Study on Separation of Gold from Tailings by Combined Floatation-Gravity Beneficiation Flowsheet

-

摘要:

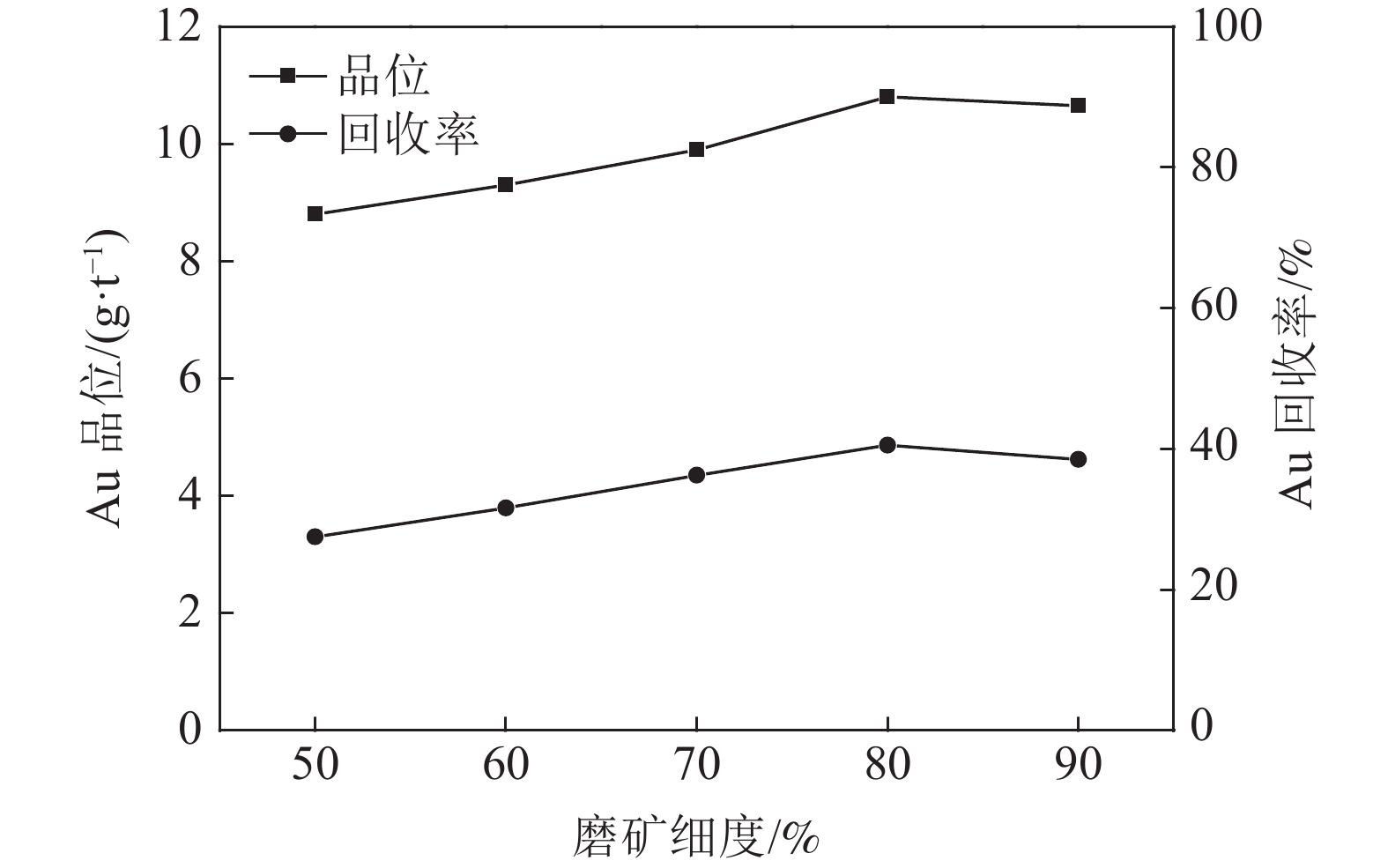

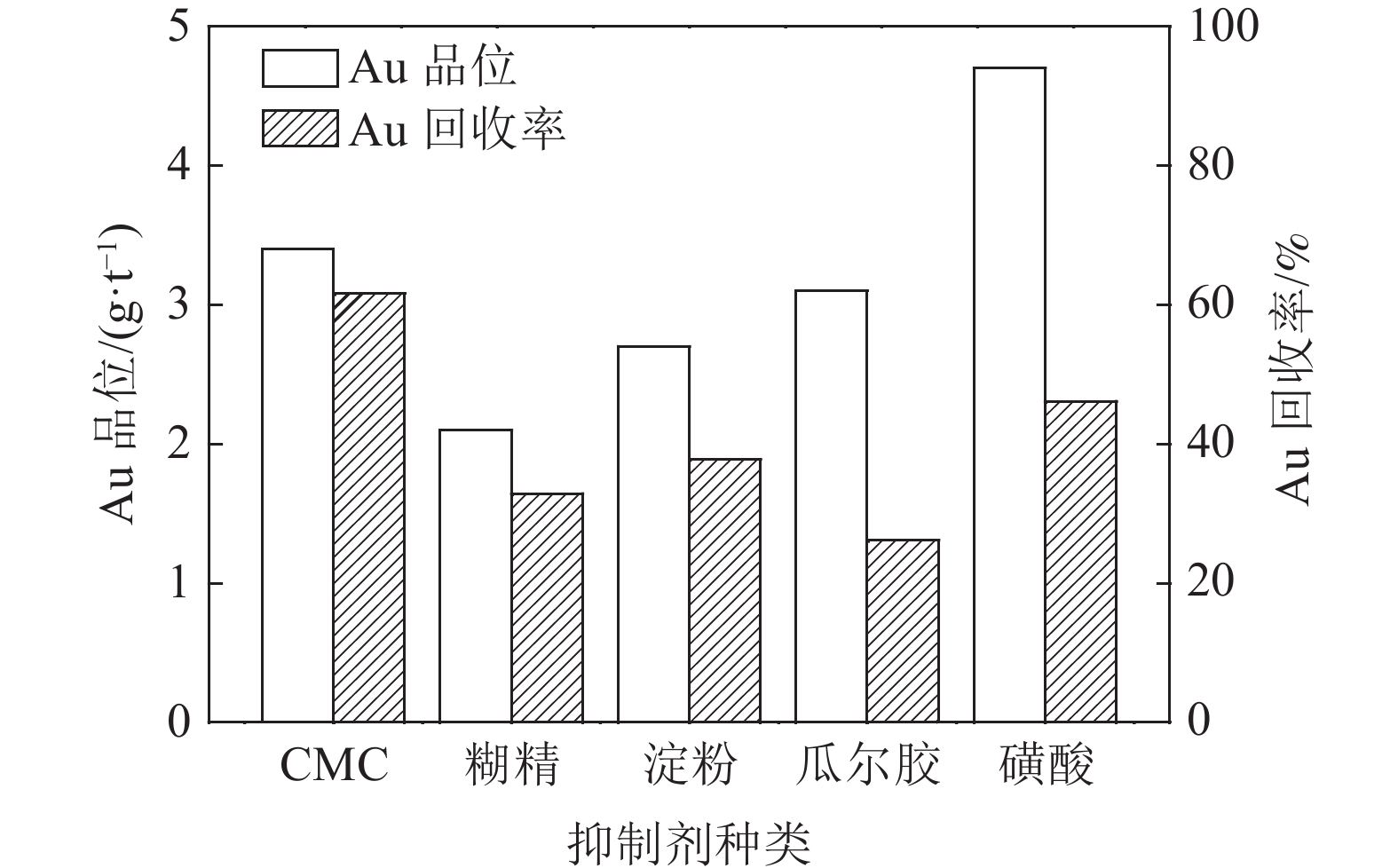

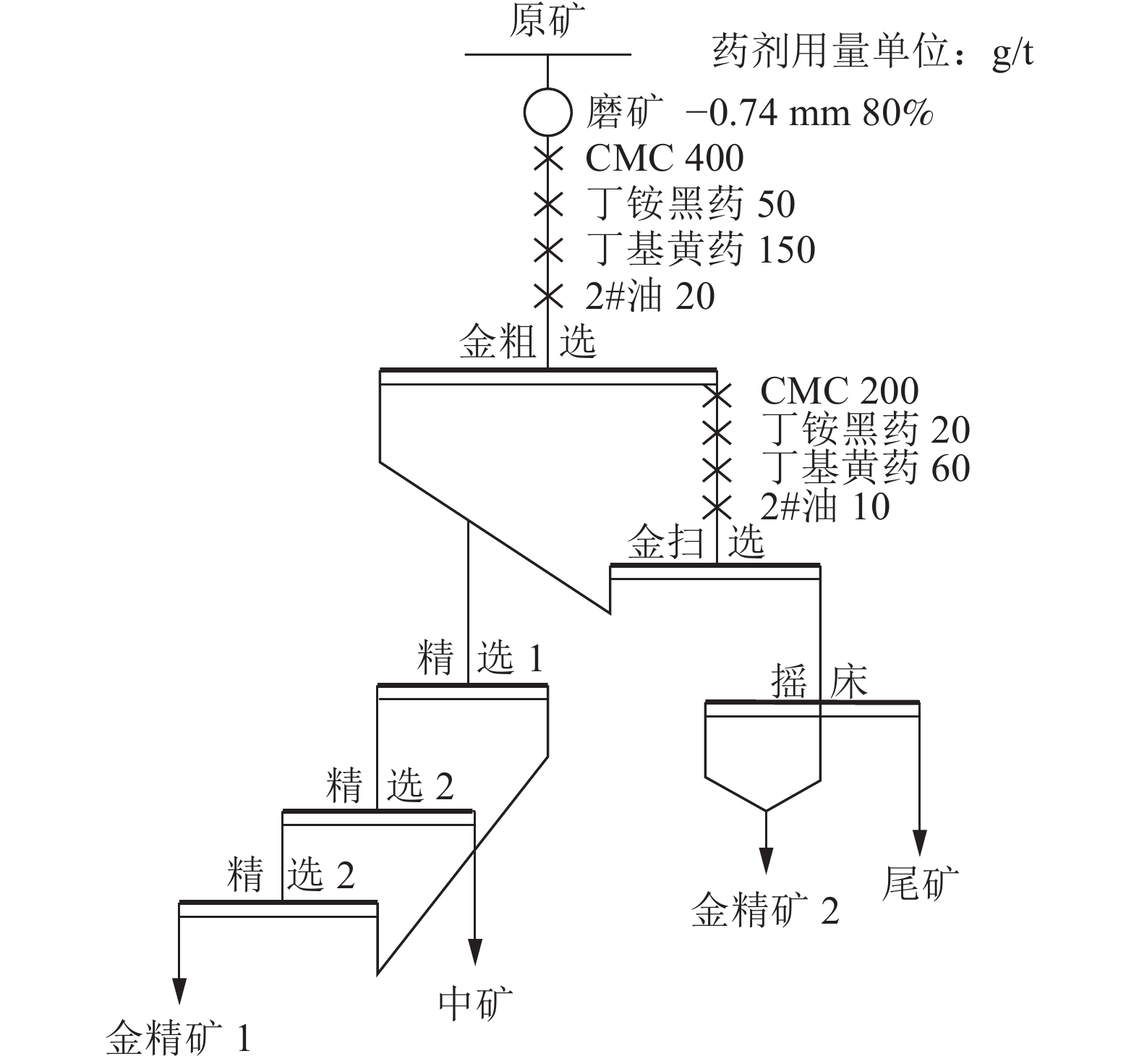

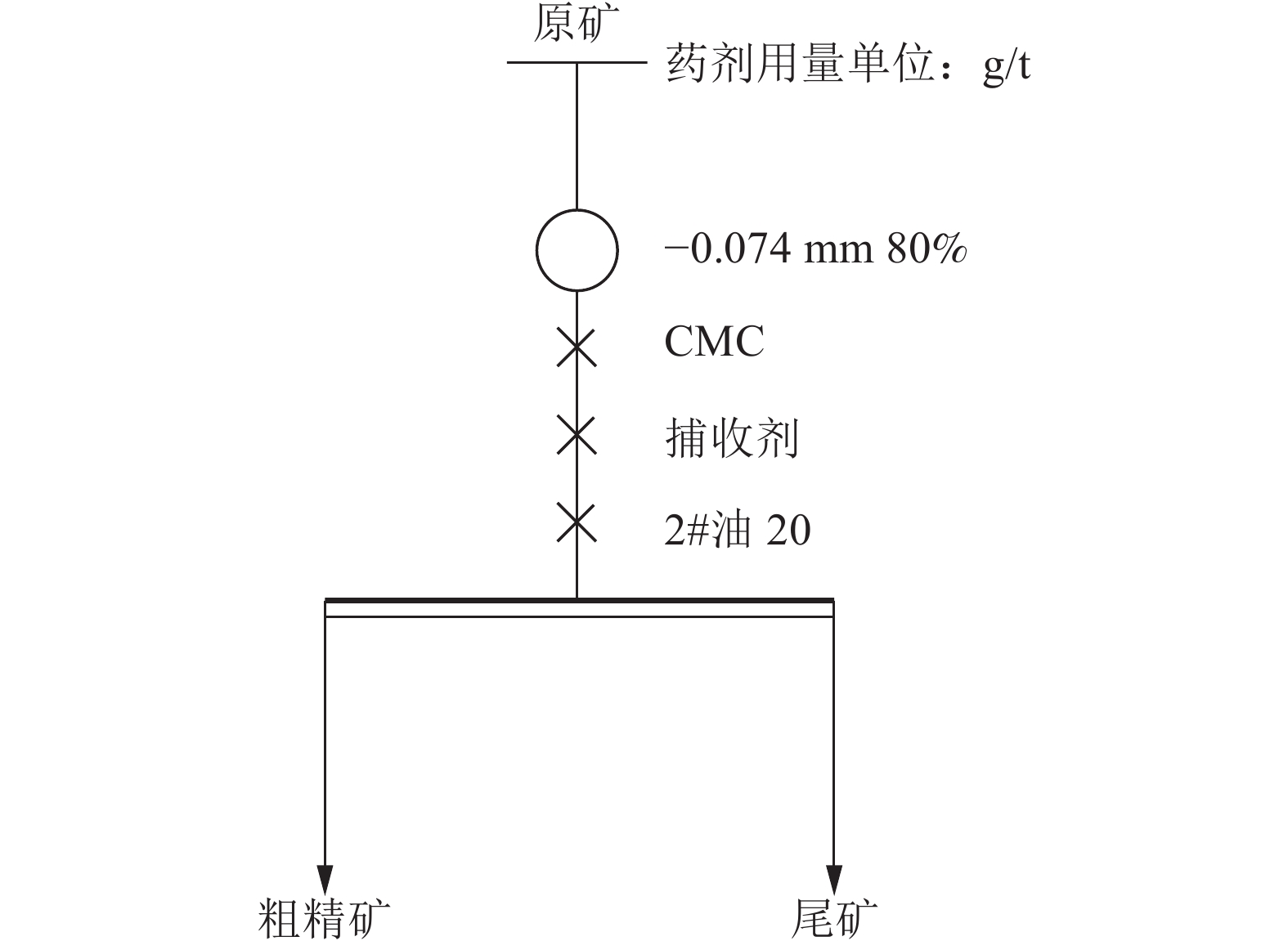

绵阳某金尾矿含金0.8 g/t、含硫 1.24%、含碳3.45%,金矿物主要以单体-连生体以及铁等氧化物包裹金的形式存在,脉石矿物有石英、硅酸盐、有机碳等,属于高碳低金矿。采用浮-重选联合流程,实验获得产率为3.06%,金品位为12.7 g/t,回收率为48.52%的浮选精矿,同时获得产率为2.82%,金品位为4.54 g/t,回收率为16.02%的摇床精矿,尾矿中金含量仅为0.23 g/t,为综合回收该尾矿中的金提供了技术依据。

Abstract:A gold tailings in Mianyang contains 0.8 g/t gold, 1.24% sulfur and 3.45% carbon, and the gold mainly existing as particles, intergrowth with gangue minerals and wrapped in iron oxides. The gangue minerals are mainly quartz, silicate and organic carbon, etc, which named as high carbon and low gold deposit. The combined beneficiation flowsheet was developed to recovery gold, and good results were achieved. Flotation concentrate with a yield of 3.06% and grade of 12.7 g/t was achieved, which makes up 48.52% of total gold. Meanwhile, gravity concentrate with a yield of 2.82% and grade of 4.54 g/t was achieved, account for 16.02% of total gold. The final tailing with grade of 0.23 g/t was obtained. Therefore, the developed beneficiation flowsheet provides a technical basis for comprehensive recovery of tailings.

-

Key words:

- Tailings /

- Flotation /

- Gravity separation /

- Combined beneficiation flowsheet

-

-

表 1 金矿多元素分析结果/%

Table 1. Results of multi-element analysis of gold ore

Au* As TFe S Sn Cu Pb Ag* 0.80 0.04 5.36 1.24 0.043 0.011 0.008 未检出 Al2O3 CaO MgO SiO2 Cd Cr C Hg* 7.98 2.01 3.51 58.54 0.001 0.013 3.45 0.25 *单位为g/t。 表 2 金物相分析结果

Table 2. Metallographic analysis results

相别 单体金+连

生金硅酸盐

中金硫化物中

包裹金铁等氧化矿物中

包裹金总金 含量/(g·t-1)

占有率/%0.36

45.000.09

11.250.06

7.500.29

36.250.80

100.00表 3 矿石主要矿物组成/%

Table 3. Main mineral composition of ore

矿物 石英 绢云母 方解石 白云石 石墨碳质 黄铁矿 褐铁矿 黄铜矿 方铅矿 闪锌矿 含量 73.82 11.24 3.16 2.98 3.83 2.71 1.86 微量 微量 微量 表 4 联合工艺实验结果

Table 4. Combined process experimental results

名称 产率/% 品位/% 回收率/% 金 * 碳 金 碳 金精矿1 3.06 12.7 5.12 48.52 4.12 金精矿2 2.82 4.54 3.45 16.02 2.56 中矿 11.08 0.84 4.56 11.59 13.27 尾矿 83.04 0.23 3.67 23.87 80.06 原矿 100 0.8 3.81 100 100.00 *单位为g/t。 -

[1] 李得立, 曾小波, 魏友华, 等. 矿山企业矿产资源开发利用水平评价方法研究 ——以湖南省金矿矿山为例[J]. 矿产综合利用, 2019(5):22-27. doi: 10.3969/j.issn.1000-6532.2019.05.005

LI D L, ZENG X B, WEI Y H, et al. Research on evaluation method of mineral exploration level for mine enterprise-taking Hunan Province gold mine enterprise as an example[J]. Multipurpose Utilization of Mineral Resources, 2019(5):22-27. doi: 10.3969/j.issn.1000-6532.2019.05.005

[2] 明平田, 李飞. 某微细粒蚀变岩型金矿高效浮选新工艺研究[J]. 矿产综合利用, 2019(5):127-133. doi: 10.3969/j.issn.1000-6532.2019.05.027

MING P T, LI F. Study on a new high-efficiency flotation process for a microgranular altered rock gold mine[J]. Multipurpose Utilization of Mineral Resources, 2019(5):127-133. doi: 10.3969/j.issn.1000-6532.2019.05.027

[3] 刘静宇. 某金矿重选尾矿回收金、铜的工艺研究[J]. 矿产综合利用, 2020(1):112-115. doi: 10.3969/j.issn.1000-6532.2020.01.023

LIU J Y. Recovery of gold and copper from tailings of gravity separation in a gold ore[J]. Multipurpose Utilization of Mineral Resources, 2020(1):112-115. doi: 10.3969/j.issn.1000-6532.2020.01.023

[4] 张虹, 张雨田, 孙景敏, 等. 缅甸某金矿的重-浸选矿试验研究[J]. 矿产综合利用, 2020(4):106-110. doi: 10.3969/j.issn.1000-6532.2020.04.017

ZHANG H, ZHANG Y T, SUN J M, et al. Experimental study on a gold ore with gravity separation-cyanidation for gravity tailings process[J]. Multipurpose Utilization of Mineral Resources, 2020(4):106-110. doi: 10.3969/j.issn.1000-6532.2020.04.017

[5] 杨波, 童雄, 谢贤, 等. 选冶联合提高甘肃某难浸金矿浮选尾矿金回收率的试验研究[J]. 黄金科学技术, 2020, 28(2):123-130.

YANG B, TONG X, XIE X, et al. Experimental study on improving the recovery rate of gold from flotation tailings of a refractory gold mine in Gansu by combining beneficiation and metallurgy[J]. Gold Science and Technology, 2020, 28(2):123-130.

[6] 杨俊龙, 郭艳华, 郭海宁, 等. 碳酸盐型难选金矿石选矿工艺流程试验研究[J]. 有色金属(选矿部分), 2020(1):42-47.

YANG J L, GUO Y H, GUO H N, et al. Experimental study on beneficiation process of carbonate-type refractory gold ore[J]. Nonferrous Metals (Mineral Processing Section), 2020(1):42-47.

[7] 黄长峰, 曹玉川. 湖南某金矿浮选工艺研究[J]. 矿冶工程, 2020, 195(5):68-70. doi: 10.3969/j.issn.0253-6099.2020.05.017

HUANG C F, CAO Y C. Research on flotation process of a gold mine in Hunan[J]. Mining and Metallurgy Engineering, 2020, 195(5):68-70. doi: 10.3969/j.issn.0253-6099.2020.05.017

-

下载:

下载: