Experimental Study on Recovery of Copper from Tailings by CCF Flotation Column

-

摘要:

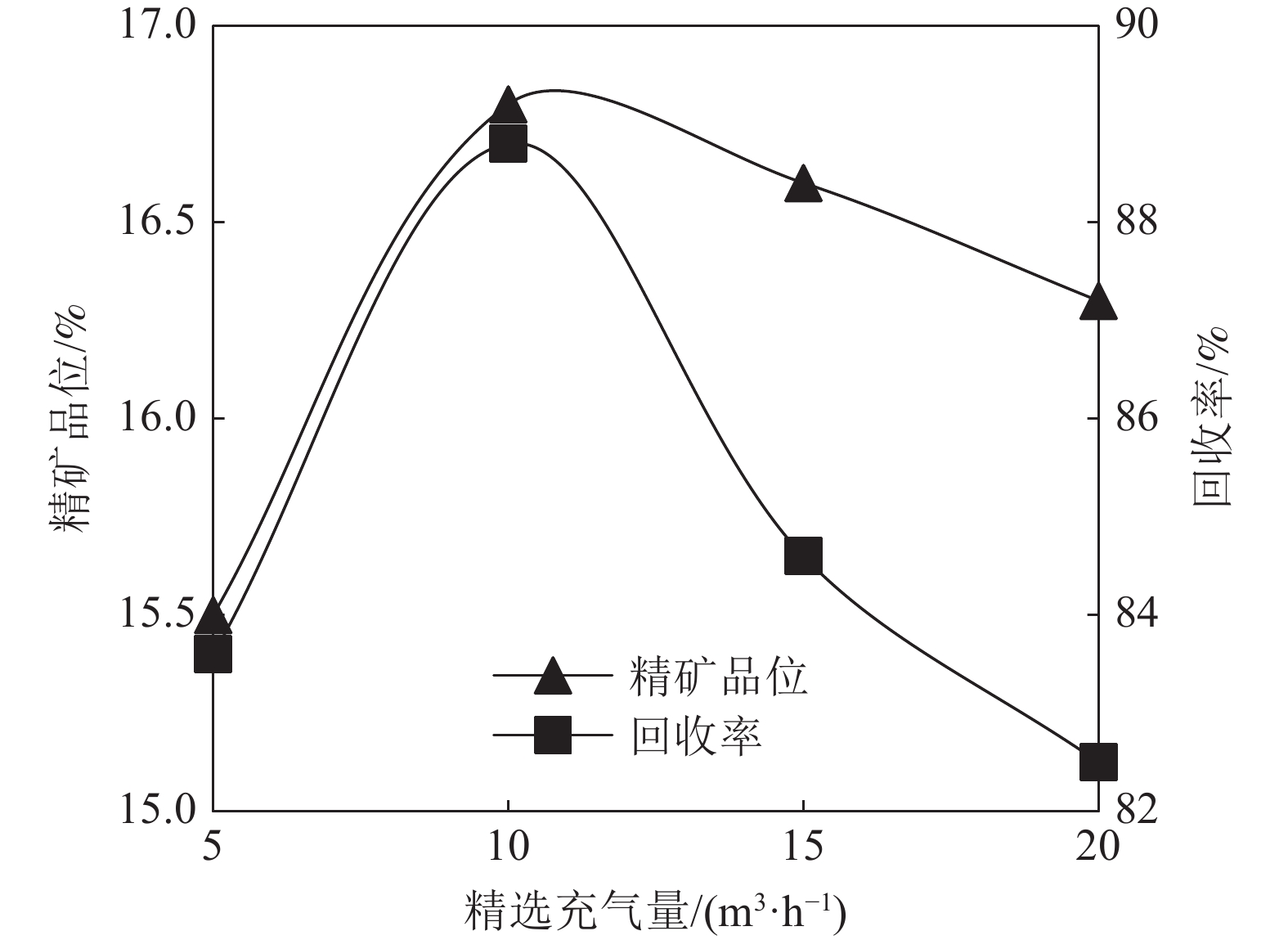

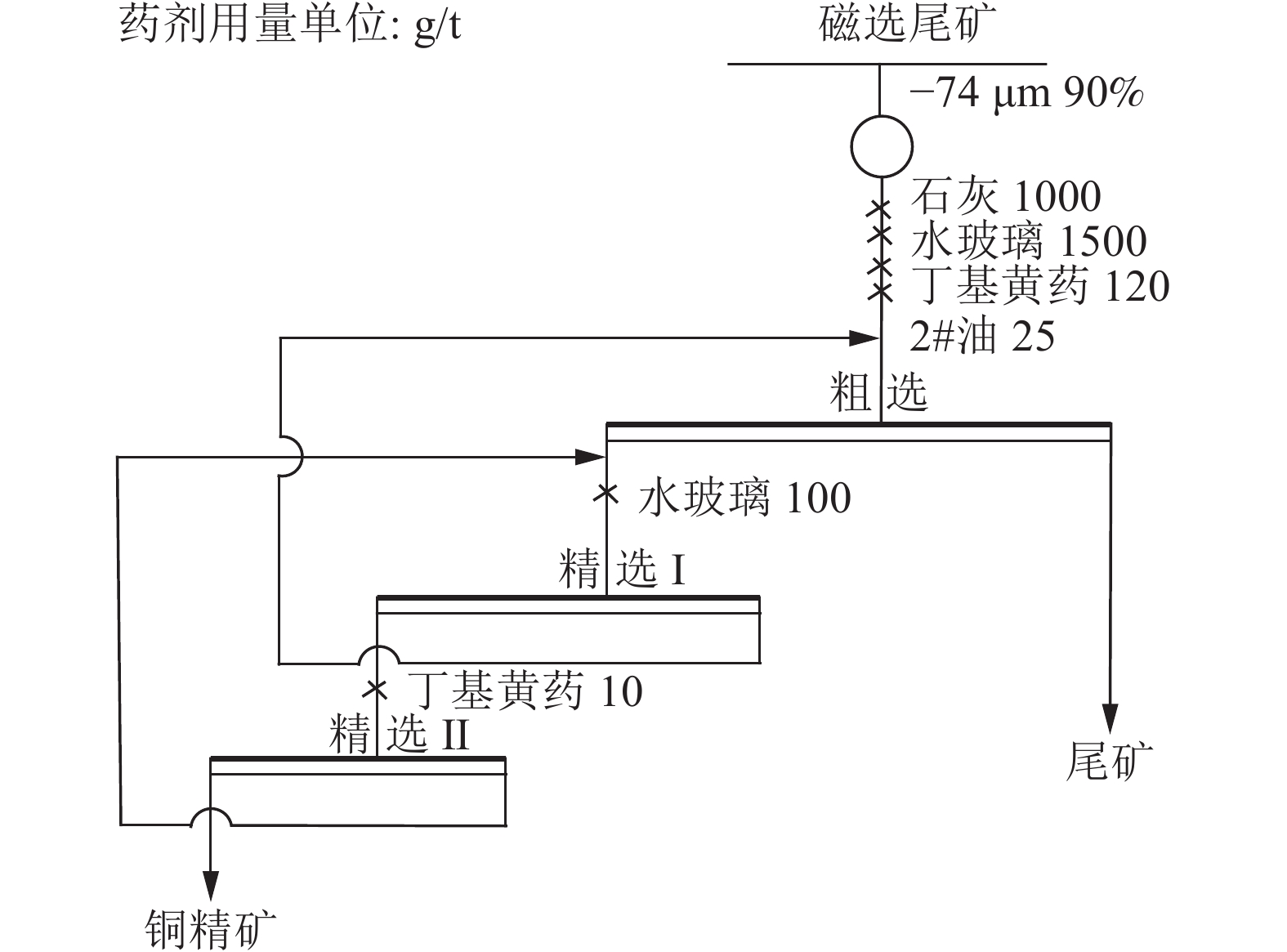

本文以湖北某磁选尾矿中铜的综合回收为研究对象,通过工艺矿物学研究表明,该磁选尾矿组分较为复杂,铜含量较低为0.38%,嵌布粒度较细,铜主要赋存于原生硫化铜中,分布率为74.08%,铜矿物主要是黄铜矿,少量铜蓝、辉铜矿等,脉石矿物主要是石英,其次为方解石、白云石、绢云母,少量长石、高岭石等。针对尾矿中铜矿物“贫、细、杂”的特点,采用CCF浮选柱进行回收铜的选矿实验研究,研究结果表明,经过一次粗选一次扫选和两次精选作业,可从含铜0.38%的尾矿中获得铜品位16%以上,铜回收率76% 以上的铜精矿,实验指标良好,实现矿产资源综合回收利用。

Abstract:In this paper, the comprehensive recovery of copper from a magnetic separation tailings in Hubei Province is studied. The process mineralogical study shows that the composition of the tailings is relatively complex, with low copper content of 0.38% and fine disseminated particle size. Copper mainly occurs in primary copper sulfide, with a distribution rate of 74.08%. The copper ore is mainly chalcopyrite, a small amount of copper blue, chalcocite, etc., and the gangue mineral is mainly quartz, the second is calcite, dolomite, sericite, a small amount of feldspar, kaolinite and so on. According to the characteristics of "poor, fine and miscellaneous" copper minerals in tailings, the CCF flotation column was used to carry out the beneficiation test of recovering copper. The results show that after one roughing, one scavenging and two cleaning operations, the copper concentrate with copper grade of more than 16% and copper recovery of more than 76% can be obtained from the tailings containing 0.38% copper. The test index is good, and the comprehensive recovery and utilization of mineral resources can be realized.

-

Key words:

- Tailings /

- Copper /

- CCF flotation column

-

-

表 1 尾矿多元素分析结果/%

Table 1. Multi-elementary analysis results of tailings

Cu Fe S As SiO2 Al2O3 MgO CaO K2O Na2O 0.38 7.80 4.82 0.02 48.88 4.36 3.23 15.46 1.05 0.33 表 2 尾矿中铜的化学物相分析

Table 2. Chemical phase analysis of copper in tailings

名称 原生硫化铜 次生硫化铜 氧化铜 总铜 含量/% 0.283 0.059 0.040 0.382 分布率/% 74.08 15.45 10.47 100.00 表 3 矿石中主要矿物的相对含量

Table 3. Relative content of the main minerals in the ore

矿物 含量/% 矿物 含量/% 黄铜矿 0.8 方解石 19.8 铜蓝、辉铜矿 0.1 白云石 14.3 孔雀石 微量 绢云母 8.0 黄铁矿 8.6 长 石 3.0 赤铁矿、褐铁矿 3.5 高岭石 5.4 磁铁矿 0.2 其他 0.3 石英 36.0 合计 100.0 表 4 半工业实验浮选柱较佳工艺参数

Table 4. Process parameters of semi-industrial test

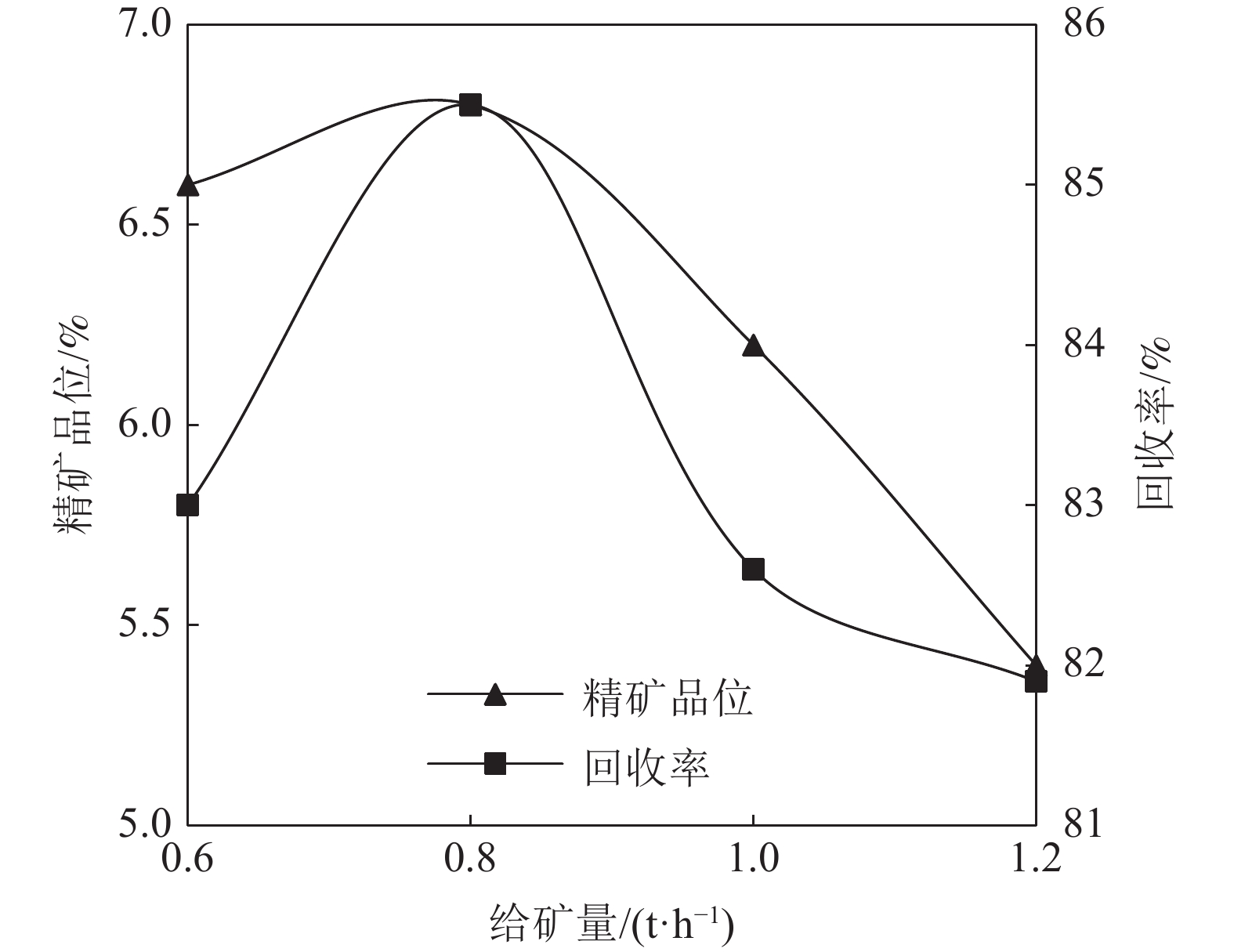

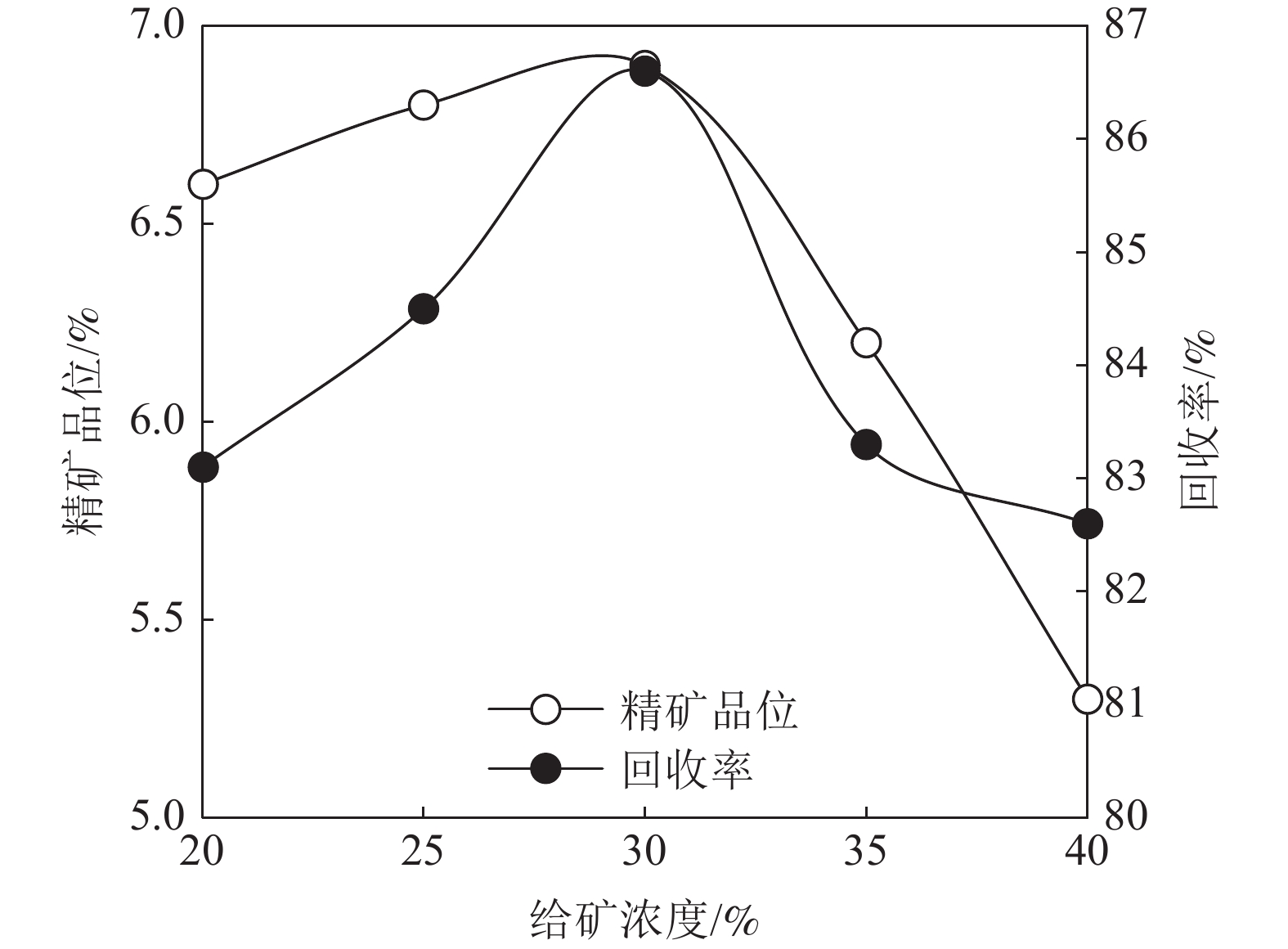

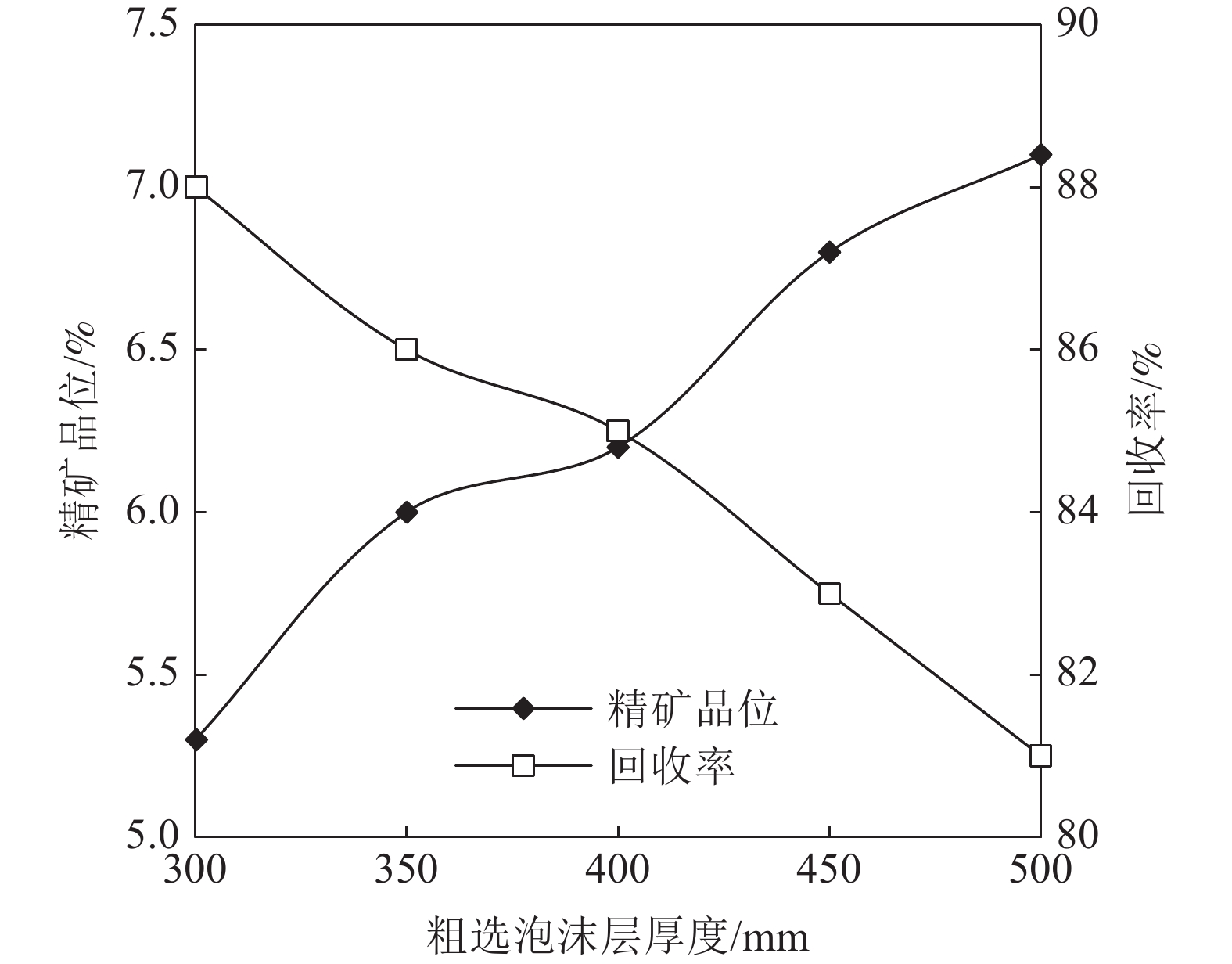

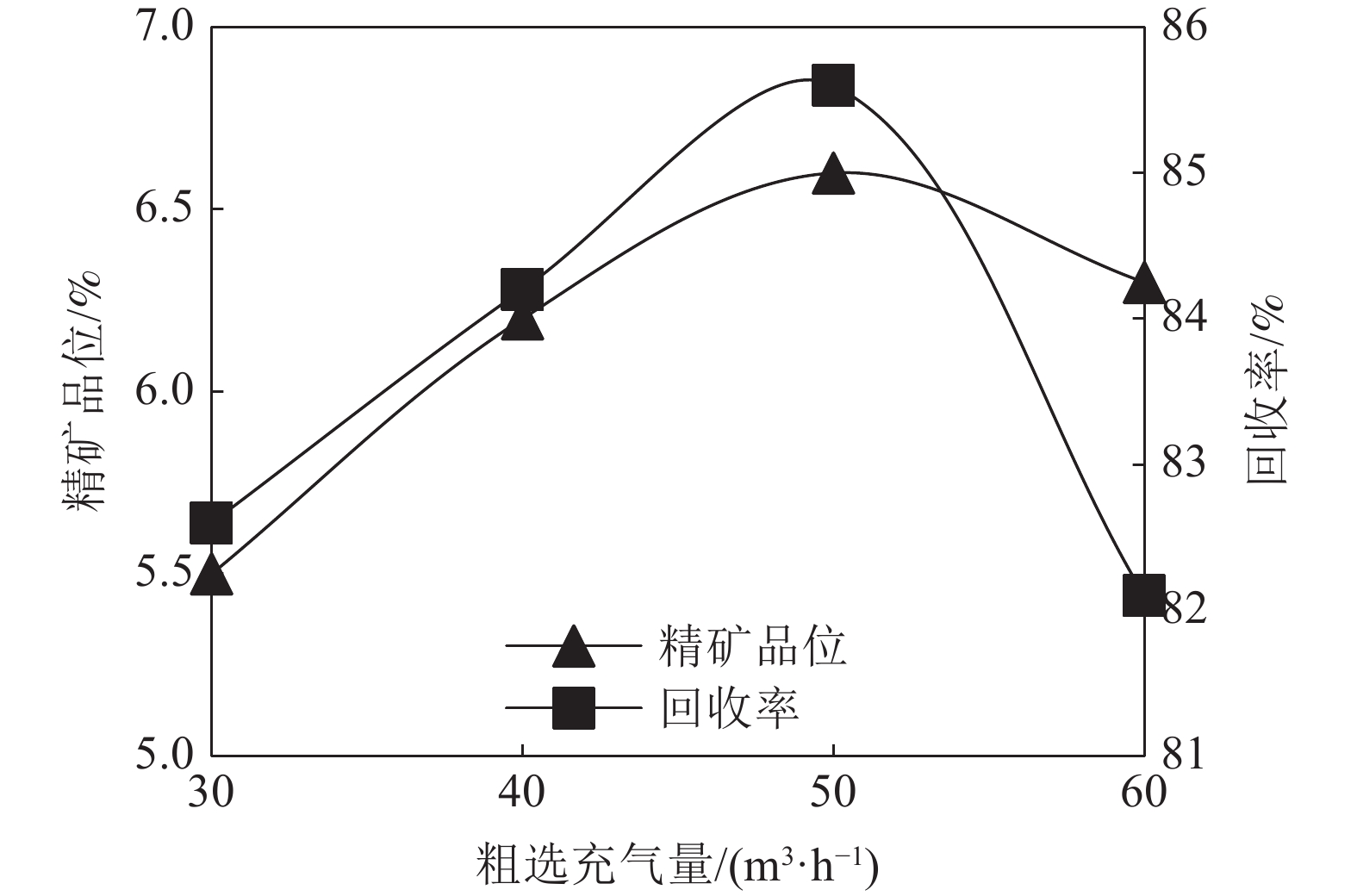

处理量/

(t·h-1)作业

名称给矿

浓度/%泡沫层

厚度/mm充气量/

(m3·h-1)充气

压力/MPa0.8 粗选 30 400 50 0.45 精选 750 10 0.30 表 5 半工业条件实验结果

Table 5. Results of semi-industrial condition test

产品名称 产率/% Cu品位/% 回收率/% 精矿 1.70 16.80 77.19 尾矿

给矿98.30

100.000.09

0.3723.91

100.00表 6 连续实验结果

Table 6. Results of continuous test

班次 给矿/% 精矿/% 尾矿/% 回收率/% 1 0.380 16.420 0.081 79.07 2 0.377 16.360 0.076 80.21 3 0.382 16.690 0.088 77.37 4 0.379 16.540 0.086 77.71 5 0.369 16.330 0.086 77.10 6 0.388 16.870 0.092 76.71 7 0.376 16.660 0.098 74.37 8 0.385 16.600 0.102 73.96 9 0.386 16.690 0.095 75.82 平均 0.380 16.573 0.089 76.92 -

[1] 程雄伟, 王怀法. 新型射流浮选柱充气性能试验研究[J]. 矿产综合利用, 2019(4):38-41. doi: 10.3969/j.issn.1000-6532.2019.04.007

CHENG X W, WANG H F. Experimental study on the aeration performance of a new type of jet flotation column[J]. Multipurpose Utilization of Mineral Resources, 2019(4):38-41. doi: 10.3969/j.issn.1000-6532.2019.04.007

[2] 王选毅, 吴铁生, 薛明向, 等. 浮选柱用于白钨精选的工业试验研究[J]. 有色金属(选矿部分), 2012(6):60-64.

WANG X Y, WU T S, XUE M X, et al. Flotation column used in industrial test research of scheelite concentration[J]. Non-ferrous metals (mineral processing part), 2012(6):60-64.

[3] 梁冰, 韩苗苗, 韩继康, 等. 一种新型浮选柱发泡器生成气泡特性研究[J]. 矿产综合利用, 2020(3):190-196. doi: 10.3969/j.issn.1000-6532.2020.03.033

LIANG B, HAN M M, HAN J K, et al. Bubble generation characteristics of a new type of flotation column[J]. Multipurpose Utilization of Mineral Resources, 2020(3):190-196. doi: 10.3969/j.issn.1000-6532.2020.03.033

[4] 卿林江. CCF浮选柱在钼和钨浮选的应用[J]. 矿业工程, 2018, 16(2):42-44. doi: 10.16672/j.cnki.kygc.2018.02.014

QING L J. Application of CCF flotation column in flotation of molybdenum and tungsten[J]. Mining Engineering, 2018, 16(2):42-44. doi: 10.16672/j.cnki.kygc.2018.02.014

[5] 黄建芬, 余江鸿. 某铜尾矿选矿试验研究[J]. 世界有色金属, 2018, 513(21):49-51. doi: 10.3969/j.issn.1002-5065.2018.21.020

HUANG J F, YU J H. Experimental research on the beneficiation of a copper tailings[J]. World Nonferrous Metals, 2018, 513(21):49-51. doi: 10.3969/j.issn.1002-5065.2018.21.020

[6] 欧乐明, 王立军, 冯其明, 等. 利用微泡浮选柱分选中低品位铝土矿的试验研究[J]. 矿冶工程, 2011, 31(3):40-43. doi: 10.3969/j.issn.0253-6099.2011.03.010

OU L M, WANG L J, FENG Q M, et al. Experimental research on sorting low-grade bauxite using micro-bubble flotation column[J]. Mining and Metallurgical Engineering, 2011, 31(3):40-43. doi: 10.3969/j.issn.0253-6099.2011.03.010

-

下载:

下载: