The Effect of Acidized Sodium Silicate on Flotation Separation Behavior of Barite and Dolomite

-

摘要:

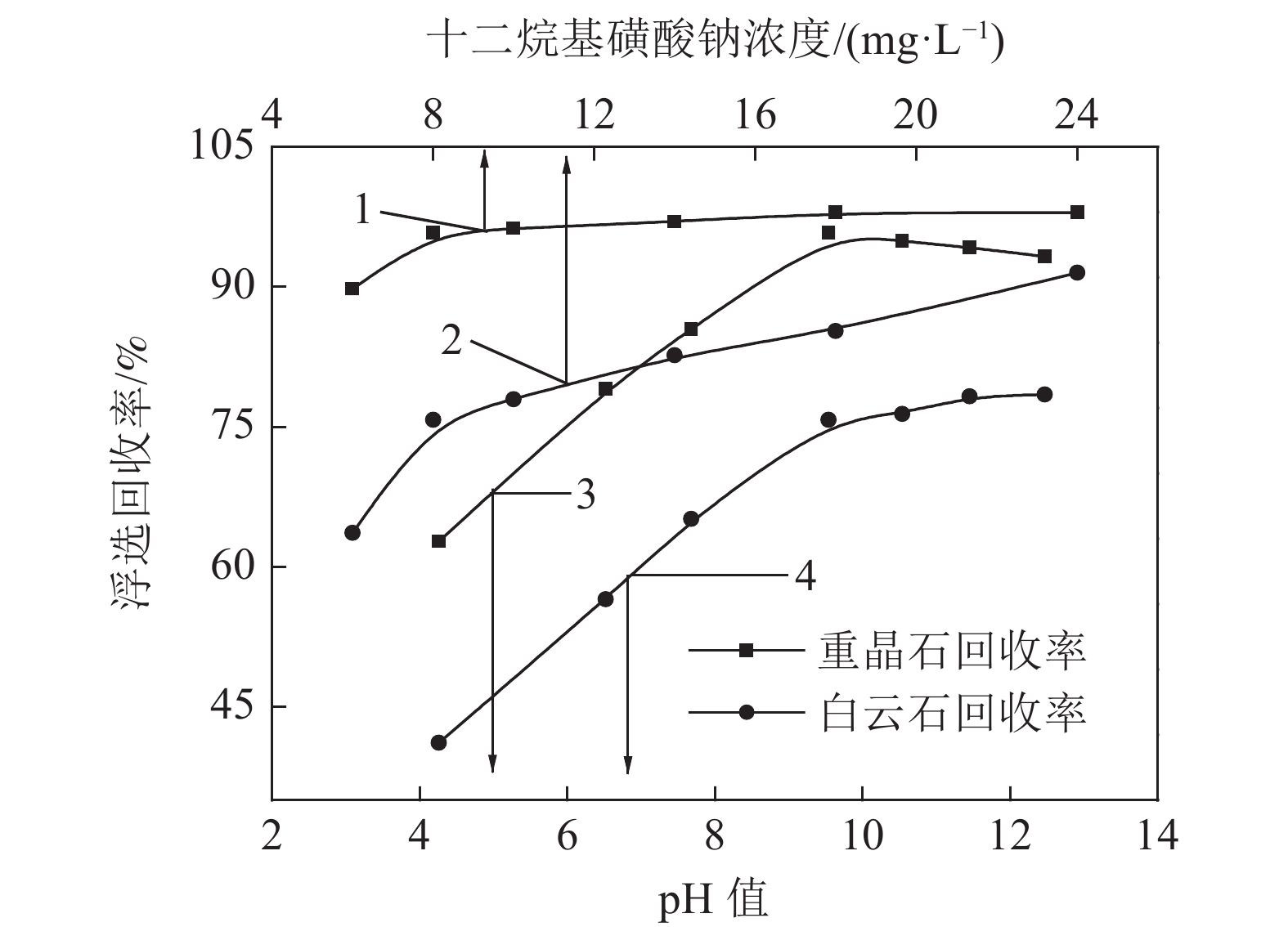

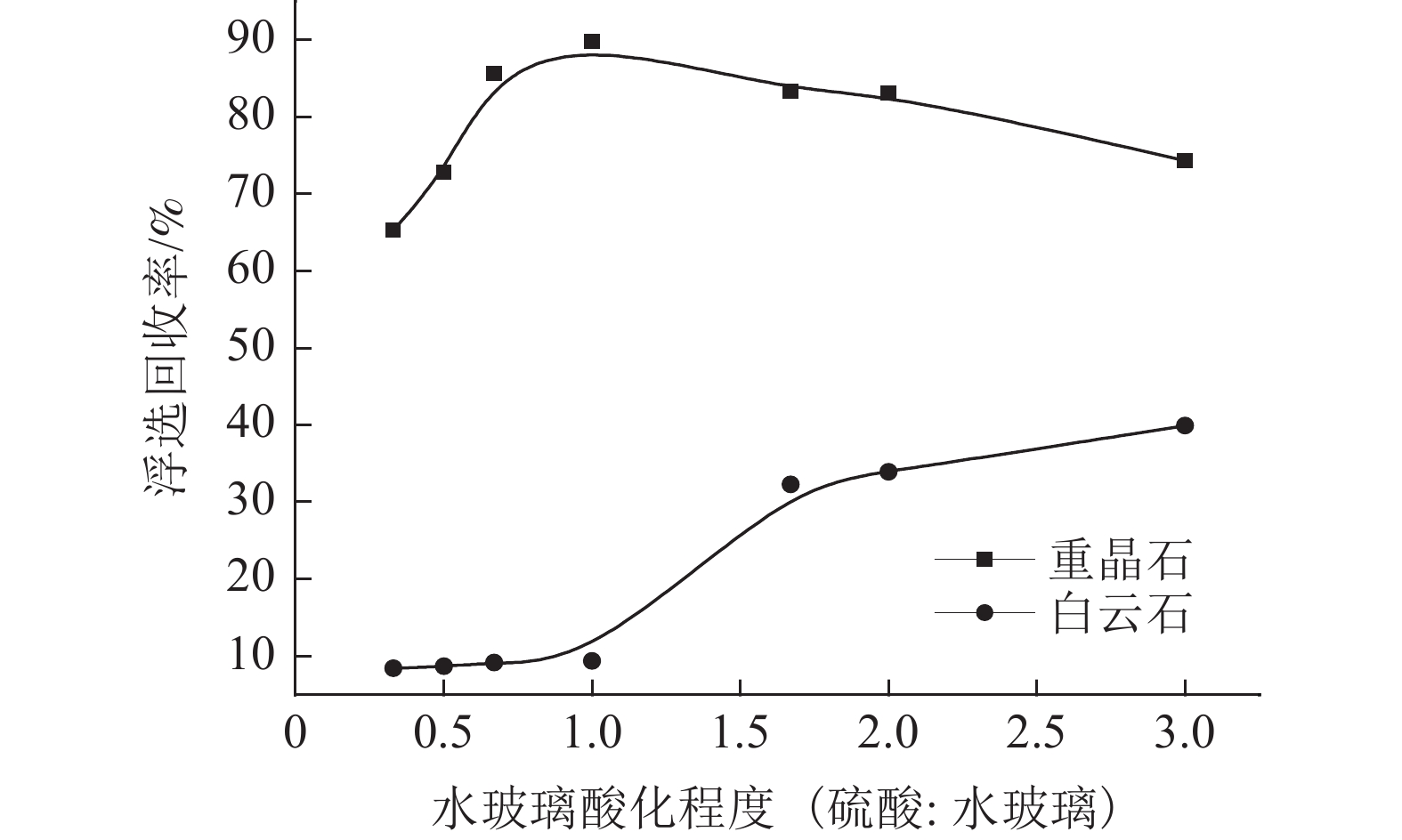

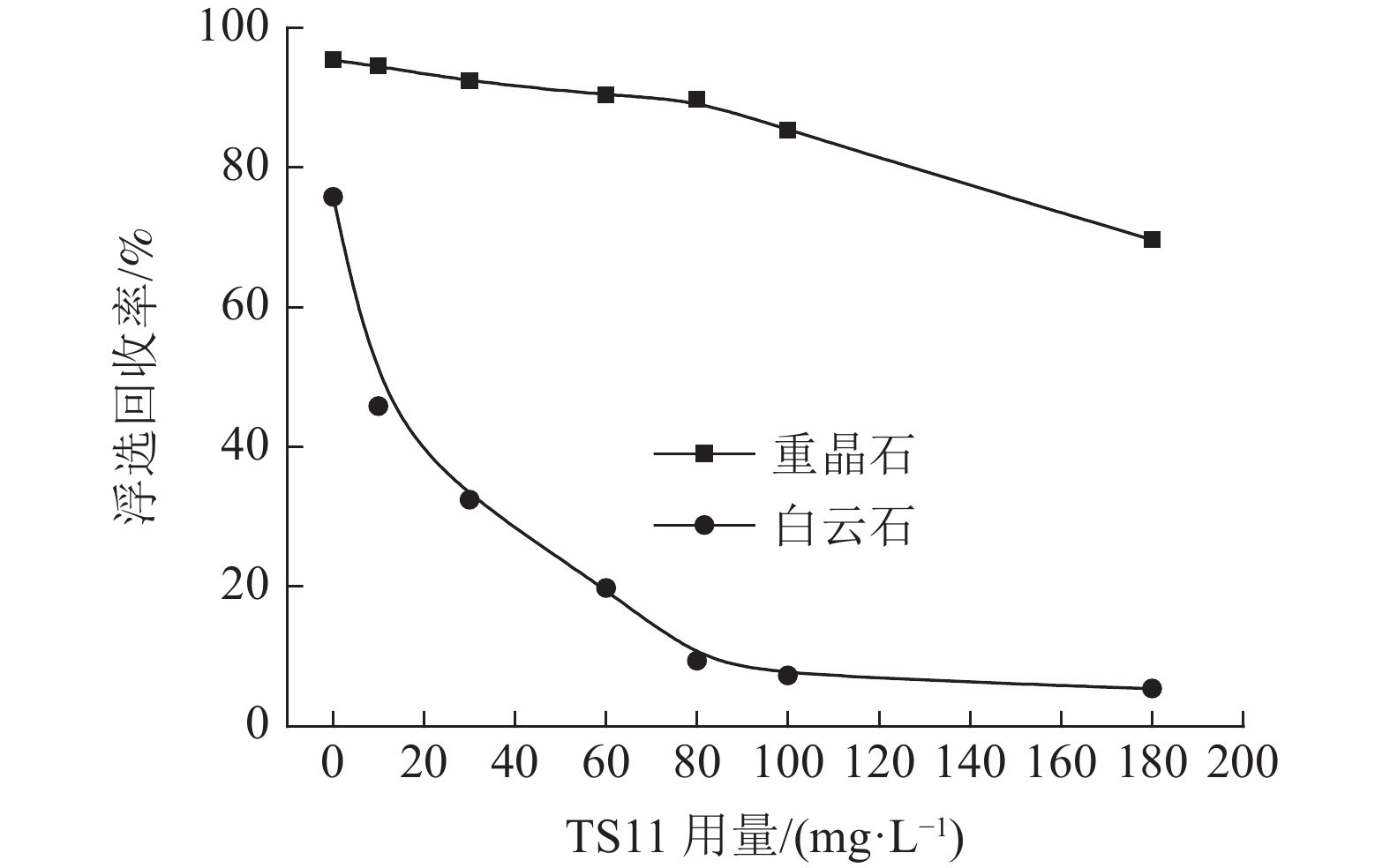

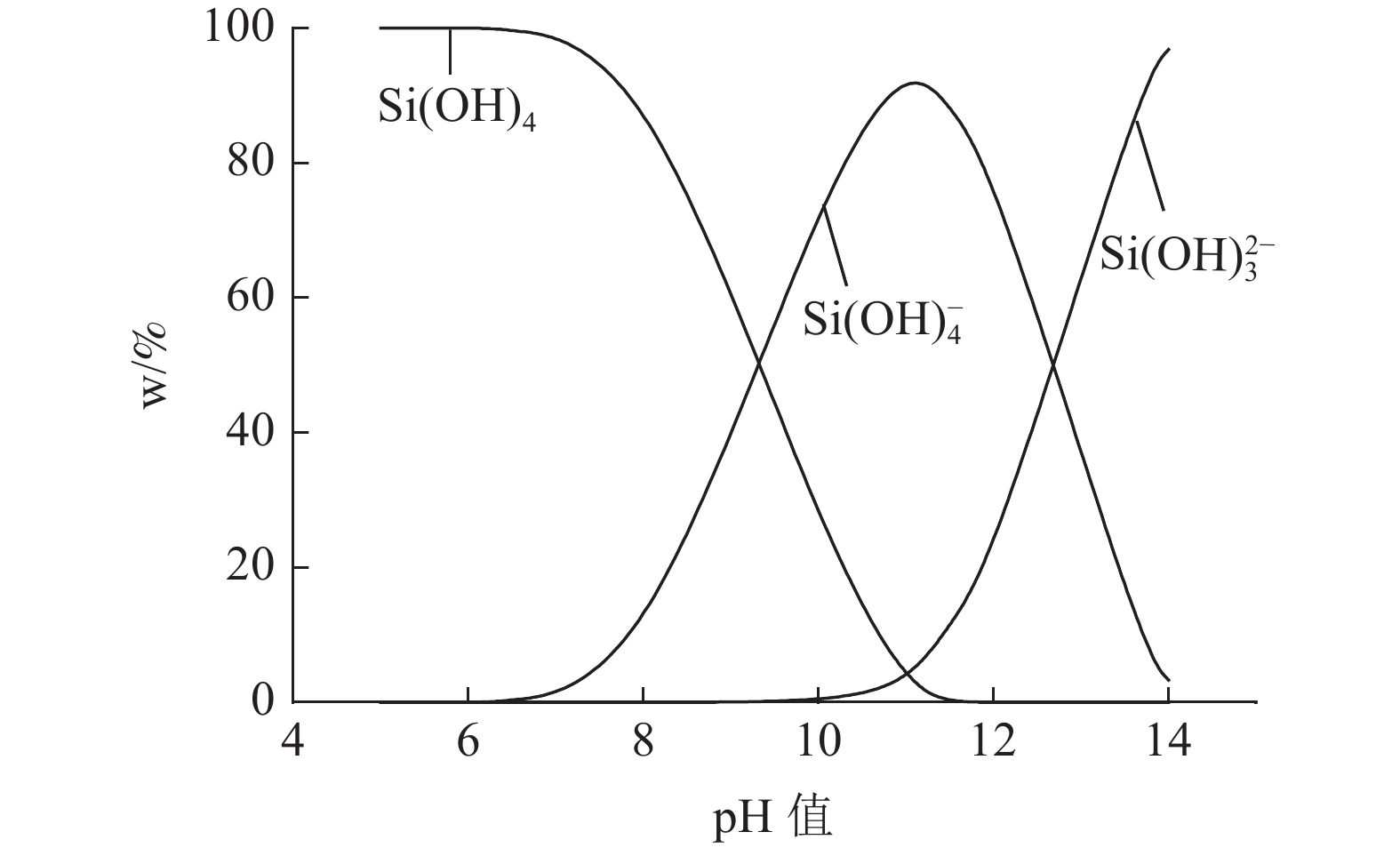

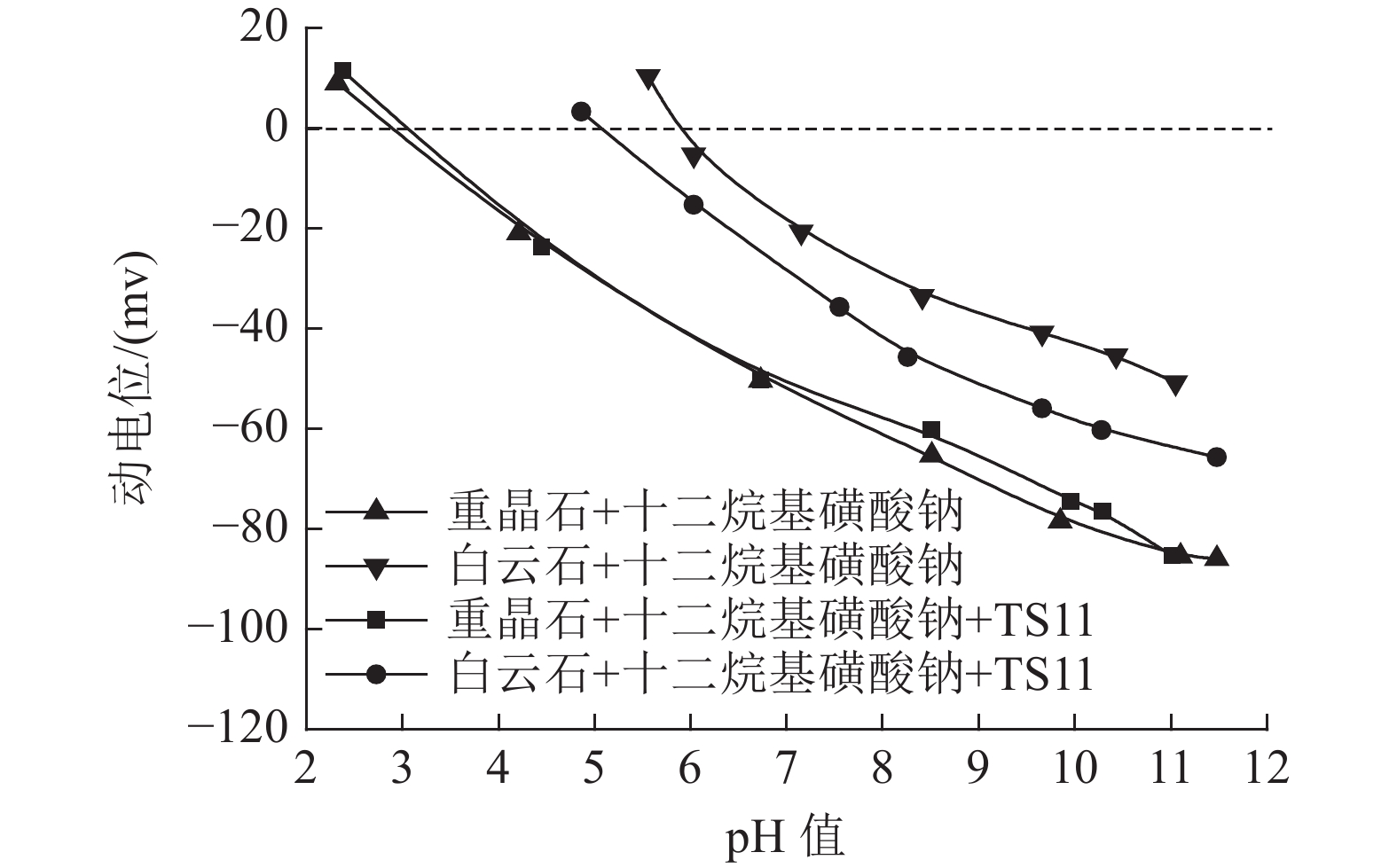

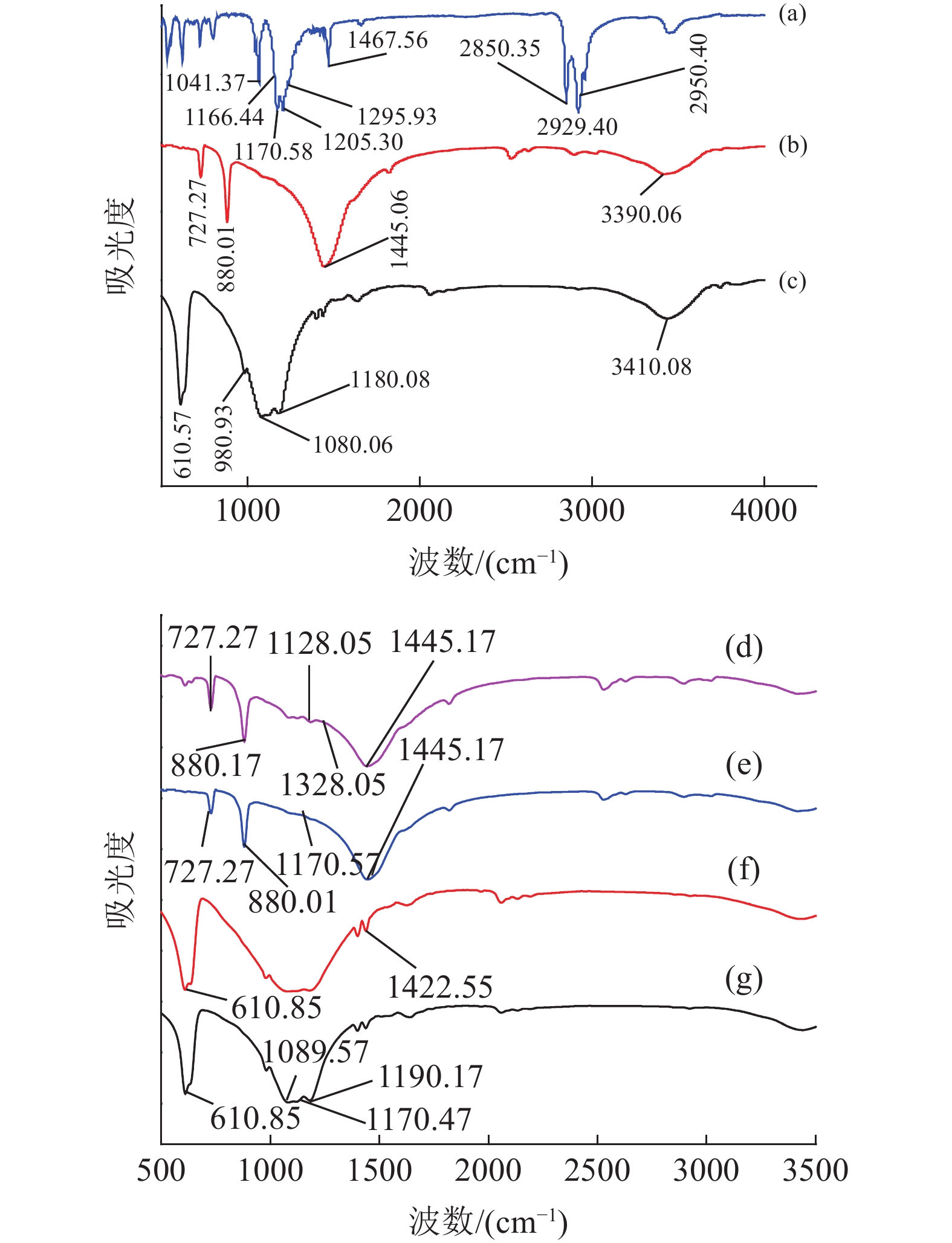

通过单矿物浮选、接触角测量、浮选溶液化学计算、Zeta电位测试等手段研究了不同酸化程度的水玻璃对重晶石与白云石可浮性的影响以及其可能的作用原理。浮选结果表明:酸化程度为1的水玻璃(TS11)可以很好地抑制白云石的上浮,而对重晶石的可浮性影响较小。机理研究结果显示:在十二烷基磺酸钠浮选体系下,TS11水解生成具有很强亲水性的硅酸胶粒Si(OH)4与白云石表面的Ca2+发生较强的化学吸附,并通过竞争吸附挤走吸附在白云石表面的C12H25OS

$ {\mathrm{O}}_{3}^{-} $ Abstract:Effects of different degree of acidification water glass on the floatability of barite and dolomite as well as its possible principle of action were studied by means of single mineral flotation, solution chemical calculation, Zeta potential test and infrared spectroscopy. The flotation results indicate that: dolomite can be well suppressed and barite floatability is less affected by acidification degree of 1 water glass (TS11). Mechanism study results show that: under the sodium dodecyl sulfonate flotation system, TS11 hydrolysis generation a strong hydrophilic silicate particles Si(OH)4 with the dolomite surface Ca2+ occurs strong chemical adsorption, and squeeze C12H25OS

$ {\mathrm{O}}_{3}^{-} $ -

Key words:

- Acidized sodium silicate /

- Barite /

- Dolomite /

- Mechanism /

- Competitive adsorption

-

-

表 1 TS11用量对接触角的影响

Table 1. Effect on contact angle of TS11 dosage

TS11用量/(mg·L-1) 重晶石 白云石 接触角/θ 可浮性/(1-  )

)接触角/θ 可浮性/(1-  )

)0 125 1.57 75 0.74 10 120 1.50 45 0.29 30 118 1.47 36 0.19 60 115 1.42 30 0.13 80 115 1.42 21 0.07 100 114 1.41 20 0.06 180 112 1.37 20 0.06 -

[1] 童义隆, 付金涛, 舒超, 等. 贵州重晶石与方解石常温浮选分离实验研究[J]. 矿产综合利用, 2020(1):54-58. doi: 10.3969/j.issn.1000-6532.2020.01.011

TONG Y L, FU J T, SHU C, et al. Research on flotation test of separation of barite and calcite from Guizhou at normal temperature[J]. Multipurpose Utilization of Mineral Resources, 2020(1):54-58. doi: 10.3969/j.issn.1000-6532.2020.01.011

[2] 邓海波, 徐 轲, 缪亚兵, 等. 沉积型含白云石复杂难选重晶石矿的选矿工艺研究[J]. 化工矿物与加工, 2015(6):9-12.

DENG H B, XU K, MIU Y B, et al. Research on beneficiation technology of sedimentary dolomite-bearing complex refractory barite ore[J]. Chemical Minerals and Processing, 2015(6):9-12.

[3] 惠 博, 邓伟, 王越. 贵州老文溪重晶石矿工艺矿物学[J]. 矿产综合利用, 2019(4):91-93. doi: 10.3969/j.issn.1000-6532.2019.04.019

HUI B, DENG W, WANG Y. Process mineralogy research on Laowenxi barite ore in Guizhou province[J]. Multipurpose Utilization of Mineral Resources, 2019(4):91-93. doi: 10.3969/j.issn.1000-6532.2019.04.019

[4] 崔瑞, 王旭, 魏骞, 等. 湖北某重晶石-萤石型矿综合利用研究[J]. 矿产综合利用, 2019(2):70-74. doi: 10.3969/j.issn.1000-6532.2019.02.014

CUI R, WANG X, WEI Q, et al. Study on comprehensive utilization of a barite-fluorite ore in Hubei province[J]. Multipurpose Utilization of Mineral Resources, 2019(2):70-74. doi: 10.3969/j.issn.1000-6532.2019.02.014

[5] 邓传宏, 马军二, 张国范, 等. 水玻璃在钛铁矿浮选中的作用[J]. 中国有色金属学报, 2010, 20(3):551-556.

DENG C H, MA J E, ZHANG G F, et al. The role of water glass in the flotation of ilmenite[J]. Chinese Journal of Nonferrous Metals, 2010, 20(3):551-556.

[6] 李雪, 赵海雷, 李兴旺, 等. 硫酸-水玻璃体系的成胶特点[J]. 化工学报, 2007, 58(2):501-506. doi: 10.3321/j.issn:0438-1157.2007.02.037

LI X, ZHAO H L, LI X W, et al. Gel-forming characteristics of sulfuric acid-water glass system[J]. Chinese Journal of Chemical Industry, 2007, 58(2):501-506. doi: 10.3321/j.issn:0438-1157.2007.02.037

[7] 叶群杰, 谢海云, 陈禄政, 等. 铁矿选矿中的分析测试技术研究进展[J]. 矿业研究与开发, 2015(8):39-44.

YE Q J, XIE H Y, CHEN L Z, et al. Research progress of analysis and testing technology in iron ore beneficiation[J]. Mining Research and Development, 2015(8):39-44.

-

下载:

下载: