Mineral Processing of Low Grade Beryllium Ores in the Jiulong Area of Western Sichuan

-

摘要:

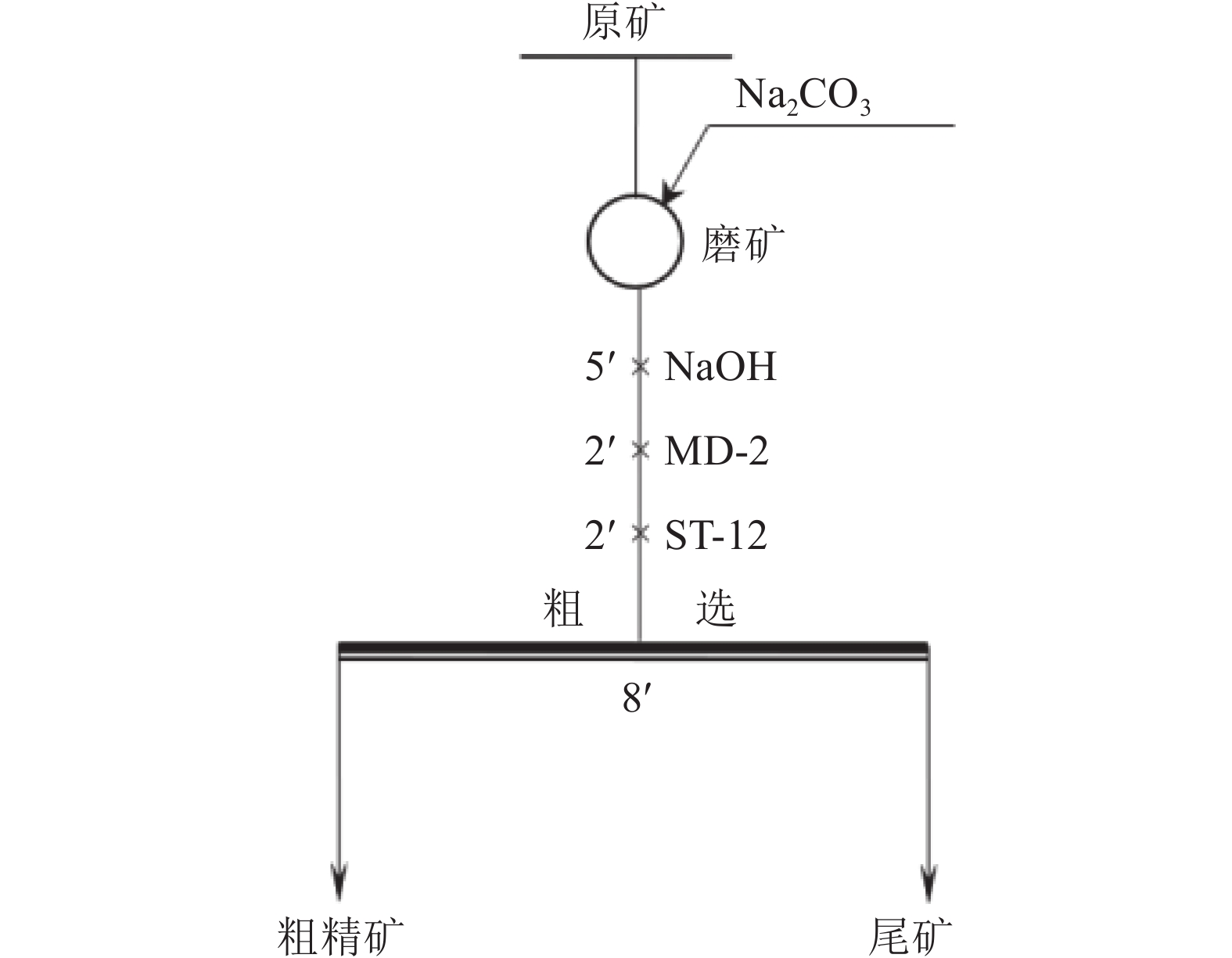

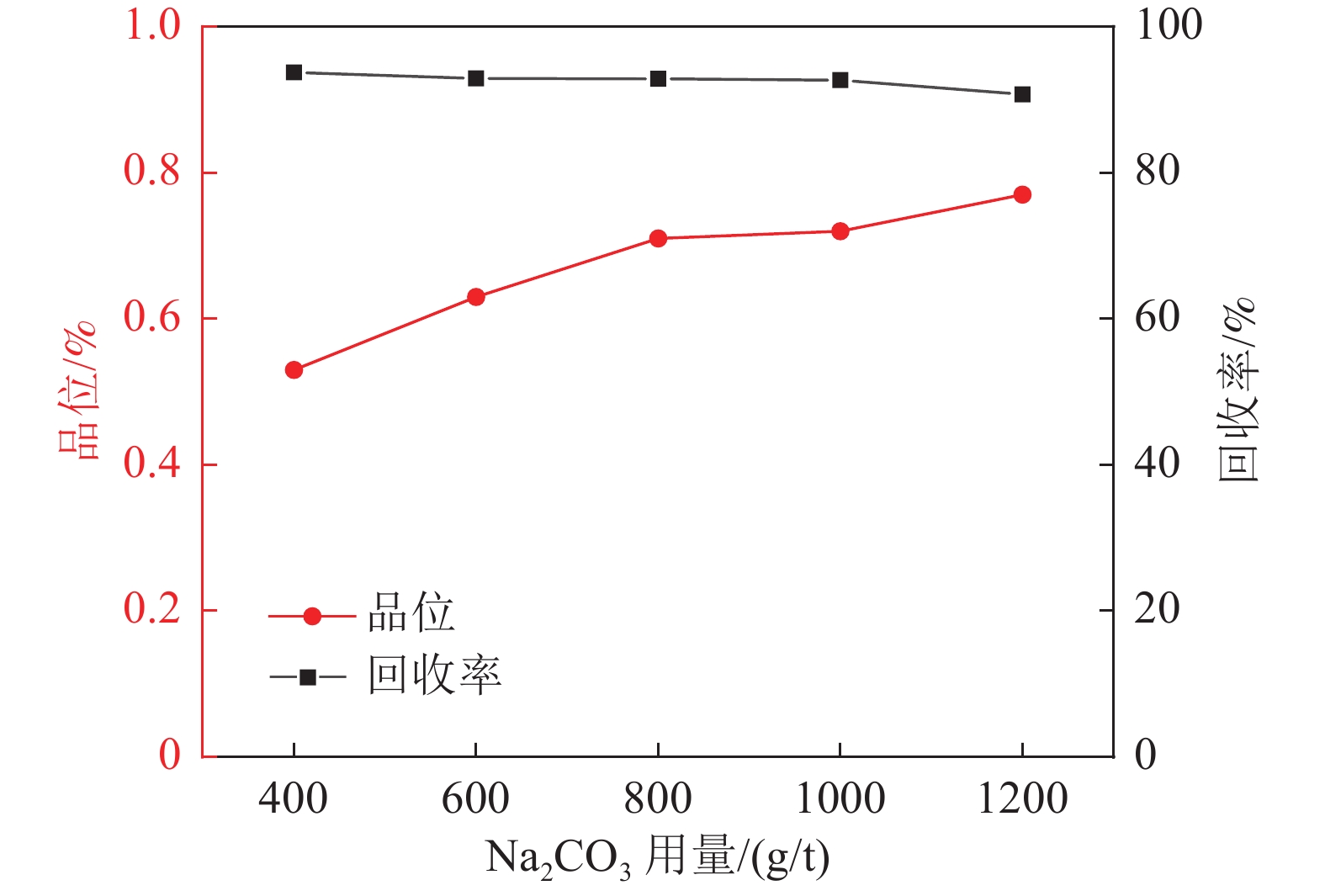

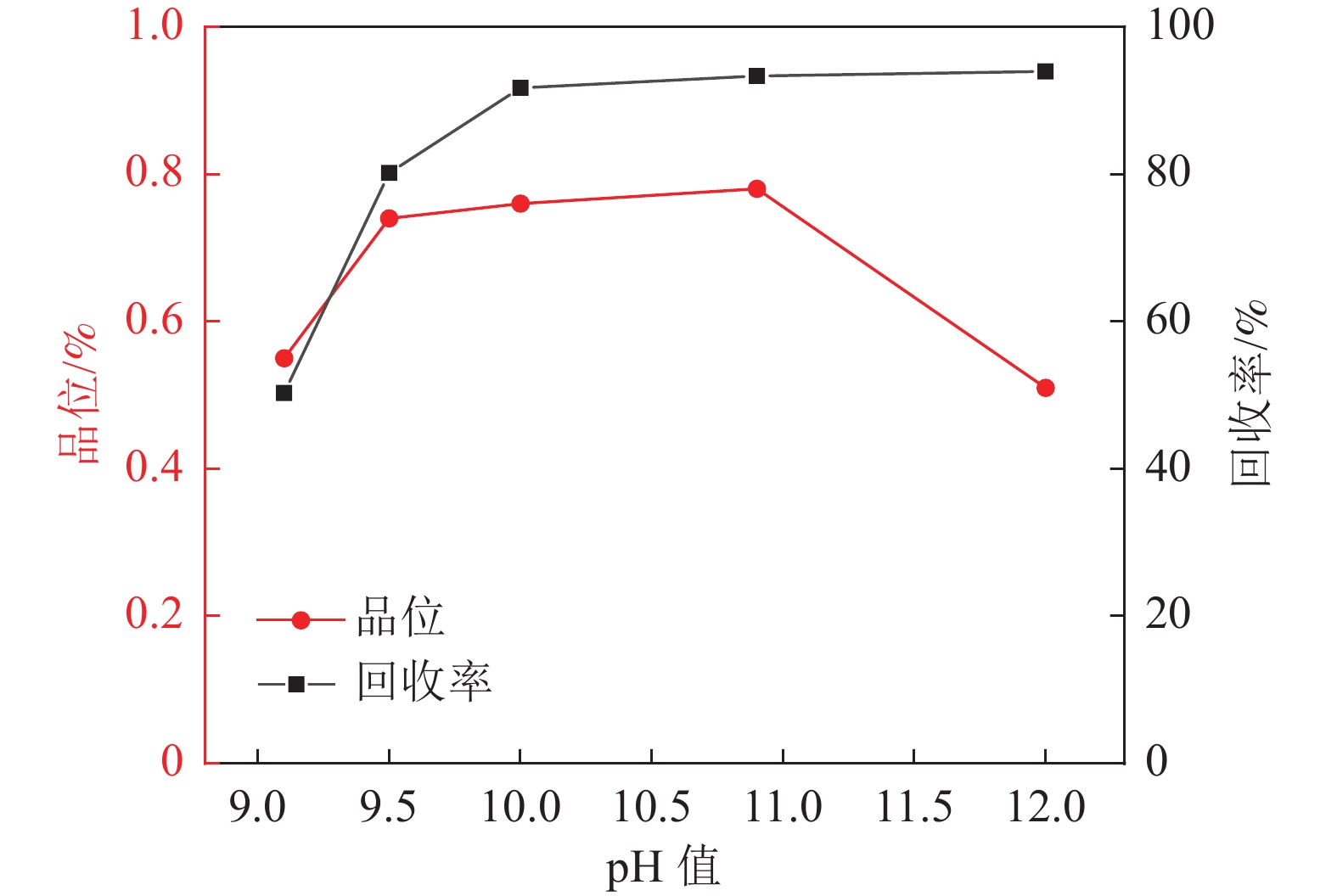

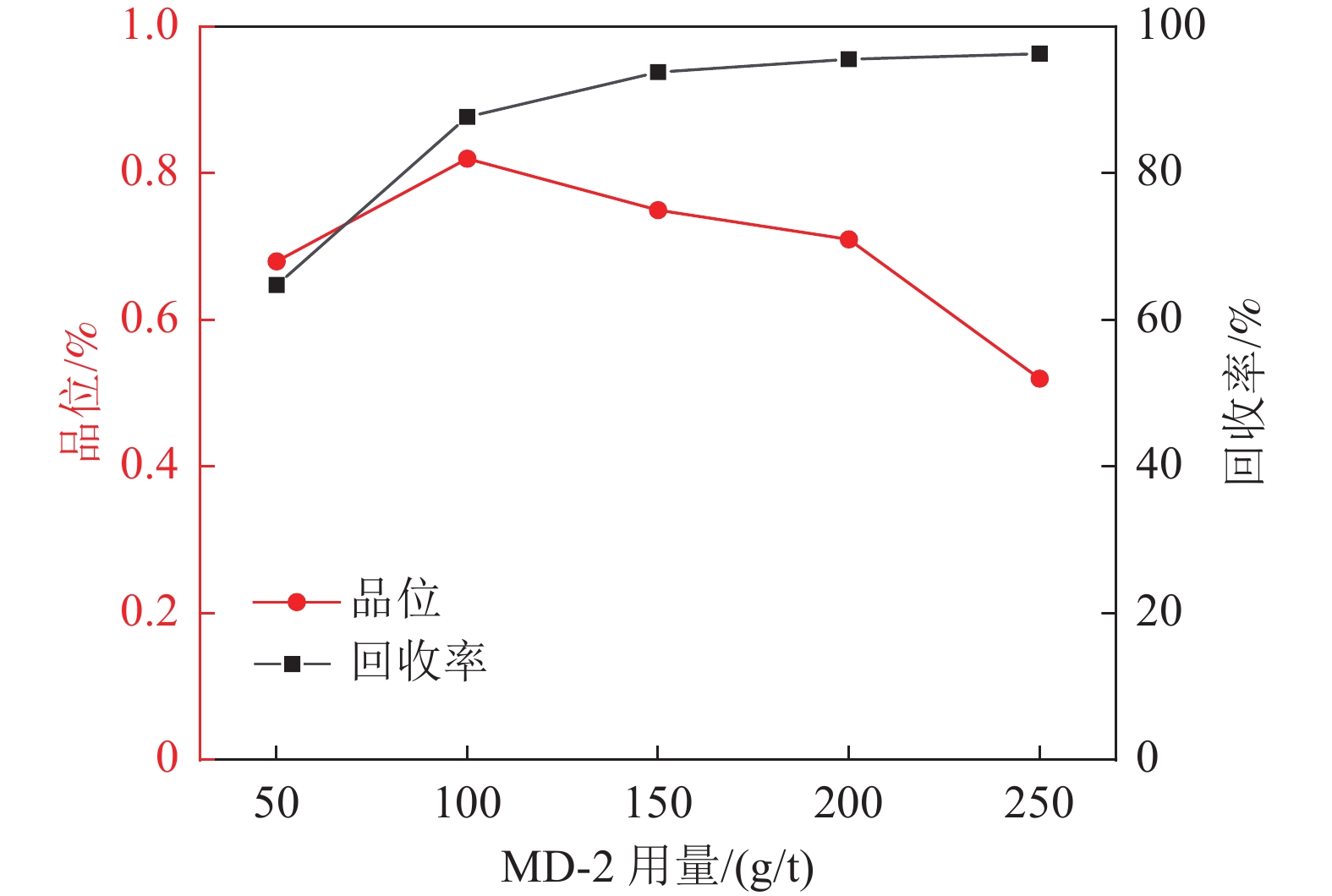

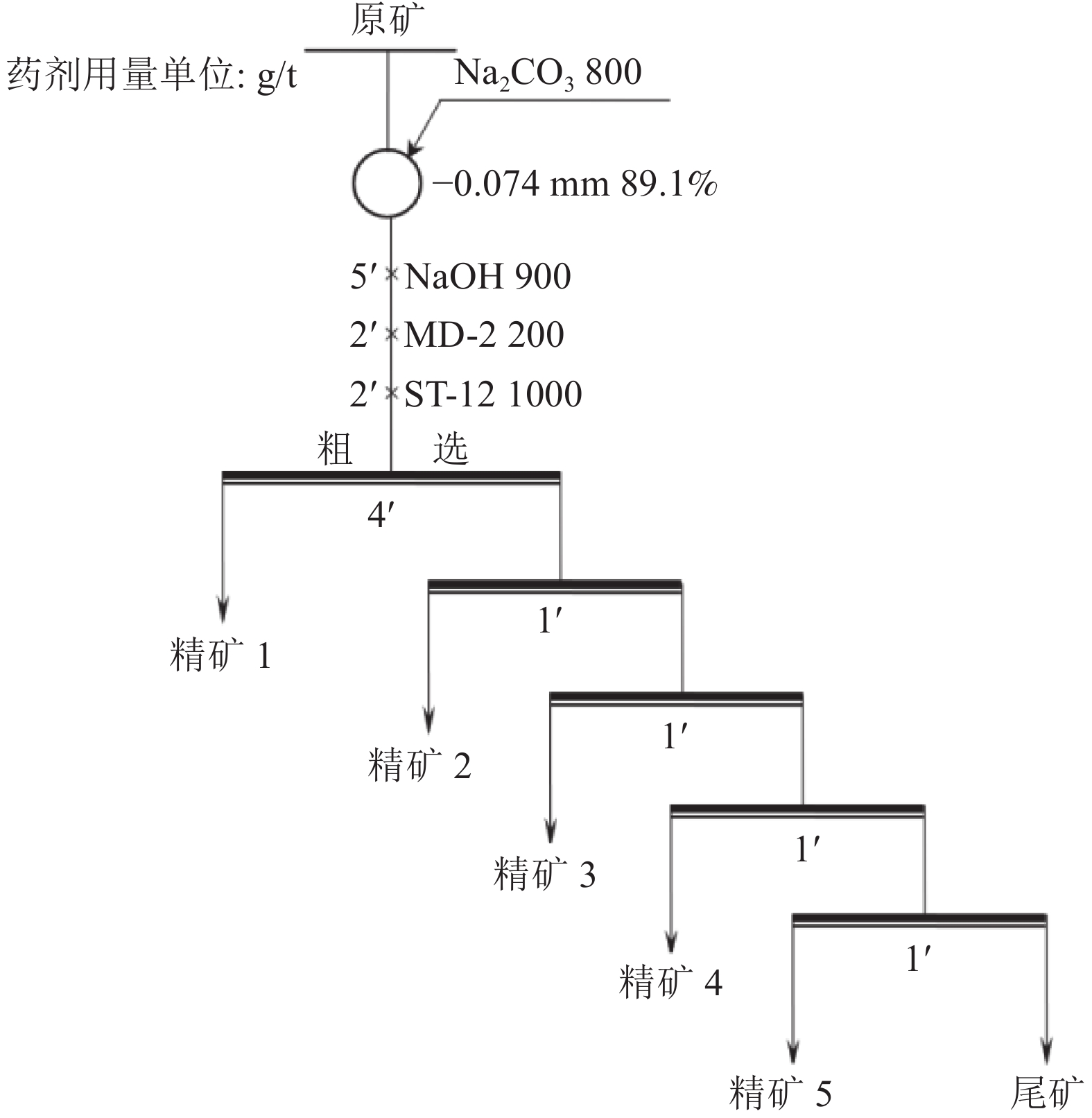

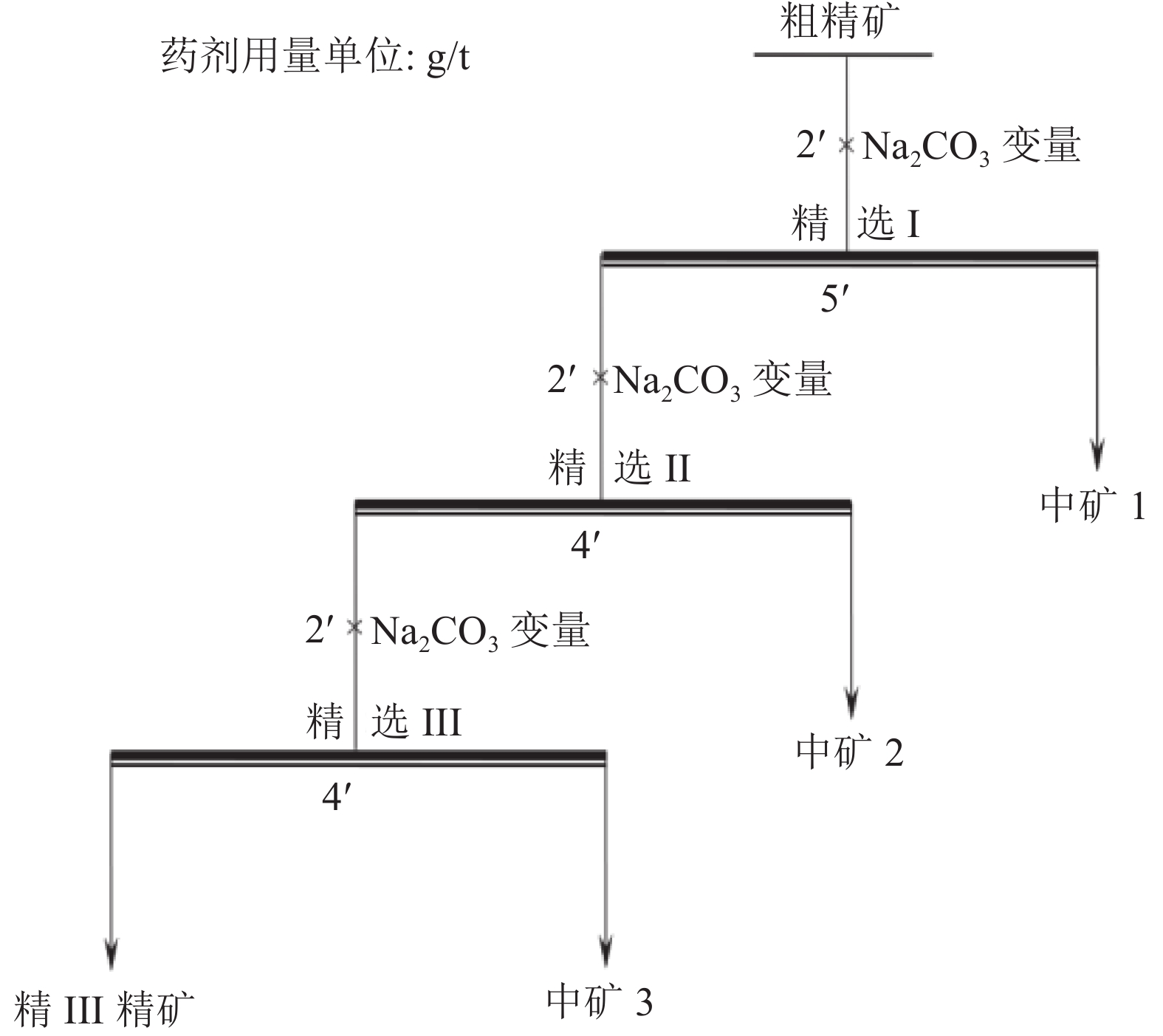

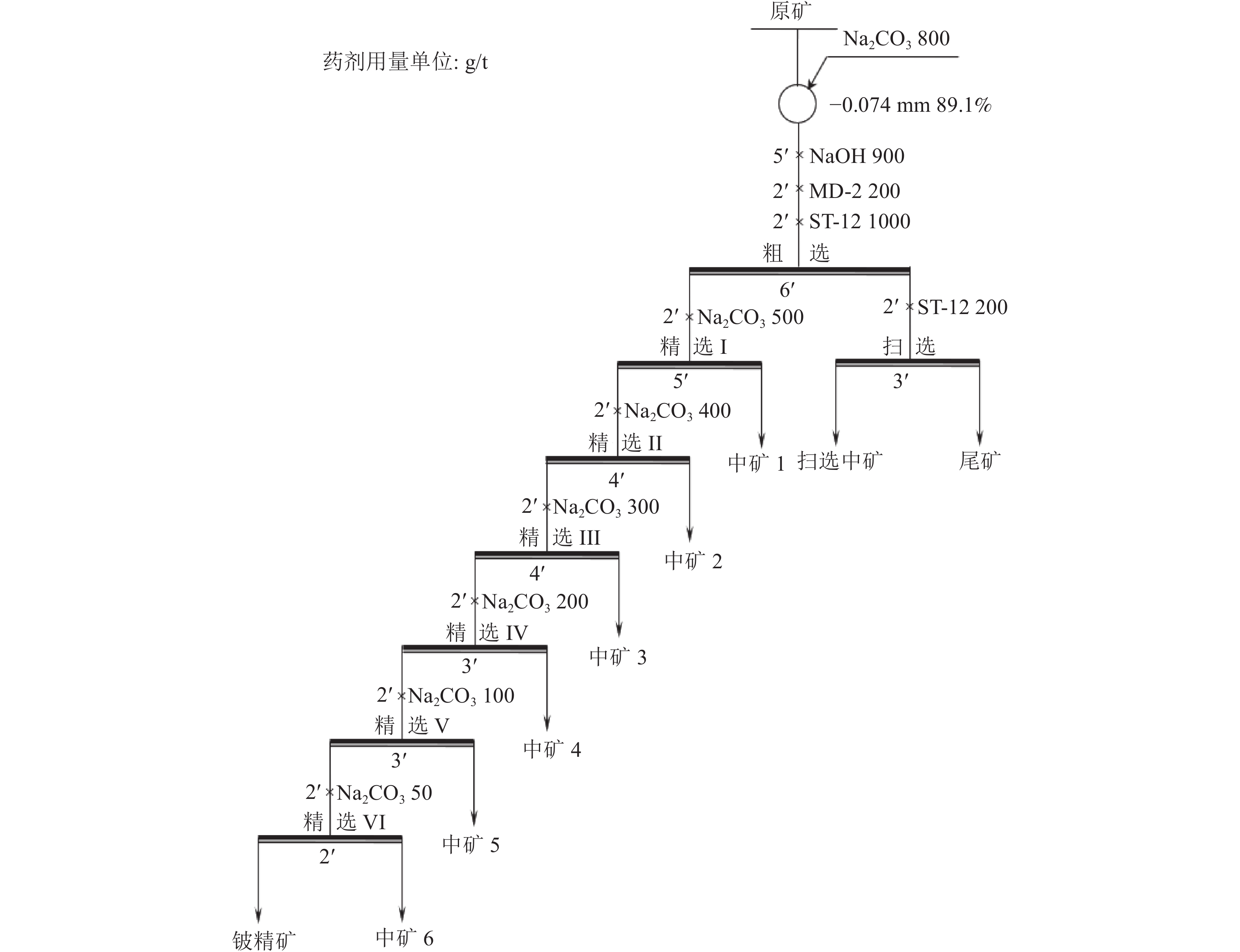

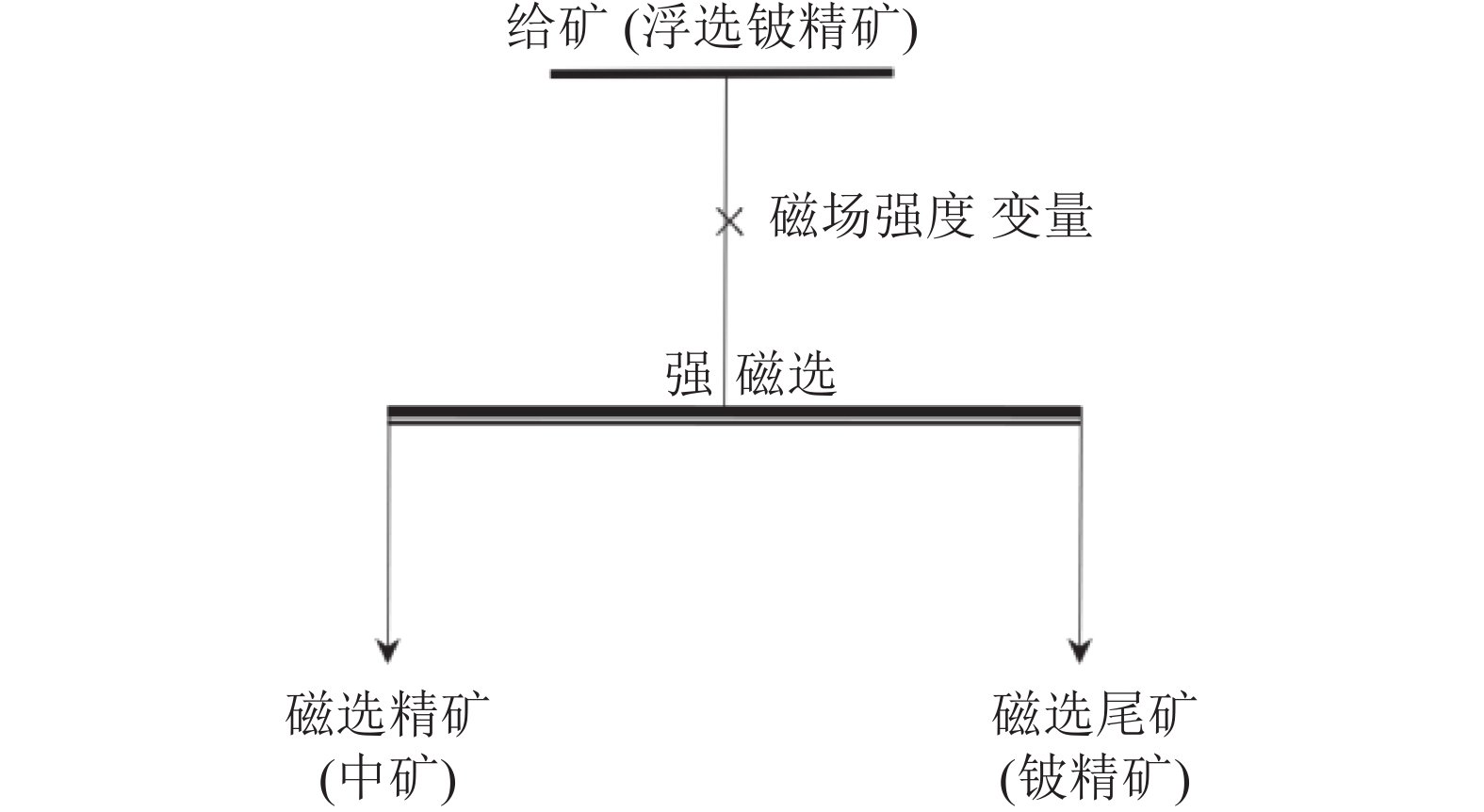

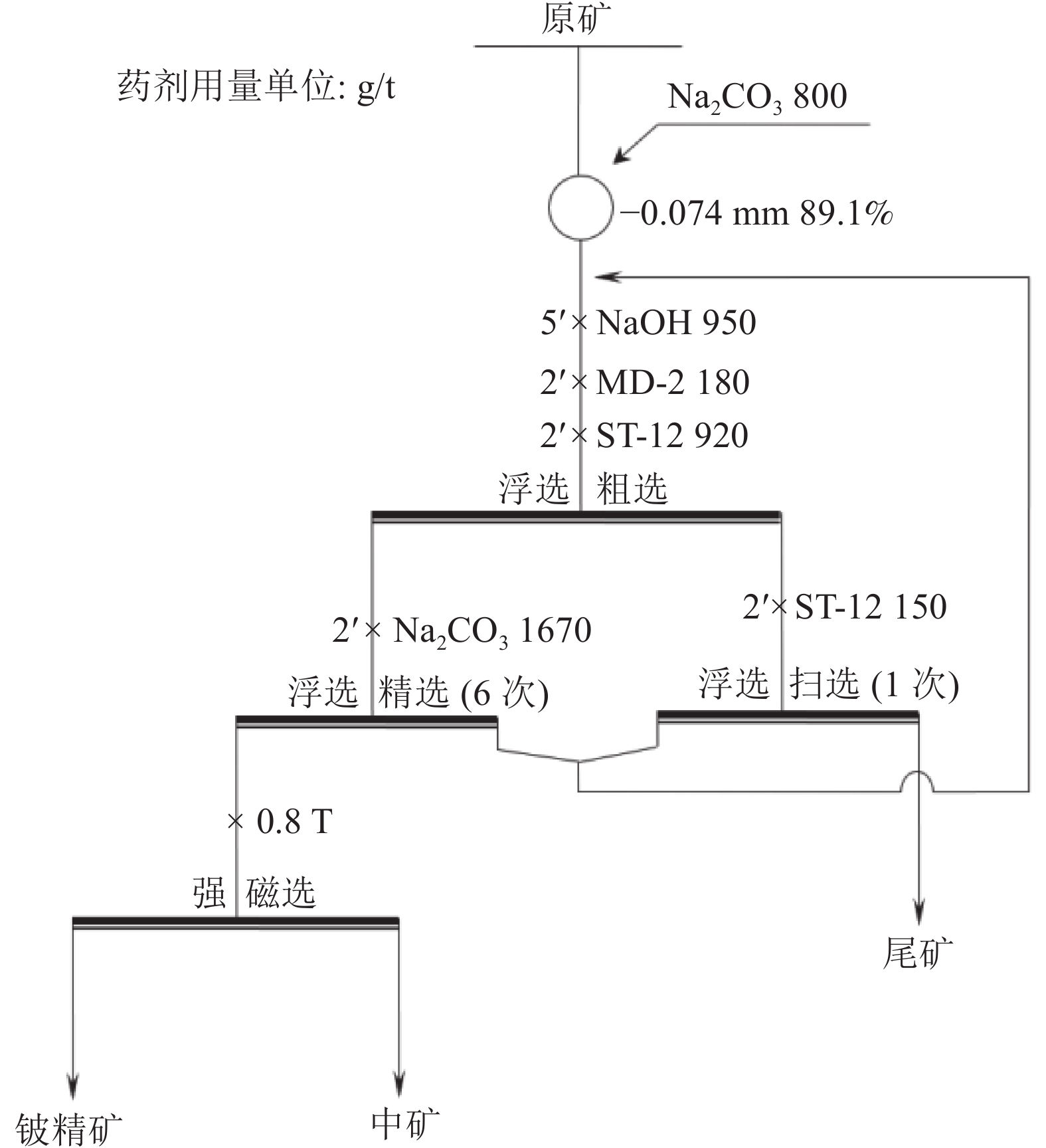

这是一篇矿物加工工程领域的文章。铍有“超级金属”和“尖端金属”之称,被列为我国关键性和战略性矿产资源。绿柱石是铍金属的重要来源,但由于原矿品位低和受选矿技术的限制,低品位绿柱石的可利用性难题至今未能得到解决,因此本文对川西低品位铍矿进行选矿实验研究。本文采用自主研制的新型高效的无机组合活化剂MD-2以及螯合捕收剂ST-12,针对九龙地区BeO品位0.089%的原矿,在磨矿细度-0.074 mm含量89.1%的条件下,经“一次粗选、一次扫选、六次精选”的浮选闭路实验,获得了BeO品位4.09%、BeO回收率89.60%的铍精矿。闭路浮选铍精矿经磁场强度为0.8 T的一段强磁选后,可将BeO品位由4%提高到5%以上,达到合格铍精矿品位要求,且BeO作业回收率较高,达到了87.08%,技术指标良好。本次实验开发出的“浮选富集-磁选提质”选矿整体技术,最终获得精矿BeO品位为5.47%,BeO回收率为78.09%。本研究成果可为该矿以及同类矿产资源的开发利用提供重要的技术支撑。

Abstract:This is an essay in the field of mineral processing engineering . Beryllium is known as "super metal" and "cutting-edge metal", and is listed as a key and strategic mineral resource in China. Beryl is an important source of beryllium, but due to the low grade of the raw ore and the limitations of beneficiation technology, the problem of the availability of low-grade beryl has not been solved yet. Therefore, this article conducts beneficiation experiments on extremely low-grade beryllium ore in western Sichuan. Self-developed new and efficient inorganic combination activator MD-2 and chelating collector ST-12 are developed and employed. For the raw ore with a BeO grade of 0.089% in the Jiulong area, under the condition of grinding fineness of -0.074 mm content of 89.1%, a beryllium concentrate with a BeO grade of 4.09% and a BeO recovery rate of 89.60% was obtained through a flotation closed circuit experiment of "one roughing, one scavenging, and six cleanings". After a stage of high intensity separation with a magnetic field strength of 0.8 T, the BeO grade of the closed circuit flotation of beryllium concentrate can be increased from 4% to over 5%, meeting the requirements for qualified beryllium concentrate grade. The BeO operation recovery rate reaches 87.08%, and the technical indicators are good. The overall beneficiation technology of "flotation enrichment-magnetic separation upgrading" developed in this experiment obtained concentrate with a BeO grade of 5.47% and a BeO recovery rate of 78.09%. The research findings of this study can provide important technical support for the development and utilization of this mine and similar mineral resources.

-

Key words:

- Beryllium /

- Beryl /

- Mineral processing /

- Process technology /

- Comprehensive utilization

-

-

表 1 原矿化学多元素分析结果/%

Table 1. Chemical multi-element analysis results of raw ore

BeO Li2O Nb2O5 Ta2O5 Sn SiO2 MgO Al2O3 Fe2O3 K2O Na2O CaO Rb2O Cs2O 0.089 0.037 0.0052 0.0040 0.079 74.90 0.042 13.45 0.29 5.30 3.70 0.16 0.17 0.0092 表 2 矿石的矿物含量/%

Table 2. Mineral contents of ore

钠长石 钾长石 石英 云母类 绿柱石 磷灰石 锡石 锰铝榴石 闪石 萤石 铁锰氧化物 其他微量矿物 32.10 28.29 31.17 6.56 0.80 0.12 0.06 0.35 0.08 0.03 0.10 0.34 表 3 浮选探索实验结果

Table 3. Test results of flotation exploration

药剂种类

及用量/(g/t)产品

名称产率/% BeO

品位/%BeO回收

率/%Na2CO3 1000

NaOH 700

CaCl2 80

731+环烷酸皂 1000粗精矿 12.97 0.34 49.84 尾矿 87.03 0.051 50.16 原矿 100.00 0.088 100.00 Na2CO3 1000

NaOH 700

CaCl2 80

油酸钠 1000粗精矿 9.87 0.31 33.63 尾矿 90.13 0.067 66.37 原矿 100.00 0.091 100.00 Na2CO3 1000

NaOH 700

FeCl3 200

731+环烷酸皂 1000粗精矿 11.81 0.31 43.00 尾矿 88.19 0.055 57.00 原矿 100.00 0.085 100.00 Na2CO3 1000

NaOH 700

CaCl2 80

ST-8 1000粗精矿 11.85 0.48 67.48 尾矿 88.15 0.0311 32.52 原矿 100.00 0.084 100.00 Na2CO3 1000

NaOH 700

MD-2 150

ST-8 1000粗精矿 10.75 0.66 78.71 尾矿 89.25 0.0215 21.29 原矿 100.00 0.090 100.00 Na2CO3 1000

NaOH 700

MD-2 150

ST-12 1000粗精矿 11.20 0.71 91.89 尾矿 88.80 0.0079 8.11 原矿 100.00 0.086 100.00 表 4 浮选时间实验结果

Table 4. Test results of flotation time

浮选时间/min 产品名称 产率/% BeO品位/% BeO回收率/% 4 精矿1 8.13 0.98 89.85 1 精矿2 1.51 0.19 3.19 1 精矿3 1.22 0.12 1.68 1 精矿4 1.04 0.032 0.37 1 精矿5 0.64 0.026 0.19 尾 矿 87.46 0.0048 4.72 原 矿 100.00 0.089 100.00 表 5 精选条件实验结果

Table 5. Test results of cleaning condition

药剂条件/(g/t) pH值 产品名称 作业产率/% BeO品位/% BeO作业回收率/% 精选Ⅰ:Na2CO3 300

精选Ⅱ:Na2CO3 200

精选Ⅲ:Na2CO3 100精选Ⅰ:10.6

精选Ⅱ:10.3

精选Ⅲ:10.0精Ⅲ精矿 30.25 2.17 88.73 中矿3 7.00 0.43 4.09 中矿2 10.08 0.17 2.36 中矿1 52.67 0.068 4.82 粗精矿 100.00 0.74 100.00 精选Ⅰ:Na2CO3 500

精选Ⅱ:Na2CO3 400

精选Ⅲ:Na2CO3 300精选Ⅰ:10.9

精选Ⅱ:10.7

精选Ⅲ:10.5精Ⅲ精矿 24.31 2.89 91.58 中矿3 7.42 0.30 2.87 中矿2 10.23 0.13 1.78 中矿1 58.04 0.050 3.77 粗精矿 100.00 0.77 100.00 精选Ⅰ:Na2CO3 700

精选Ⅱ:Na2CO3 600

精选Ⅲ:Na2CO3 500精选Ⅰ:11.2

精选Ⅱ:11.0

精选Ⅲ:10.7精Ⅲ精矿 22.55 2.91 87.04 中矿3 8.74 0.45 5.26 中矿2 12.83 0.18 3.08 中矿1 55.88 0.062 4.62 粗精矿 100.00 0.75 100.00 精选Ⅰ:Na2CO3 500

MD-2 80

精选Ⅱ:Na2CO3 400 MD-2 60

精选Ⅲ:Na2CO3 300 MD-2 40精选Ⅰ:11.0

精选Ⅱ:10.7

精选Ⅲ:10.4精Ⅲ精矿 27.17 2.63 90.16 中矿3 7.56 0.36 3.44 中矿2 9.24 0.21 2.45 中矿1 56.03 0.056 3.95 粗精矿 100.00 0.79 100.00 表 6 浮选开路实验结果/%

Table 6. Test results of flotation open circuit

产品名称 产率/% BeO品位/% BeO回收率/% 铍精矿 1.52 4.32 72.15 中矿6 0.34 1.83 6.93 中矿5 0.41 0.84 3.75 中矿4 0.49 0.53 2.87 中矿3 1.04 0.32 3.69 中矿2 1.30 0.12 1.76 中矿1 7.14 0.053 4.18 扫选中矿 1.14 0.042 0.52 尾 矿 86.62 0.0043 4.15 原 矿 100.00 0.091 100.00 表 7 浮选闭路实验结果 /%

Table 7. Test results of flotation closed circuit

产品名称 产率/% BeO品位/% BeO回收率/% 铍精矿 1.98 4.09 89.60 尾 矿 98.02 0.0096 10.40 原 矿 100.00 0.090 100.00 表 8 其他有价金属在闭路产品中的走向

Table 8. Trends of other valuable metals in closed circuit products

产品名称 产率/% 品 位/% 回收率/% Li2O Nb2O5 Ta2O5 Li2O Nb2O5 Ta2O5 铍精矿 1.98 0.16 0.21 0.19 8.69 77.23 83.96 尾 矿 98.02 0.034 0.0013 0.0007 91.31 22.77 16.14 原 矿 100.00 0.040 0.0055 0.0045 100.00 100.00 100.00 表 9 磁选实验结果

Table 9. Test results of magnetic separation

磁场

强度/T产品

名称作业

产率/%BeO品位/% BeO作业

回收率/%1.2 铍精矿 50.82 5.79 71.12 中 矿 49.18 2.43 28.88 给 矿 100.00 4.14 100.00 0.8 铍精矿 65.63 5.47 87.08 中 矿 34.37 1.55 12.92 给 矿 100.00 4.12 100.00 0.4 铍精矿 76.14 4.96 92.19 中 矿 23.86 1.34 7.81 给 矿 100.00 4.10 100.00 表 10 全流程实验结果

Table 10. Test results of entire process

产品名称 产率/% BeO品位/% BeO回收率/% 铍精矿 1.30 5.47 78.09 中 矿 0.68 1.55 11.57 尾 矿 98.02 0.0096 10.34 原 矿 100.00 0.091 100.00 表 11 精矿化学多元素分析结果/%

Table 11. Chemical multi-element analysis results of concentrate

BeO Nb2O5 Ta2O5 Li2O SiO2 Fe2O3 Al2O3 CaO MgO K2O Na2O Rb2O Cs2O Sn 5.47 0.21 0.19 0.16 50.16 3.05 14.71 6.90 0.042 1.08 0.66 0.056 0.073 4.85 表 12 铍精矿的矿物组成含量表/%

Table 12. Mineral composition of beryllium concentrate

绿柱石 锡石 云母 磷灰石 石英 钾长石 钠长石 伊利石 重晶石 萤石 细晶石 铌钽

铁矿锡钽

锰矿49.86 6.74 10.02 8.81 6.98 4.41 2.68 2.26 1.28 1.26 0.07 0.02 0.01 表 13 尾矿化学多元素分析结果/%

Table 13. Chemical multi-element analysis results of tailings

BeO Nb2O5 Ta2O5 Li2O SiO2 Fe2O3 Al2O3 CaO K2O Na2O Rb2O Cs2O Sn 0.0096 0.0013 0.0007 0.034 74.99 0.30 14.10 0.037 5.48 3.91 0.17 0.00788 0.0045 表 14 浮选尾矿矿物组成/%

Table 14. Mineral composition of tailings

石英 钠长石 钾长石 云母类 铁、锰矿物 绿柱石 铝硅钙杂质 锰铝榴石、磷灰石、锂辉石、方铅矿、方解石等 30.80 30.16 29.93 8.57 0.11 0.06 0.37 极微量或偶见 -

[1] 梁飞, 赵汀, 王登红, 等. 中国铍资源供需预测与发展战略[J]. 中国矿业, 2018, 27(11):6-10+7. LIANG F, ZHAO T, WANG D H, et al. Supply and demand forecast and development strategy of beryllium resources in China[J]. China Mining Magazine, 2018, 27(11):6-10+7.

LIANG F, ZHAO T, WANG D H, et al. Supply and demand forecast and development strategy of beryllium resources in China[J]. China Mining Magazine, 2018, 27(11): 6-10+7.

[2] 李建康, 邹天人, 王登红, 等. 中国铍矿成矿规律[J]. 矿床地质, 2017, 36(4):951-78. LI J K, ZOU T R, WANG D H, et al. A review of beryllium metallogenic regularity in China[J]. Mineral Deposits, 2017, 36(4):951-78.

LI J K, ZOU T R, WANG D H, et al. A review of beryllium metallogenic regularity in China[J]. Mineral Deposits, 2017, 36(4): 951-78.

[3] 刘劲松, 高丽丽. 美国铍矿产业供需格局及产业政策分析[J]. 中国矿业, 2022, 31(3):31-6. LIU J S, GAO L L. Analysis on the supply and demand pattern and industrial policy of beryllium mineindustry in the United States[J]. China Mining Magazine, 2022, 31(3):31-6.

LIU J S, GAO L L. Analysis on the supply and demand pattern and industrial policy of beryllium mineindustry in the United States[J]. China Mining Magazine, 2022, 31(3): 31-6.

[4] 许秀婷, 教镇渤, 海国泉, 等. 铍矿产业发展现状[J]. 新疆有色金属, 2021, 44(1):4-8. XU X T, JIAO Z B, HAI G Q, et al. Development status of beryllium ore industry[J]. Xinjiang Nonferrous Metals, 2021, 44(1):4-8.

XU X T, JIAO Z B, HAI G Q, et al. Development status of beryllium ore industry[J]. Xinjiang Nonferrous Metals, 2021, 44(1): 4-8.

[5] 吴西顺, 王登红, 黄文斌, 等. 全球锂矿及伴生铍铌钽的采选冶技术发展趋势[J]. 矿产综合利用, 2020(1):1-9. WU X S, WANG D H, HUANG W B, et al. Global technical development trends of litihium minerals and associated beryllium-niobium-tantalum exploitation[J]. Multipurpose Utilization of Mineral Resources, 2020(1):1-9.

WU X S, WANG DH , HUANG W B, et al. Global technical development trends of litihium minerals and associated beryllium-niobium-tantalum exploitation [J]. Multipurpose Utilization of Mineral Resources, 2020 (1): 1-9.

[6] 高亢亢, 马靖, 韦娉婷, 等. 超级金属铍: 未来路在何方[J]. 矿物岩石地球化学通报, 2023, 42(1):248-52. GAO K K, MA J, WEI P T, et al. Super metal beryllium: where the future lies[J]. Bulletin of Mineralogy, Petrology and Geochemistry, 2023, 42(1):248-52.

GAO K K, MA J, WEI P T, et al. Super metal beryllium: where the future lies [J]. Bulletin of Mineralogy, Petrology and Geochemistry, 2023, 42(1): 248-52.

[7] 李宏, 谭秀民, 张秀峰, 等. 铍资源现状及其选冶技术进展[J]. 有色金属科学与工程, 2022, 13(4):44-53. LI H, TAN X M, ZHANG X F, et al. The current situation of beryllium resources and the progress of beneficiation and metallurgy technology[J]. Nonferrous Metals Science and Engineering, 2022, 13(4):44-53.

LI H, TAN X M, ZHANG X F, et al. The current situation of beryllium resources and the progress of beneficiation and metallurgy technology[J]. Nonferrous Metals Science and Engineering, 2022, 13(4): 44-53.

[8] 汪泰, 胡真, 王威. 锂铍稀有金属选矿及综合利用研究现状和展望[J]. 有色金属(选矿部分), 2020(6):24-9. WANG T, HU Z, WANG W. Research status and prospects of lithium beryllium rare metals beneficiation and comprehensive utilization[J]. Nonferrous Metals(Mineral Processing Section), 2020(6):24-9.

WANG T, HU Z, WANG W. Research status and prospects of lithium beryllium rare metals beneficiation and comprehensive utilization[J]. Nonferrous Metals(Mineral Processing Section), 2020(6): 24-9.

[9] 毛素荣, 李光明, 钟乐乐, 等. 铍的选矿研究现状和展望[J]. 有色金属(选矿部分), 2022(6):17-24+154. MAO S R, LI G M, ZHONG L L, et al. Present situation and prospect of mineral processing of beryllium[J]. Nonferrous Metals(Mineral Processing Section), 2022(6):17-24+154.

MAO S R, LI G M, ZHONG L L, et al. Present situation and prospect of mineral processing of beryllium[J]. Nonferrous Metals(Mineral Processing Section), 2022(6): 17-24+154.

[10] 邓伟, 颜世强, 谭洪旗, 等. 我国铍矿资源概况及选矿技术研究现状[J]. 矿产综合利用, 2023(1):148-54. DENG W, YAN S Q, TAN H Q, et al. General situation of beryllium ore resources and research status of mineral processing technology in China[J]. Multipurpose Utilization of Mineral Resources, 2023(1):148-54.

DENG W, YAN S Q, TAN H Q, et al. General situation of beryllium ore resources and research status of mineral processing technology in China[J]. Multipurpose Utilization of Mineral Resources, 2023(1): 148-54.

[11] 《矿产资源工业要求手册》编委会. 矿产资源工业要求手册 [M]. 北京: 地质出版社, 2010.

Editorial Committee of the Mineral Resources Industry Requirements. Manual handbook of industrial requirements for mineral resources[M]. Beijing: Geological Publishing House, 2010.

[12] 赖杨, 邓伟. 川西九龙打枪沟锂铍矿石特征及其铷元素赋存状态和分布规律研究[J]. 矿产综合利用, 2022(5):185-92. LAI Y, DENG W. Characteristics of lithium beryllium ore and occurrence anddistribution of rubidium element in ore, in Daqianggou, Jiulong, West Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2022(5):185-92.

LAI Y, DENG W. Characteristics of lithium beryllium ore and occurrence anddistribution of rubidium element in ore, in Daqianggou, Jiulong, West Sichuan[J]. Multipurpose Utilization of Mineral Resources, 2022(5): 185-92.

[13] 李凤久, 孔亚然, 贾清梅. 某萤石矿选矿实验研究[J]. 矿产综合利用, 2023(2):81-6+123. LI F J, KONG Y R, JIA M Q. Experimental study on mineral processing of a fluorite mine[J]. Multipurpose Utilization of Mineral Resources, 2023(2):81-6+123.

LI F J, KONG Y R, JIA M Q. Experimental study on mineral processing of a fluorite mine[J]. Multipurpose Utilization of Mineral Resources, 2023(2): 81-6+123.

-

下载:

下载: