Study on the Preparation and Performance of Lead-Zinc Mine Steam-free and Burn-free Brick

-

摘要:

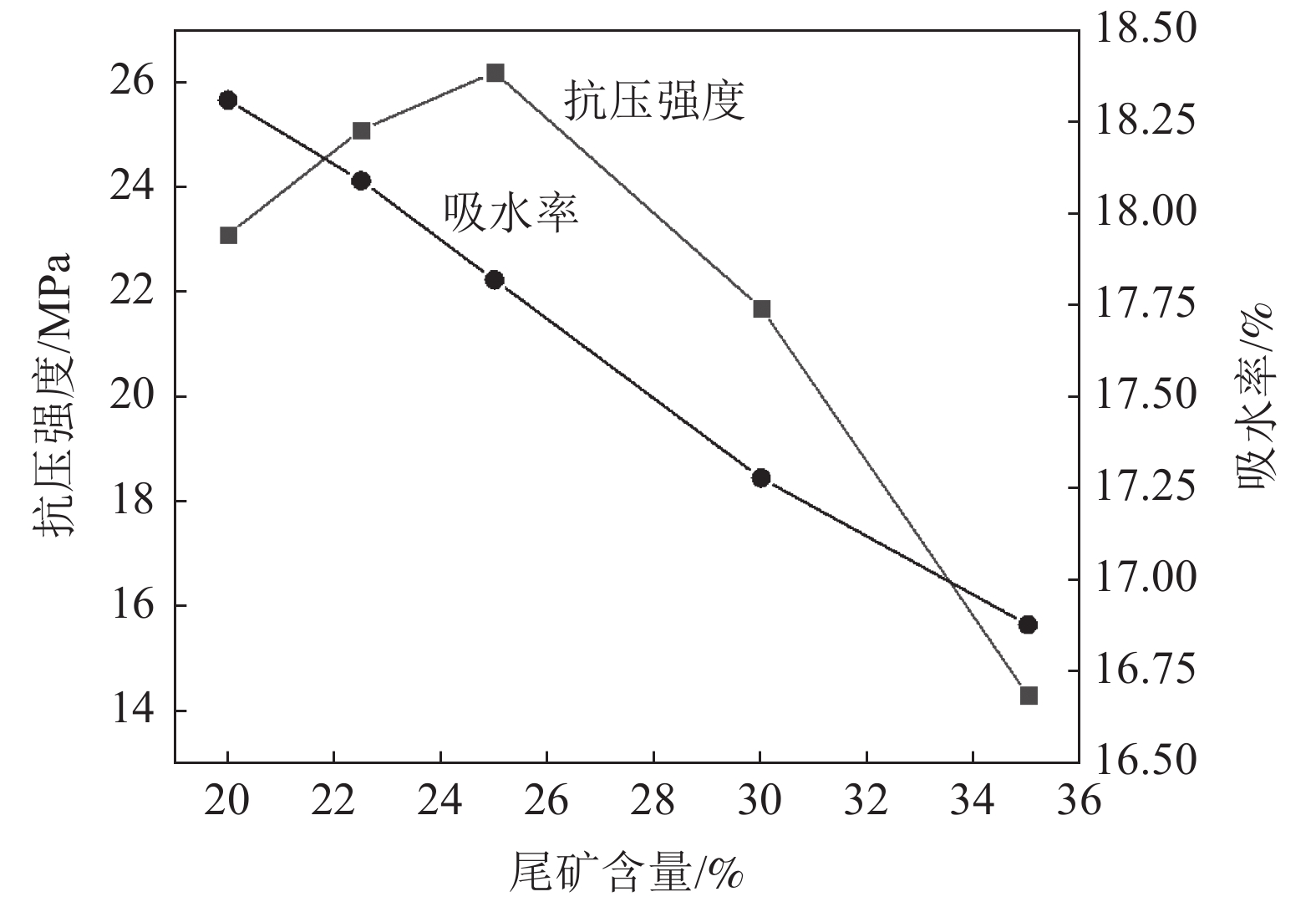

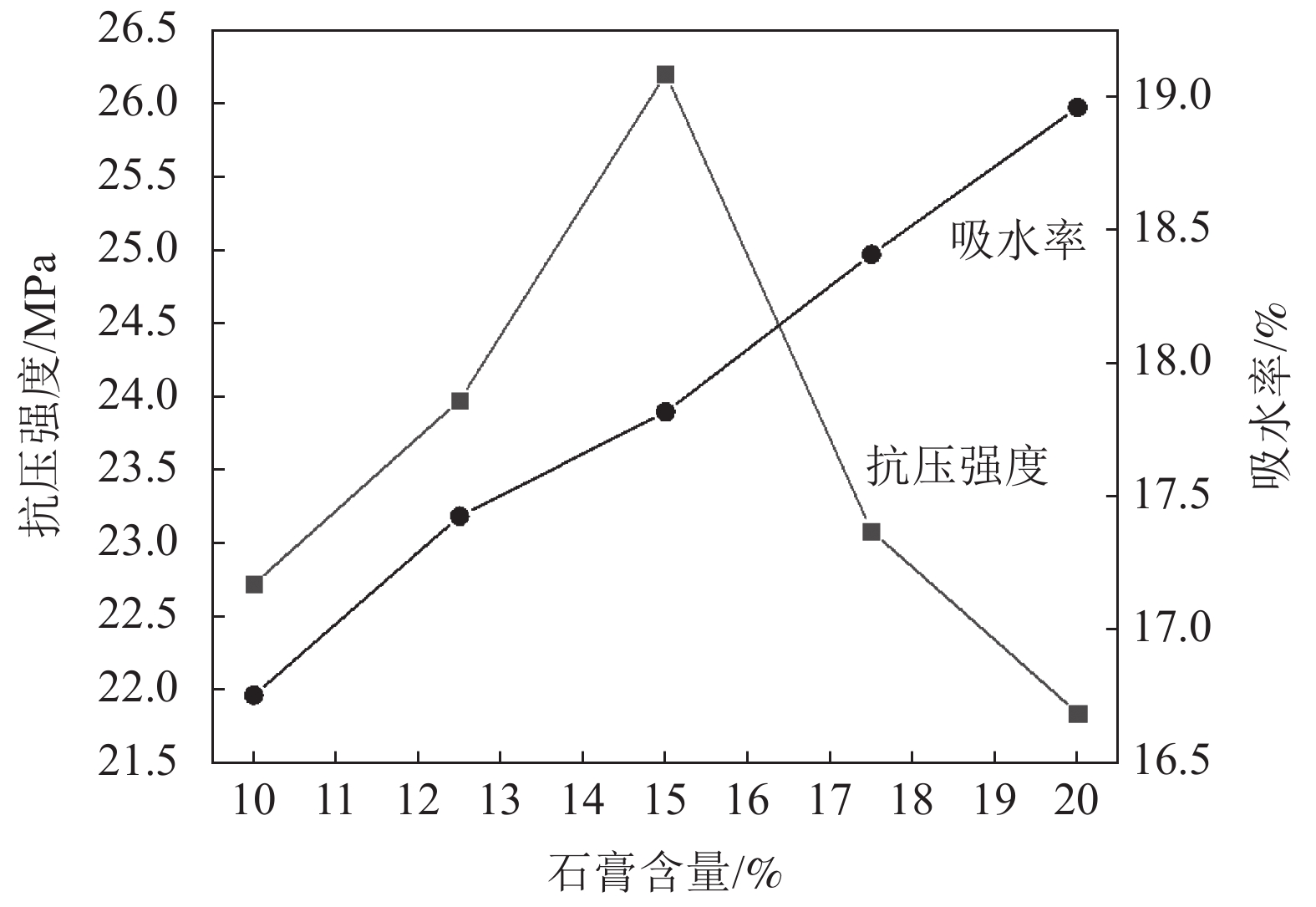

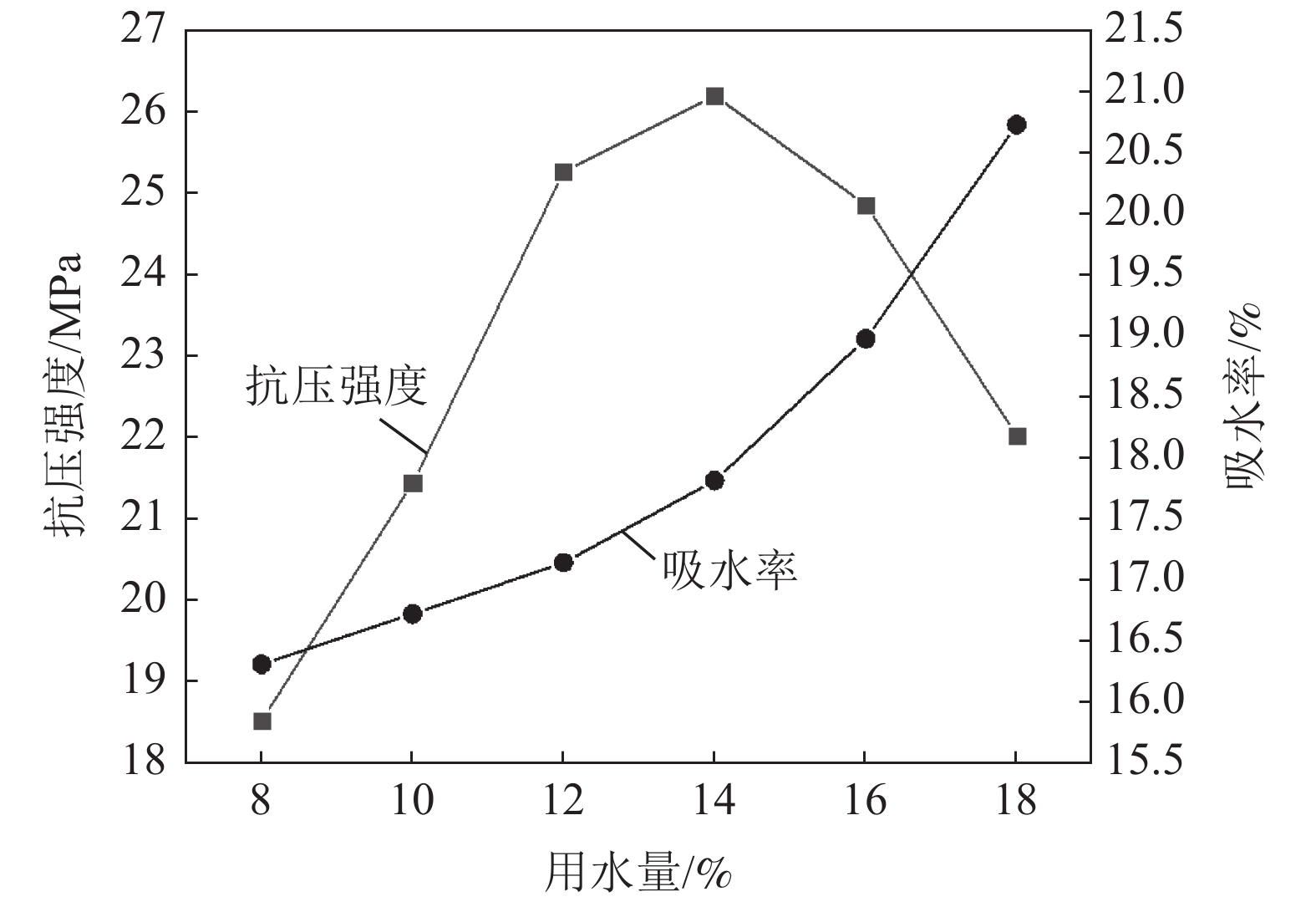

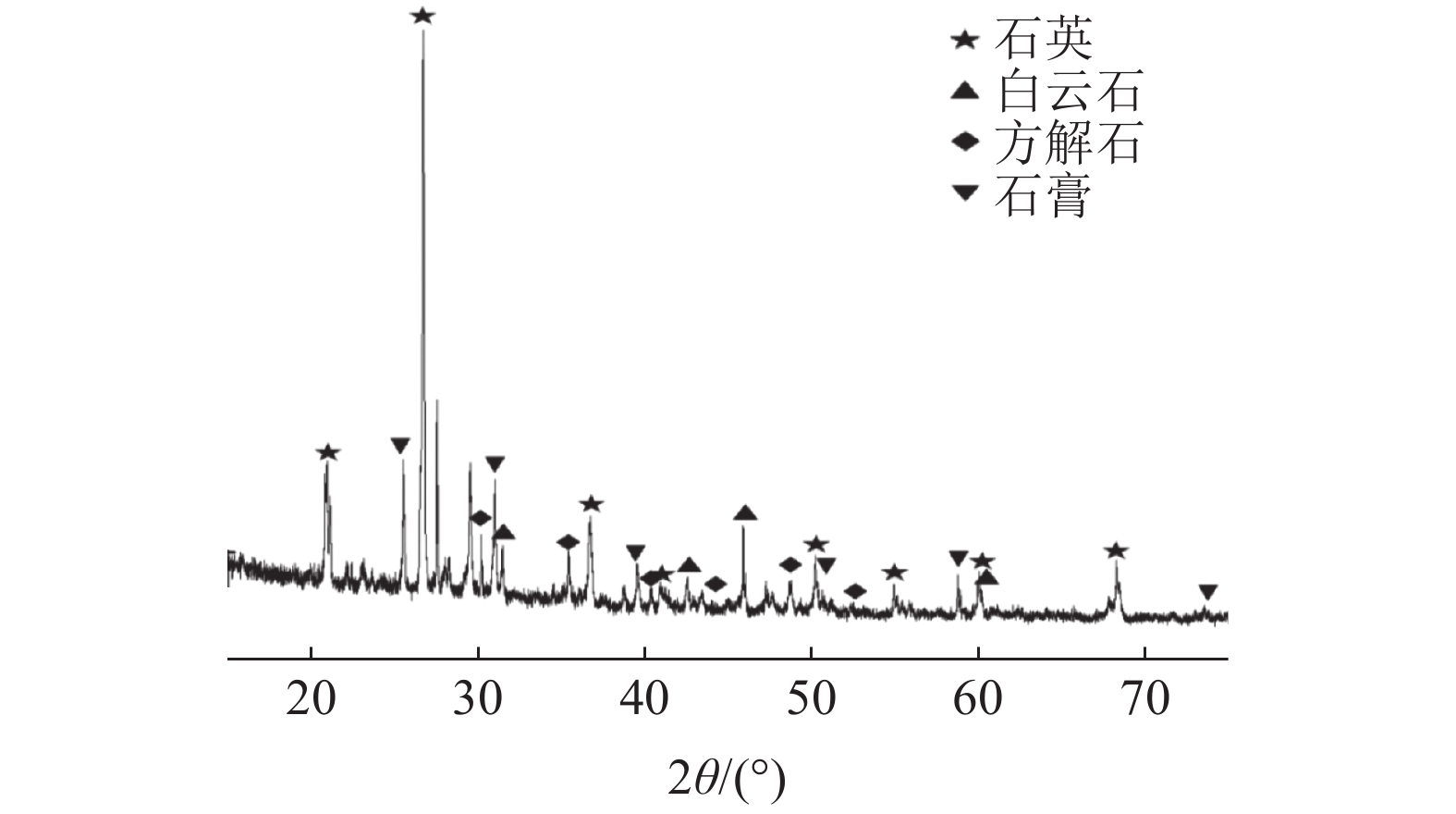

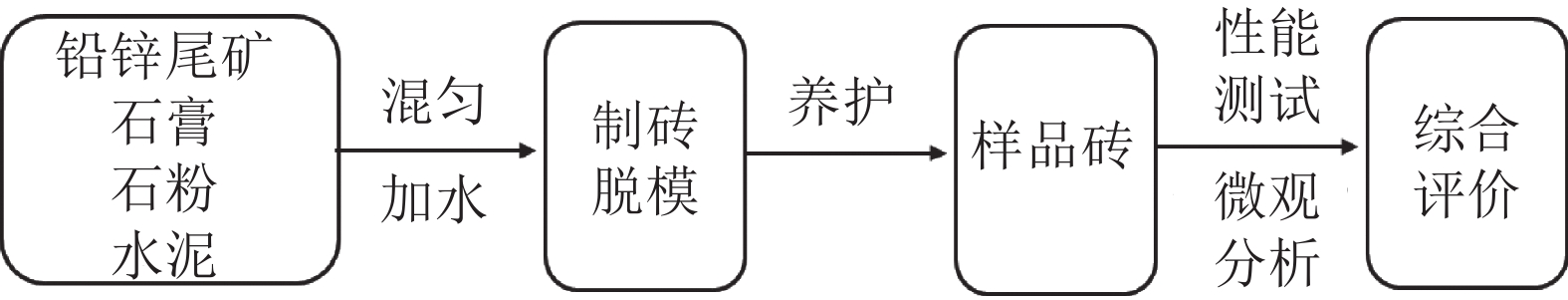

以铅锌尾矿为主要原料,掺入石膏、石粉、水泥制备免烧砖,考察了各组分含量和用水量对免烧砖性能影响。结果显示,较佳成型水分为14%,成型压力为20 MPa,尾矿∶石膏∶水泥∶石粉=2.5∶1.5∶1∶5时,制备的免烧砖满足《非烧结垃圾尾矿砖》MU25级别要求,固废使用量达到25%,实现了固体废弃物的资源化。

Abstract:Using tailings, gypsum, cement and stone powder to prepare the no-fire brick, the mechanical properties are discussed by change of the proportion of tailings、gypsum、cement and stone powder, and the dosage of the water. The results show that the best preparation condition is that the proportion of tailings、gypsum、cement and stone powder being 2.5∶1.5∶1∶5, the water consumption accounting for 14% of the total solid materials. The prepared non-fired bricks can meet the standard requirements of iron tailings, the use of solid waste reached 25%, realizing the recycling of solid waste.

-

Key words:

- Component ratio /

- Water consumption /

- Non-fired brick /

- Compressive strength /

- Water absorption

-

-

表 1 粒级分布

Table 1. Particle size distribution

粒级/mm +0.600 -0.600

+0.300-0.300

+0.150-0.150

+0.075-0.075 含量/% 16.38 18.81 8.54 1.78 54.40 -

[1] 唐谦, 黄建平, 鱼高学, 等. 某铅锌矿选矿生产指标考察与分析研究[J]. 矿产综合利用, 2019(1):128-131.

TANG Q, HUANG J P, YU G X, et al. Investigation and analysis of beneficiation production index of a lead-zinc ore[J]. Multipurpose Utilization of Mineral Resources, 2019(1):128-131.

[2] 刘洋, 张春霞. 钢铁渣的综合利用现状及发展趋势[J]. 矿产综合利用, 2019(2):21-25. doi: 10.3969/j.issn.1000-6532.2019.02.004

LIU Y, ZHANG C X. Present situation and development trend of comprehensive utilization of iron and steel slag[J]. Multipurpose Utilization of Mineral Resources, 2019(2):21-25. doi: 10.3969/j.issn.1000-6532.2019.02.004

[3] 李冲, 许亚丽, 于岩, 等. 铅锌尾矿免烧吸附砖的制备与研究[J]. 材料科学与工艺, 2016, 24(4):46-51. doi: 10.11951/j.issn.1005-0299.20160407

LI C, XU Y L, YU Y, et al. Preparation and research of lead-zinc tailings unfired adsorption brick[J]. Materials Science and Technology, 2016, 24(4):46-51. doi: 10.11951/j.issn.1005-0299.20160407

[4] RUAN Z, WANG Y, WU A, et al. A theoretical model for the bake blockage mitigation in deep cone thickener: a case study of lead-zinc mine in China[J]. Mathematical Problems in Engineering, 2019:1-7.

[5] 赵玉容. 水口山柏坊铜矿尾砂应用于建筑材料的试验研究[D]. 衡阳: 南华大学, 2011.

ZHAO Y R. Experimental study on the application of tailings in building materials of Baifang copper mine in Shuikoushan [D]. Hengyang: University of South China, 2011.

[6] 崔瑞, 冯海强, 张舰, 等. 河南灵宝金尾矿制砖的试验研究[J]. 矿业研究与开发, 2019, 39(2):116-121.

CUI R, FENG H Q, ZHANG J, et al. Experimental study on making bricks from Henan Lingbao gold tailings[J]. Mining Research and Development, 2019, 39(2):116-121.

[7] 毛玉成. 聚羧酸大分子的合成及其在模具石膏中的应用[D]. 无锡: 江南大学, 2014.

MAO Y C. Synthesis of polycarboxylic acid macromolecules and its application in mold gypsum [D]. Wuxi: Jiangnan University, 2014.

[8] 曹耀华, 高照国, 刘红召. 鞍本地区某铁尾矿制备免蒸免烧砖试验研究[J]. 矿产综合利用, 2009(6):43-46.

CAO Y H, GAO Z G, LIU H Z. Experimental study on preparation of non-steam-free brick from an iron tailings in Anbeng area[J]. Multipurpose Utilization of Mineral Resources, 2009(6):43-46.

[9] 连坤. CFB炉渣/脱硫石膏高强免烧砖抗冻性能研究[D]. 太原: 中北大学, 2018.

LIAN K. Research on antifreeze properties of CFB sag/gypsum high-strength unfired brick [D]. Taiyuan: North University of China, 2018.

[10] 李燕怡, 常亮亮, 李春. 铁尾矿免烧砖的制备及性能研究[J]. 商洛学院学报, 2016, 30(6):30-33.

LI Y Y, CHANG L L, LI C. Study on the preparation and properties of iron tailings unfired brick[J]. Journal of Shangluo University, 2016, 30(6):30-33.

[11] 黄世伟, 李妍妍, 程麟, 等. 用梅山铁尾矿制备免烧免蒸砖[J]. 金属矿山, 200(4): 81-84.

HUANG S W, LI Y Y, CHENG L, et al. Preparation of no-firing and no-steam brick from Meishan iron tailings [J]. Metal Mine, 2007(4): 81-84.

[12] MADUREIRA J, SLEZAKOVA K, SILVA A I, et al. Assessment of indoor air exposure at residential homes: inhalation dose and lung deposition of PM 10, PM 2.5 and ultrafine particles among newborn children and their mothers[J]. Elsevier B. V., 2020:717.

[13] CHAO Y. Research status and development trend of baking-free brick with red mud from alumina refinery[J]. Journal of Jiaozuo University, 2013.

-

下载:

下载: