Inductively Coupled Plasma Atomic Emission Spectrometric Determination of Lithium、Beryllium、Niobium and Tantalum in Sample of Beneficiation Process of Rare Metal Ore after Closed Digestion

-

摘要:

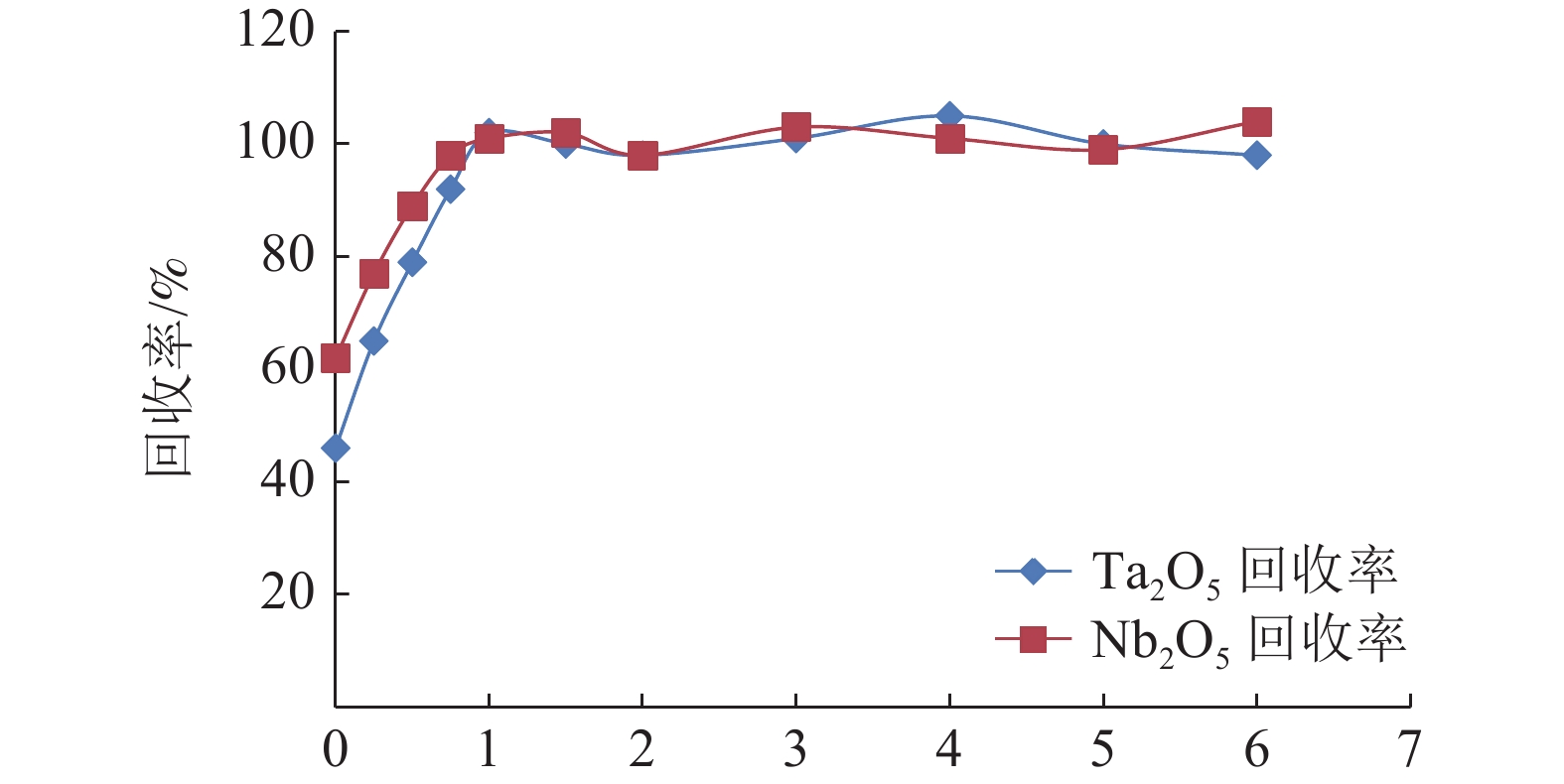

这是一篇矿物分析领域的论文。采用盐酸、硝酸、氢氟酸、硫酸于聚四氟乙烯密闭消解罐中加热消解,酒石酸—稀盐酸介质提取,以电感耦合等离子体光谱法同时测定溶液中锂、铍、铌和钽。Li和Be在0~50 μg/mL、Nb2O5和Ta2O5在0~100 μg/mL范围内呈良好测现性关系,校准曲线相关系数r均大于0.9999,方法检出限分别为0.1 μg /g、0.5 μg /g、1.0 μg /g、0.1 μg /g。用于实际样品分析,加标回收率为94.6%~105.6%,锂、铍、铌、钽的相对标准偏差(n=11)分别为1.08%~7.04%、0.65%~13.06%、2.59~7.32%、2.02%~7.60%,用标准样品分析,测定值与认定值相符。

Abstract:This is an essay in the field of mineral analysis. The ore sample was digested with Hydrochloric acid、nitric acid、 hydrofluoric acid、 sulfuric acid in a closed polytetrafluoroethylene digestion tank. Hydrochloric acid and tartaric acid medium is used for extraction. The Lithium、Beryllium、niobium and tantalum in the prepared solution were determined by inductively coupled plasma atomic emission spectrometry (ICP-AES). The emission spectral intensity of Lithium、Beryllium、niobium and tantalum showed a good linear relationship with ρ(Li) and ρ(Be) in the range of 0~50 μg/mL、ρ(Nb2O5) and ρ(Ta2O5) in the range of 0~100 μg/mL. The correlation coefficients of the calibration curve for Lithium、Beryllium、niobium and tantalum were both 0.9999.The detection limits for Lithium、Beryllium、niobium and tantalum were 0.1 μg/g、0.5 μg/g、1.0 μg/g、0.1 μg/g, respectively.The proposed method was applied to the determination of the actual sample giving recovery rate of 94.6%~105.6% and the relative standard deviations (RSD n=11) of Lithium、Beryllium、niobium and tantalum are 1.08%~7.04%、0.65%~13.06%、2.59~7.32%、2.02%~7.60%, respectively.This method was applied to the analysis of the standard sample and the results were consistent with the certified values.

-

-

表 1 标准溶液中锂、铍、铌、钽元素浓度

Table 1. Concentrations of Li 、Be、 Nb and Ta in the standard solutions

标准溶液编号 含量/(μg/mL) Li Be Nb2O5 Ta2O5 1 0 0 0 0 2 0.5 0.5 0.5 0.5 3 1 1 1 1 4 5 5 5 5 5 10 10 10 10 6 50 50 50 50 7 100 100 表 2 不同样品消解方法测定比较/%

Table 2. Comparision of determination results by different digestion method

样品 元素 a常压高氯酸冒烟 b常压硫酸冒烟 Li2O BeO Nb2O5 Ta2O5 Li2O BeO Nb2O5 Ta2O5 样品1 5.49 0.18 0.0748 0.0323 5.47 0.22 0.0727 0.0291 样品2 0.14 0.0038 0.0026 0.0012 0.15 0.0044 0.0027 0.0011 样品3 1.37 0.0425 0.0023 0.0008 1.34 0.0495 0.0027 0.0009 样品4 5.34 0.22 0.0034 0.0024 5.26 0.29 0.0036 0.0031 样品 元素 c密闭高氯酸冒烟 d密闭硫酸冒烟 Li2O BeO Nb2O5 Ta2O5 Li2O BeO Nb2O5 Ta2O5 样品1 5.48 0.23 0.0809 0.0412 5.49 0.25 0.0811 0.0391 样品2 0.14 0.0058 0.0022 0.0013 0.14 0.0062 0.0020 0.0012 样品3 1.32 0.0668 0.0023 0.0008 1.33 0.0691 0.0031 0.0010 样品4 5.31 0.35 0.0036 0.0025 5.23 0.39 0.0037 0.0033 表 3 加标回收(n=3)

Table 3. Standerd addition recovery (n=3)

样品 Li2O BeO 样品含量/% 加入量/% 测定平均值/% 回收率/% 样品含量/% 加入量/% 测定平均值/% 回收率/% A1 5.49 5 10.30 96.2 0.25 0.25 0.49 98.3 A2 0.1441 0.1 0.2421 98 0.0062 0.01 0.0168 105.6 A3 1.33 1 2.34 101.3 0.0691 0.1 0.1712 102.1 A4 5.23 5 10.12 97.7 0.39 0.5 0.88 97.66 样品 Nb2O5 Ta2O5 样品含量/% 加入量/% 测定平均值/% 回收率/% 样品含量/% 加入量/% 测定平均值/% 回收率/% A1 0.0811 0.1 0.1802 99.1 0.0391 0.05 0.0901 101.9 A2 0.0020 0.0025 0.0044 94.68 0.0012 0.001 0.0022 96.4 A3 0.0031 0.0025 0.0055 96.2 0.001 0.001 0.0020 95.2 A4 0.0037 0.0025 0.0062 101.9 0.0033 0.005 0.0082 97.7 表 4 方法的精密度和准确度

Table 4. Precision and the accuracy of the method

标准物质编号 Li2O BeO Nb2O5 Ta2O5 GBW07152-1 0.46 0.018 0.0031 0.0040 GBW07152-2 0.46 0.017 0.0030 0.0044 GBW07152-3 0.44 0.018 0.0028 0.0050 GBW07152-4 0.45 0.019 0.0033 0.0047 GBW07152-5 0.44 0.02 0.0029 0.0048 GBW07152-6 0.47 0.017 0.0031 0.0050 GBW07152-7 0.45 0.018 0.0027 0.0051 GBW07152-8 0.46 0.019 0.0032 0.0045 GBW07152-9 0.46 0.018 0.0028 0.0047 GBW07152-10 0.46 0.017 0.0030 0.0051 GBW07152-11 0.44 0.017 0.0026 0.0046 测定平均值/% 0.45 0.018 0.0030 0.0047 认定值/% 0.46 0.018 0.0027 0.0049 RSD/% 2.28 5.56 7.21 7.17 标准物质编号 Li2O BeO Nb2O5 Ta2O5 GBW07154-1 0.78 0.032 0.0046 0.0083 GBW07154-2 0.79 0.034 0.0048 0.0081 GBW07154-3 0.81 0.033 0.0052 0.0086 GBW07154-4 0.76 0.033 0.0046 0.0094 GBW07154-5 0.78 0.032 0.0050 0.0086 GBW07154-6 0.79 0.034 0.0048 0.0088 GBW07154-7 0.77 0.031 0.0044 0.0089 GBW07154-8 0.80 0.030 0.0046 0.0085 GBW07154-9 0.78 0.033 0.0049 0.0084 GBW07154-10 0.77 0.036 0.0043 0.0082 GBW07154-11 0.79 0.035 0.0051 0.0085 测定平均值/% 0.78 0.033 0.0048 0.0086 认定值/% 0.79 0.033 0.0042 0.0089 RSD/% 1.84 5.25 5.92 4.23 标准物质编号 Li2O BeO Nb2O5 Ta2O5 GBW07183-1 3.00 GBW07183-2 3.01 GBW07183-3 3.00 GBW07183-4 3.02 GBW07183-5 2.99 GBW07183-6 2.98 GBW07183-7 3.01 GBW07183-8 3.03 GBW07183-9 3.02 GBW07183-10 3.00 GBW07183-11 3.05 测定平均值/% 3.01 认定值/% 未给定 3.02 未给定 未给定 RSD/% 0.65 标准物质编号 Li2O BeO Nb2O5 Ta2O5 GBW07184-1 3.86 0.018 0.0088 0.013 GBW07184-2 3.80 0.018 0.0082 0.013 GBW07184-3 3.83 0.016 0.0086 0.014 GBW07184-4 3.92 0.017 0.0093 0.013 GBW07184-5 3.86 0.019 0.0086 0.012 GBW07184-6 3.88 0.017 0.0083 0.014 GBW07184-7 3.89 0.018 0.0089 0.014 GBW07184-8 3.80 0.016 0.0085 0.012 GBW07184-9 3.83 0.017 0.0084 0.015 GBW07184-10 3.91 0.019 0.008 0.012 GBW07184-11 3.89 0.016 0.0085 0.014 测定平均值/% 3.86 0.017 0.009 0.013 认定值/% 3.89 0.016 0.0081 0.013 RSD/% 1.08 6.59 3.96 7.76 标准物质编号 Li2O BeO Nb2O5 Ta2O5 GBW07185-1 0.011 0.0020 0.53 1.01 GBW07185-2 0.012 0.0018 0.50 1.03 GBW07185-3 0.012 0.0016 0.52 0.99 GBW07185-4 0.011 0.0013 0.49 1.02 GBW07185-5 0.011 0.0017 0.50 1.01 GBW07185-6 0.010 0.0019 0.51 0.98 GBW07185-7 0.010 0.0018 0.51 1.05 GBW07185-8 0.012 0.0017 0.53 1.03 GBW07185-9 0.011 0.0014 0.52 1.04 GBW07185-10 0.010 0.0015 0.50 1.02 GBW07185-11 0.011 0.0015 0.52 1.01 测定平均值/% 0.011 0.0017 0.51 1.02 认定值/% 0.011 0.0012 0.52 1.02 RSD/% 7.04 12.72 2.60 2.01 -

[1] 吴西顺, 王登红, 黄文斌, 等. 全球锂矿及伴生铍铌钽的采选冶技术发展趋势[J]. 矿产综合利用, 2019(1):1-6. WU X S, WANG D H, HUANG W B, et al. Global technical development trends of litihium minerals and associated beryllium-niobium-tantalum exploitation[J]. Multipurpose Utilization of Mineral Resources, 2019(1):1-6. doi: 10.3969/j.issn.1000-6532.2019.01.001

WU X S, WANG D H, HUANG W B, et al. Global technical development trends of litihium minerals and associated beryllium-niobium-tantalum exploitation[J]. Multipurpose Utilization of Mineral Resources, 2019(1): 1-6. doi: 10.3969/j.issn.1000-6532.2019.01.001

[2] 徐正震, 梁精龙, 李慧, 等. 含锂资源中锂的提取研究现状及展望[J]. 矿产综合利用, 2021(5):32-37. XU Z Z, LIANG J L, LI H, et al. Research status and prospects of lithium extraction from lithium containing resources[J]. Multipurpose Utilization of Mineral Resources, 2021(5):32-37. doi: 10.3969/j.issn.1000-6532.2021.05.005

XU Z Z, LIANG J L, LI H, et al. Research status and prospects of lithium extraction from lithium containing resources[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 32-37. doi: 10.3969/j.issn.1000-6532.2021.05.005

[3] 李成秀, 程仁举, 刘星. 我国锂辉石选矿技术研究现状及展望[J]. 矿产综合利用, 2021(5):1-8. LI C X, CHENG R J, LIU X. Research status and prospects of spodumene ore beneficiation technology in China[J]. Multipurpose Utilization of Mineral Resources, 2021(5):1-8. doi: 10.3969/j.issn.1000-6532.2021.05.001

LI C X, CHENG R J, LIU X. Research status and prospects of spodumene ore beneficiation technology in China[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 1-8. doi: 10.3969/j.issn.1000-6532.2021.05.001

[4] 何飞, 高利坤, 饶兵, 等. 从锂云母中提锂及综合利用的研究进展[J]. 矿产综合利用, 2022(5):82-89. HE F, GAO L K, RAO B, et al. Research progress on lithium extraction and comprehensive utilization from lepidolite[J]. Multipurpose Utilization of Mineral Resources, 2022(5):82-89.

HE F, GAO L K, RAO B, et al. Research progress on lithium extraction and comprehensive utilization from lepidolite [J]. Multipurpose Utilization of Mineral Resources, 2022(5): 82-89.

[5] 高丹. 微波消解——电感耦合等离子体原子发射光谱法测定矿石样品中的铍[J]. 科技传播, 2010(18):167-168. GAO D. Determination of beryllium in ore samples by microwave digestion inductively coupled plasma atomic emission spectrometry[J]. Public Communication of Science & Technology, 2010(18):167-168.

GAO D , et al. Determination of beryllium in ore samples by microwave digestion inductively coupled plasma atomic emission spectrometry[J]. Public Communication of Science & Technology, 2010(18): 167-168.

[6] 杨萍, 陈云红. ICP-AES法测定矿石中的BeO[J]. 分析试验室, 2002(5):16-17. YANG P, CHENG Y H. Determination of BeO in ores by ICP-AES[J]. Chinese Journal of Analysis Laboratory, 2002(5):16-17. doi: 10.3969/j.issn.1000-0720.2002.05.006

YANG P, CHENG Y H , et al. Determination of BeO in ores by ICP-AES[J]. Chinese Journal of Analysis Laboratory, 2002(5): 16-17. doi: 10.3969/j.issn.1000-0720.2002.05.006

[7] 潘钢, 易建春. 恒温电热板湿法消解-ICP-AES对地质样品中铌和钽的连续测定[J]. 光谱实验室, 2012, 29(3):1597-1600. PAN G, YI J C. Continuous determination of niobium and tantalum in geological samples by ICP-AES with constant temperature electric heating plate wet digestion[J]. Chinese Journal of Spectroscopy Laboratory, 2012, 29(3):1597-1600. doi: 10.3969/j.issn.1004-8138.2012.03.073

PAN G, YI J C , et al. Continuous determination of niobium and tantalum in geological samples by ICP-AES with constant temperature electric heating plate wet digestion[J]. Chinese Journal of Spectroscopy Laboratory, 2012, 29(3): 1597-1600. doi: 10.3969/j.issn.1004-8138.2012.03.073

[8] 韩晓, 方迪. 电感耦合等离子体原子发射光谱(ICP-AES)法测定岩矿中锂的含量[J]. 中国无机分析化学, 2021, 11(2):36-39. HAN X, FANG D. Determination of lithium in rock and ore by inductively coupled plasma atomic emission spectrometric(ICP-AES)[J]. Chinese Journal of Inorganic Analytical Chemistry, 2021, 11(2):36-39. doi: 10.3969/j.issn.2095-1035.2021.02.008

HAN X, FANG D, et al. Determination of lithium in rock and ore by inductively coupled plasma atomic emission spectrometric(ICP-AES) [J]. Chinese Journal of Inorganic Analytical Chemistry, 2021, 11(2): 36-39. doi: 10.3969/j.issn.2095-1035.2021.02.008

[9] 姚玉玲, 赵朝辉, 刘淑君. 树脂交换分离—电感耦合等离子质谱法测定锡矿石的铌钽[J]. 矿产综合利用, 2021(5):146-151. YAO Y L, ZHAO C H, LIU S J. Determination of niobium and tantalum in tin ore by inductively coupled plasma mass spectrometry with resin exchange separation[J]. Multipurpose Utilization of Mineral Resources, 2021(5):146-151. doi: 10.3969/j.issn.1000-6532.2021.05.023

YAO Y L, ZHAO C H, LIU S J. Determination of niobium and tantalum in tin ore by inductively coupled plasma mass spectrometry with resin exchange separation[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 146-151. doi: 10.3969/j.issn.1000-6532.2021.05.023

[10] 赵学沛. 多种酸溶矿ICP-AES测定稀有金属矿中锂铍铌钽锡[J]. 化学研究与应用, 2017, 29(11):1714-1718. ZHAO X P. Determination of lithium, beryllium, niobium and tantalum in rare matal ores by four acid soluble ICP-AES[J]. Chemical Research and Application, 2017, 29(11):1714-1718. doi: 10.3969/j.issn.1004-1656.2017.11.017

ZHAO X P , et al. Determination of lithium, beryllium, niobium and tantalum in rare matal ores by four acid soluble ICP-AES [J]. Chemical Research and Application, 2017, 29(11): 1714-1718. doi: 10.3969/j.issn.1004-1656.2017.11.017

[11] 胡兰基, 朱琳, 赵玉卿, 等. 电感耦合等离子体质谱法测定花岗伟晶岩中锂、铍、铷、铯、铌和钽[J]. 化工矿产地质, 2020, 42(4):348-351. HU L J, ZHU L, ZHAO Y Q, et al. Determination of Li、Be、Rb、Cs、Nb and Ta in granite-pegmatite by inductively coupled plasma mass spectrometric[J]. Geology of Chemical Minerals, 2020, 42(4):348-351. doi: 10.3969/j.issn.1006-5296.2020.04.011

HU L J, ZHU L, ZHAO Y Q, et al. Determination of Li、Be、Rb、Cs、Nb and Ta in granite-pegmatite by inductively coupled plasma mass spectrometric [J]. Geology of Chemical Minerals, 2020, 42(4): 348-351. doi: 10.3969/j.issn.1006-5296.2020.04.011

-

下载:

下载: