Effect of Rare Earth Tailing on Properties of Recycled Aggregate Concrete

-

摘要:

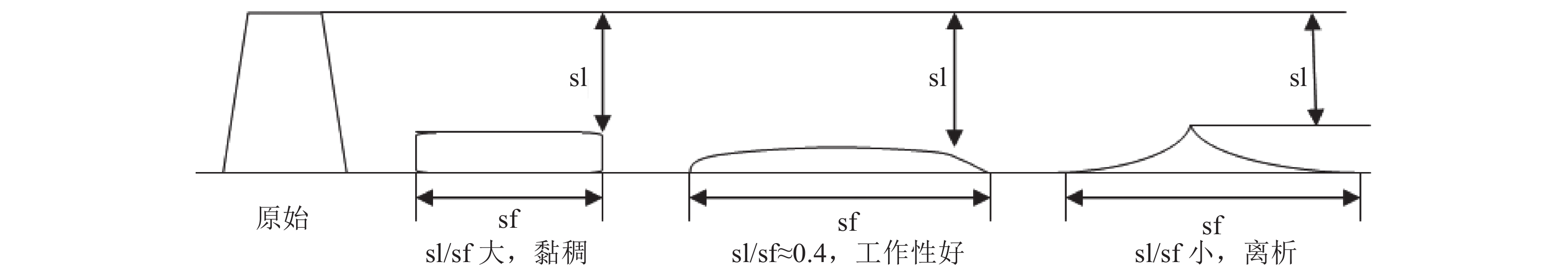

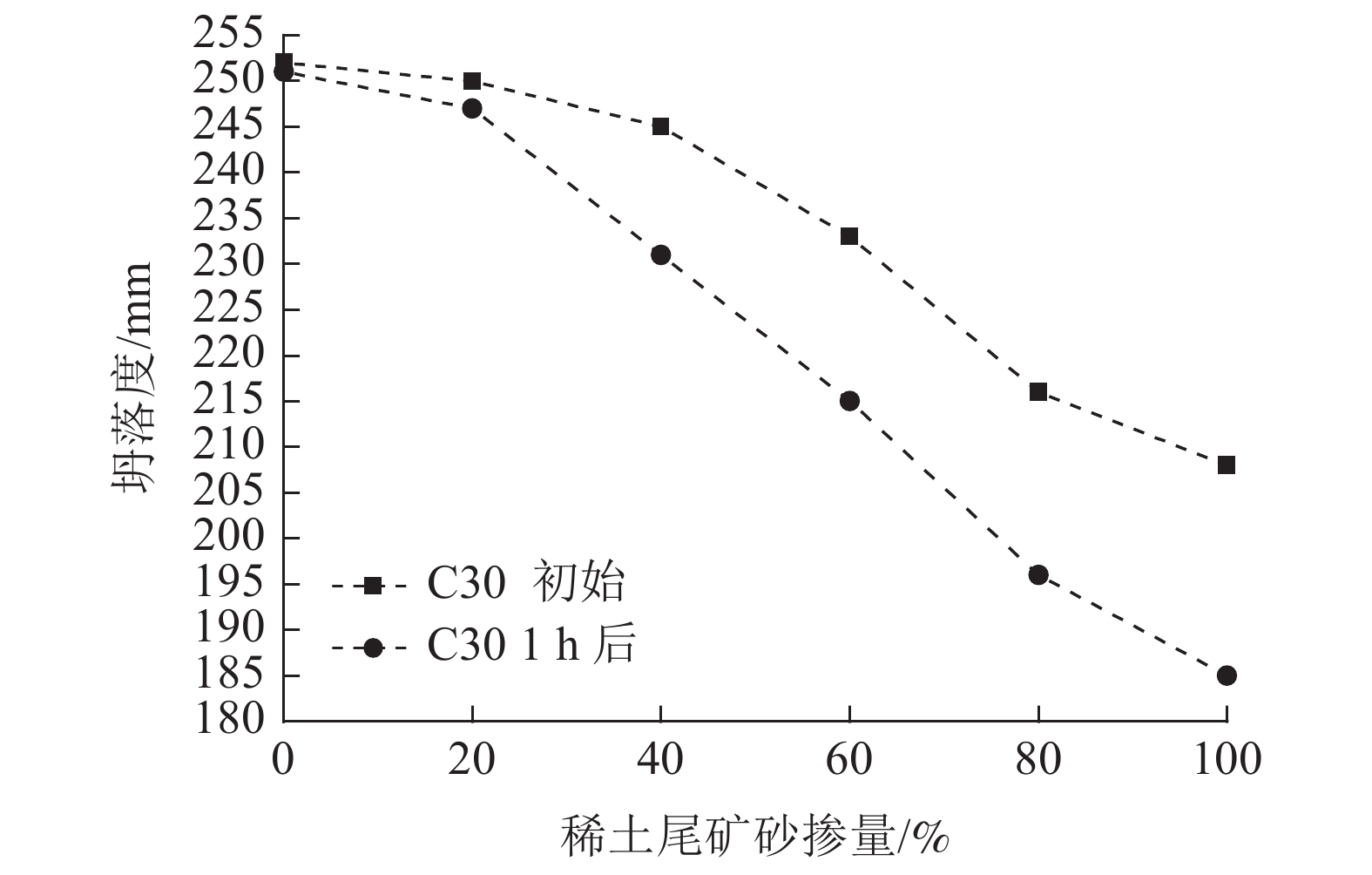

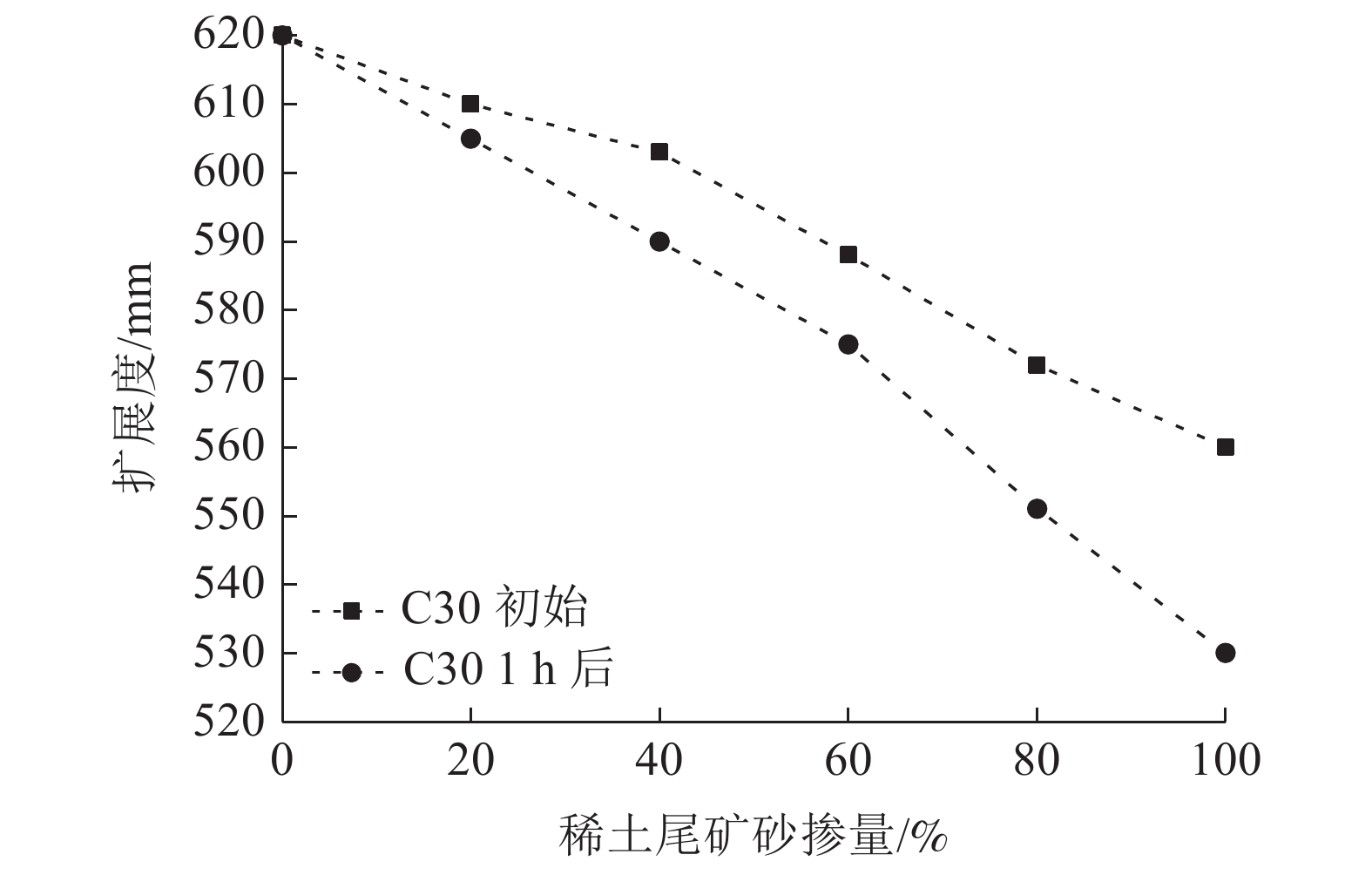

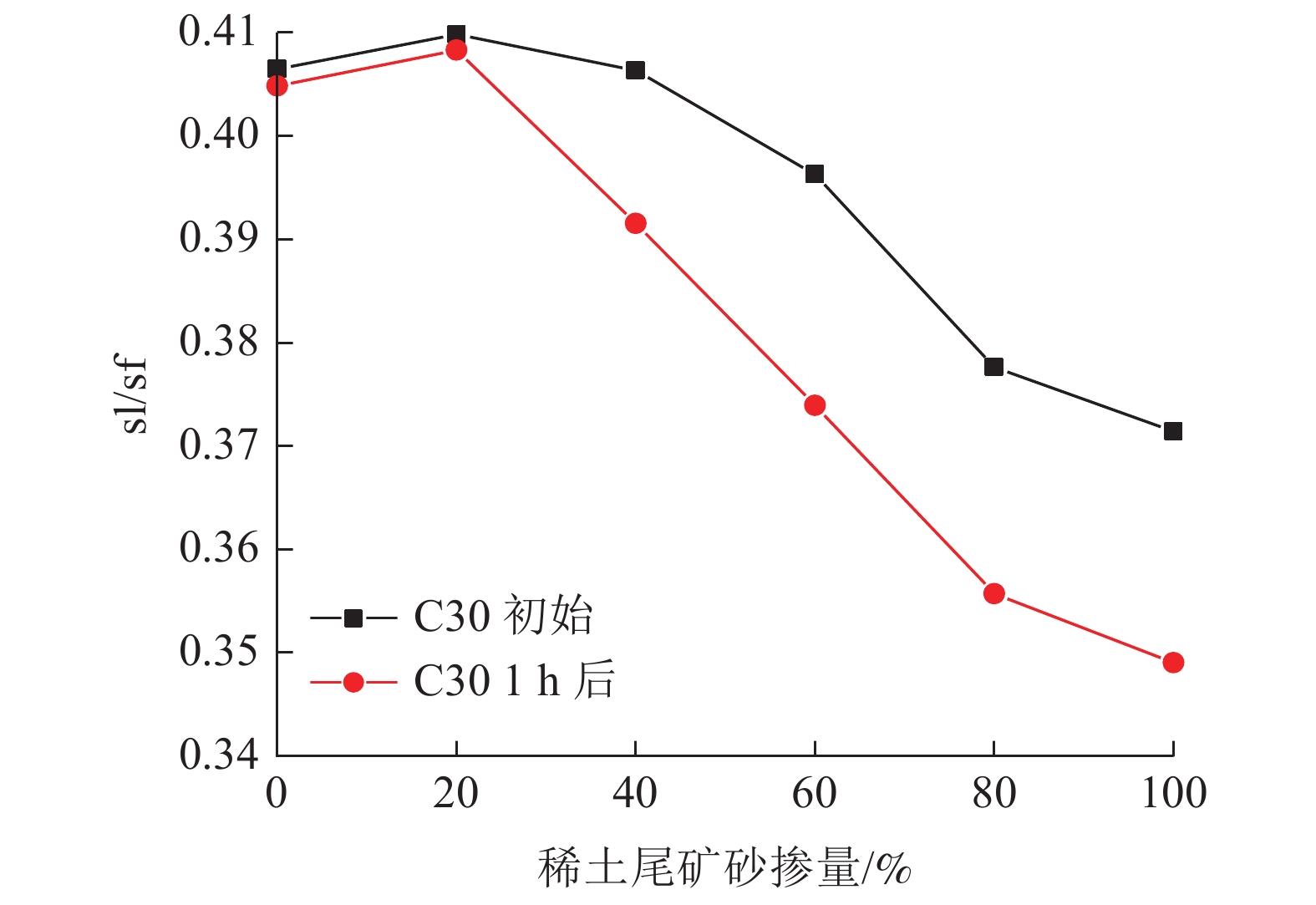

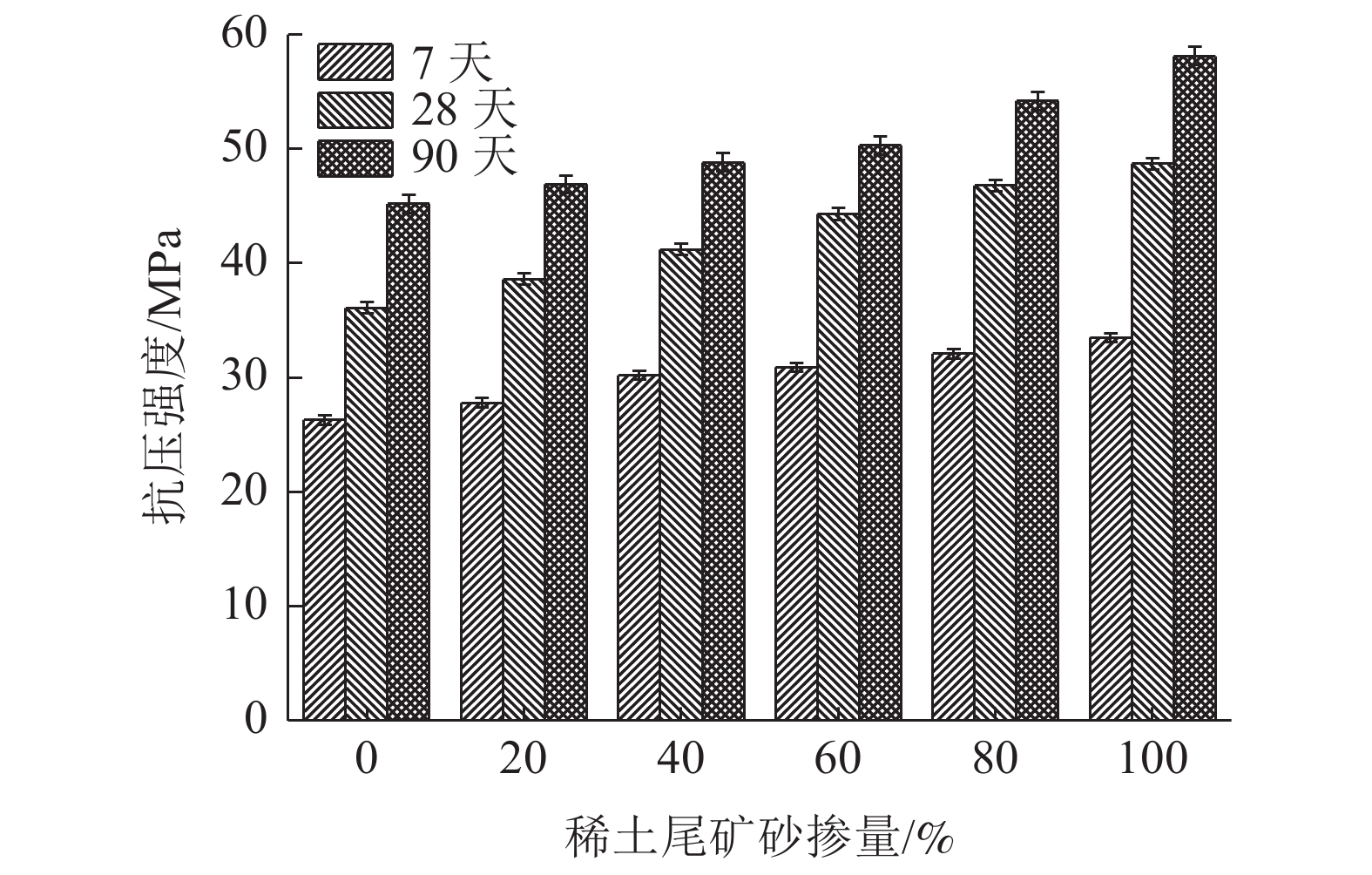

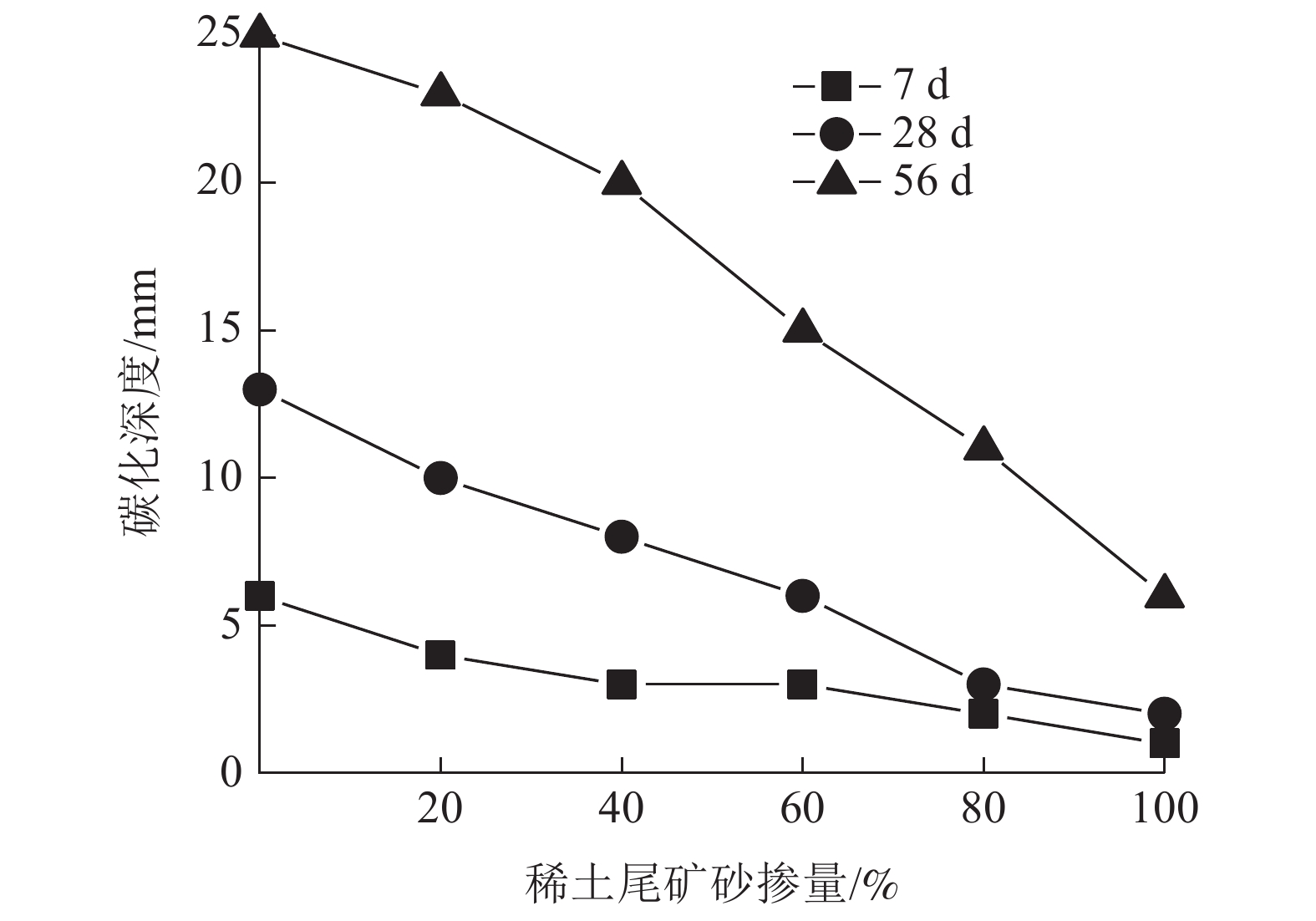

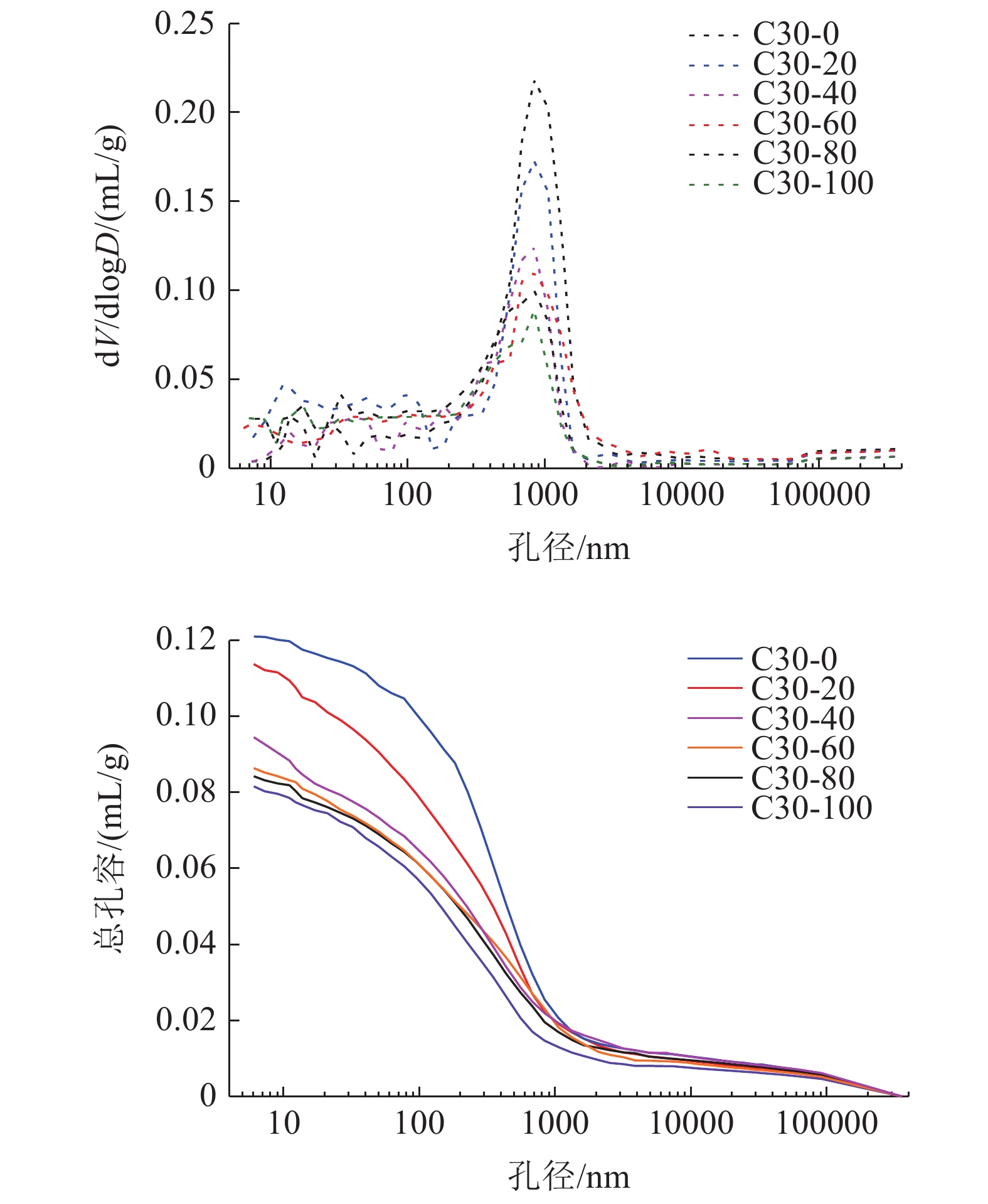

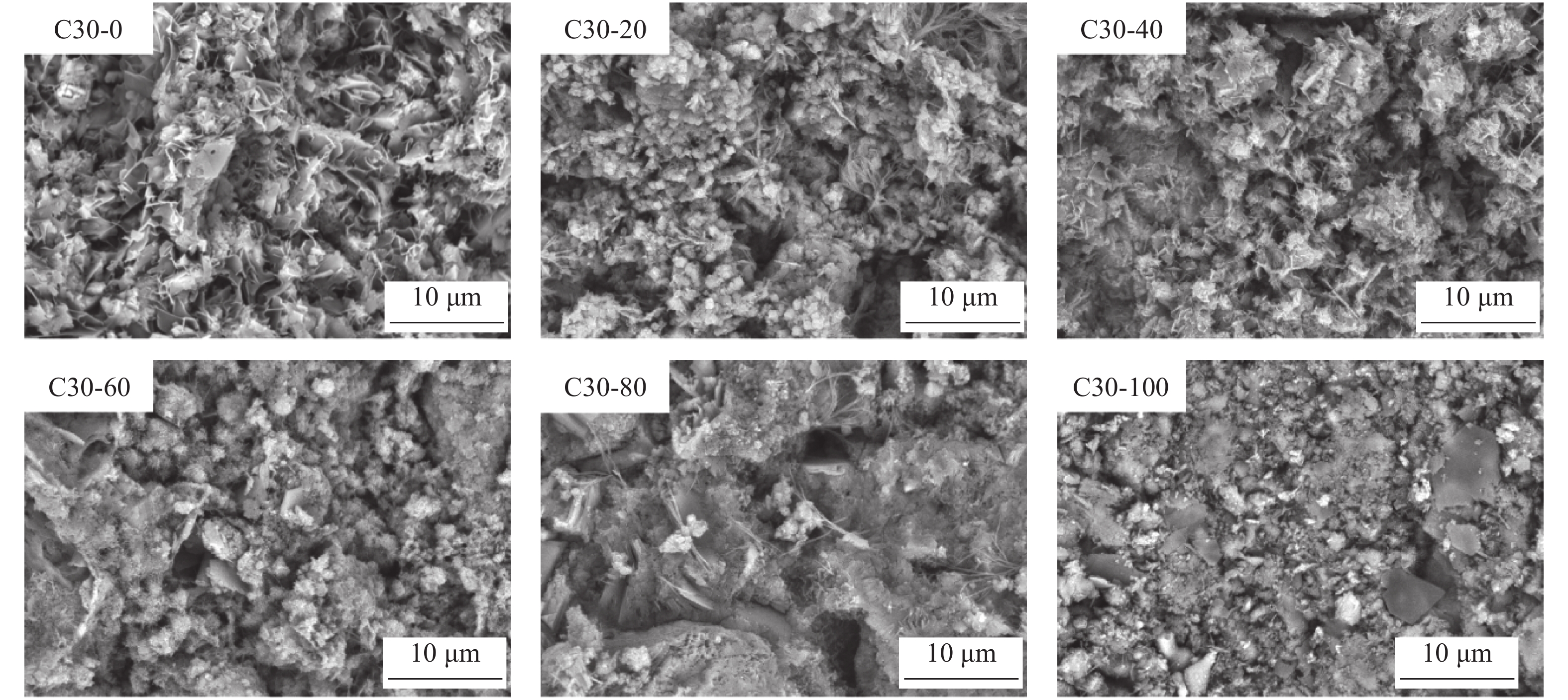

这是一篇陶瓷及复合材料领域的文章。为进一步提高稀土尾矿利用率,本研究以稀土尾矿砂为细骨料设计制备了C30再生骨料混凝土,研究了尾矿砂的掺量对再生骨料混凝土的工作性、力学性能及耐久性的影响。实验结果表明:以稀土尾矿砂为细骨料能够制备出满足标准要求的C30及C40混凝土,随着尾矿砂掺量的增加,混凝土工作性降低,但完全采用尾矿砂作为细骨料的混凝土的和易性可达到使用需求。随着尾矿砂掺量的增加,混凝土微观孔隙结构致密化,抗压强度得到提高,当尾矿砂掺量为100%时混凝土的28 d抗压强度提升了34.9%。尾矿砂的掺入改善了混凝土的抗冻性能及抗碳化性能。

Abstract:This is an essay in the field of ceramics and composites. In order to improve the utilization rate of rare earth tailings, this study designed and prepared C30 recycled aggregate concrete with rare earth tailings as fine aggregate. The influence of tailing sand content on workability, mechanical properties and durability of recycled aggregate concrete was studied. The results show that C30 and C40 concrete can be prepared by using rare earth tailing sand as fine aggregate to meet the requirements of the standard. With the increase of tailing sand content, the workability of concrete decreases, but the workability of concrete using tailing sand as fine aggregate can meet the requirements of use. With the increase of tailing sand content, the micro-pore structure of concrete becomes densified and the compressive strength is improved. When tailing sand content is 100%, the 28 d compressive strength of concrete is increased by 34.9%. The addition of tailing sand improves the frost resistance and carbonation resistance of concrete.

-

-

表 1 原材料化学组成/%

Table 1. Chemical composition of raw materials

原料 CaO Al2O3 SO3 SiO2 Fe2O3 K2O Na2O MgO TiO2 累计 P.O42.5水泥 79.15 3.4 0.80 12.14 4.85 0.03 0.08 0.54 0.34 99.51 粉煤灰 12.2 17.8 1.31 56.1 6.12 2.56 0.36 0.90 2.18 99.53 表 2 水泥基本物理性能

Table 2. Basic physical properties of cement

标准稠度

用水量/g安定性 容重/

(g/cm3)凝结时间/

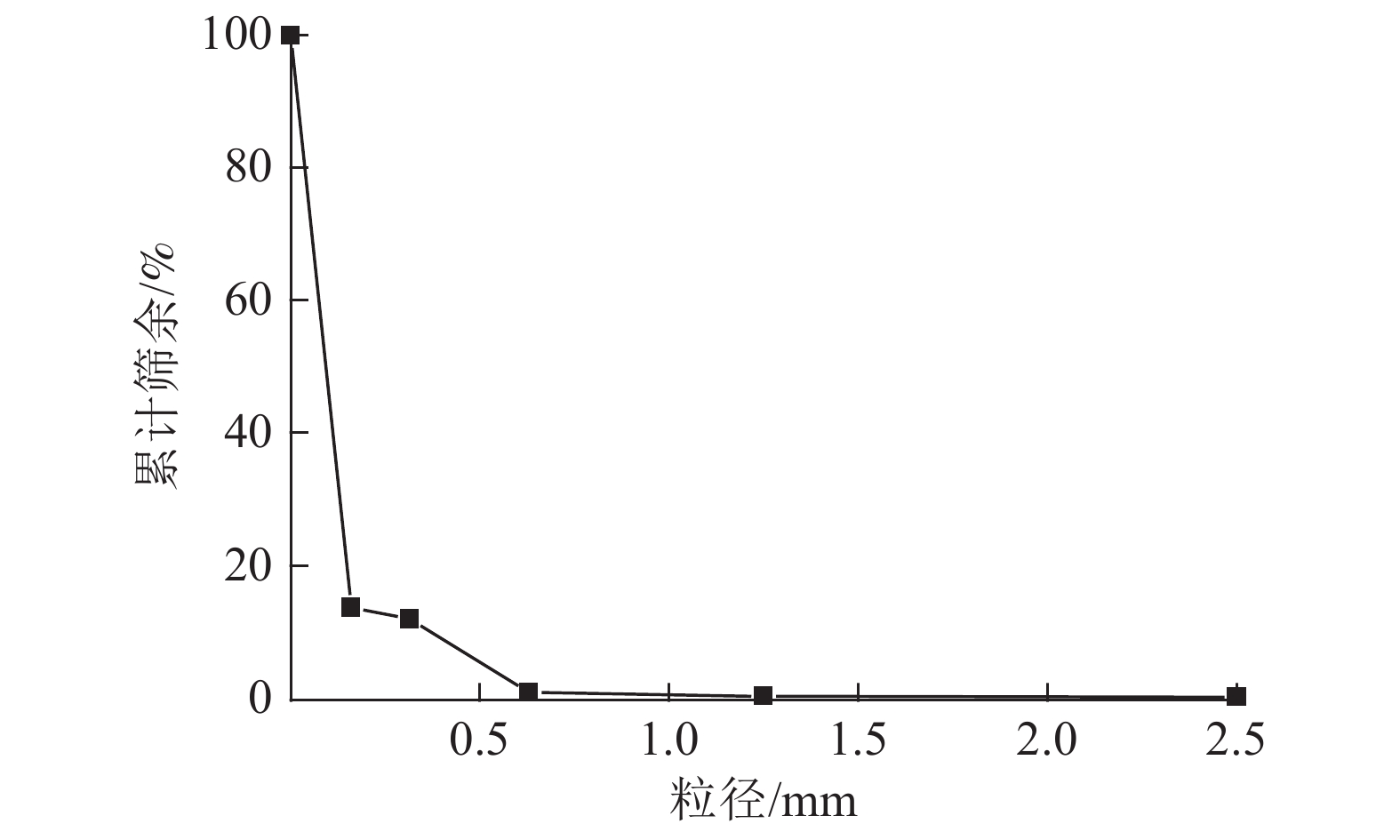

min强度/MPa 抗压 抗折 初凝 终凝 3 d 28 d 3 d 28 d 135 合格 3.11 130 200 24.1 48.5 5.9 9.0 表 3 砂级配合比/%

Table 3. Sand grade mixing ratio

粒径/mm 4.75 2.36 1.18 0.6 0.3 0.15 0.075 分计筛余 4.2 16.1 19.2 18.5 30.6 8.9 2.5 累计筛余 4.2 20.3 39.5 58 88.6 97.5 100 表 4 混凝土配合比设计/(kg/m3)

Table 4. Concrete mix ratio design

编号 稀土尾矿砂 砂 再生骨料 水泥 粉煤灰 水 外加剂 C30-0 0 850 1010 294 56 165 7.3 C30-20 170 680 1010 294 56 165 7.3 C30-40 340 510 1010 294 56 165 7.3 C30-60 510 340 1010 294 56 165 7.3 C30-80 680 170 1010 294 56 165 7.3 C30-100 850 0 1010 294 56 165 7.3 表 5 尾矿砂基本物理性能

Table 5. Basic physical properties of tailing sand

表观密度

/(g/cm3)堆积密度

/(g/cm3)紧密堆积密度

/(g/cm3)含泥量

/%2.50 1.32 1.61 9.30 -

[1] Abaka-Wood G B, Zanin M, Addai-Mensah J, et al. Recovery of rare earth elements minerals from iron oxide–silicate rich tailings – part 1: magnetic separation[J]. Minerals Engineering, 2019, 136:50-61. doi: 10.1016/j.mineng.2019.02.026

[2] 李潇雨, 惠博, 熊文良, 等. 白云鄂博稀土资源综合利用现状概述[J]. 矿产综合利用, 2021(5):17-24. LI X Y, HUI B, XIONG W L, et al. Multipurpose utilization of rare earth resources in Bayan Obo[J]. Multipurpose Utilization of Mineral Resources, 2021(5):17-24.

LI X Y, HUI B, XIONG W L, et al. Multipurpose utilization of rare earth resources in Bayan Obo[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 17-24.

[3] 熊文良, 黄阳, 张丽军, 等. 稀土尾矿配料煅烧硅酸盐水泥熟料的实验研究[J]. 矿产综合利用, 2021(5):76-80. XIONG W L, HUANG Y, ZHANG L J, et al. Experimental study on calcination of portland cement clinker with rare earth tailings[J]. Multipurpose Utilization of Mineral Resources, 2021(5):76-80.

XIONG W L, HUANG Y, ZHANG L J, et al. Experimental study on calcination of portland cement clinker with rare earth tailings[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 76-80.

[4] 王维维, 李二斗, 王其伟, 等. 白云鄂博微细粒稀土矿工艺矿物学及浮选实验研究[J]. 矿产综合利用, 2021(5):81-85. WANG W W, LI E D, WANG Q W, et al. Study on process mineralogy and flotation test of the Bayan Obo finegrained rare earth ore[J]. Multipurpose Utilization of Mineral Resources, 2021(5):81-85.

WANG W W, LI E D, WANG Q W, et al. Study on process mineralogy and flotation test of the bayan obo finegrained rare earth ore[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 81-85.

[5] 秦玉芳, 马莹, 李娜. 白云鄂博尾矿库及其资源利用研究概况[J]. 矿产综合利用, 2020(6):100-109. QIN Y F, MA Y, LI N. Research overview of Bayan Obo tailings pond and its resource utilization[J]. Multipurpose Utilization of Mineral Resources, 2020(6):100-109.

QIN Y F, MA Y, LI N. Research overview of Bayan Obo tailings pond and its resource utilization[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 100-109.

[6] Xiong Beibei, Demartino Cristoforo, Xu Jinjun, et al. High-strain rate compressive behavior of concrete made with substituted coarse aggregates: Recycled crushed concrete and clay bricks[J]. Construction and Building Materials, 2021, 301:123875. doi: 10.1016/j.conbuildmat.2021.123875

[7] Kim Jeonghyun. Properties of recycled aggregate concrete designed with equivalent mortar volume mix design[J]. Construction and Building Materials, 2021, 301:124091. doi: 10.1016/j.conbuildmat.2021.124091

[8] Chen Xue-Fei, Kou Shi-Cong, Xing Feng. Mechanical and durable properties of chopped basalt fiber reinforced recycled aggregate concrete and the mathematical modeling[J]. Construction and Building Materials, 2021, 298:123901. doi: 10.1016/j.conbuildmat.2021.123901

[9] Lin ShuKen, Wu ChungHao. Improvement of bond srength and durability of recycled aggregate concrete incorporating high volume blast furnace slag[J]. Materials, 2021, 14(13):3708. doi: 10.3390/ma14133708

[10] 胡立志, 代飞, 李伟青, 等. 搅拌站废浆对水泥水化的影响[J]. 矿产综合利用, 2019(5):102-106. HU L Z, DAI F, LI W Q, et al. Study on effect of the slurry of concrete mmixing plant upon cement hydration[J]. Multipurpose Utilization of Mineral Resources, 2019(5):102-106.

HU L Z, DAI F, LI W Q, et al. Study on effect of the slurry of concrete mmixing plant upon cement hydration[J]. Multipurpose Utilization of Mineral Resources, 2019(5): 102-106.

[11] 杨树桐, 李琳桢, 于淼. 碱激发海砂再生骨料混凝土的制备及其拉伸强度的确定[J]. 材料导报, 2021, 35(S2):176-182. YANG S T, LI L Z, YU M. Production and tensile strength determination of alkali activated sea sand recycled aggregate concrete[J]. Materials Review, 2021, 35(S2):176-182.

YANG S T, LI L Z, YU M. Production and tensile strength determination of alkali activated sea sand recycled aggregate concrete[J]. Materials Review, 2021, 35(S2): 176-182.

[12] 刘春阳, 高英棋, 顾一凡, 等. 钢纤维大粒径再生粗骨料混凝土梁受弯性能试验研究[J]. 建筑结构, 2021, 51(21):68-72+89. LIU C Y, GAO Y Q, GU Y F, et al. Experimental study on the flexural behavior of concrete beams with large particle size recycled coarse aggregate and steel fiber[J]. Building Structure, 2021, 51(21):68-72+89.

LIU C Y, GAO Y Q, GU Y F, et al. Experimental study on the flexural behavior of concrete beams with large particle size recycled coarse aggregate and steel fiber [J]. Building Structure, 2021, 51(21): 68-72+89.

-

下载:

下载: