Research on Mineral Processing Technology of Ultrafine Ilmenite Resources in Panzhihua-Xichang Area

-

摘要:

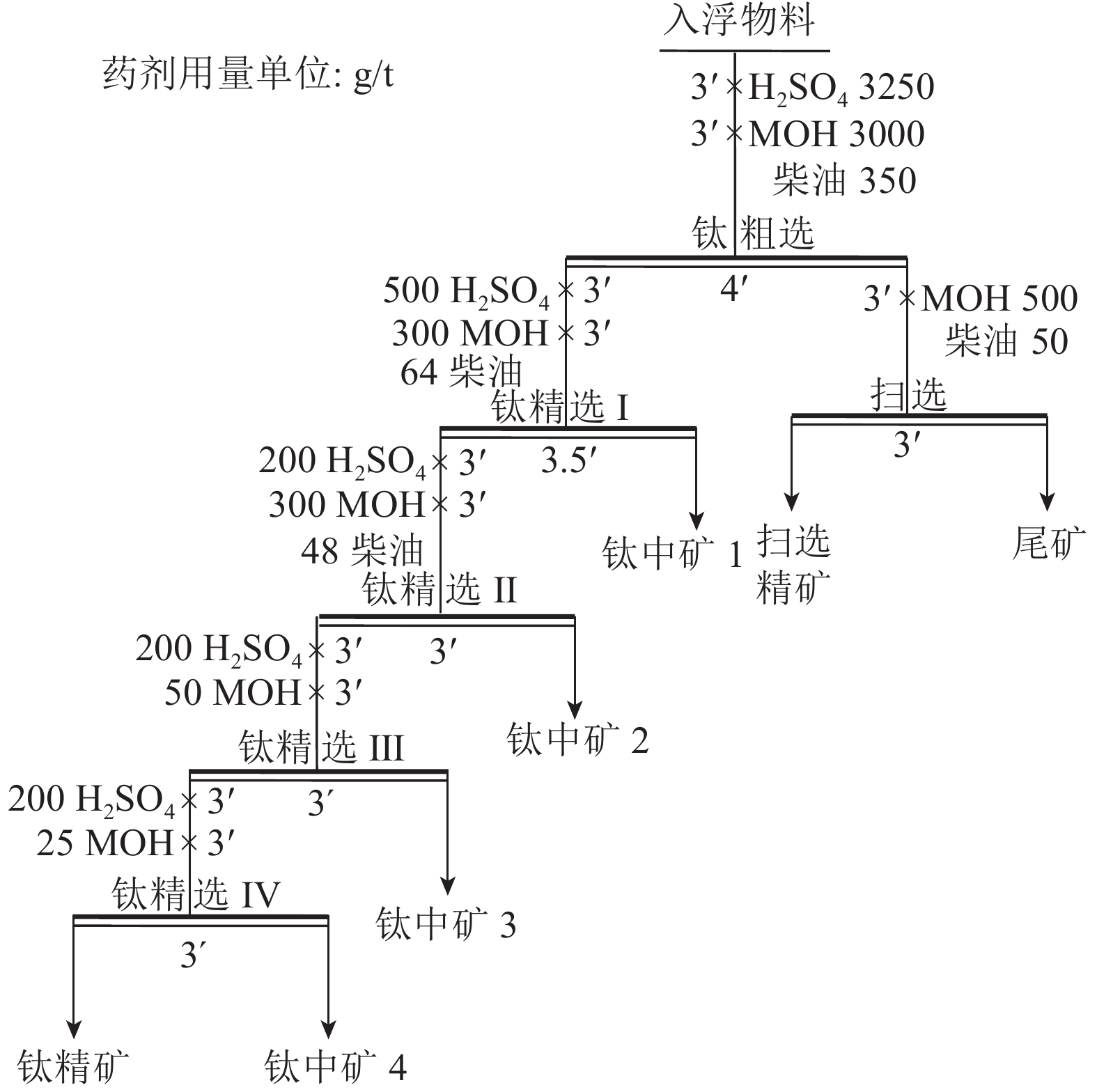

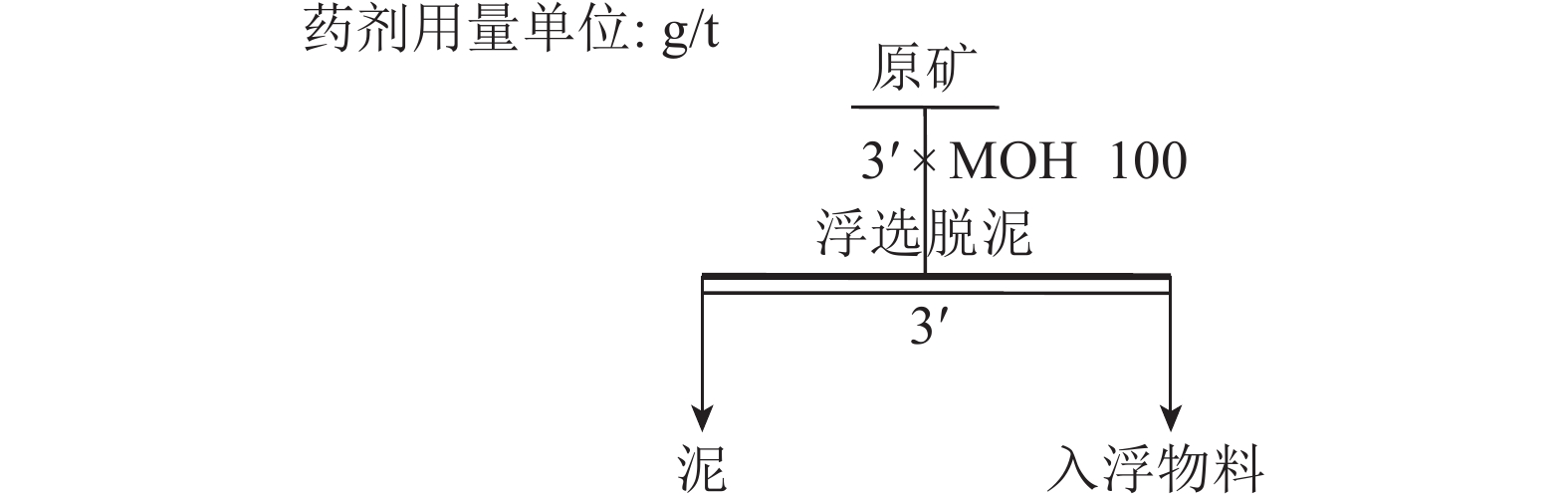

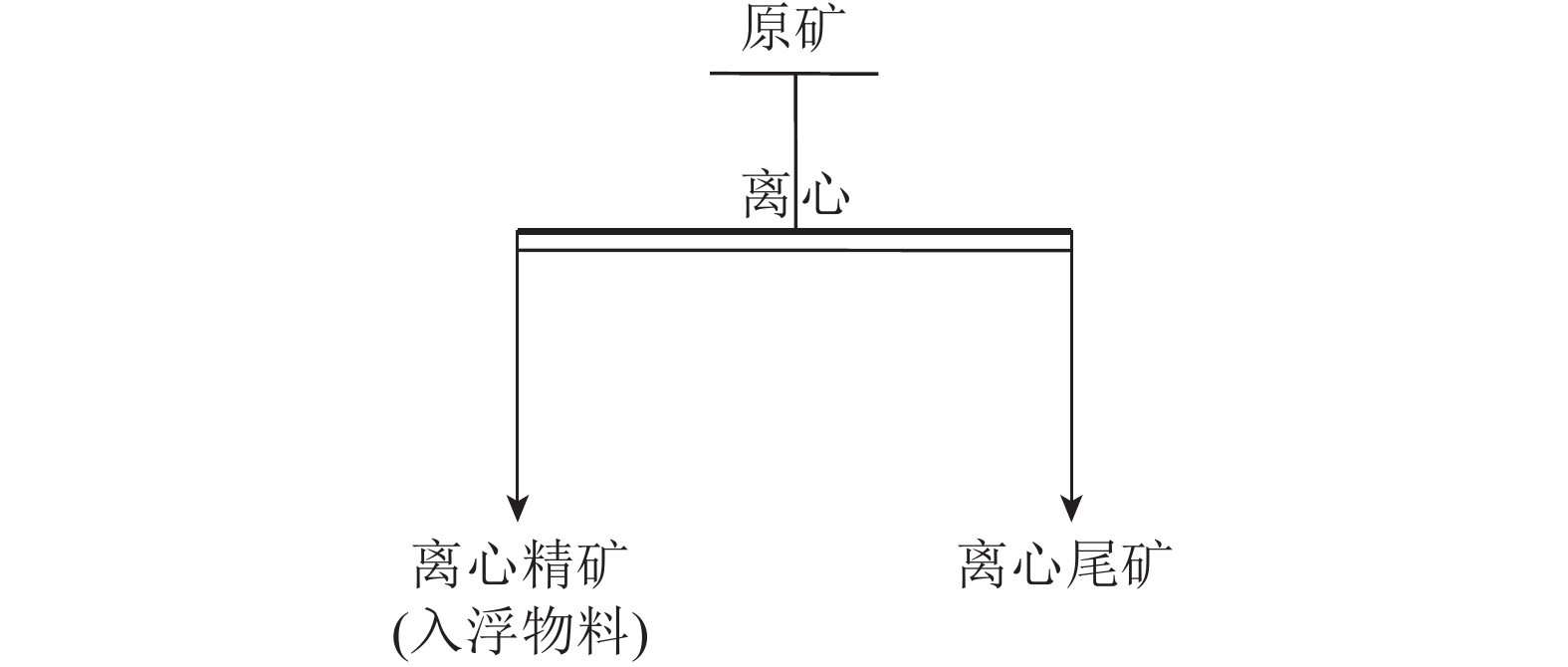

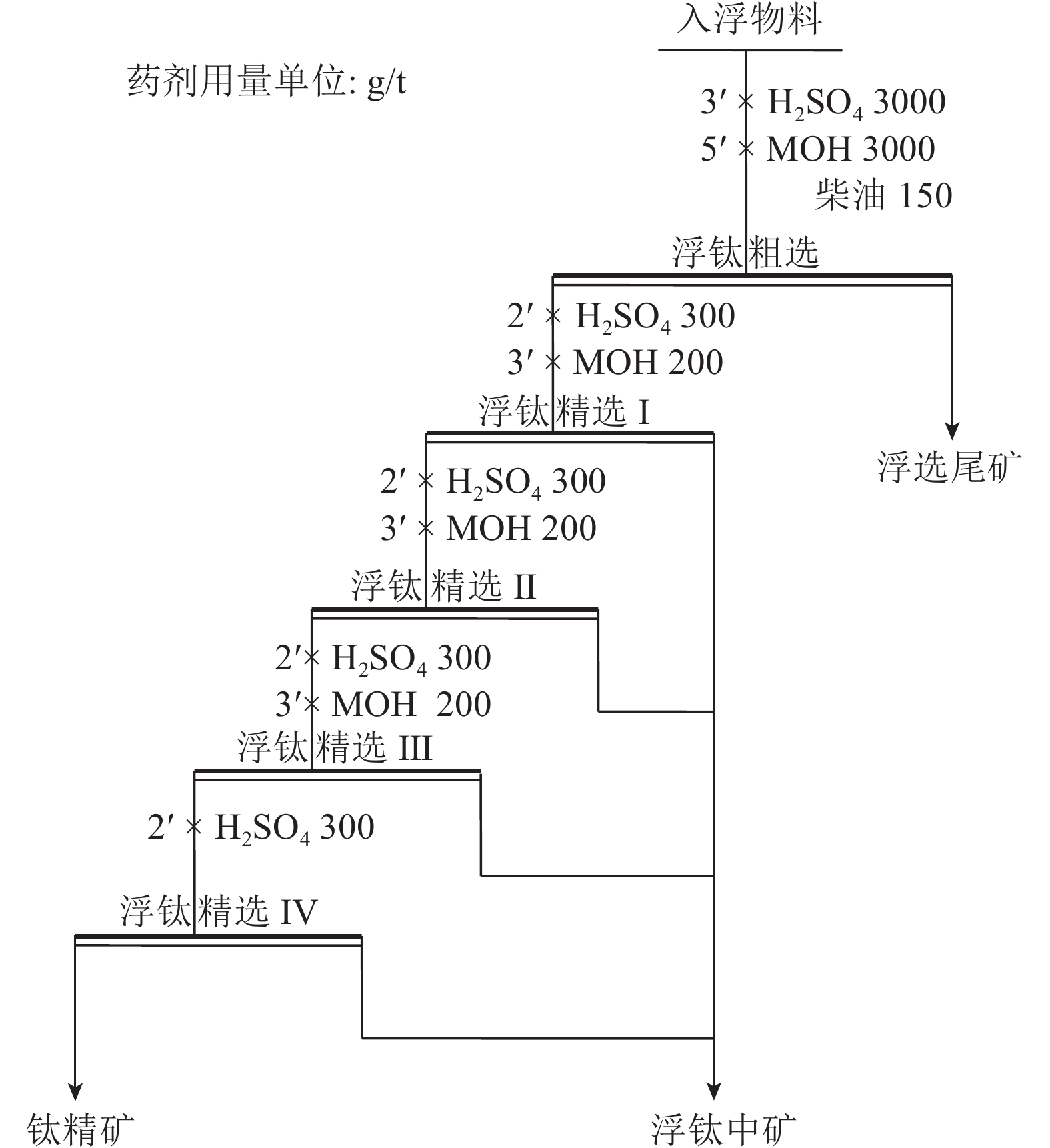

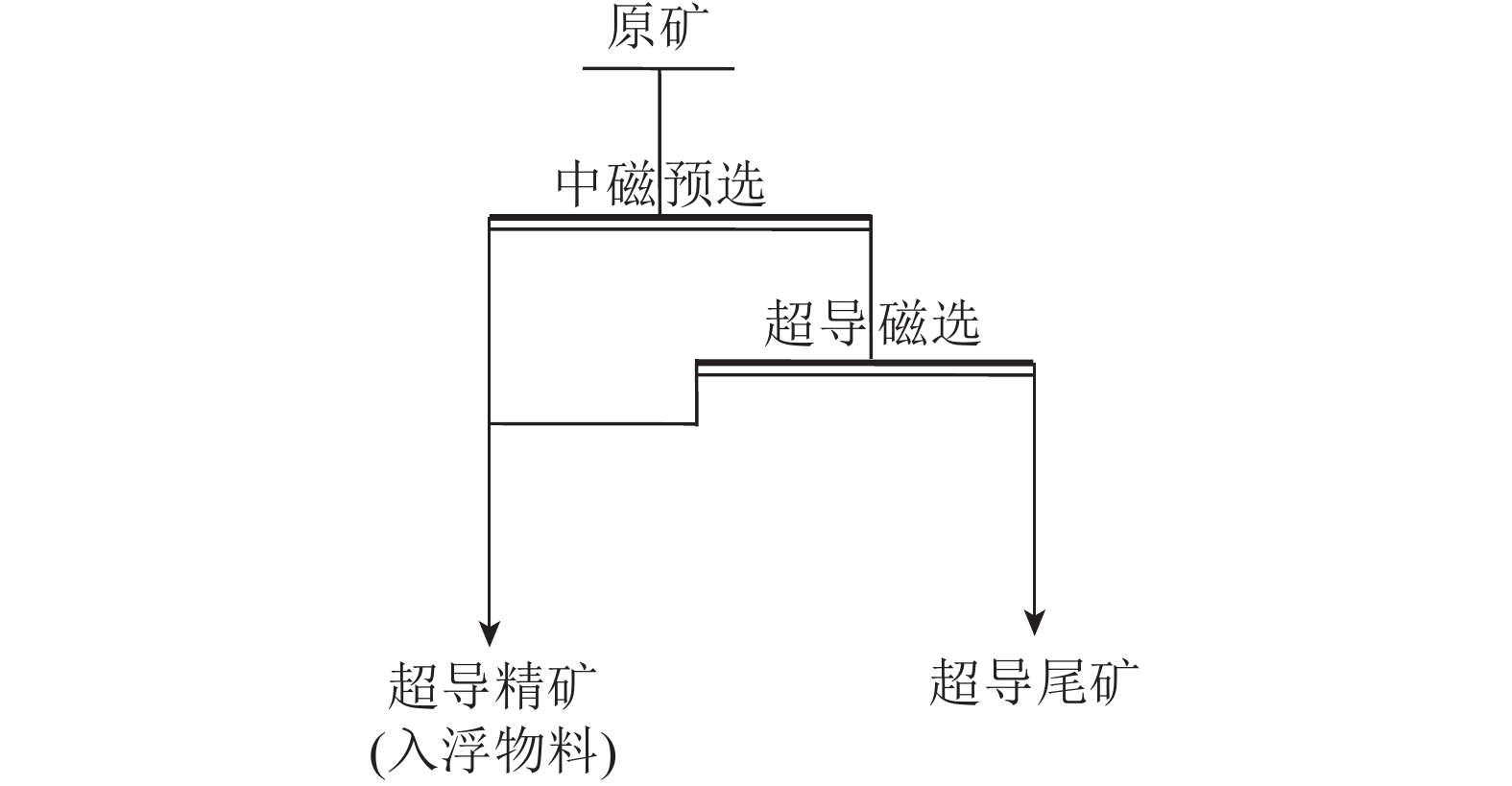

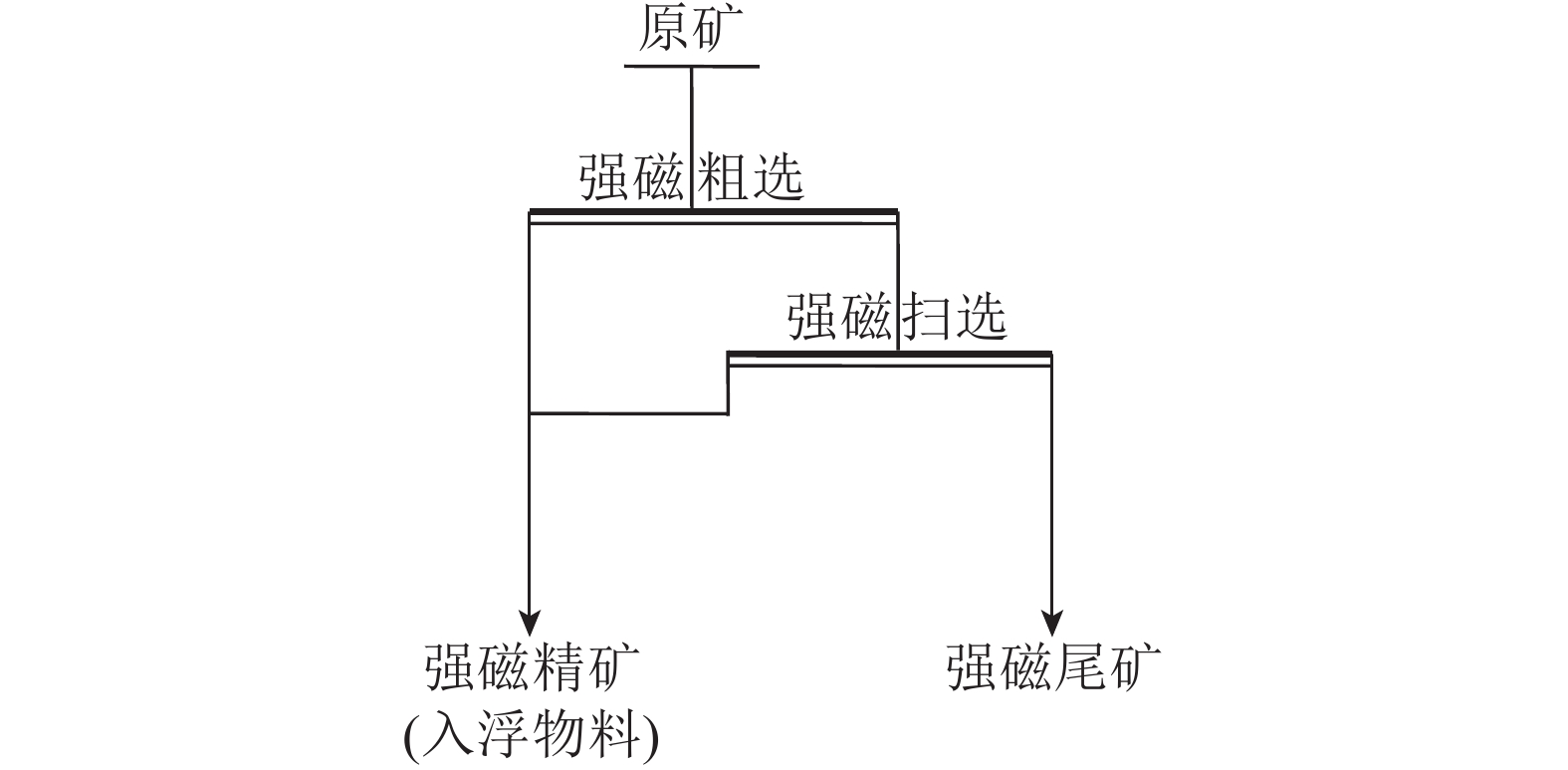

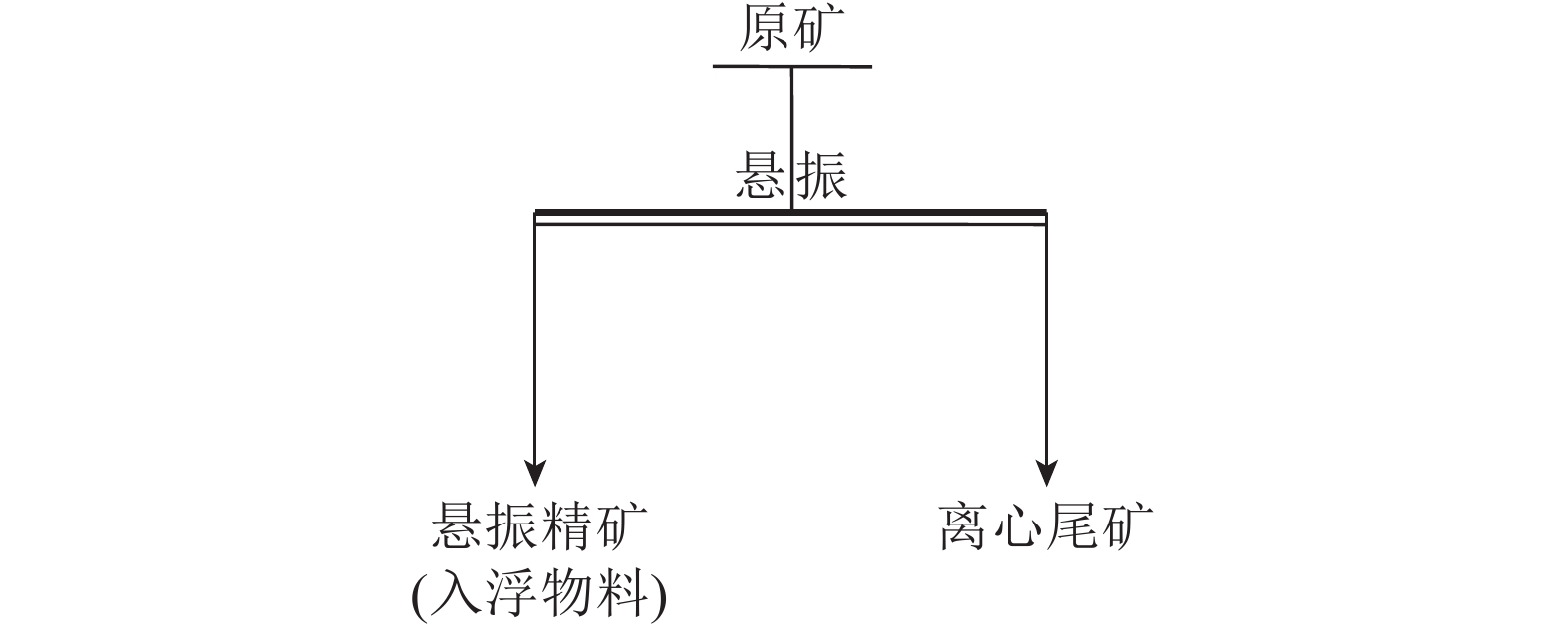

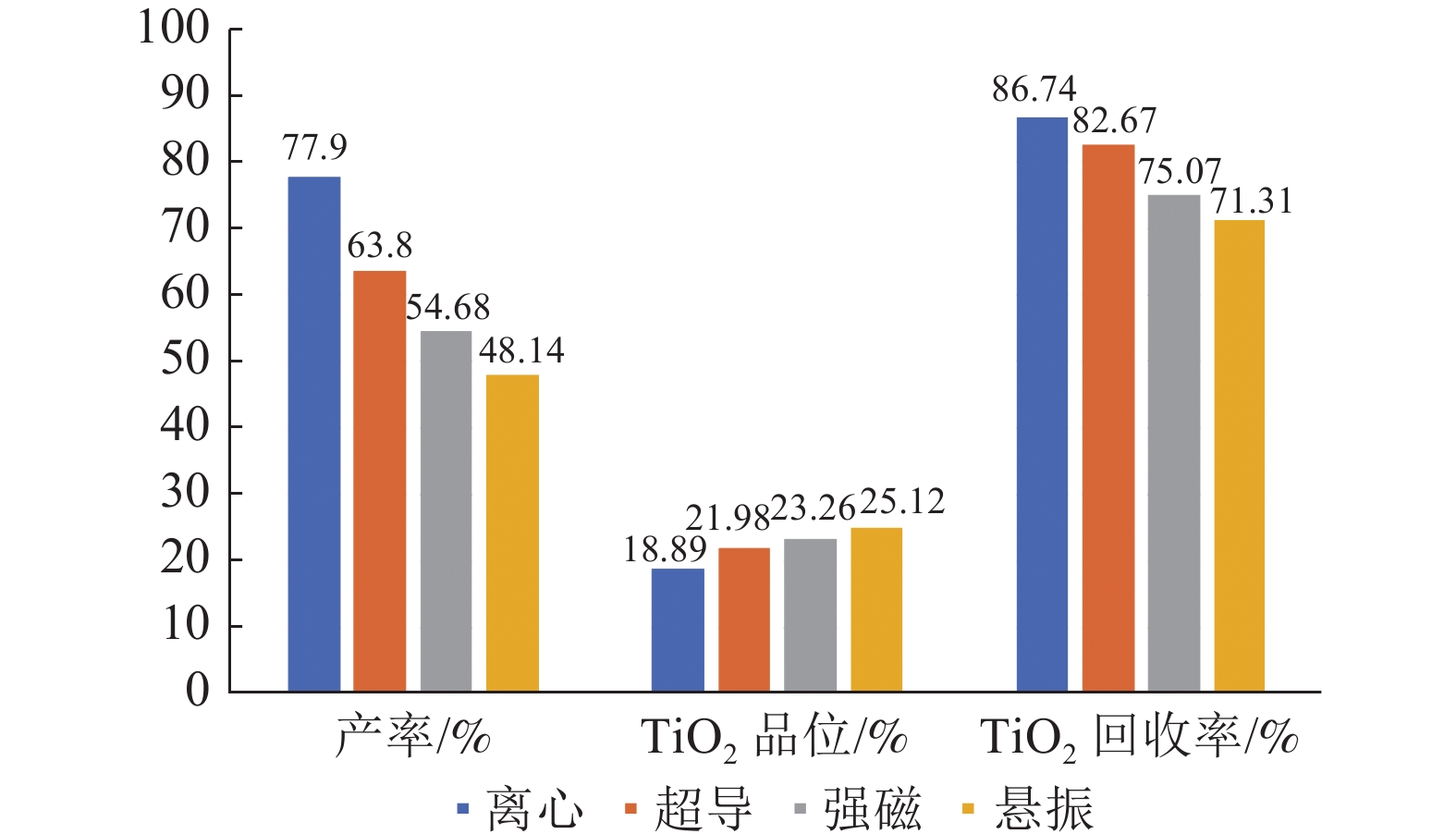

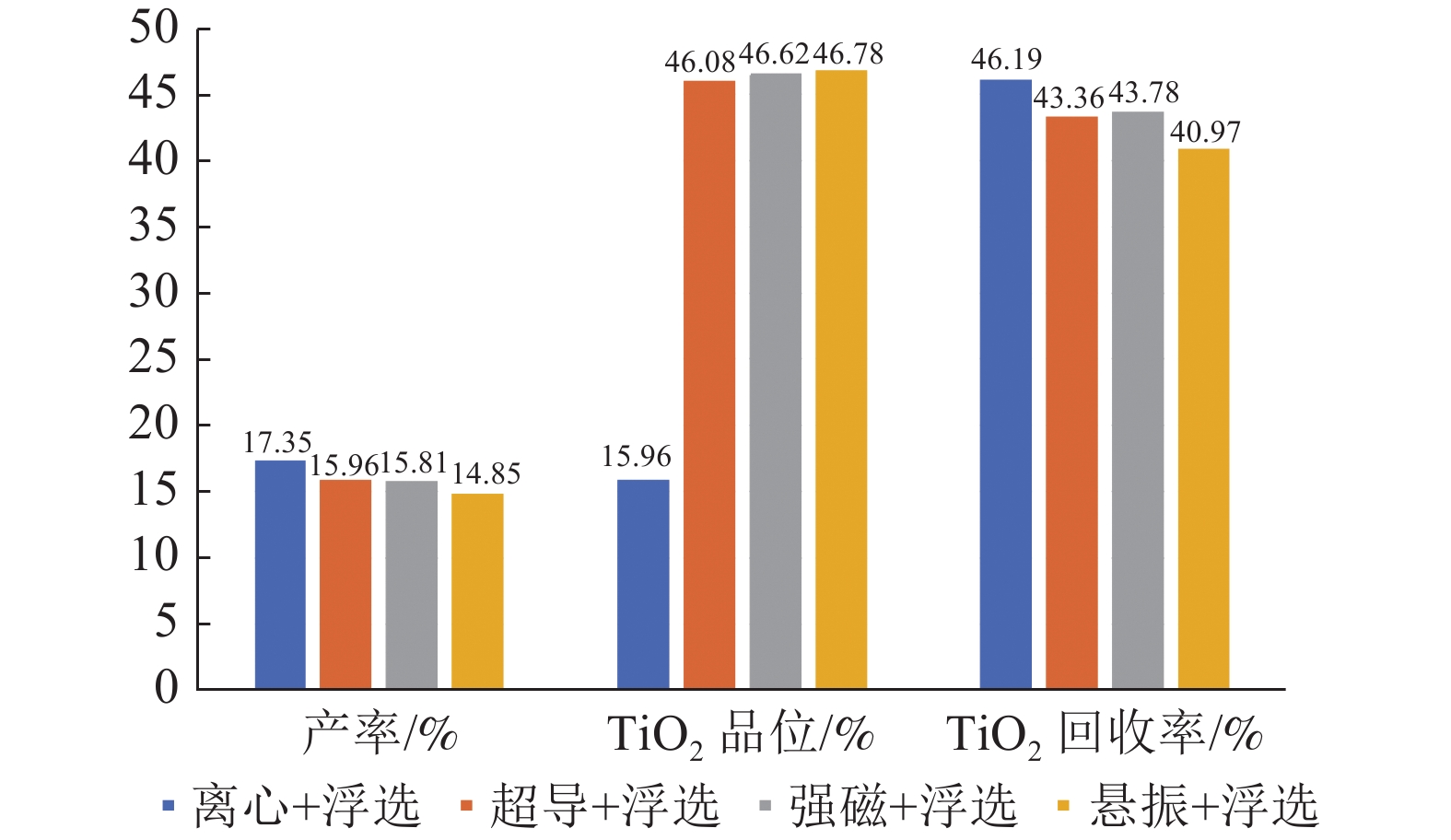

这是一篇矿物加工工程领域的论文。针对攀西地区某选矿厂的超微细粒级钛铁矿难回收的问题,进行了浮选工艺流程的对比研究。采用直接浮选、脱泥-浮选、 “离心-浮选”、“超导-浮选”、“强磁-浮选”、“悬振-浮选”等选矿工艺流程,试验结果表明:直接浮选和脱泥-浮选工艺无法获得TiO2品位大于46%的钛精矿产品;悬振和强磁选可以获得品位较高的预富集精矿,有利于后续浮选作业,离心和超导可以获得回收率较高的预富集精矿,可保证钛铁矿的有效回收。但考虑到超导预富集工艺工业实施投入大、目前尚无成熟工业案例;而强磁选和悬振预富集工艺易于工业化实施,但悬振选矿机的单机处理能力有限。因此,最终确定最优选矿工艺为“强磁-浮选”,可获得钛精矿品位46.62%,开路浮选作业回收率58.32%,全流程回收率43.78%的指标。

Abstract:This is an essay in the field of mineral processing engineering. Aiming at the problem of difficult recovery of ultrafine ilmenite from a concentrator in Panzhihua-Xichang Area, a comparative study of flotation process was carried out. Using direct flotation, desliming flotation, "centrifugal-flotation", "superconducting flotation", "strong magnetic flotation", "suspension vibration-flotation" and other beneficiation processes, the test results show that: direct flotation and desliming flotation processes can not obtain titanium concentrate products with TiO2 grade greater than 46%. Suspension vibration and high intensity magnetic separation can obtain higher grade preenriched concentrate, which is conducive to the subsequent flotation operation. Centrifugation and superconductivity can obtain higher recovery of preenriched concentrate, which can ensure the effective recovery of ilmenite. But considering that superconducting preenrichment technology industry implementation investment is large, there is no mature industrial case at present; The high intensity magnetic separation and suspended vibration preconcentration process are easy to be industrialized, but the single processing capacity of the suspended vibration separator is limited. Therefore, the optimal flotation process was finally determined to be "strong magnetic flotation", which could obtain the index of titanium concentrate grade of 46.62%, recovery rate of 58.32% in open flotation operation and recovery rate of 43.78% in the whole process.

-

-

表 1 原矿的多元素化学分析结果/%

Table 1. Multi-element chemical analysis results of raw ore

TFe TiO2 S SiO2 Al2O3 CaO MgO Al2O3 Na2O 其他 16.31 16.94 0.34 28.94 5.71 8.32 11.88 5.71 0.60 5.25 表 2 原矿筛分分析结果

Table 2. Screening analysis results of raw ore

粒级/mm 产率/% 品位/% 分布率/% TiO2 TFe TiO2 TFe +0.045 0.39 4.22 12.11 0.10 0.29 -0.045+0.028 6.75 6.04 11.08 2.41 4.58 -0.028+0.019 13.65 12.35 14.31 9.95 11.97 -0.019+0.010 37.17 17.22 16.35 37.79 37.25 -0.010 42.05 20.04 17.81 49.75 45.91 原矿 100.00 16.94 16.31 100.00 100.00 表 3 原矿中主要矿物的含量/%

Table 3. Content of main minerals in raw ore

钛磁铁矿 钛铁矿 黄铁矿 橄榄石 辉石 绿泥石 斜长石 其他 3.7 32.37 0.22 9.84 39.65 5.63 2.31 6.28 表 4 主要矿物解离度数据/%

Table 4. Dissociation data for major minerals

矿物 解离

度钛铁

矿黄铁

矿铬尖

晶石赤铁

矿磷灰

石一水硬

铝石黄铜

矿榍石 方解

石钙钛

矿石英 橄榄

石透辉

石角闪

石黑云

母绿泥

石长石 绿帘

石误差 钛铁矿 75.84 0 0.01 0.06 0.01 0.01 0.03 0.01 0.46 0.02 0.02 0 0.32 15.36 0.83 0.45 1.01 2.76 0.03 2.77 黄铁矿 69.97 1.38 0 0 0 0.12 0.1 0.05 0.3 0 0 0 0.56 19.65 0.89 0.71 2.01 2.15 0 2.11 橄榄石 81.51 1.11 0.02 0.01 0.19 0 0 0 0.09 0.02 0 0 0 7.59 0.83 0.26 0.9 1.09 0.03 6.36 透辉石 80.51 4.87 0.06 0.06 0.06 0.03 0.02 0.02 0.28 0.04 0.02 0.01 0.7 0 2.16 0.59 1.35 1.53 0.07 7.63 长石 63.73 7.44 0.06 0.07 0.03 0.04 0.02 0.01 0.3 0.05 0.02 0.02 0.86 13.02 2.32 1.16 1.4 0 0.23 9.24 表 5 直接浮选实验结果

Table 5. Test results of traditional flotation

产品名称 产率/% TiO2品位/% TiO2回收率/% 钛精矿 17.74 39.96 41.74 中矿4 2.50 25.77 3.79 中矿3 3.58 16.13 3.82 中矿2 7.22 15.90 7.61 中矿1 9.41 16.18 8.96 扫选精矿 19.66 11.46 16.74 尾矿 39.90 7.38 17.35 原矿 100.00 16.98 100.00 表 6 脱泥-浮选实验结果

Table 6. Test results of desliming and flotation

产品名称 产率/% TiO2品位/% TiO2回收率/% 钛精矿 17.12 42.24 42.76 钛中矿4 2.17 34.18 4.38 钛中矿3 3.25 20.77 3.99 钛中矿2 5.55 16.64 5.46 钛中矿1 9.44 10.82 6.04 扫选精矿 10.93 16.78 10.84 矿泥 19.32 15.14 17.30 尾 矿 32.22 4.85 9.24 给 矿 100.00 16.92 100.00 表 7 离心-浮选实验结果

Table 7. Test results of centrifugal-flotation

产品名称 产率/% TiO2品位/% TiO2回收率/% 离心尾矿 22.10 10.18 13.26 离心精矿 钛精矿 77.90 17.35 18.89 45.17 86.74 46.19 浮钛中矿 42.22 14.45 35.95 浮选尾矿 18.33 4.25 4.59 原矿 100.00 16.97 100.00 表 8 超导-浮选实验结果

Table 8. Test results of superconductivity-flotation

产品名称 产率/% TiO2品位/% TiO2回收率/% 超导尾矿 36.20 8.12 15.41 超导精矿 钛精矿 63.80 15.96 21.98 46.08 82.67 43.36 浮钛中矿 32.98 18.28 34.47 浮选尾矿 15.86 5.18 4.84 原矿 100.00 16.96 100.00 表 9 强磁-浮选实验结果

Table 9. Test results of high intensity magnetic flotation

产品名称 产率/% TiO2品位/% TiO2回收率/% 强磁尾矿 45.32 9.32 24.93 强磁精矿 钛精矿 54.68 15.91 23.26 46.62 75.07 43.78 浮钛中矿 25.49 18.60 27.99 浮选尾矿 13.28 4.21 3.30 原矿 100.00 16.94 100.00 表 10 悬振+浮选试验结果

Table 10. Test results of suspension vibration + flotation

产品名称 产率/% TiO2品位/% TiO2回收率/% 悬振尾矿 51.86 9.38 28.69 悬振精矿 钛精矿 48.14 35.27 14.85 25.12 32.84 46.78 71.31 68.32 40.97 浮钛中矿 20.42 22.71 27.35 浮选尾矿 12.87 3.95 2.99 原矿 100.00 16.96 100.00 -

[1] 严伟平, 曾小波. 攀西地区钒钛磁铁矿资源开发利用水平评估方法研究[J]. 矿产综合利用, 2020(6):79-83. YAN W P, ZENG X B. Study on the evaluation method of development and utilization level of vanadium-titanium magnetite mine in Panxi district[J]. Multipurpose Utilization of Mineral Resources, 2020(6):79-83. doi: 10.3969/j.issn.1000-6532.2020.06.014

YAN W P, ZENG X B. Study on the evaluation method of development and utilization level of vanadium-titanium magnetite mine in Panxi district[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 79-83. doi: 10.3969/j.issn.1000-6532.2020.06.014

[2] 惠 博, 杨耀辉. 攀西红格矿区橄辉岩型钒钛磁铁矿矿石性质研究及对选矿工艺的影响[J]. 矿产综合利用, 2020(4):126-129. HUI B, YANG Y H. Properties of olive-pyroxene vanadium-titanium magnetite ore in Hongge mining area of Panxi research and influence on mineral processing technology[J]. Multipurpose Utilization of Mineral Resources, 2020(4):126-129. doi: 10.3969/j.issn.1000-6532.2020.04.021

HUI B, YANG Y H. Properties of olive-pyroxene vanadium-titanium magnetite ore in Hongge mining area of Panxi research and influence on Mineral Processing Technology[J]. Multipurpose Utilization of Mineral Resources, 2020(4): 126-129. doi: 10.3969/j.issn.1000-6532.2020.04.021

[3] 叶恩东, 吴轩. 攀西钛精矿主要杂质元素赋存状态研究[J]. 钢铁钒钛, 2017, 38(4):63-68. YE E D, WU X. Research of the occurrence state of the main impurities in Panxi ilmenite[J]. Iron Steel Vanadium Titanium, 2017, 38(4):63-68. doi: 10.7513/j.issn.1004-7638.2017.04.013

YE E D, WU X. Research of the occurrence state of the main impurities in Panxi ilmenite[J]. Iron Steel Vanadium Titanium, 2017, 38(4): 63-68. doi: 10.7513/j.issn.1004-7638.2017.04.013

[4] 吴本羡. 攀西地区钛铁矿的工艺特征[J]. 矿产综合利用, 1987(1):74-79. WU B X. Technological characteristics of ilmenite in Panzhihua-Xichang area[J]. Multipurpose Utilization of Minerals, 1987(1):74-79.

WU B X. Technological characteristics of ilmenite in Panzhihua-Xichang area[J]. Comprehensive Utilization of Minerals, 1987 (1): 74-79.

[5] 曹玉川, 黄光耀, 刘星. -38 μm粒级钛铁矿高效回收试验研究[J]. 矿冶工程, 2012, 32(4):48-50. CAO Y C, HUANG G Y, LIU X. Study on high-efficiency recovery of ultrafine ilmenite( - 38 μm)[J]. Mining and Metallurgical Engineering, 2012, 32(4):48-50. doi: 10.3969/j.issn.0253-6099.2012.04.013

CAO Y C, HUANG G Y, LIU X. Study on high-efficiency recovery of ultrafine ilmenite( - 38 um)[J]. Mining and Metallurgical Engineering, 2012, 32(4): 48-50. doi: 10.3969/j.issn.0253-6099.2012.04.013

[6] 谢泽君. 选钛厂细粒钛铁矿浮选探讨[J]. 攀钢技术, 1998(6):24-28. XIE Z J. Discussion on flotation of fine ilmenite from titanium separation plant[J]. Pangang Technology, 1998(6):24-28.

XIE Z J. Discussion on flotation of fine ilmenite from titanium separation plant[J]. Pangang Technology, 1998(6): 24-28.

[7] 余家华, 刘洪贵. 国内外钛矿和富钛料生产现状及发展趋势[J]. 世界有色金属, 2003(6):4-8. YU J H, LIU H G. Status quo of production of titanium ores and concentrates at home and abroad and trend of development[J]. World Nonferrous Metals, 2003(6):4-8.

YU J H, LIU H G. Status quo of production of titanium ores and concentrates at home and abroad and trend of development[J]. World Nonferrous Metals, 2003(6): 4-8.

[8] Chen L, Ren N, Xiong D. Experimental studyon performance of continuous centrifugal concentrator in reconcentrating fine hematite[J]. International Journal of Mineral Processing, 2008, 87(1/2):9-16.

[9] Xiong D. Research and commercialization of treatment of fine ilmenite. with Slon magnetic separators[J]. Magnetic and Elictrical Separation, 2000, 4(10):121-127.

[10] 张松, 杨波. 悬振锥面选矿机的工业应用现状[J]. 矿产综合利用, 2019(3):22-26. ZHANG S, YANG B. Industrial application status of hang and vibrate of cone concentrator[J]. Multipurpose Utilization of Mineral Resources, 2019(3):22-26. doi: 10.3969/j.issn.1000-6532.2019.03.005

ZHANG S, YANG B. Industrial application status of hang and vibrate of cone concentrator[J]. Multipurpose Utilization of Mineral Resources, 2019(3): 22-26. doi: 10.3969/j.issn.1000-6532.2019.03.005

[11] 闫艳军. 白云鄂博共伴生矿高梯度超导磁选预富集工艺研究[D]. 包头: 内蒙古科技大学, 2019.

YAN Y J. Study on Preconcentration of Bayan Obo associated ore using high gradient superconducting magnetic separation [D]. Baotou: Inner Mongolia University of Science and Technology, 2019.

-

下载:

下载: