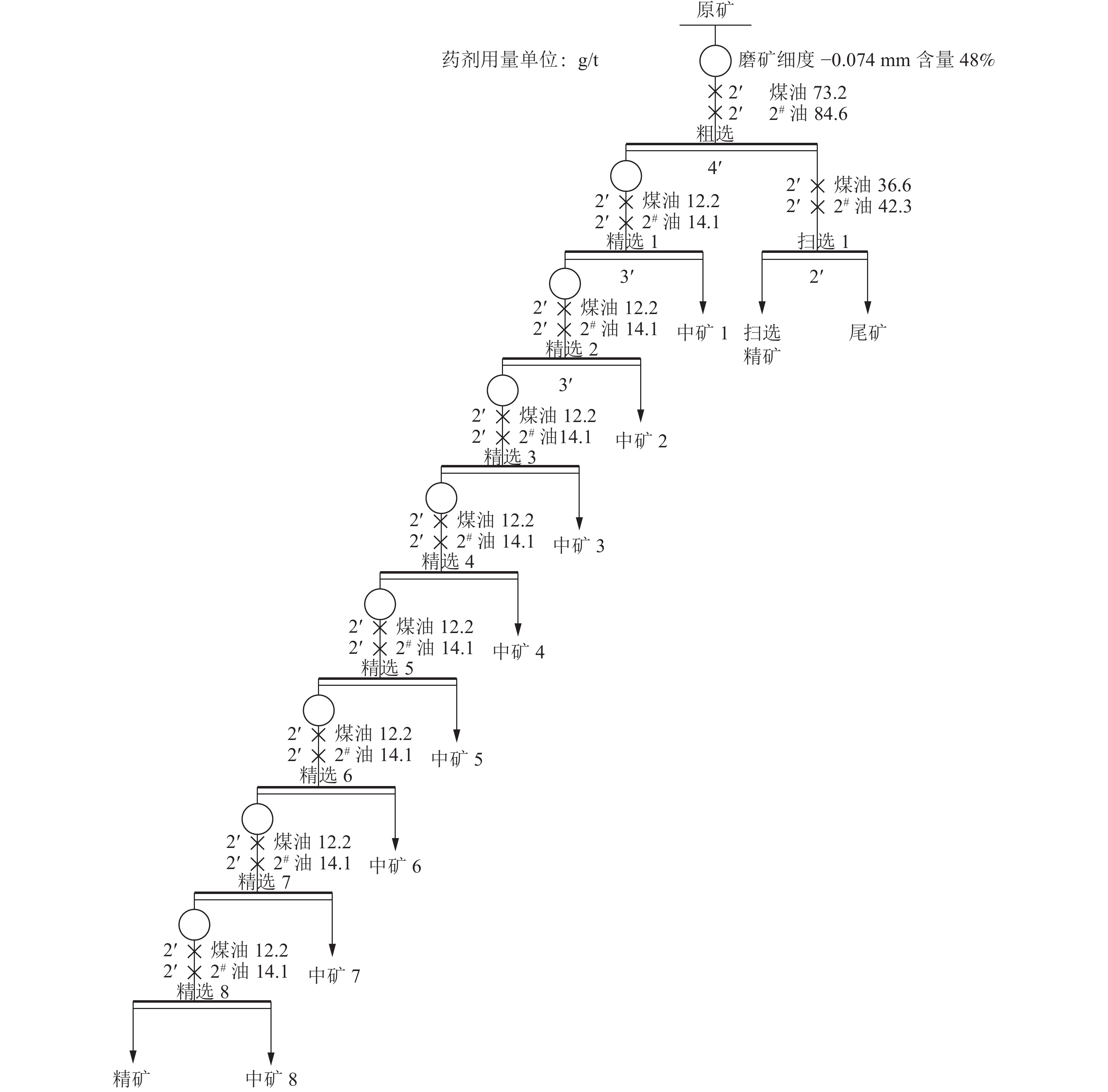

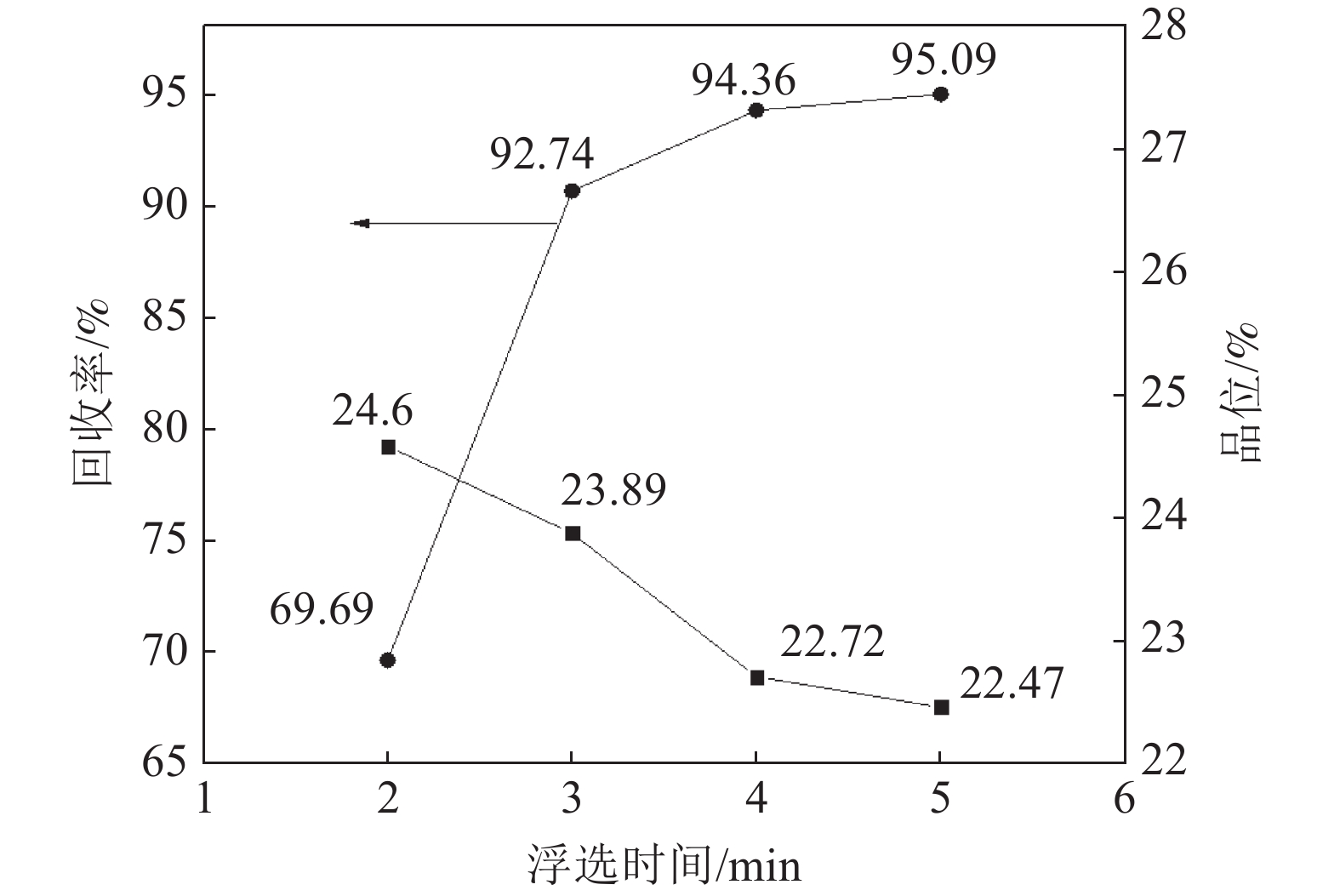

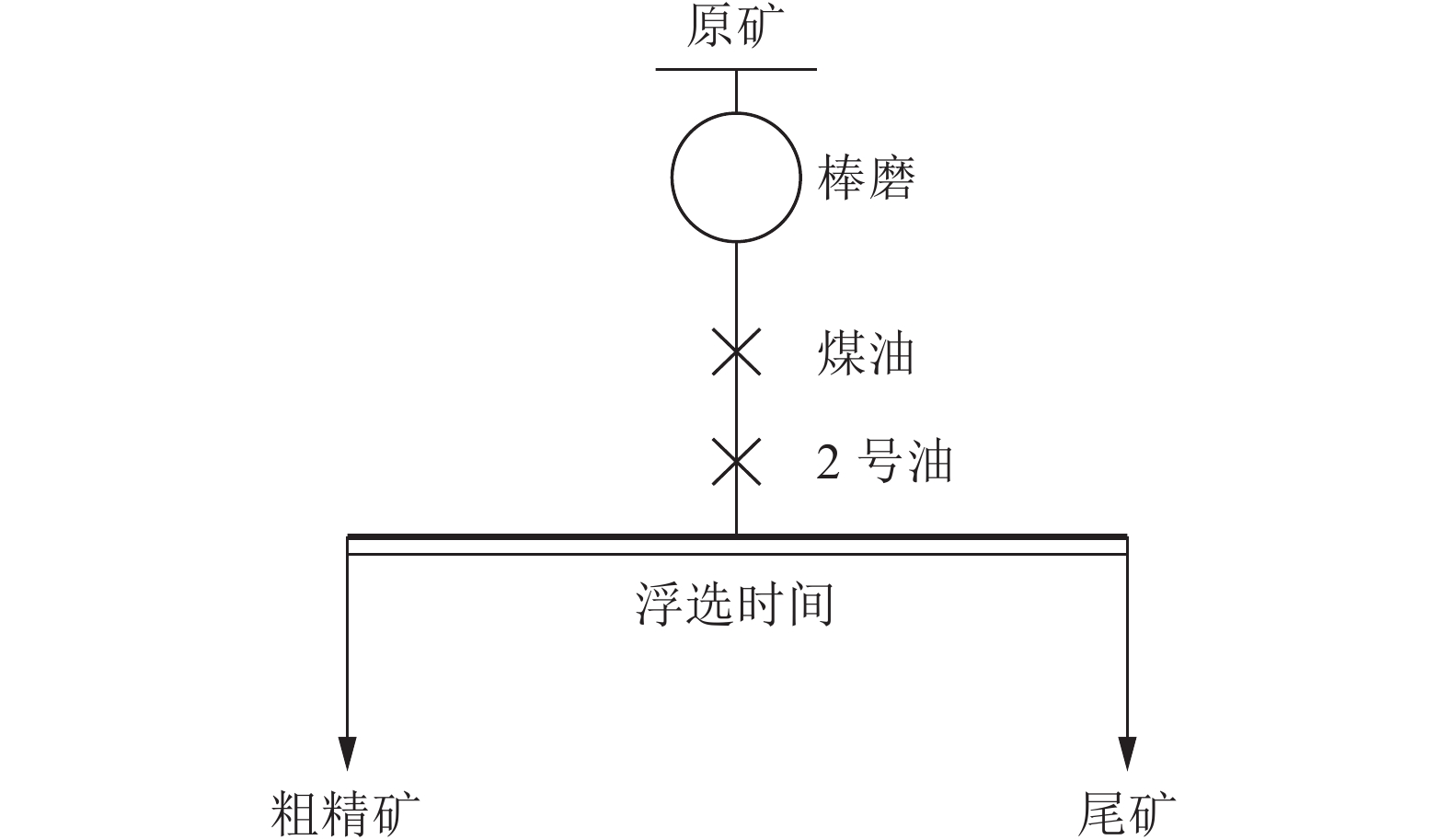

黑龙江某片麻岩鳞片石墨矿石结构属于片麻岩型石墨矿,脉石矿物以石英、长石、白云母为主,金属矿物有少量的褐铁矿。原矿总固定碳含量为8.03%,通过酸浸-碱熔-酸洗分析得知:原矿中+0.15 mm大鳞片石墨的固定碳含量占总固定碳含量的37.58%。原矿经一次粗选一次扫选、粗精矿八次再磨八次精选的阶段磨浮工艺流程,最终获得的精矿固定碳品位90.53%、精矿固定碳回收率94.07%。其中+0.15 mm精矿固定碳品位达到95.26%、固定碳回收率为17.67%,+0.15 mm大鳞片石墨的保护率为47.02%。

-

关键词:

- 石墨 /

- +0.154 mm大鳞片 /

- 浮选 /

- 品位 /

- 回收率

Abstract:The structure of a certain graphite ore in Heilongjiang province belongs to gneiss type graphite ore, the gangue minerals are mainly quartz, feldspar and mica, and the metal minerals contain a small amount of limonite. The total fixed carbon content of the raw ore is 8.03%. The fixed carbon content of + 100 mesh large scale graphite in the raw ore accounts for 37.58% of the total fixed carbon content. After the process of one roughing, one scavenging and eight regrinding and eight cleaning, the fixed carbon grade of concentrate is 90.53% and the fixed carbon recovery rate of concentrate is 94.07%. Among them, the fixed carbon grade of + 0.15 mm concentrate is 95.26%, the fixed carbon recovery rate is 17.67%, and the protection rate of +0.15 mm large scale graphite is 47.02%.

-

Key words:

- Graphite /

- +0.15 mm large scale /

- Flotation /

- Grade /

- Recovery

-

-

表 1 化学多项分析/%

Table 1. Chemical analysis of multi-elements

固定碳 SiO2 Al2O3 TFe2O3 MgO CaO Ag* Na2O K2O S MnO TiO2 P2O5 Au* 8.03 59.08 14.21 4.8 1.11 2.47 0.66 0.73 3.1 0.036 0.037 0.51 0.13 0.025 *单位为g/t。 表 2 原矿大鳞片石墨分布

Table 2. Large flake graphite distribution of the ore

粒级/mm 产率/% 固定碳/% 固定碳分布率/% +0.27 0.65 94.63 7.66 -0.27+0.198 1.67 95.84 19.93 -0.198+0.15 0.85 94.36 9.99 -0.15 96.83 5.18 62.42 合计原矿 100.00 8.03 100.00 表 3 开路实验结果

Table 3. Results of open-circuit test

产品名称 产率/% 固定碳品位/% 固定碳回收率/% 精矿 5.96 91.22 67.79 中矿8 0.83 61.73 6.39 中矿7 0.83 55.88 5.78 中矿6 0.90 29.30 3.29 中矿5 1.10 17.20 2.36 中矿4 1.94 8.59 2.08 中矿3 2.66 5.01 1.66 中矿2 6.93 3.88 3.35 中矿1 10.94 1.23 1.68 扫选精矿 2.51 7.82 2.45 尾矿 65.40 0.39 3.17 合计原矿 100.00 8.02 100.00 表 4 产品分析结果

Table 4. Product analysis results

产品名称 产率/% 固定碳回收率/% 固定碳品位/% +0.15 mm精矿 1.49 17.68 95.26 -0.15 mm精矿 6.85 76.38 89.52 合计精矿 8.34 94.06 90.55 尾矿 91.66 5.94 0.52 合计原矿 100.00 100.00 8.03 -

[1] 郭佳, 张作伦, 江伟华, 等. 我国典型晶质石墨产区鳞片石墨的特征及其开发利用[J]. 矿产保护与利用, 2018(5):28-31.

GUO J, ZHANG Z L, JIANG W H, et al. Characteristics of flake graphite and its development and utilization in typical crystalline graphite producing areas in China[J]. Protection and Utilization of Mineral Resources, 2018(5):28-31.

[2] 肖骏, 董艳红, 杨建文, 等. 河南某难选晶质石墨矿选矿实验研究[J]. 矿产综合利用, 2018(5):28-31. doi: 10.3969/j.issn.1000-6532.2018.05.006

XIAO J, DONG Y H, YANG J W, et al. Experimental study on beneficiation of a refractory crystalline graphite ore in Henan Province[J]. Multipurpose Utilization of Mineral Resources, 2018(5):28-31. doi: 10.3969/j.issn.1000-6532.2018.05.006

[3] 刘海营, 劳德平, 李崇德, 等. 黑龙江萝北鳞片石墨浮选新工艺研究[J]. 中国矿业, 2015(S2):182-185.

LIU H Y, LAO D P, LI C D, et al. Research on new flotation process of flake graphite from Luobei, Heilongjiang Province[J]. China Mining Industry, 2015(S2):182-185.

[4] 张韬, 程飞飞, 于阳辉. 内蒙古某低品位大鳞片石墨矿选矿实验研究[J]. 矿产综合利用, 2019(1):57-60. doi: 10.3969/j.issn.1000-6532.2019.01.012

ZHANG T, CHENG F F, YU Y H. Experimental research on beneficiation of a low-grade and large flake graphite ore in inner mongolia[J]. Multipurpose Utilization of Mineral Resources, 2019(1):57-60. doi: 10.3969/j.issn.1000-6532.2019.01.012

[5] 龙渊, 张国旺. 保护石墨鳞片的磨矿效果表征[J]. 中国非金属矿工业导刊, 2013(6):32-34.

LONG Y, ZHANG G W, et al. Grinding effect characterization of protective graphite flake[J]. China Nonmetallic Mineral Industry Guide, 2013(6):32-34.

-

下载:

下载: