Research Progress of Electrolytic Aluminum Overhaul Slag Disposal

-

摘要:

大修渣作为电解铝行业的主要固体废弃物,含有大量的危害物质,如何对其无害化处理并高效回收其中有价值物质,是近些年铝行业亟待解决的难题。本文分析总结了大修渣的成分、危害及目前国内外电解铝大修渣处置的发展状况,并指出了我国电解铝行业危险废物处置的发展方向。

Abstract:As the main solid waste of the electrolytic aluminum industry, overhaul slag contains a large amount of hazardous substances, and how to treat it harmlessly and efficiently recover the valuable substances in it has become an urgent problem in the aluminum industry in recent years. This article analyzes and summarizes the composition and hazards of the overhaul slag and the current development status of domestic and international electrolytic aluminum overhaul slag disposal, and points out the development direction of hazardous waste disposal in China's electrolytic aluminum industry.

-

Key words:

- Electrolytic aluminum /

- Overhaul slag /

- Harmlessness /

- Resource utilization

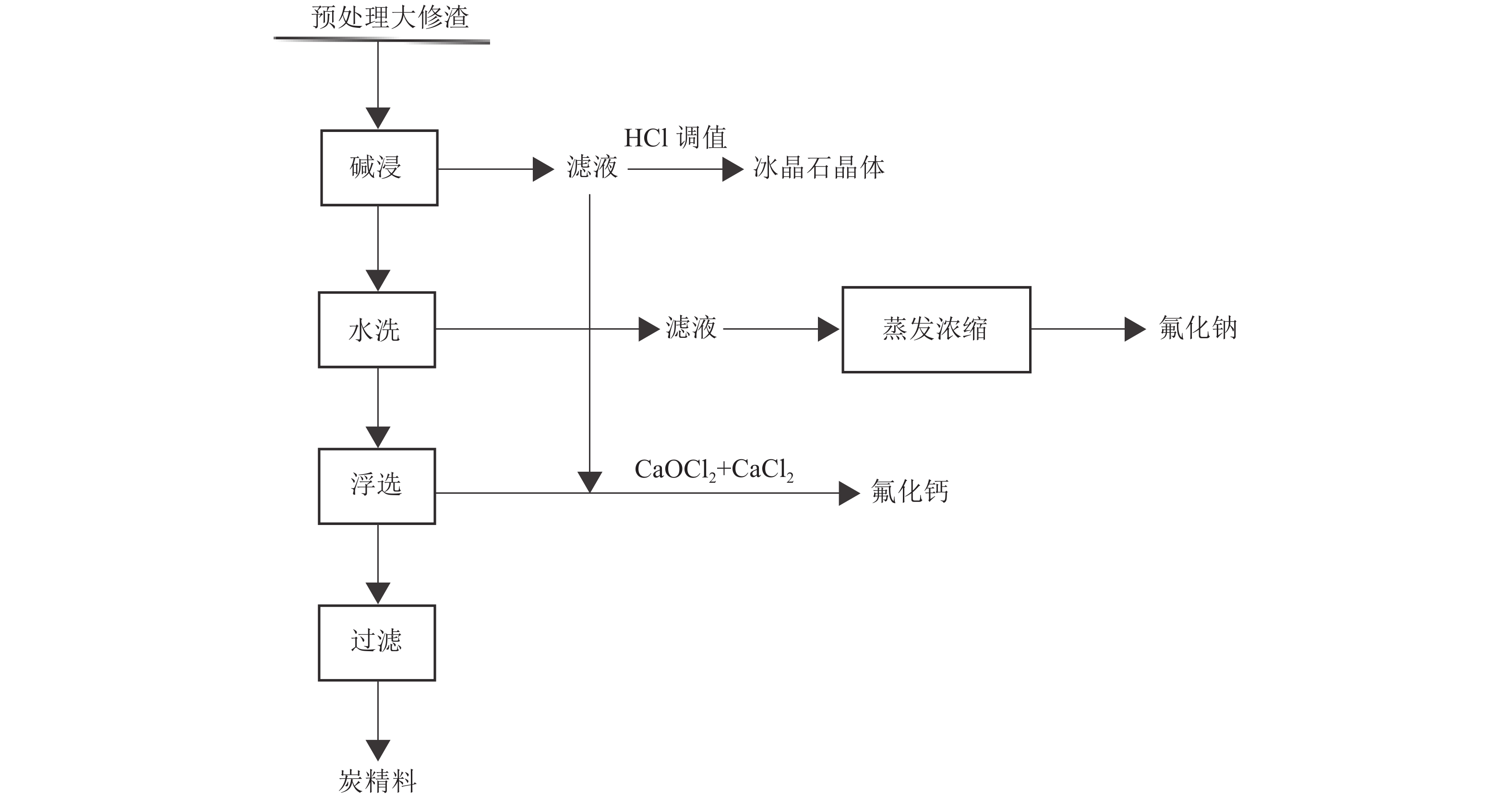

-

-

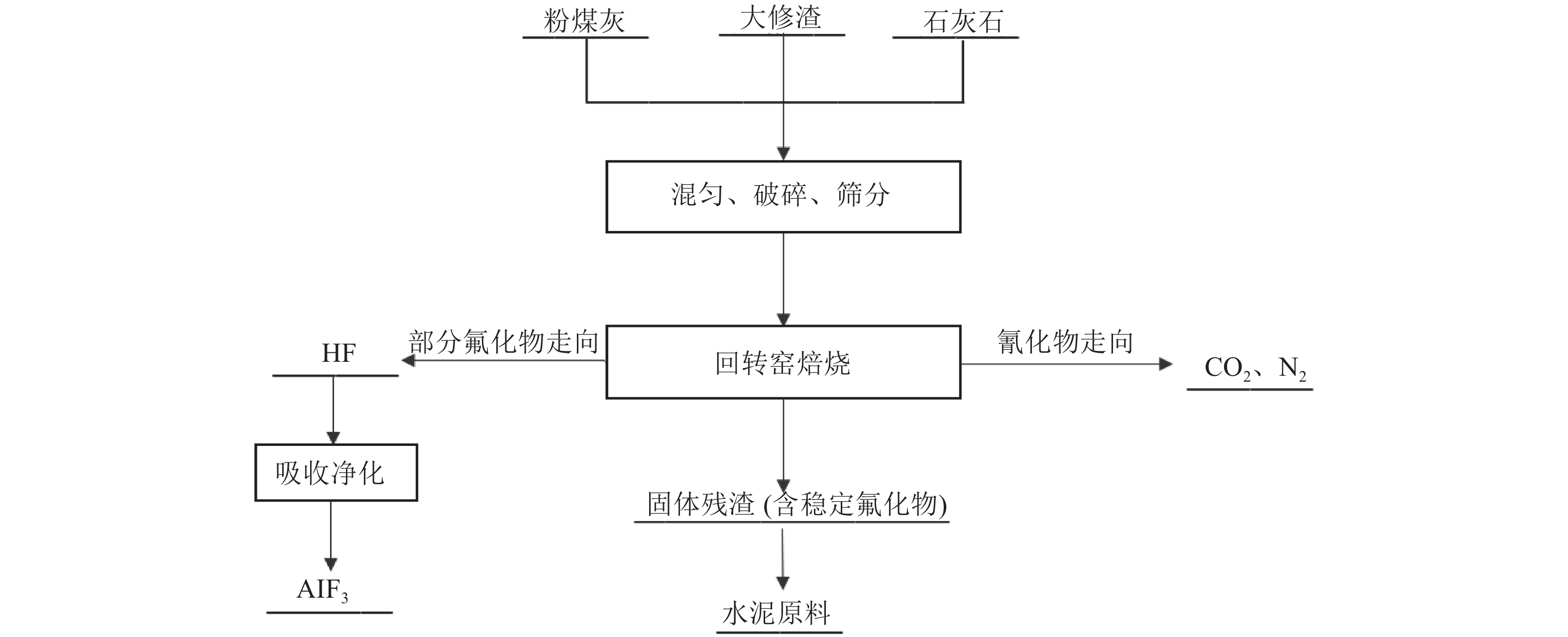

表 1 国内外大修渣部分火法无害化处置技术

Table 1. Partial fire harmless disposal technology of overhaul slag at home and abroad

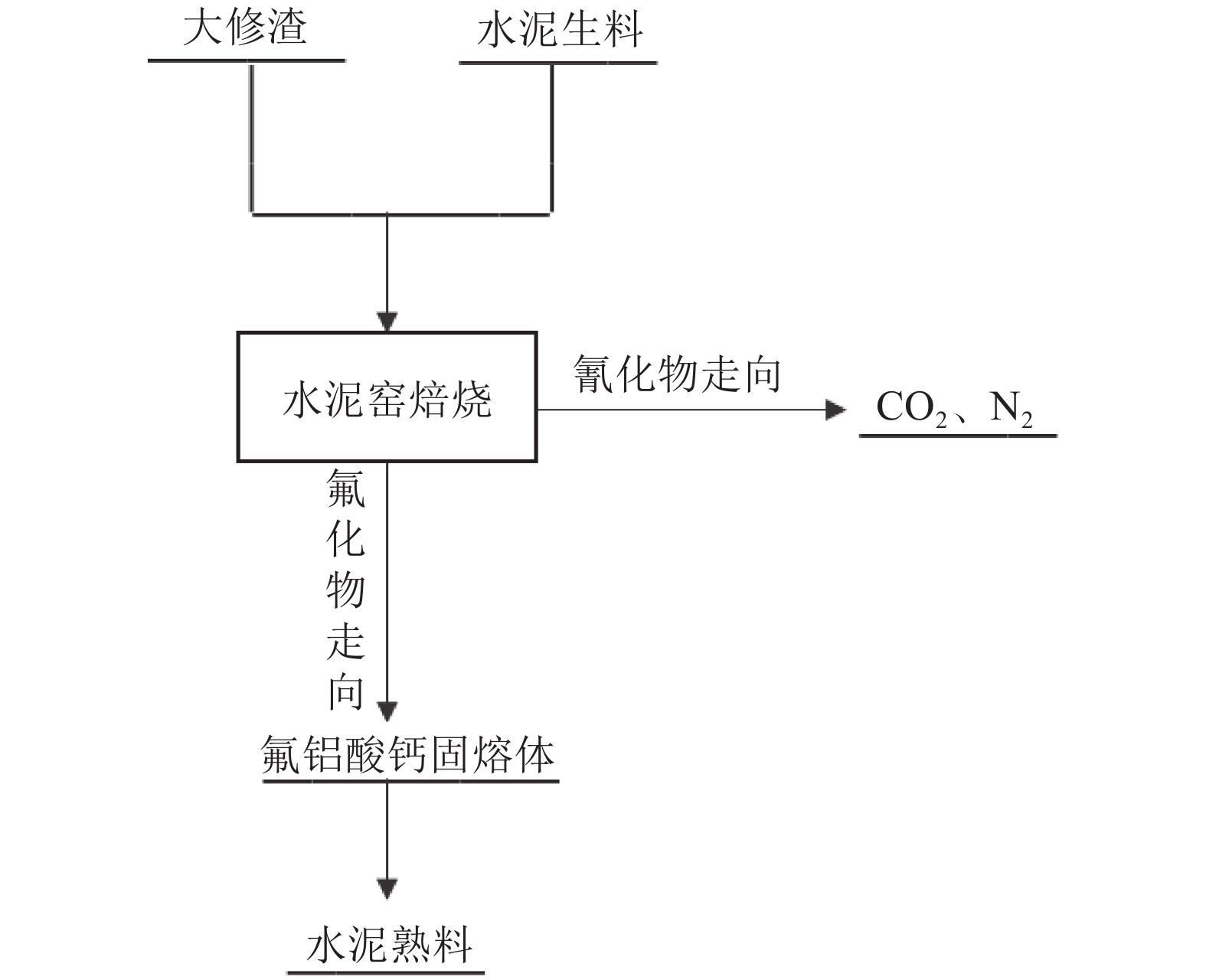

公司名称 工艺名称 所用设备 氟化物去向 氰化物去向 Alcoa SYNTHETIC SAND 回转窑 HF、AlF3 N2、CO2 Comalco Aluminum Limited COMTOR TORBED CaF2 N2、CO2 中国铝业公司 ______ 回转窑 CaF2 N2、CO2 美国铝业公司 Ausmelt 水泥窑 AlF3 N2、CO2 威斯顿铝业公司 _______ 回转窑 CaF2、 AlF3 N2、CO2 -

[1] 叶智青. 铝电解废阴极固体废物的处理技术[J]. 环境科学导刊, 2019, 38(S2):100-103. YE Z Q. Treatment technology of aluminum electrolysis waste cathode solid waste[J]. Environmental Science Guide, 2019, 38(S2):100-103.

[2] 杨桃艳, 黄晓梅, 胡学军. 浅析电解铝企业的环境污染问题及治理措施[J]. 有色金属设计, 2020, 47(1):37-41. YANG T Y, HUANG X M, HU X J. Analysis on the environmental pollution problems and treatment measures of electrolytic aluminum enterprises[J]. Nonferrous Metals Design, 2020, 47(1):37-41.

[3] 吴汉元, 宿宁, 秦军, 等. 铁水脱硫协同电解铝大修渣的应用工艺[C]. 无锡: 年炼钢生产新工艺、新技术、新产品研讨会. 2019.

WU H Y, SU N, QIN J, et al. Application process of molten iron desulfurization and electrolytic aluminum overhaul slag[C]. Wuxi: Steelmaking Production New Process, New Technology, New Product Seminar, 2019.

[4] 刘丰. 电解铝大修渣无害化处理任重道远[J]. 环境经济, 2018(17):62-63. LIU F. Harmless treatment of electrolytic aluminum overhaul slag has a long way to go[J]. Environmental Economics, 2018(17):62-63.

[5] 高宇. 电解铝工业危废处置技术现状与发展趋势[J]. 有色冶金设计与研究, 2019, 40(4):33-35. GAO Y. Status and development trend of hazardous waste disposal technology in electrolytic aluminum industry[J]. Design and Research of Nonferrous Metallurgy, 2019, 40(4):33-35. doi: 10.3969/j.issn.1004-4345.2019.04.012

[6] 郭志华. 电解铝生产固体废物大修废渣无害化处置技术[J]. 冶金与材料, 2018, 38(5):133-135. GUO Z H. The harmless disposal technology of solid waste overhaul from electrolytic aluminum production[J]. Metallurgy and Materials, 2018, 38(5):133-135. doi: 10.3969/j.issn.1674-5183.2018.05.076

[7] 高康宁, 晁波阳, 申文斌, 等. 电解铝厂大修渣污染分析与防治对策[J]. 资源节约与环保, 2017(8): 134.

GAO K N, CHAO B Y, SHEN W B, et al. Pollution analysis and prevention countermeasures of overhaul slag in electrolytic aluminum plant[J]. Resource Conservation and Environmental Protection, 2017(8): 134.

[8] 杨俊杰, 李华, 温铁军. 铝电解槽衬废弃物危废无害化处置技术研究[J]. 世界有色金属, 2020(8): 7-9.

YANG J J, LI H, WEN T J. Research on the harmless disposal technology of the lining waste of aluminum electrolysis cell[J]. World Nonferrous Metals, 2020(8): 7-9.

[9] Courbariaux Y, Chaouki J, Guy C. Update on spent potliners treatments: Kinetics of cyanides destruction at high temperature[J]. Industrial&Engineering Chemestry Research. 2004, 43(18): 5828-5837.

[10] 申士富, 王金玲, 牛庆仁, 等. 电解铝固体废弃物的环境危害及处理技术研究现状[C]. 上海: : 中国环境科学学会学术年会, 2010. .

SHEN S F, WANG J L, NIU Q R, et al. Environmental hazards and treatment technology research status of electrolytic aluminum solid waste[C]. Shanghai: Annual Academic Conference of Chinese Society of Environmental Sciences , 2010.

[11] 刘志东, 俞小花, 谢刚, 等. 碱浸浮选法处理铝电解废旧阴极的工艺研究[J]. 轻金属, 2012(3):30-33,59. LIU Z D, YU X H, XIE G, et al. Research on the process of alkaline leaching flotation process for the treatment of waste cathodes in aluminum electrolysis[J]. Light Metals, 2012(3):30-33,59. doi: 10.3969/j.issn.1002-1752.2012.03.008

[12] 宋建忠. 铝电解槽废旧内衬的回收与无害化处理[D]. 沈阳: 东北大学, 2011.

SONG J Z. Recovery and harmless treatment of waste linings of aluminum electrolytic cells[D]. Shenyang: Northeastern University, 2011.

[13] 李楠, 谢刚, 高磊, 等. 优化浮选条件提高铝电解废旧阴极浮选指标[J]. 轻金属, 2014(7):29-32. LI N, XIE G, GAO L, et al. Optimizing flotation conditions to improve the flotation index of aluminum electrolytic waste cathode[J]. Light Metal, 2014(7):29-32.

[14] Sleap S B, Turner B D, Sloan S W. Kinetics of fluoride removal from spent pot liner leachate (SPLL) contaminated groundwater[J]. Journal of Environmental Chemical Engineering, 2015, 3(4A):2580-2587.

[15] Li W, Chen X. Chemical stability of fluorides related to spent potlining[M]. LIGHT METALS, Deyoung D H, 2008, 855-858.

[16] 武正君, 宋良杰. 铝电解过程危险废物的资源化利用技术[J]. 环境科学导刊, 2019, 38(5):75-78. WU Z J, SONG L J. Resource utilization technology of hazardous waste in aluminum electrolysis process[J]. Guide of Environmental Science, 2019, 38(5):75-78.

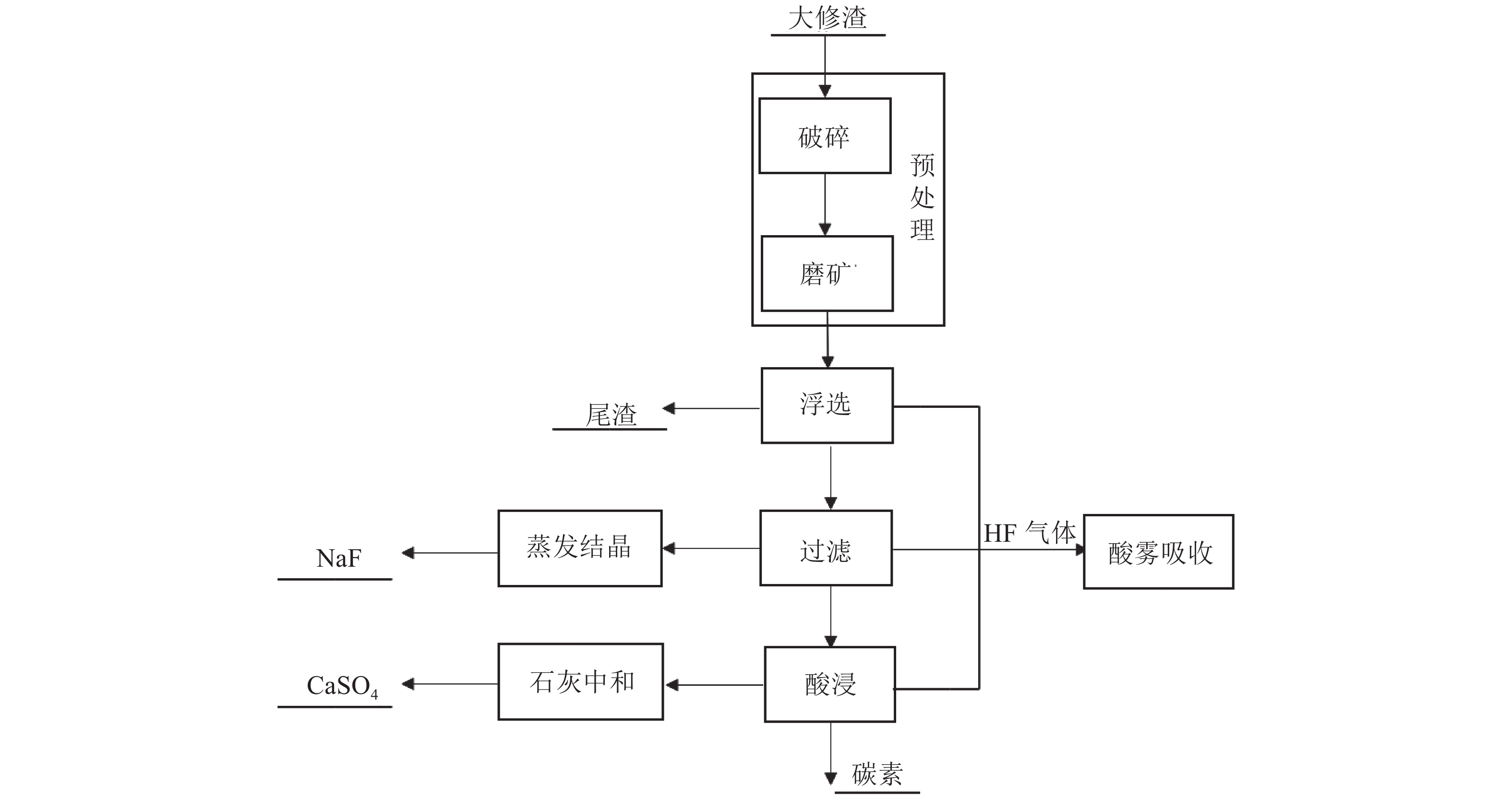

[17] 陈喜平. 电解铝废槽衬处理技术的最新研究[J]. 轻金属, 2011(12): 21-24.

CHEN X P. The latest research on the treatment technology of electrolytic aluminum waste tank lining[J]. Light Metal. 2011(12): 21-24.

[18] 赵亮, 宋兴宽, 路齐英, 等. 电解铝大修渣中总氟含量分析[J]. 环境与可持续发展, 2017, 42(4):114-115. ZHAO L, SONG X K, LU Q Y, et al. Analysis of total fluorine content in electrolytic aluminum overhaul slag[J]. Environment and Sustainable Development, 2017, 42(4):114-115. doi: 10.3969/j.issn.1673-288X.2017.04.037

[19] Lisbona D F, Somerfield C, Steel K M. Leaching of spent pot-lining with aluminium nitrate and nitric acid: Effect of reaction conditions and thermodynamic modelling of solution speciation[J]. HYDROMETALLURGY, 2013, 134:132-143.

[20] Silveira B I, Dantas A, Blasques J, et al. Effectiveness of cement-based systems for stabilization and solidification of spent pot liner inorganic fraction[J]. Journal of Hazardous Materials, 2003, 98(PII S0304-3894(02)00317-51-3): 183-190.

[21] 谢静. 电解铝废槽衬环境污染分析与对策[J]. 河南林业科技, 2008(2):63-64. XIE J. Analysis and countermeasures of environmental pollution of waste electrolytic aluminum tank lining[J]. Henan Forestry Science and Technology, 2008(2):63-64. doi: 10.3969/j.issn.1003-2630.2008.02.028

[22] Palmieri M J, Andrade-Vieira L F, Cardoso Trento M V, et al. Cytogenotoxic effects of spent pot liner (spl) and its main components on human leukocytes and meristematic cells of allium cepa[J]. Water Aair and Soil Pollution, 2016, 227(1565).

[23] 梁文强. 铝灰、碳渣、大修渣的处置及再利用方案[J]. 甘肃冶金, 2017, 39(4):86-89. LIANG W Q. Disposal and reuse plan of aluminum ash, carbon slag and overhaul slag[J]. Gansu Metallurgy, 2017, 39(4):86-89. doi: 10.3969/j.issn.1672-4461.2017.04.023

[24] 熊仁艳. 铝电解槽大修渣的环境风险管控思路浅析[J]. 有色冶金节能, 2020, 36(3):65-68. XIONG R Y. Analysis of environmental risk management and control ideas of aluminum electrolytic cell overhaul slag[J]. Energy Conservation of Nonferrous Metallurgy, 2020, 36(3):65-68.

[25] 陈华君, 刘全军. 金属矿山固体废物危害及资源化处理[J]. 金属矿山, 2009(4):154-156. CHEN H J, LIU Q J. The hazard and resource treatment of solid waste in metal mines[J]. Metal Mine, 2009(4):154-156. doi: 10.3321/j.issn:1001-1250.2009.04.043

[26] Li N, Xie G, Wang Z, et al. Recycle of Spent Potlining with Low Carbon Grade by Floatation[M]. Advanced Materials Research, Zeng J, Li J, Zhu H, 2014: 881-883, 1660.

[27] 李楠, 李荣兴, 谢刚, 等. 浮选法分离铝电解废旧阴极中的碳和电解质[J]. 轻金属, 2013(5):23-27. LI N, LI R X, XIE G, et al. Separation of carbon and electrolyte in waste cathodes of aluminum electrolysis by flotation method[J]. Light Metals, 2013(5):23-27. doi: 10.3969/j.issn.1002-1752.2013.05.007

[28] 李玉红, 李宏. 电解铝废阴极碳块资源化处理[J]. 矿产综合利用, 2018(4):126-129. LI Y H, LI H. Resource treatment of waste electrolytic aluminum cathode carbon block[J]. Multipurpose Utilization of Mineral Resources, 2018(4):126-129. doi: 10.3969/j.issn.1000-6532.2018.04.029

[29] 詹磊, 牛庆仁, 贺华, 等. 铝电解废阴极炭块无害化综合利用工业实践[J]. 轻金属, 2013(10):59-62. ZHAN L, NIU Q R, HE H, et al. Industrial practice of harmless comprehensive utilization of aluminum electrolysis waste cathode carbon block[J]. Light Metal, 2013(10):59-62.

[30] 戢运峰, 张良运, 商晓甫, 等. 铝电解工业危险废物资源化处理工艺研究[J]. 中国环保产业, 2015(11):36-39. JI Y F, ZHANG L Y, SHANG X F, et al. Research on resource treatment process of hazardous waste in aluminum electrolysis industry[J]. China Environmental Protection Industry, 2015(11):36-39. doi: 10.3969/j.issn.1006-5377.2015.11.006

[31] Yaowu W, Jianping P, Yuezhong D. Separation and recycling of spent carbon cathode blocks in the aluminum industry by the vacuum distillation process[J]. JOM. 2018, 70(9): 1877-1882.

[32] Zhao X, Ma L. Hazardous waste treatment for spent pot liner[M]. IOP Conference Series-Earth and Environmental Science, 2018: 108.

[33] 中国铝业股份有限公司郑州研究院. 铝电解槽废槽衬无害化处理技术[EB/OL]. 2007. http://www.wanfangdata.com.cn/details/detail.do?_type=techResult&id=0800260056.

Zhengzhou Research Institute of Aluminum Corporation of China Limited. Harmless treatment technology for waste lining of aluminum electrolytic cell [EB/OL]. 2007. http://www.wanfangdata.com.cn/details/detail.do?_type=techResult&id =0800260056.

[34] Tropenauer B, Klinar D, Samec N, et al. Sustainable waste-treatment procedure for the spent potlining (spl) from aluminium production[J]. MATERIALI IN TEHNOLOGIJE. 2019, 53(2): 277-284.

[35] 马建立, 商晓甫, 马云鹏, 等. 电解铝工业危险废物处理技术的发展方向[J]. 化工环保, 2016, 36(1):11-16. MA J L, SHANG X F, MA Y P, et al. Development direction of hazardous waste treatment technology in electrolytic aluminum industry[J]. Environmental Protection of Chemical Industry, 2016, 36(1):11-16. doi: 10.3969/j.issn.1006-1878.2016.01.003

[36] 谭震军. 浅析铝电解大修渣无害化处理方式[J]. 石河子科技, 2020(1):33-34. TAN Z J. Analysis on the harmless treatment of aluminum electrolysis overhaul slag[J]. Shihezi Science and Technology, 2020(1):33-34.

[37] Nie Y, Guo X, Guo Z, et al. Defluorination of spent pot lining from aluminum electrolysis using acidic iron-containing solution[J]. HYDROMETALLURGY, 2020, 194(105319).

[38] Birry L, Poirier S. The LCL&L Process: A sustainable solution for the treatment and recycling of spent pot lining[C]. Cham: Springer International Publishing, 2020.

[39] 刘佳囡, 曹诗圆, 程颖, 等. 铝土矿中铝、铁和硅有价组分的综合利用研究[J]. 矿产综合利用, 2019(4):87-90. LIU J N, CAO S Y, CHENG Y, et al. Comprehensive utilization of the valuable components of aluminum, iron and silicon in bauxite[J]. Multipurpose Utilization of Mineral Resources, 2019(4):87-90. doi: 10.3969/j.issn.1000-6532.2019.04.018

[40] Shi Z, Li W, Hu X, et al. Recovery of carbon and cryolite from spent pot lining of aluminium reduction cells by chemical leaching[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1):222-227. doi: 10.1016/S1003-6326(11)61164-3

[41] 李伟. 碱酸法处理铝电解废旧阴极的研究[D]. 辽宁: 东北大学 , 2009.

LI W. Research on the treatment of aluminum electrolysis waste cathode by alkaline acid method[D]. Liaoning: Northeastern University, 2009.

[42] Xiao J, Yuan J, Tian Z, et al. Comparison of ultrasound-assisted and traditional caustic leaching of spent cathode carbon (SCC) from aluminum electrolysis[J]. Ultrasonics Sonochemistry, 2018, 40(A):21-29.

[43] Wang Y, Peng J, Di Yuezhong. Separation and recycling of spent carbon cathode blocks in the aluminum industry by the vacuum distillation process[J]. JOM, 2018, 70(9):1877-1882. doi: 10.1007/s11837-018-2858-4

[44] 张宏忠, 王利, 胡慧丽, 等. 电解铝大修渣无害化处理研究[J]. 无机盐工业, 2017, 49(4):46-50. ZHANG H Z, WANG L, HU H L, et al. Research on the harmless treatment of electrolytic aluminum overhaul slag[J]. Inorganic Salt Industry, 2017, 49(4):46-50.

[45] Lamas W D Q, Palau J C F, Camargo J R D. Waste materials co-processing in cement industry: Ecological efficiency of waste reuse[J]. Renewable and Sustainable Energy Reviews, 2013, 19:200-207. doi: 10.1016/j.rser.2012.11.015

[46] Grillo Reno M L, Torres F M, Da Silva R J, et al. Exergy analyses in cement production applying waste fuel and mineralizer[J]. Energy Conversion and Management, 2013, 75:98-104. doi: 10.1016/j.enconman.2013.05.043

[47] 李帅, 刘万超, 杨刚, 等. 铝电解废槽衬处理技术现状[J]. 无机盐工业, 2020, 52(5):6-10. LI S, LIU W C, YANG G, et al. The status quo of treatment technology of aluminum electrolysis waste tank lining[J]. Inorganic Salt Industry, 2020, 52(5):6-10. doi: 10.11962/1006-4990.2019-0379

[48] Ghenai C, Inayat A, Shanableh A, et al. Combustion and emissions analysis of Spent Pot lining (SPL) as alternative fuel in cement industry[J]. Science of the Total Environment, 2019, 684:519-526. doi: 10.1016/j.scitotenv.2019.05.157

[49] 高康宁, 晁波阳, 申文斌, 等. 电解铝厂大修渣污染分析与防治对策[J]. 资源节约与环保, 2017(8):134. GAO K N, CHAO B Y, SHEN W B, et al. Pollution analysis and prevention countermeasures of overhaul slag in electrolytic aluminum plant[J]. Resource Conservation and Environmental Protection, 2017(8):134.

[50] B P. Treatment and reuse of spent pot lining, an industrial application in a cement kiln[J]. Metals & Materials Society, 2013.

[51] 李建伟, 马炎, 张春光, 等. 赤泥制备免烧砖的研究现状及技术要点探讨[J]. 矿产综合利用, 2019(3):7-10. LI J W, MA Y, ZHANG C G, et al. The research status and technical points of the preparation of burn-free bricks from red mud[J]. Multipupose Utilization of Mineral Resources, 2019(3):7-10.

[52] 包惠明, 傅涛. 赤泥的综合利用现状分析[J]. 矿产综合利用, 2018(5):6-12. BAO H M, FU T. Analysis of the status quo of the comprehensive utilization of red mud[J]. Multipupose Utilization of Mineral Resources, 2018(5):6-12.

[53] Xie W, Zhou F, Liu J, et al. Synergistic reutilization of red mud and spent pot lining for recovering valuable components and stabilizing harmful element[J]. Journal of Cleaner Production, 2020, 243:118624. doi: 10.1016/j.jclepro.2019.118624

-

下载:

下载: