Influence of Vanadium Tailings from Stone Coal on Sintering Brick for Building

-

摘要:

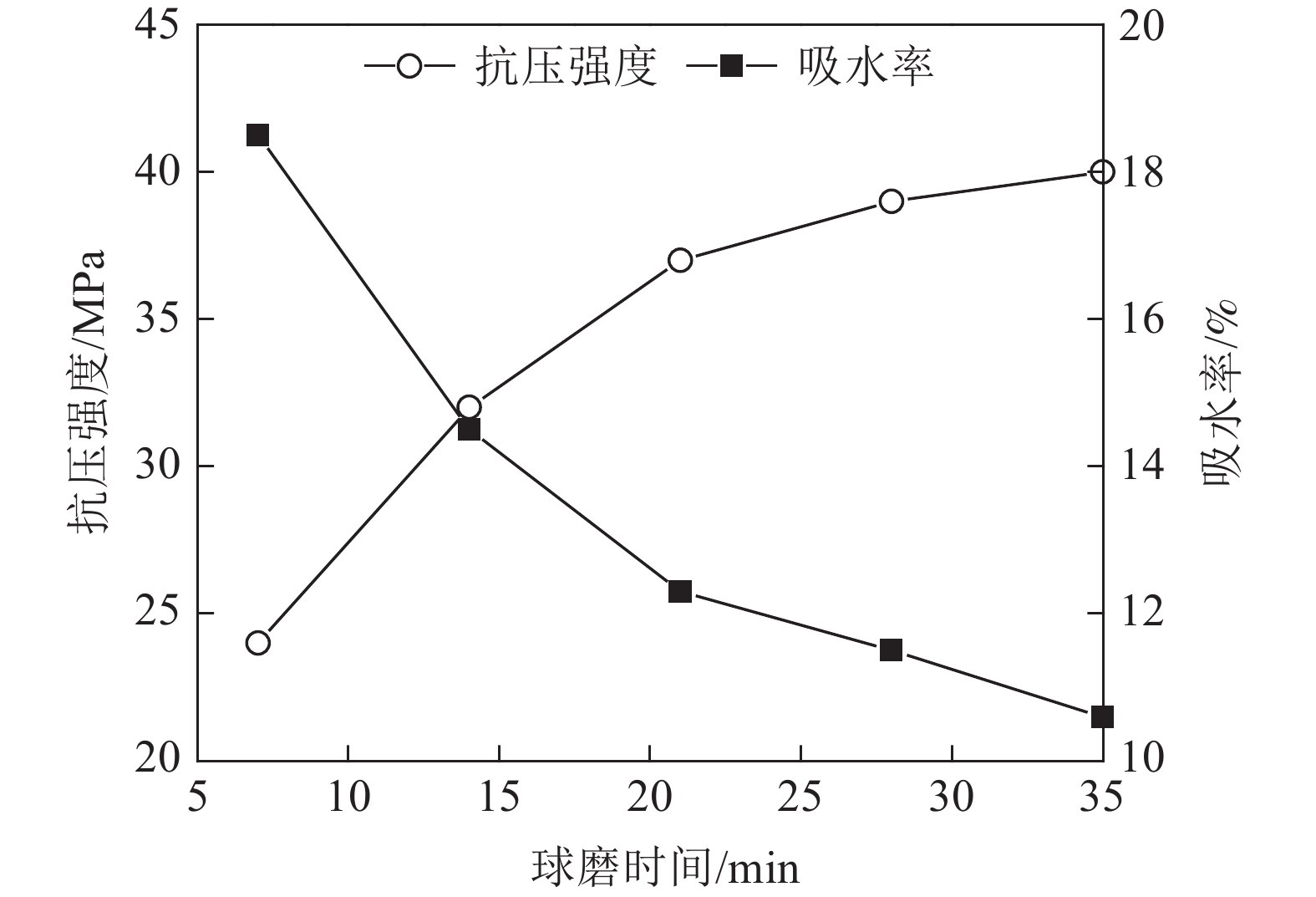

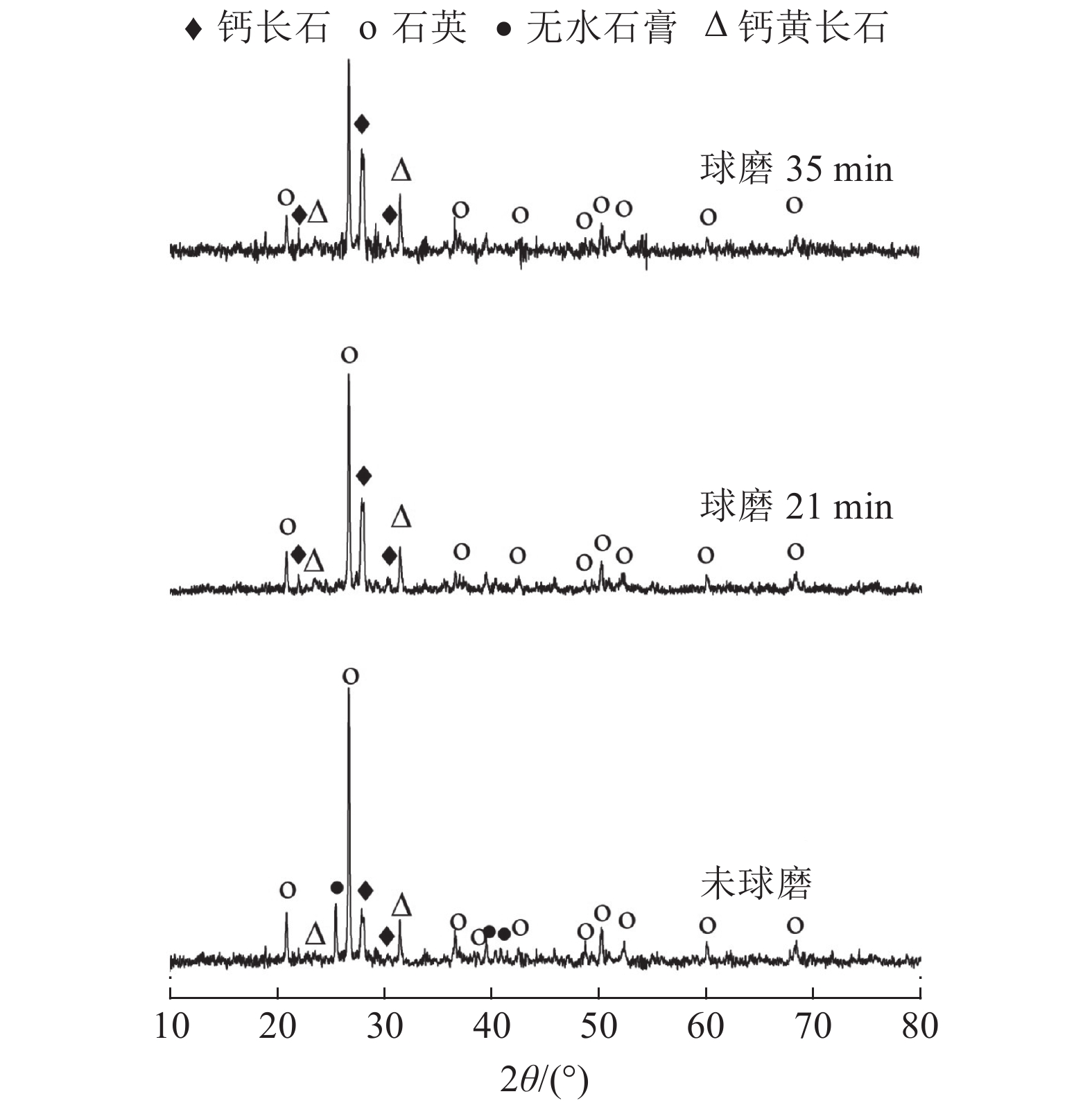

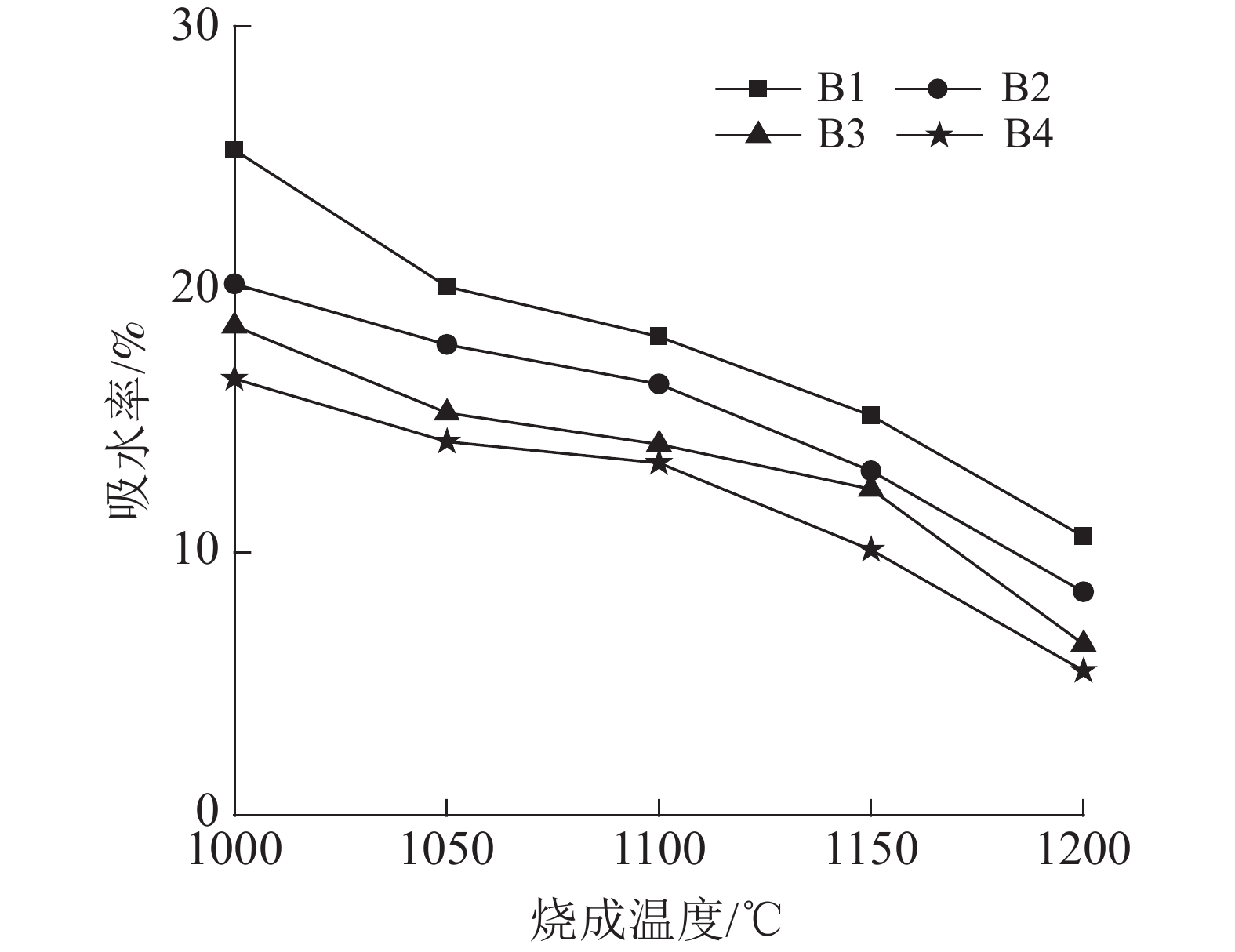

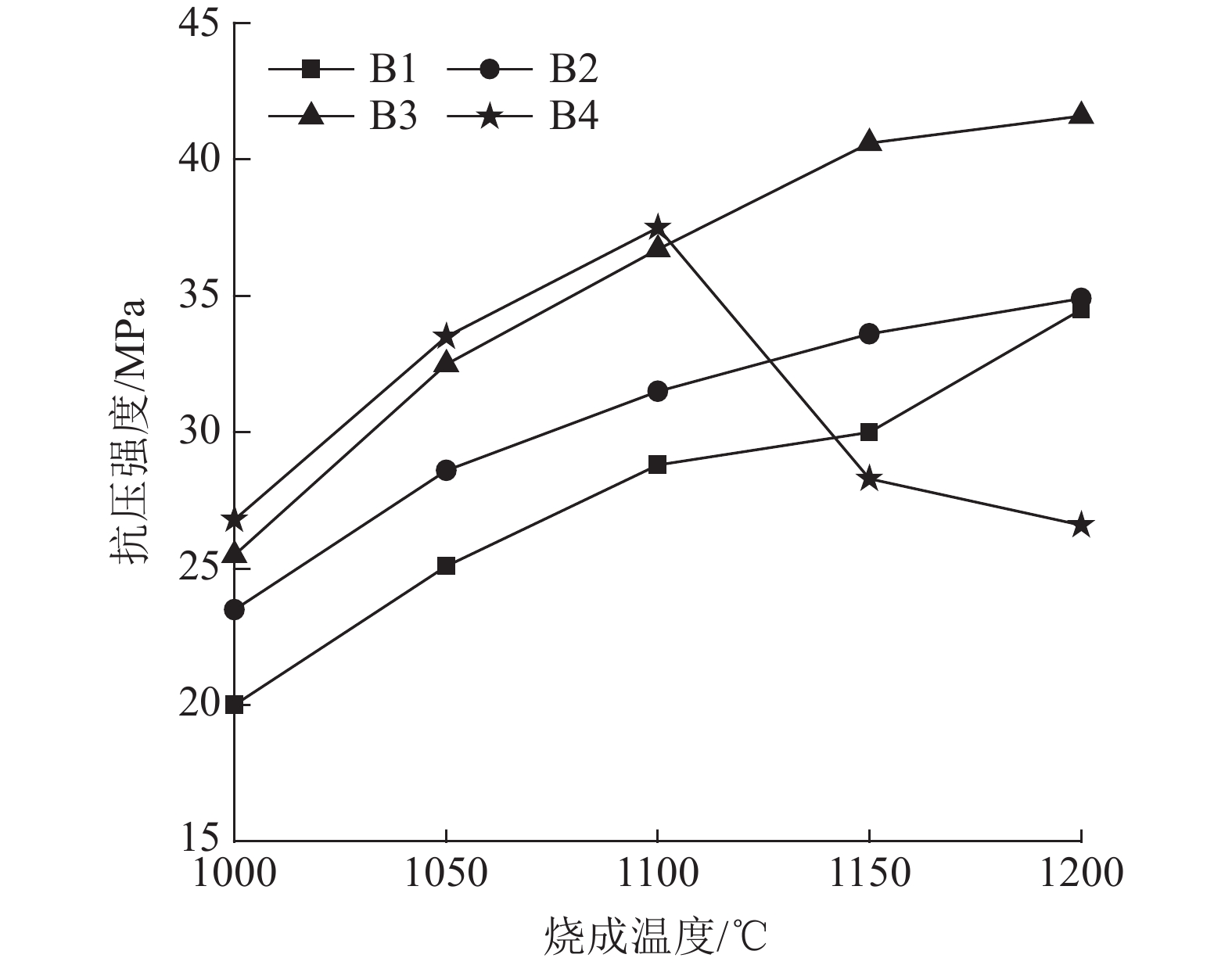

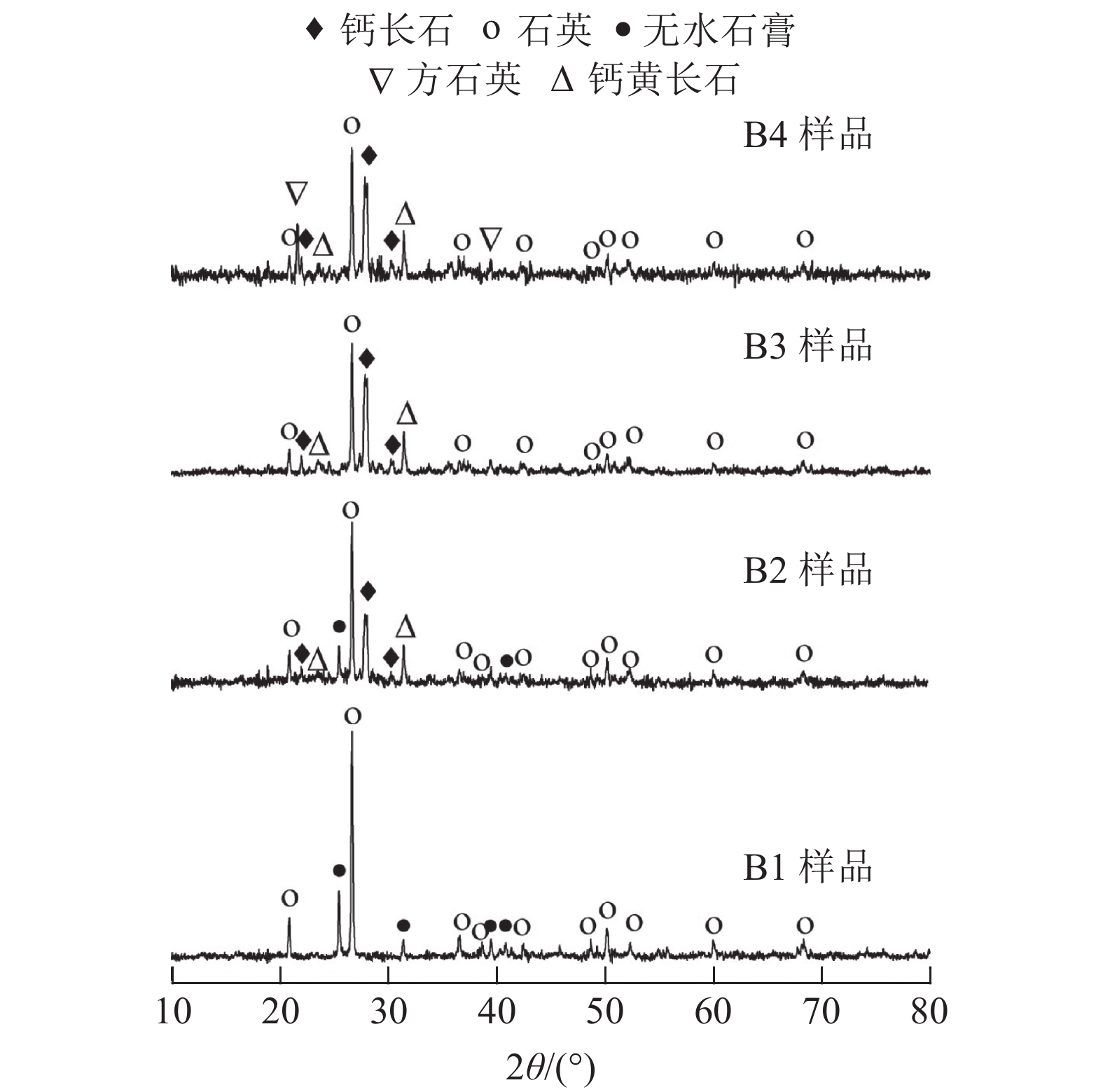

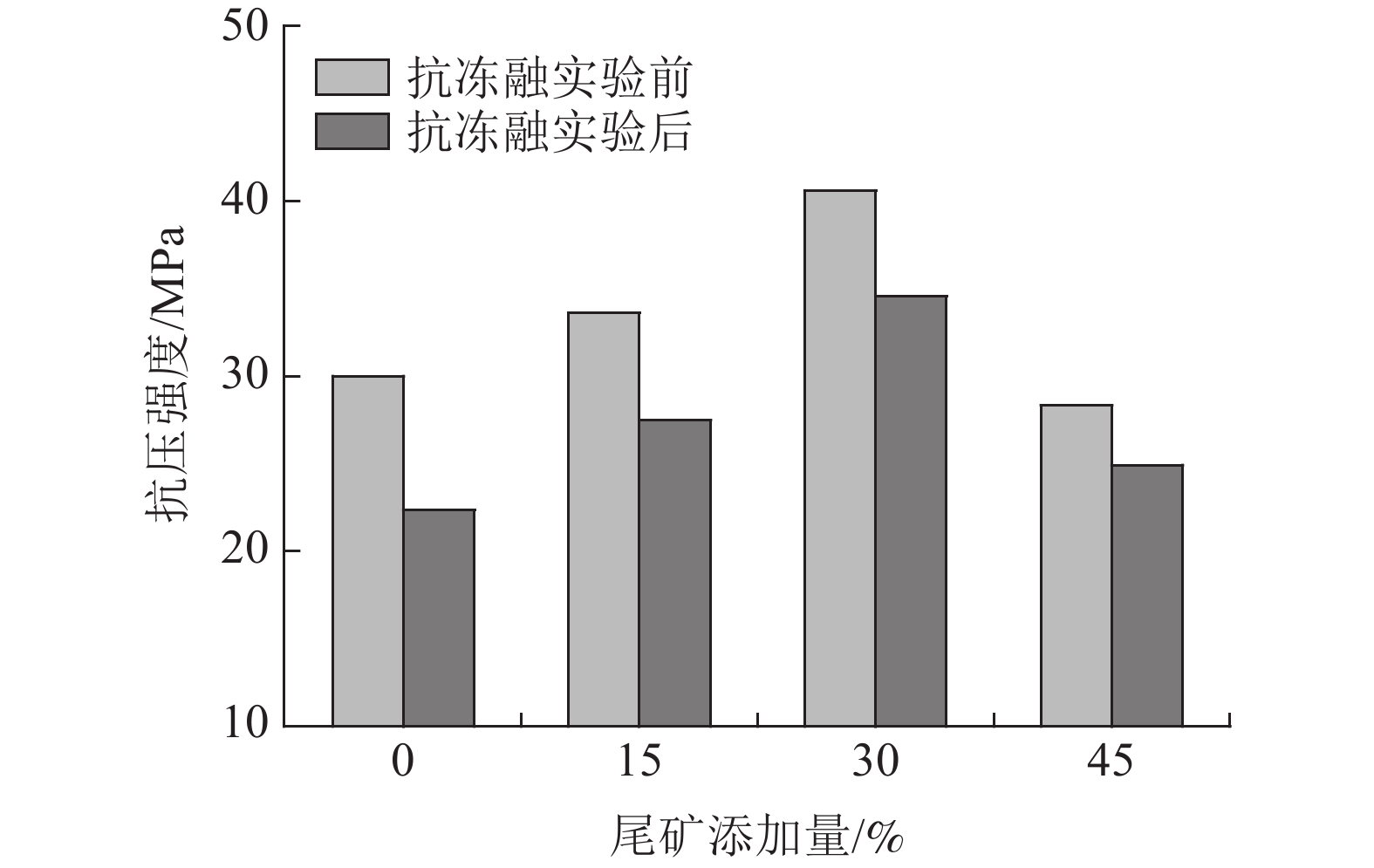

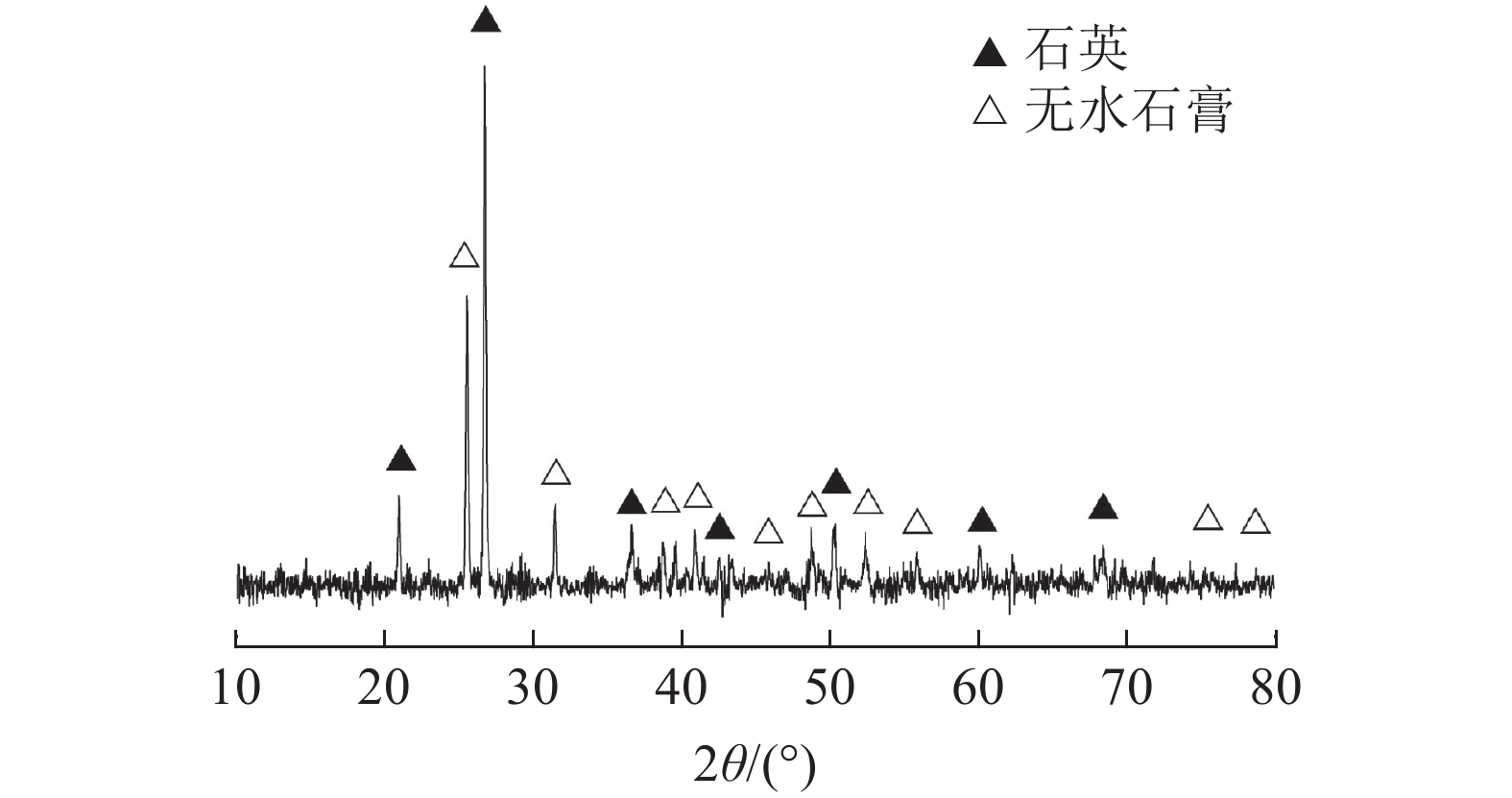

本研究以石煤提钒尾渣为原料制备了建筑用烧结砖,研究了石煤提钒尾渣细度及添加量对制品抗压强度及吸水率的影响,采用XRD和SEM表征手段分析了石煤提钒尾渣添加量调控烧结砖相组成与显微结构的机理,检测了制品的抗冻融性与使用安全性。结果表明:提高尾渣细度改善了样品的致密度与抗压强度,引入尾渣使样品的抗压强度先增大后减小。B3样品(尾渣:黏土:粉煤灰=30: 30: 40)经1150 oC烧成后,其抗压强度≥35 MPa,吸水率小于≤13%,综合性能满足《烧结普通砖》(GB/T 5101-2003)中Mu30的要求。XRD与SEM分析表明,添加15%~30%尾渣有利于生成液相,促进钙长石与钙黄长石的生成,晶粒与液相相互胶结,使制品具有较高的抗压强度与致密度及较好的抗冻融性能。

Abstract:Fired bricks for building were prepared from the tailings of vanadium extraction from stone coal. The influences of fineness and addition of tailing on the water absorption and compressive strength of samples were investigated. The mechanism of tailoring the phase compositions and microstructures of samples by tailing addition was analyzed by XRD and SEM. The freeze-thaw resistance and utilization safety of the products were tested. The results showed increasing the tailing fineness enhanced the microstructure densification and compressive strength, which firstly increased and then decreased after increasing tailing addition. B3 sample (tailings∶Clay∶fly ash = 30∶30∶40) fired at 1150 ℃ had the compressive strength of ≥35 MPa and the water absorption of ≤ 13%. The comprehensive properties meet the requirements of the Mu30 standard in the《sintered ordinary bricks》(GB/T 5101-2003). XRD and SEM analysis showed that adding 15%~30% tailing was beneficial to the formation of glass phase and promote the production of anorthite as well as anorthosite. Grain and liquid phase are cemented with each other, thus endowing the products with high compressive strength, microstructure densification, and good freeze-thaw resistance.

-

-

表 1 原料的化学组成/ %

Table 1. Chemical composition of raw materials

样品 SiO2 Al2O3 CaO MgO Fe2O3 K2O Na2O BaO ZnO V2O5 IR 共计 尾渣 63.26 12.24 8.56 3.06 4.14 1.52 0.94 1.25 1.58 0.01 3.44 100.00 黏土 56.98 19.67 0.12 1.25 4.21 1.18 0.94 1.17 1.16 - 13.32 100.00 粉煤灰 45.28 32.56 2.56 0.67 2.57 1.64 0.58 1.10 1.97 - 11.07 100.00 表 2 样品的配方组成

Table 2. Formula composition of samples

样品编号 质量配比/% 尾渣 黏土 粉煤灰 B1 0 60 40 B2 15 45 40 B3 30 30 40 B4 45 15 40 表 3 经不同时间球磨后,尾渣中-0.074 mm的百分含量

Table 3. -0.074 mm particle content in tailing after milling for different time

球磨时间/min 7 14 21 28 35 -0.074 mm含量/ % 48.63 75.22 88.56 95.63 97.89 表 4 样品冻融实验后的强度损失率

Table 4. Strength loss rate of samples after freeze-thaw test

样品编号 B1 B2 B3 B4 强度损失率/% 25.56 18.23 14.89 11.94 表 5 烧结砖中的重金属浸出浓度/(mg·L-1)

Table 5. Leaching concentration of heavy metals from sintered bricks

名称 Cu Pb Cd V Cr Ba Zn 含量 0.01 0.01 0.02 - 0.01 0.26 0.64 标准值 <3.00 <5.00 <1.00 <1.00 <15.00 <1.00 <100.00 -

[1] 史政良, 严海军, 周玉娟. 甘肃某石煤钒矿焙烧灰渣综合利用工艺研究[J]. 矿产综合利用, 2020(3):158-163. SHI Z L, YAN H J, ZHOU Y J. Study on comprehensive utilization technology of sulphate roasting ash and slag of vanadium ore from stone coal in Gansu province[J]. Multipurpose Utilization of Mineral Resources, 2020(3):158-163. doi: 10.3969/j.issn.1000-6532.2020.03.027

[2] Arbi K, Palomo A, Fernández-Jiménez A. Alkali-activated blends of calcium aluminate cement and slag/diatomite[J]. Ceramics International, 2018, 39(8):9237-9245.

[3] Xu X, Lao X, Wu J, et al. Microstructural evolution, phase transformation, and variations in physical properties of coal series kaolin powder compact during firing[J]. Applied Clay Science, 2015, 115:76-86. doi: 10.1016/j.clay.2015.07.031

[4] 焦向科, 张一敏, 陈铁军, 等. 利用低活性钒尾矿制备地聚合物的研究[J]. 非金属矿, 2011, 34(4):1-4. JIAO X K, ZHANG Y M, CHEN T J, et al. Preparation of geopolymer from vanadium tailings with low activity[J]. Nonmetal Minerals, 2011, 34(4):1-4. doi: 10.3969/j.issn.1000-8098.2011.04.001

[5] 罗立群, 王召, 魏金明, 等. 铁尾矿-煤矸石-污泥复合烧结砖的制备与特性[J]. 中国矿业, 2018(3):127-131. LUO L Q, WANG Z, WEI J M, et al. Preparation and characteristics of iron tailings coal gangue sludge composite sintered brick[J]. China Mining, 2018(3):127-131.

[6] 刘俊杰, 梁 钰, 曾 宇, 等. 利用铁尾矿制备免烧砖的研究[J]. 矿产综合利用, 2020(5):136-141. LIU J J, LIANG Y, ZENG Y, et al. Preparation of baking-free bricks by iron tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(5):136-141. doi: 10.3969/j.issn.1000-6532.2020.05.021

[7] 汪朋, 韩兵强, 柯昌明, 等. 以高钛型高炉渣提钛后尾渣为结合剂的刚玉浇注料性能研究[J]. 钢铁钒钛, 2016, 37(4):76-82. WANG P, HAN B Q, KE C M, et al. Study on properties of corundum castable with high titanium blast furnace slag tailings as binder[J]. Steel Vanadium and Titanium, 2016, 37(4):76-82. doi: 10.7513/j.issn.1004-7638.2016.04.015

[8] 刘强, 潘志华, 李庆彬, 等. 钙长石系轻质隔热砖的制备及钙长石形成过程[J]. 硅酸盐通报, 2010, 29(6):1269-1274. LIU Q, PAN Z H, LI Q B, et al. Preparation of anorthite series lightweight thermal insulation brick and formation process of anorthite[J]. Silicate Bulletin, 2010, 29(6):1269-1274. doi: 10.16552/j.cnki.issn1001-1625.2010.06.027

[9] 林亚梅, 李翠伟, 汪长安. 莫来石含量对钙长石/莫来石复相多孔陶瓷组织结构与性能的影响[J]. 无机材料学报, 2011, 26(10):1095-1100. LIN Y M, LI C W, WANG C A. Effect of mullite content on microstructure and properties of anorthite/mullite multiphase porous ceramics[J]. Acta Inorganic Materials, 2011, 26(10):1095-1100. doi: 10.3724/SP.J.1077.2011.01095

[10] 李亮, 彭富昌. 浇注法制备提钒尾渣多孔陶瓷试验研究[J]. 钢铁钒钛, 2017, 3(38):84-88. LI L, PENG F C. Experimental study on preparation of porous ceramics from vanadium extraction tailings by casting method[J]. Steel Vanadium and Titanium, 2017, 3(38):84-88.

-

下载:

下载: