Characteristic Study on Water Absorption and Dehydration of 4A Molecular Sieve

-

摘要:

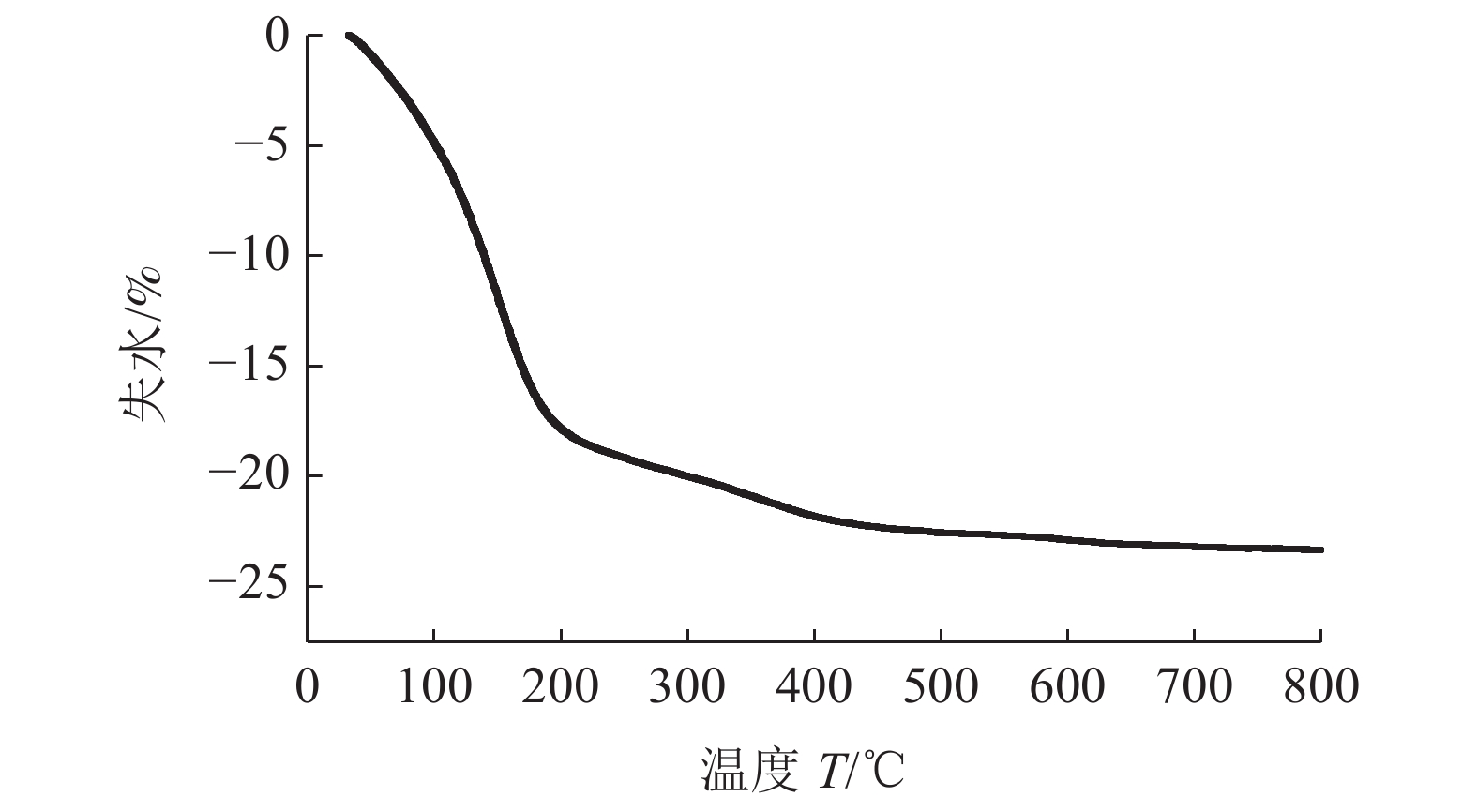

这是一篇陶瓷复合材料领域的论文。为了解4A分子筛在吸水脱水过程中水含量分布特征,采用高温脱水与低温吸水计算方法,探讨了不同脱附温度与气氛下4A分子筛水含量分布,结果表明,脱附温度为200~230 ℃时,在非真空气氛脱附时,有效残留水含量为4%~5%,有效脱附水含量达到了24%~25%,吸水率为83%~87%;在真空气氛下脱附时,有效残留水含量为1%~2%,有效脱附水含量达到了27%~28%,吸水率为93%~97%。为了使有效残留水含量低于2%,较佳脱附再生条件为真空气氛、脱附温度不低于200 ℃。采用差热失重法可以估算分子筛在非真空气氛下的有效脱水含量与有效残余水含量。真空脱附后样品吸水速率大于非真空脱附的吸水速率。

Abstract:This is a paper in the field of ceramics and composites. In order to understand the water content distribution characteristics of 4A molecular sieve in the process of water absorption and dehydration, the calculation methods of high temperature dehydration and low temperature water absorption were used to discuss the water content distribution of 4A molecular sieve under different desorption temperature and atmosphere. The results showed that when the desorption temperature was 200~230 ℃, the effective residual water was 4%~5%, the effective desorption water was 24%~25% and the water absorption was 83%~87% in the non vacuum air desorption under vacuum, the effective residual water was 1%~2%, the effective desorption water was 27%~28%, and the water absorption is 93%~97%. In order to make the effective residual water content less than 2%, the best desorption regeneration conditions are vacuum atmosphere and desorption temperature not less than 200 ℃.The effective dewater and residual water of molecular sieve in non vacuum atmosphere can be estimated by differential thermal analysis. The water absorption rate of the sample after vacuum desorption is higher than that of the sample without vacuum desorption.

-

-

[1] 国家发展和改革委员会. SY/T 0076-2008. 天然气脱水设计规范[S]. 北京: 石油工业出版社, 2008.

National Development and Reform Commission. SY/T 0076-2008. Design specification for natural gas dehydration[S]. Beijing: Petroleum Industry Press, 2008.

[2] 胡晓敏, 陆永康, 曾亮泉. 分子筛脱水工艺简述[J]. 天然气与石油, 2008, 26(1):39-41. HU X M, LU Y K, ZENG L Q. A brief description of molecular sieve dehydration process[J]. Natural Gas and Petroleum, 2008, 26(1):39-41.

HU X M, LU Y K, ZENG L Q. A brief description of molecular sieve dehydration process[J]. Natural Gas and Petroleum, 2008, 26(1): 39-41.

[3] 梁政, 李双双, 张力文, 等. CNG脱水用4A分子筛再生性能实验研究[J]. 石油与天然气化工, 2014(4):362-365. LIANG Z, LI S S, ZHANG L W, et al. Experimental study on regeneration performance of 4A molecular sieve for CNG dehydration[J]. Chemical Engineering of Oil and Gas, 2014(4):362-365.

LIANG Z, LI S S, ZHANG L W, et al. Experimental study on regeneration performance of 4A molecular sieve for CNG dehydration[J]. Chemical Engineering of Oil and Gas, 2014(4): 362-365.

[4] 杨上闰, 徐军, 王爱军. NaA沸石分子筛吸水性能的研究[J]. 石油化工, 1992(10):667-670. YANG S R, XU J, WANG A J. Study of water absorption properties of NaA zeolite molecular sieve[J]. Petrochemicals, 1992(10):667-670.

YANG S R, XU J, WANG A J. Study of water absorption properties of NaA zeolite molecular sieve[J]. Petrochemicals, 1992(10): 667-670.

[5] Muller J C M, Hakvoort G, Jansen J C. DSC and TG study of water adosorption and desorption on zeolite NaA powder and and attached as layer on metal[J]. Journal of Thermal Analysis and Calorimetry. 1998, 53: 449-466.

[6] Jain S. Proper regeneration of molecular sieves in TSA processes[J]. Hydrocarbon Processing. 2018(4): 1-7.

[7] Gramlich V, Meier W M. The crystal structure of hydrated NaA: a detailed refinement of a pseudosymmetric zeolite structure[J]. Zeitschrift fur Kristallographie -new crystal structures. 1971, 133: 134-149.

-

下载:

下载: