Influence of Minerals and Nanomaterials on the Properties of Reactive Powder Concrete

-

摘要:

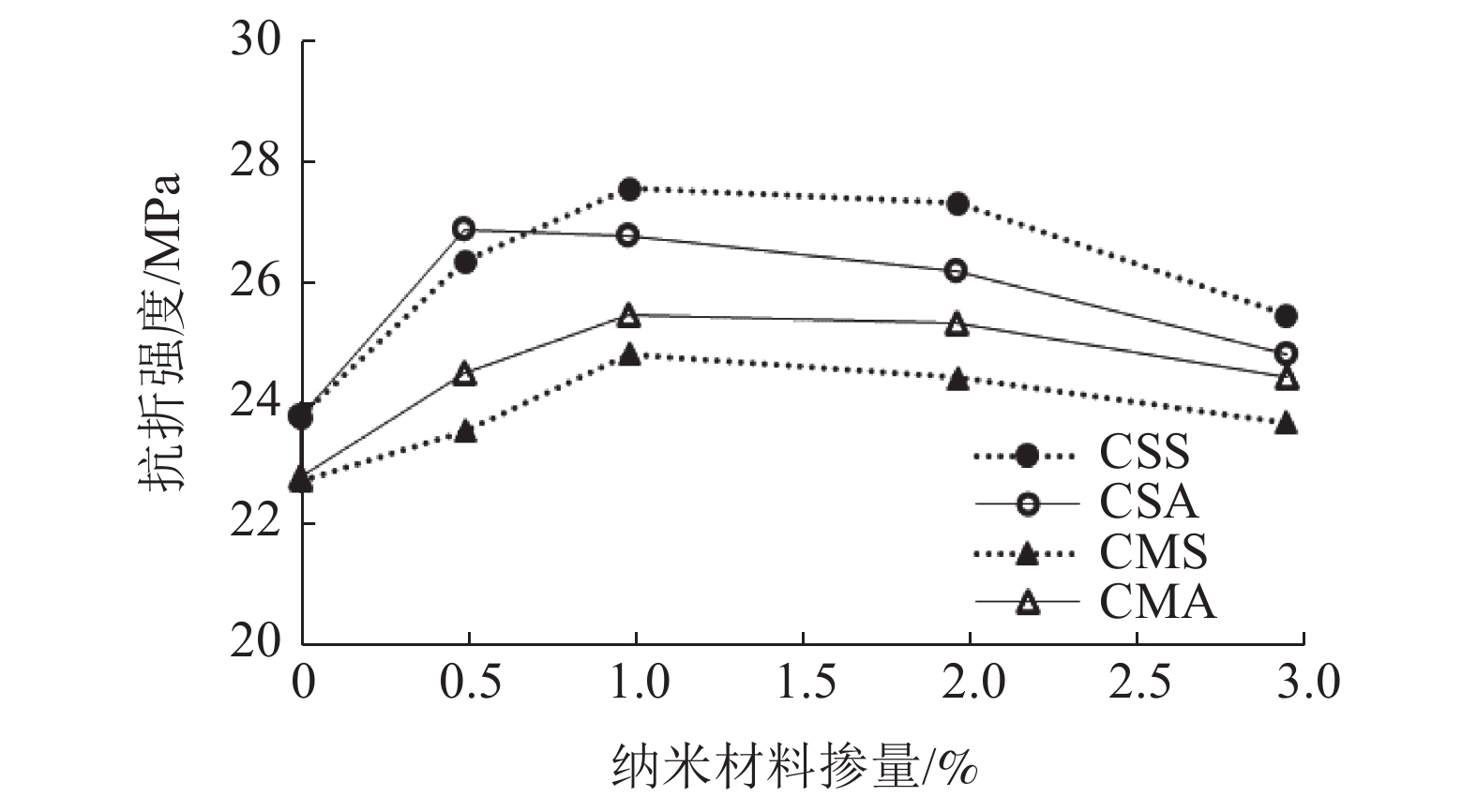

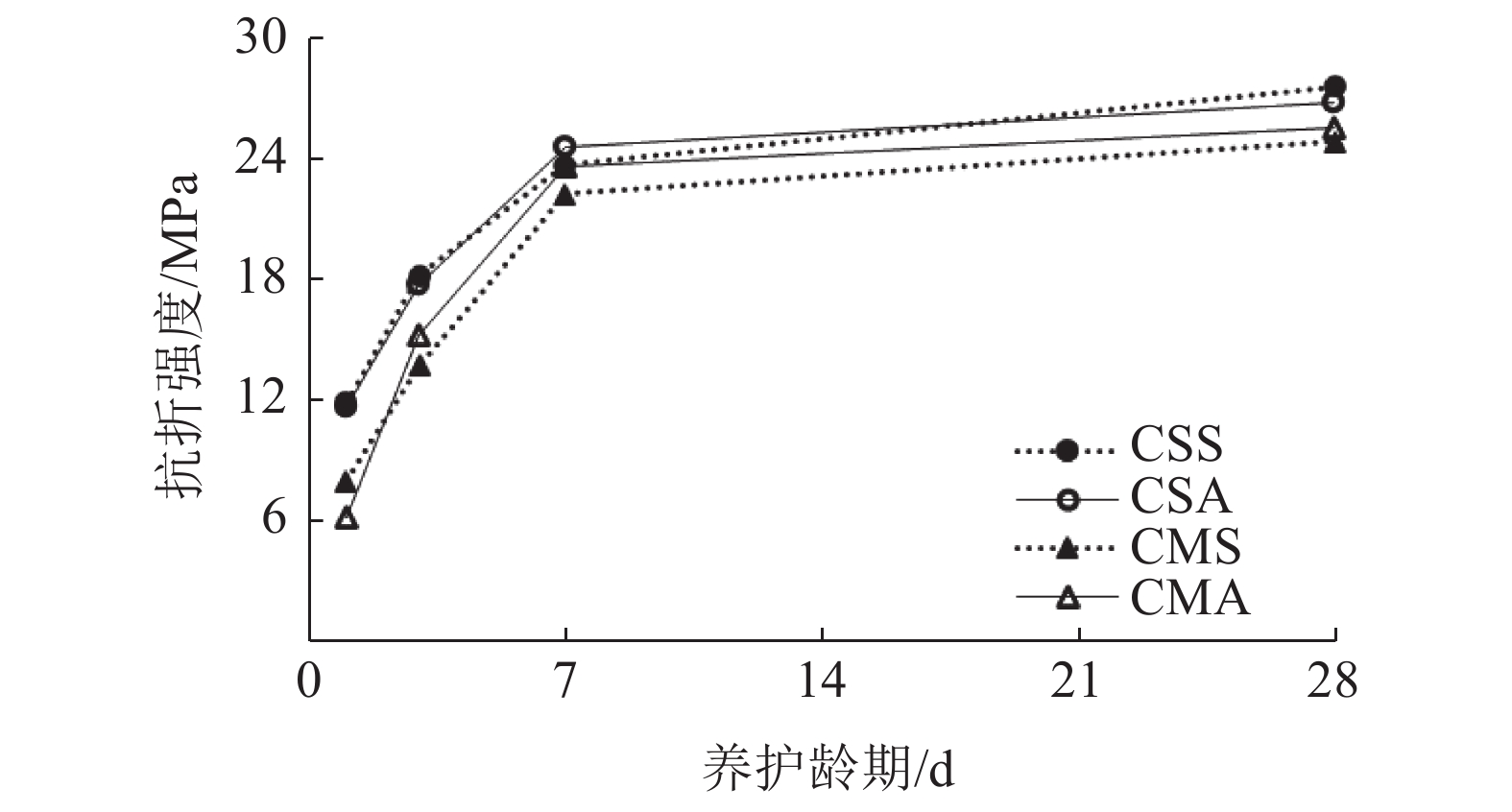

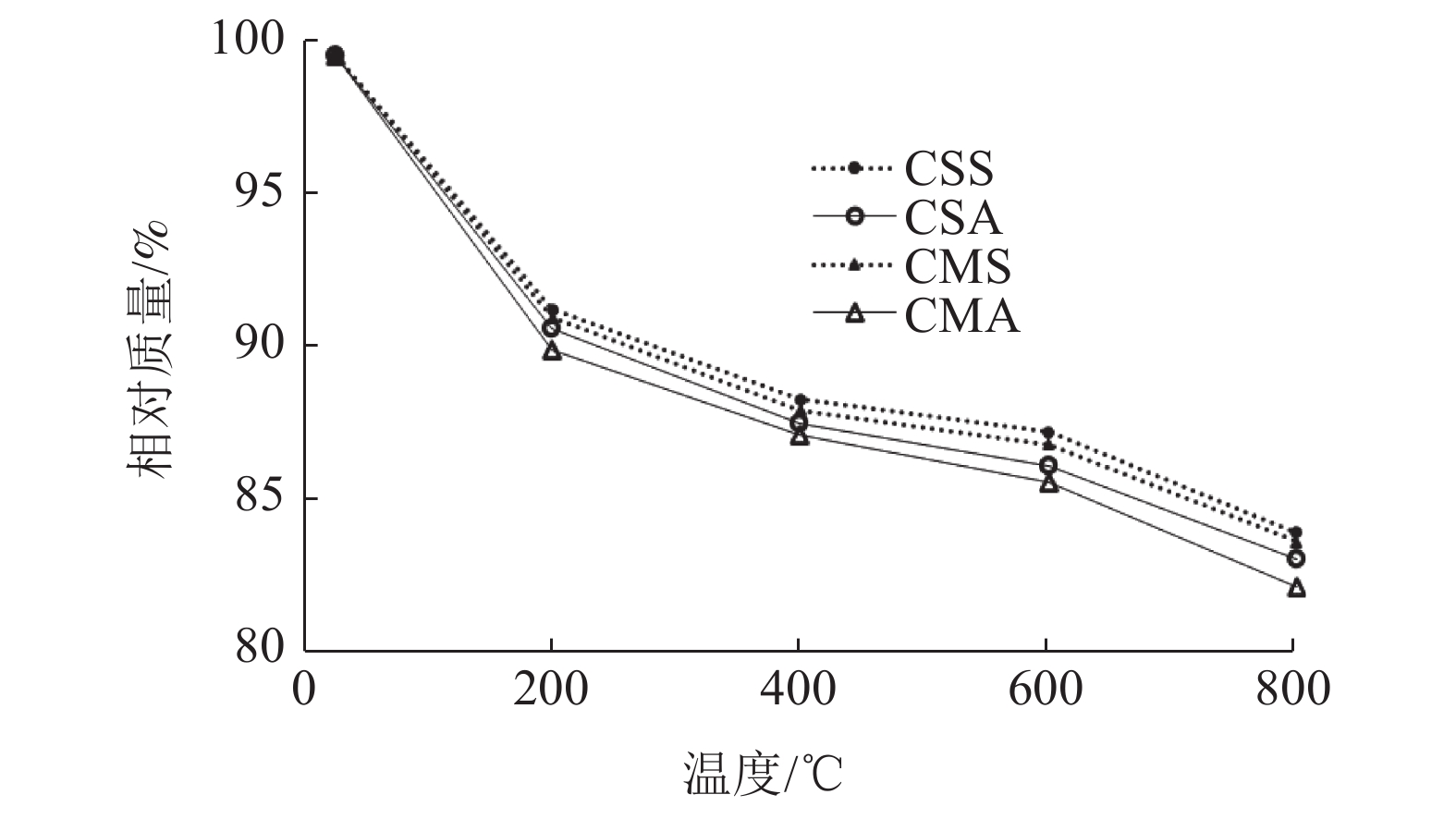

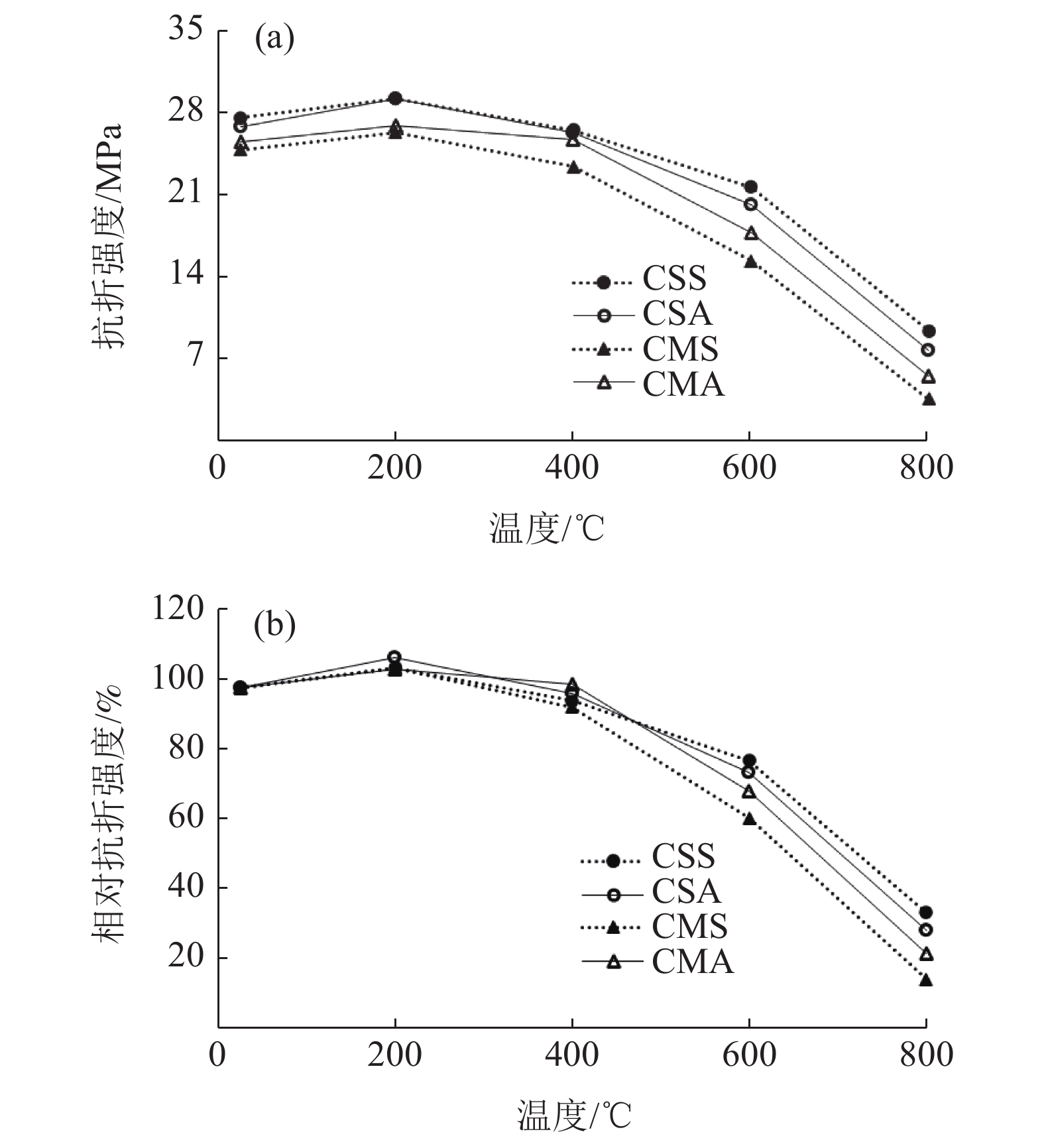

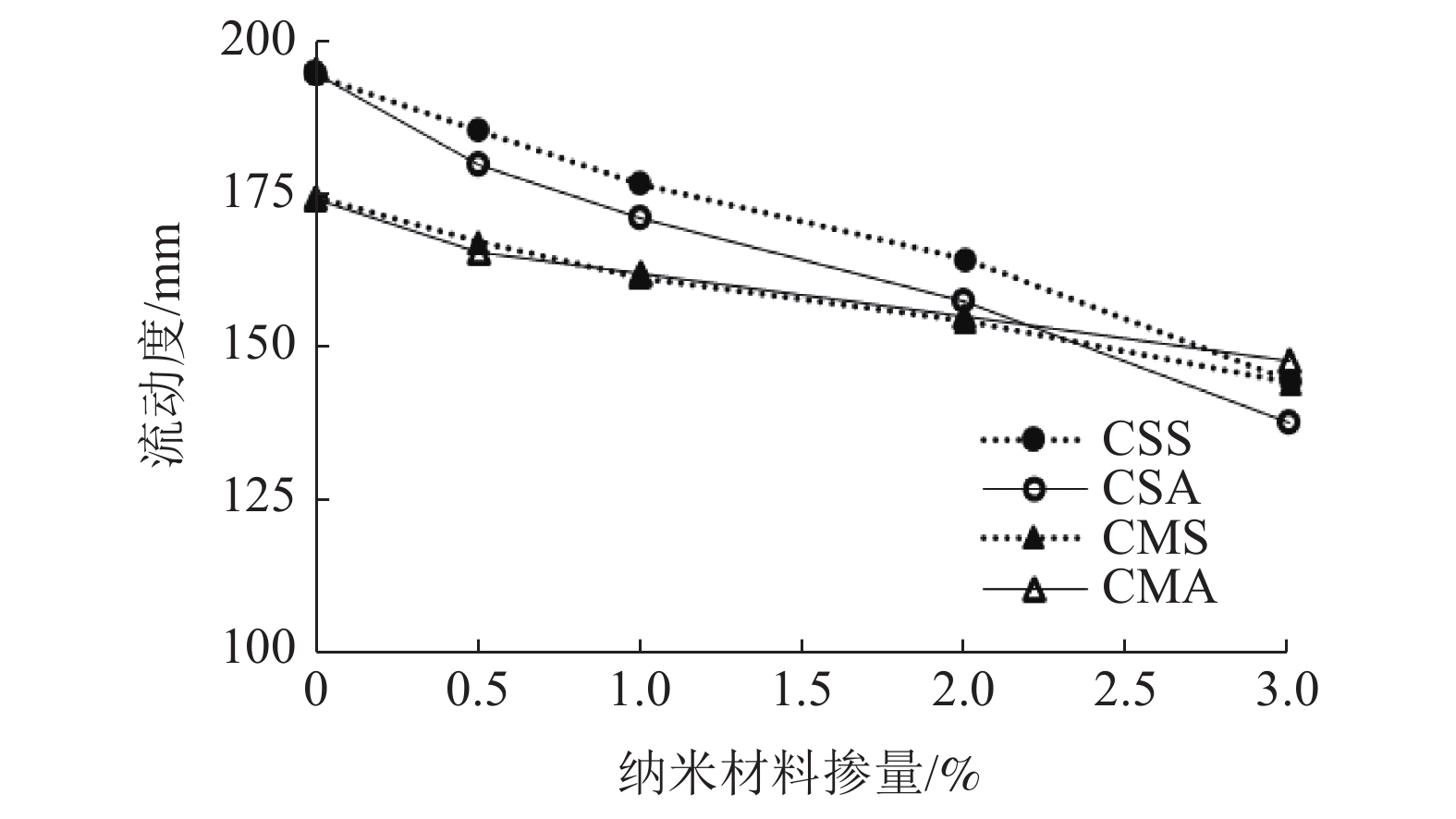

这是一篇陶瓷及复合材料领域的论文。利用硅粉、偏高岭土和纳米材料制备了活性粉末混凝土,并对矿物成分和纳米材料对活性粉末混凝土基本特性的影响规律进行了研究。硅粉和偏高岭土按照固定比例掺入,纳米二氧化硅和纳米氧化铝则分别按照水泥质量0.5%、1%、2%和3%的比例进行掺入。通过新拌混凝土的密度和流动度实验以及不同龄期下的强度实验对改性后的活性粉末混凝土的基本特性进行测试,结果表明随着纳米材料的掺入,混凝土的密度逐渐增加,而流动度则不断减小;抗压强度和抗折强度随着纳米材料掺入量的增加先增后减,由此得出纳米材料的较优掺量为1%~2%。高温实验结果表明活性粉末混凝土的抗压强度和抗折强度随着温度先增后减,较佳温度为200 ℃;温度导致的强度下降的速度为CSS>CSA>CMA>CMS。此外,SEM分析表明高温会导致混凝土内部出现劣化。

Abstract:This is an essay in the field of ceramics and composites. Reactive powder concrete was prepared using silica fume, metakaolin and nanomaterials, and then the influence of mineral composition and nanomaterials on the basic characteristics of reactive powder concrete was studied. Silica fume and metakaolin are mixed in fixed proportions, while nano-silica and nano-alumina are mixed in proportions of 0.5%, 1%, 2% and 3% of the cement mass, respectively. The basic characteristics of the modified reactive powder concrete were tested through the density and fluidity experiments of fresh concrete and the strength tests were conducted at different curing ages. The results showed that with the incorporation of nanomaterials, the density of concrete gradually increased, whilethe fluidity continues to decrease; the compressive strength and flexural strength of samples first increase and then decrease with the increase of nanomaterials, and it is concluded that the optimal dosage of nanomaterials is 1%~2%. The high temperature test results show that the compressive strength and flexural strength of reactive powder concrete increase first and then decrease with the temperature, the best temperature is 200 ℃; the rate of strength decrease caused by temperature is CSS>CSA>CMA>CMS. In addition, SEM analysis also shows that high temperature will cause deterioration of the interior of the concrete.

-

-

表 1 水泥和矿物掺料的化学成分/%

Table 1. Chemical composition of cement and mineral admixtures

材料 SiO2 Al2O3 Fe2O3 CaO MgO SO3 TiO2 烧失量 水泥 20.66 4.88 4.58 65.74 0.88 2.14 0 1.12 硅粉 33.91 21.35 1.45 30.22 9.48 0.19 0.85 2.55 偏高岭土 53 37.5 2.5 1.6 0.14 0.037 3.78 1.9 表 2 纳米材料的基本特性

Table 2. Basic characteristics of nanomaterials

纳米材料 密度/

(g/cm3)比表面积/

(g/cm3)直径/

nm纯度/

%二氧化硅 220 0.05 30 99.5 三氧化二铝 200 0.12 20 99.6 表 3 试样编号及配比设计/kg

Table 3. Sample number and proportion design

编号 混凝土 水 砂 硅粉 偏高

岭土纳米二

氧化硅纳米二

氧化铝减水剂 CS 750 200 1275 187.5 0 0 0 30 CSS0.5 746.25 200 1275 187.5 0 3.75 0 30 CSS1 742.5 200 1275 187.5 0 7.5 0 30 CSS2 735 200 1275 187.5 0 15 0 30 CSS3 727.5 200 1275 187.5 0 22.5 0 30 CSA0.5 746.25 200 1275 187.5 0 0 3.75 30 CSA1 742.5 200 1275 187.5 0 0 7.5 30 CSA2 735 200 1275 187.5 0 0 15 30 CSA3 727.5 200 1275 187.5 0 0 22.5 30 CM 750 200 1275 0 187.5 0 0 30 CMS0.5 746.25 200 1275 0 187.5 3.75 0 30 CMS1 742.5 200 1275 0 187.5 7.5 0 30 CMS2 735 200 1275 0 187.5 15 0 30 CMS3 727.5 200 1275 0 187.5 22.5 0 30 CMS0.5 746.25 200 1275 0 187.5 0 3.75 30 CMS1 742.5 200 1275 0 187.5 0 7.5 30 CMS2 735 200 1275 0 187.5 0 15 30 CMS3 727.5 200 1275 0 187.5 0 22.5 30 -

[1] 王晓飞. 活性粉末混凝土单轴循环压缩试验条件下力学特性研究[J]. 硅酸盐通报, 2019, 38(7):2321-2328. WANG X F. Study on mechanical properties of reactive powder concrete under uniaxial cyclic compression test[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(7):2321-2328.

WANG X F. Study on mechanical properties of reactive powder concrete under uniaxial cyclic compression test[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(7): 2321-2328.

[2] 李新星, 杨才千, 周泉, 等. 基于正交试验的活性粉末混凝土强度及流动性研究[J]. 硅酸盐通报, 2019, 38(4):1201-1210. LI X X, YANG C Q, ZHOU Q, et al. Research on the strength and fluidity of reactive powder concrete based on orthogonal test[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(4):1201-1210.

LI X X, YANG C Q, ZHOU Q, et al. Research on the strength and fluidity of reactive powder concrete based on orthogonal test[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(4): 1201- 1210.

[3] 孙婧, 刘宏波, 王宏, 等. 基于Design-expert的铁尾矿活性粉末混凝土配合比优化试验研究[J]. 硅酸盐通报, 2020, 39(3):762-769. SUN J, LIU H B, WANG H, et al. Experimental research on optimization of mixture ratio of reactive powder concrete with iron tailings based on design-expert[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(3):762-769.

SUN J, LIU H B, WANG H, et al. Experimental research on optimization of mixture ratio of reactive powder concrete with iron tailings based on design-expert[J]. Bulletin of the Chinese Ceramic Society, 2020, 39(3): 762-769.

[4] 王雪莲. 粉煤灰微珠活性粉末混凝土力学与收缩特性研究[J]. 硅酸盐通报, 2019, 38(10):3373-3377. WANG X L. Study on the mechanical and shrinkage characteristics of fly ash microbead reactive powder concrete[J]. Bulletin of the Chinese Ceramic Society, 2019, 38(10):3373-3377.

WANG X L. Study on the mechanical and shrinkage characteristics of fly ash microbead reactive powder concrete[J]. Bulletin of the Chinese Ceramic Society , 2019, 38(10): 3373-3377.

[5] 张一帆, 杜红秀, 石丽娜. 碳纤维及硅灰掺量对活性粉末混凝土强度和温敏性的影响[J]. 混凝土, 2019(7):79-81. ZHANG Y F, DU H X, SHI L N. The influence of carbon fiber and silica fume content on the strength and temperature sensitivity of reactive powder concrete[J]. Concrete, 2019(7):79-81.

ZHANG Y F, DU H X, SHI L N. The influence of carbon fiber and silica fume content on the strength and temperature sensitivity of reactive powder concrete[J]. Concrete, 2019(7): 79-81.

[6] 李根, 胡康旭. 复掺纤维活性粉末混凝土高温力学性能研究[J]. 混凝土与水泥制品, 2019(2):48-51. LI G, HU K X. Study on high temperature mechanical properties of composite fiber reactive powder concrete[J]. Concrete and Cement Products, 2019(2):48-51.

LI G, HU K X. Study on high temperature mechanical properties of composite fiber reactive powder concrete[J]. Concrete and Cement Products, 2019(2): 48-51.

[7] 赵洪, 黄向阳, 龙广成, 等. 生态型活性粉末混凝土性能实验研究[J]. 混凝土与水泥制品, 2020(6):90-93. ZHAO H, HUANG X Y, LONG G C, et al. Experimental study on the performance of ecological reactive powder concrete[J]. Concrete and Cement Products, 2020(6):90-93.

ZHAO H, HUANG X Y, LONG G C, et al. Experimental study on the performance of ecological reactive powder concrete[J]. Concrete and Cement Products, 2020(6): 90-93.

[8] Grzeszczyk S, Matuszek C A, Vejmelková E, et al. Reactive powder concrete containing basalt fibers: strength, abrasion and porosity[J]. Materials, 2020, 13(13):2948. doi: 10.3390/ma13132948

[9] 刘数华, 巫美强, 高志扬. 废弃玻璃粉在活性粉末混凝土中的应用研究[J]. 混凝土, 2019(7):125-127. LIU S H, WU M Q, GAO Z Y. Research on the application of waste glass powder in reactive powder concrete[J]. Concrete, 2019(7):125-127.

LIU S H, WU M Q, GAO Z Y. Research on the application of waste glass powder in reactive powder concrete[J]. Concrete, 2019(7): 125-127.

[10] 石东升, 薛欣欣, 李科. 粒化高炉矿渣代砂活性粉末混凝土配合比及力学性能试验[J]. 混凝土, 2019(9):135-138. SHI D S, XUE X X. Experiment on the mix ratio and mechanical properties of granulated blast furnace slag instead of sand reactive powder concrete[J]. Concrete, 2019(9):135-138.

SHI D S, XUE X X. Experiment on the mix ratio and mechanical properties of granulated blast furnace slag instead of sand reactive powder concrete[J]. Concrete, 2019(9): 135-138.

[11] 刘晓仙, 杜红秀, 徐瑶瑶. 复掺纤维对RPC高温后力学性能及超声规律的影响[J]. 混凝土, 2021(1):87-90+97. LIU X X, DU H X, XU Y Y. The effect of composite fiber on the mechanical properties and ultrasonic law of RPC after high temperature[J]. Concrete, 2021(1):87-90+97. doi: 10.3969/j.issn.1002-3550.2021.01.021

LIU X X, DU H X, XU Y Y . The effect of composite fiber on the mechanical properties and ultrasonic law of RPC after high temperature [J]. Concrete, 2021(1): 87-90+97. doi: 10.3969/j.issn.1002-3550.2021.01.021

[12] Sultan H K, Alyaseri I. Effects of elevated temperatures on mechanical properties of reactive powder concrete elements[J]. Construction and Building Materials, 2020, 261:120555. doi: 10.1016/j.conbuildmat.2020.120555

-

下载:

下载: