Preparation and Characterization of Pervious Brick with High Titanium Blast Furnace Slag

-

摘要:

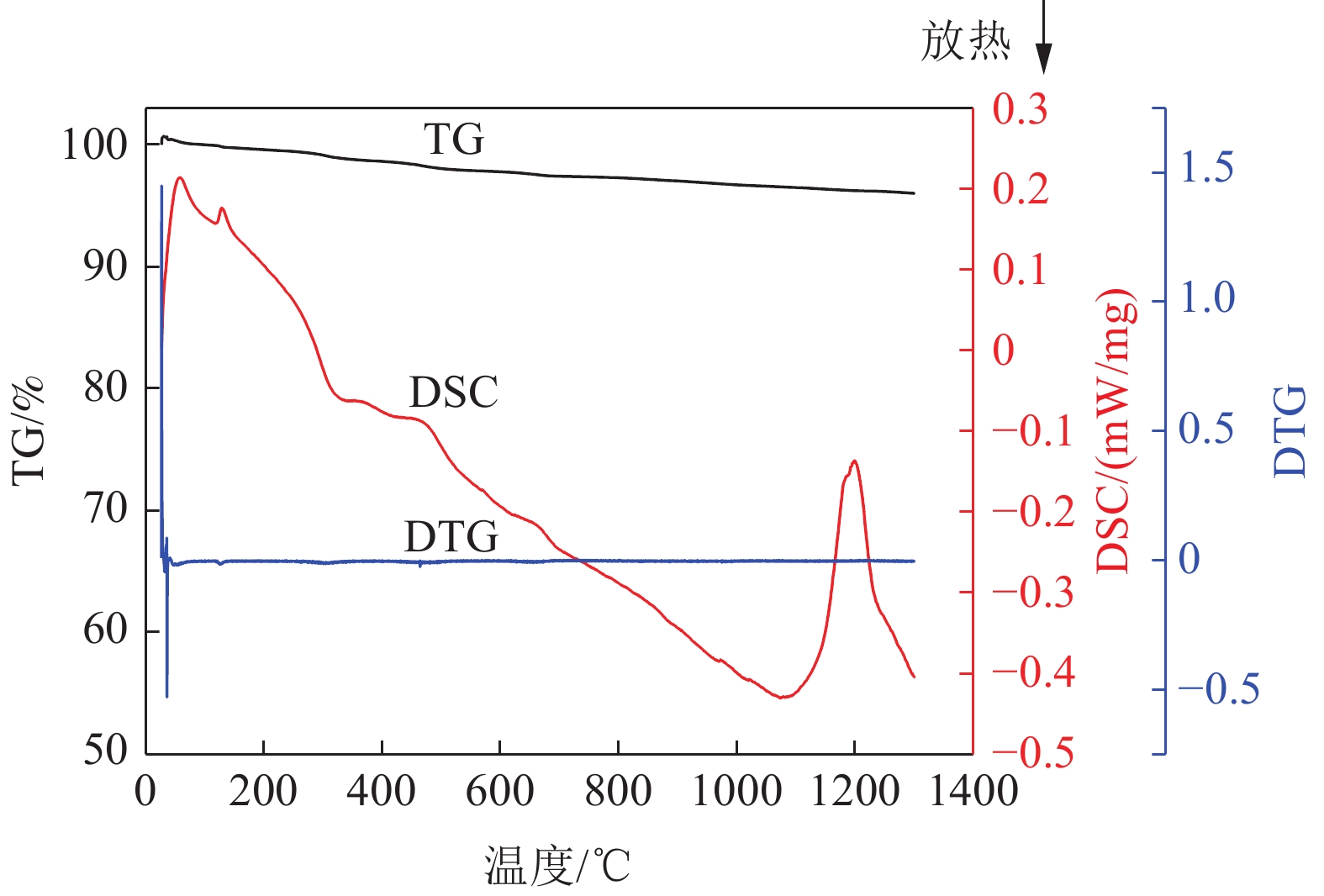

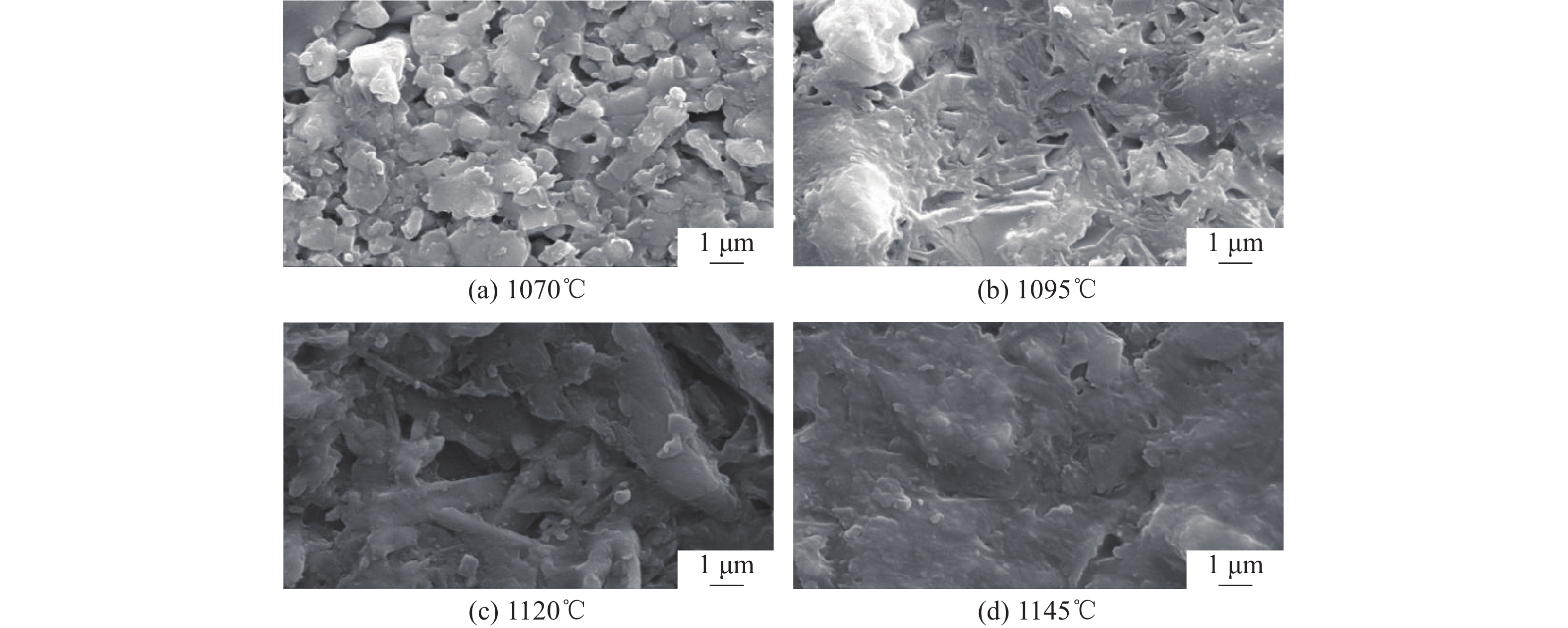

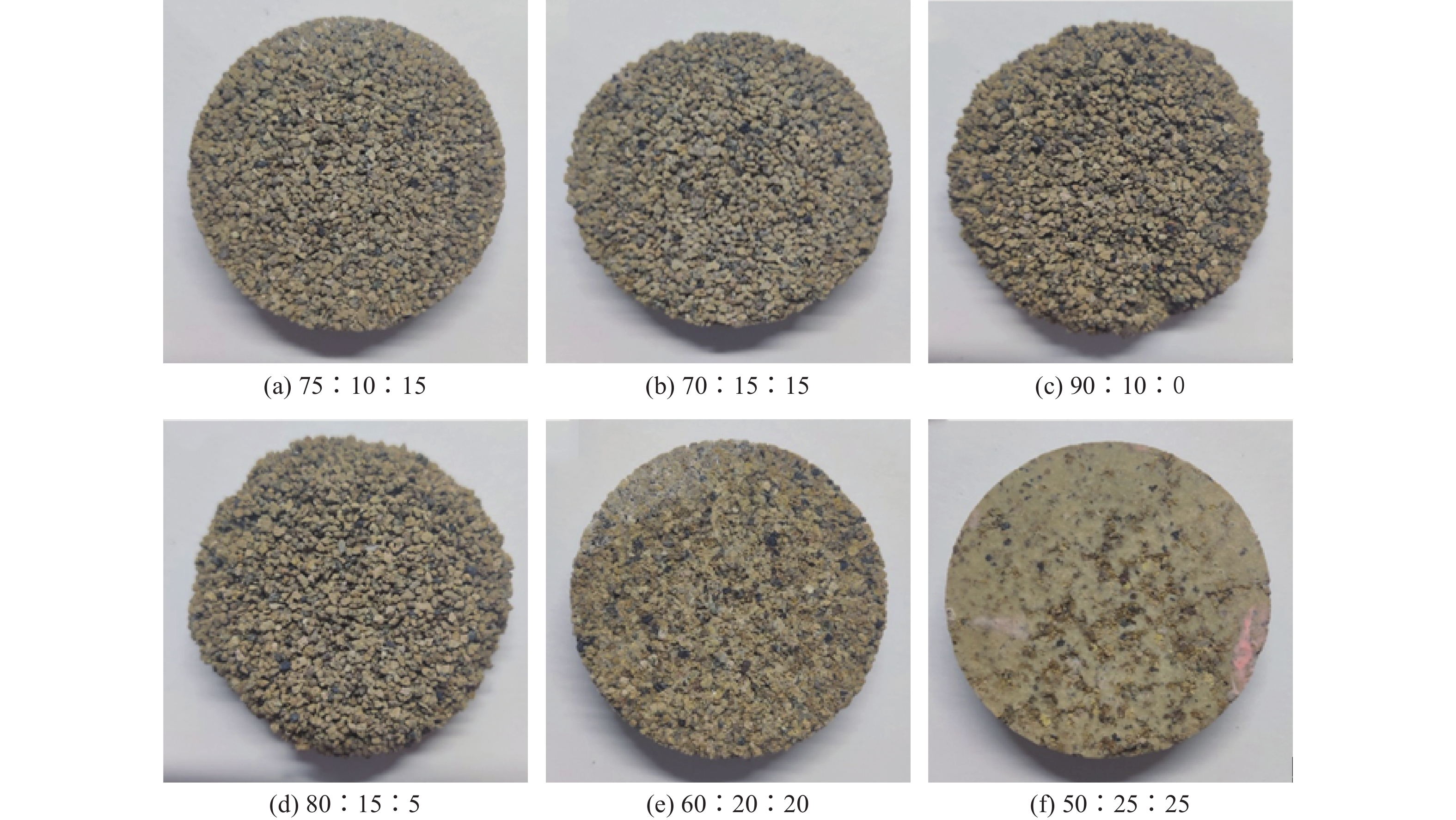

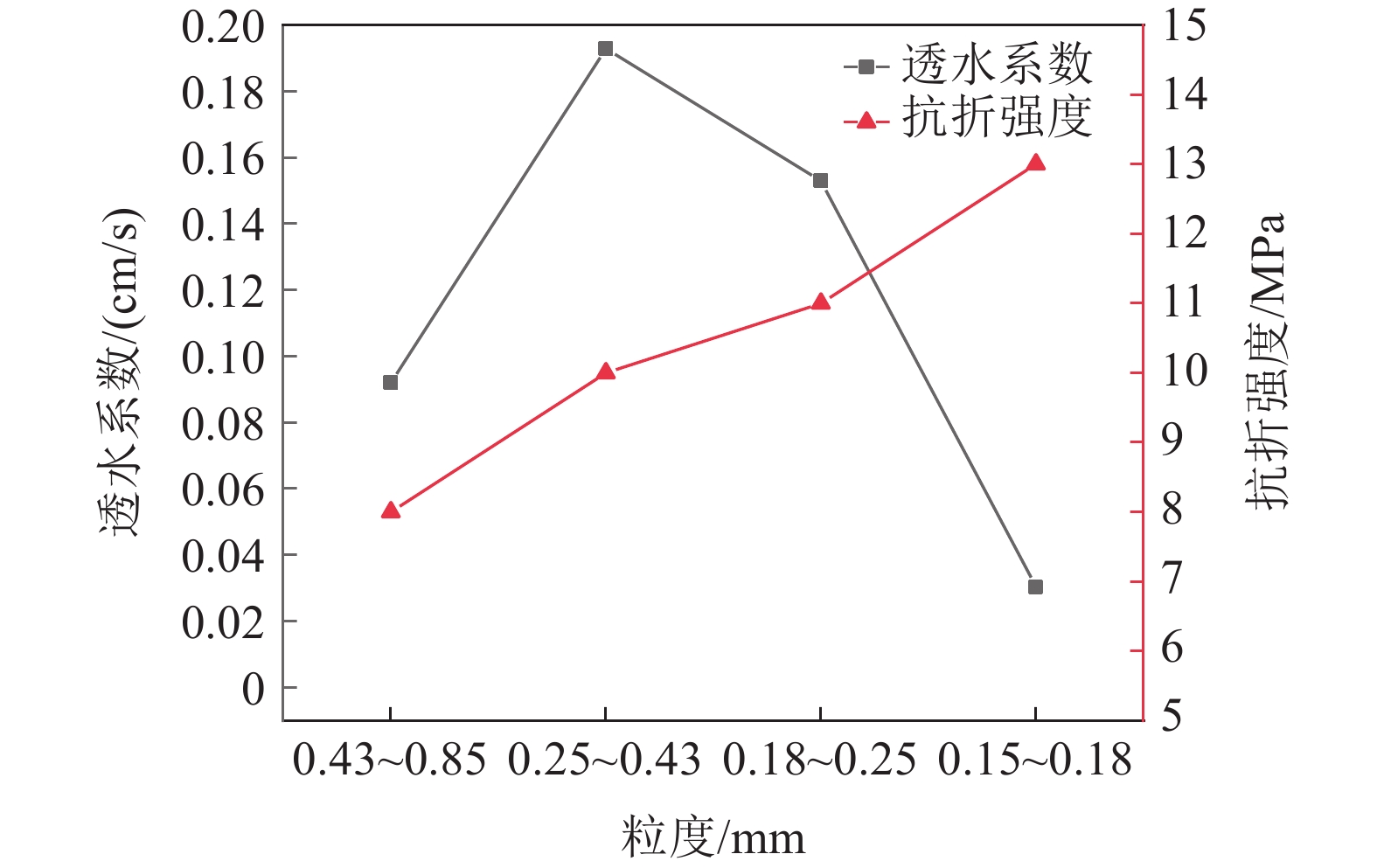

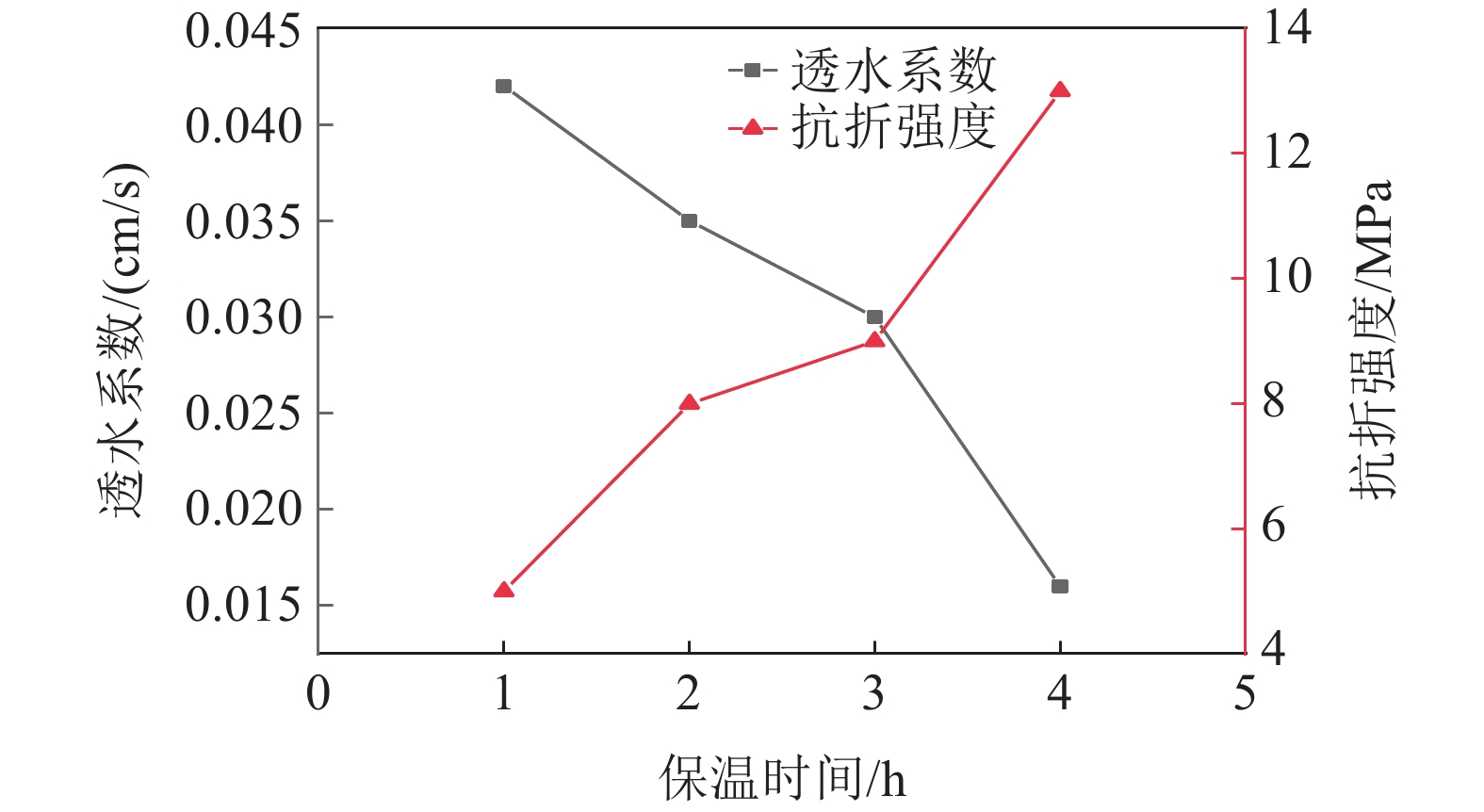

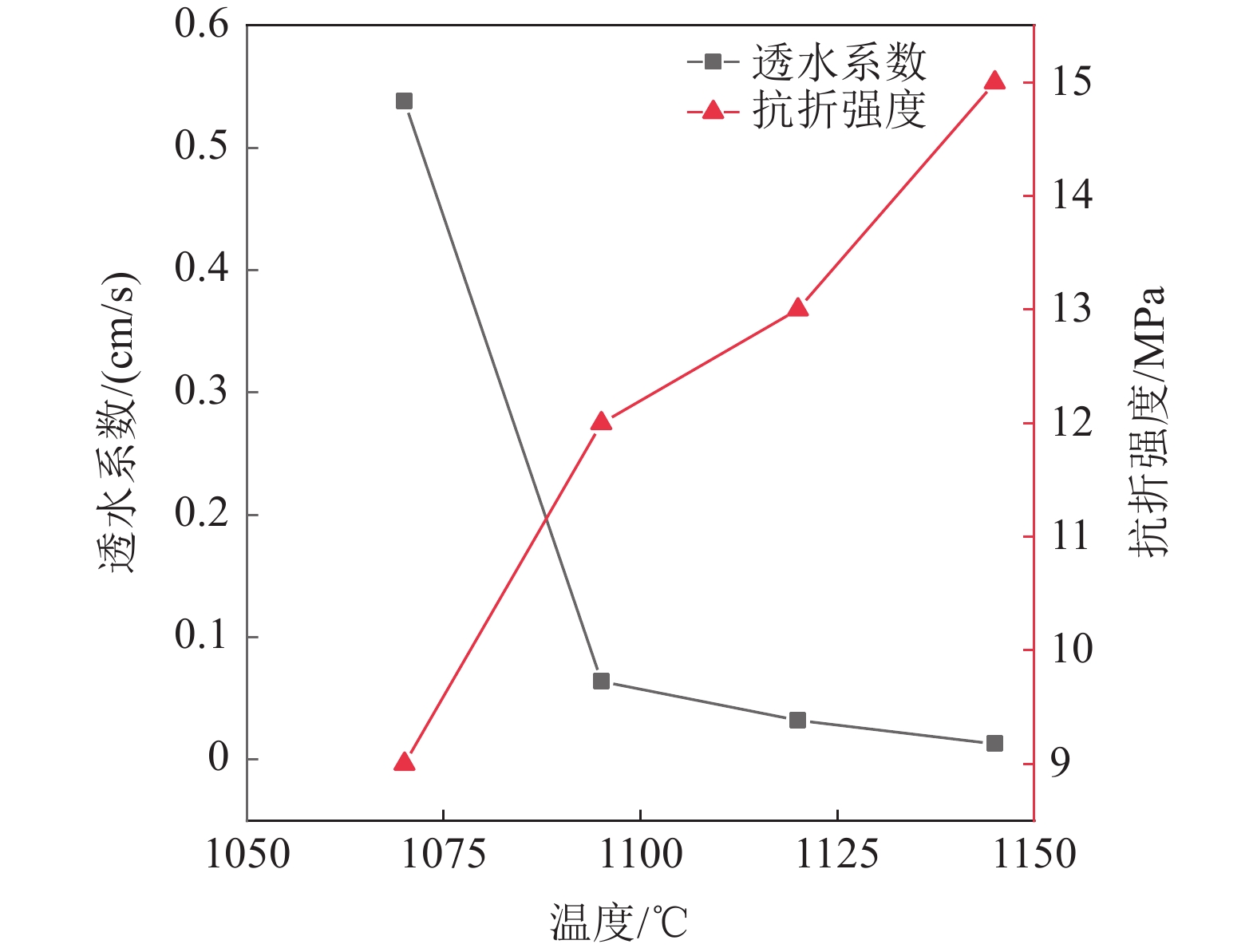

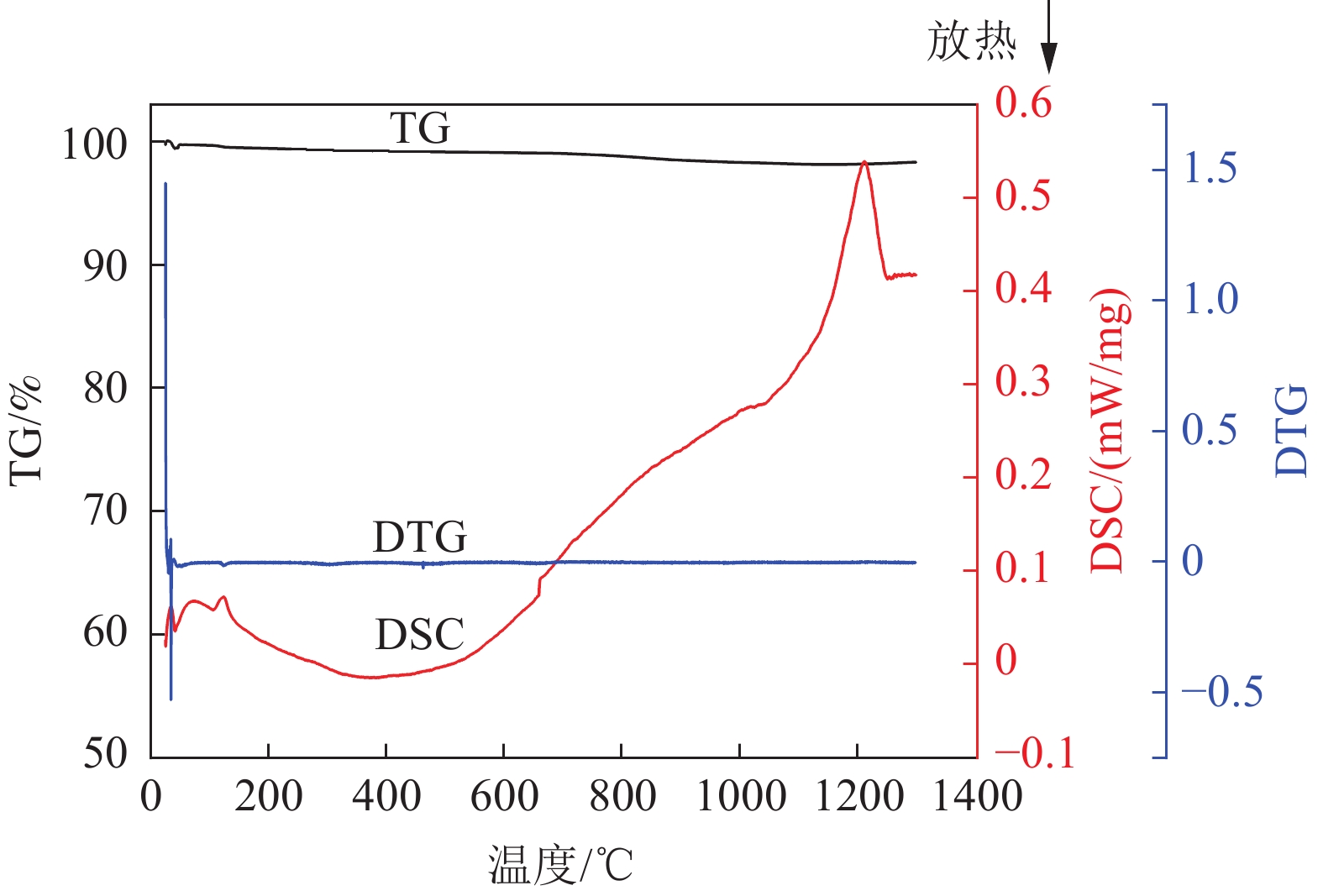

这是一篇陶瓷及复合材料领域的论文。为实现高钛型高炉渣固废的再次资源化利用,解决大掺量高钛型高炉渣制备透水砖问题,本文以高炉渣为骨料,高岭土、钾长石为粘结剂和助融剂,经坯体成型、烧结制备了透水砖。采用TG-DSC综合热分析法、SEM形貌分析法研究了物料的热性能及高温下的形貌变化;讨论了高炉渣及辅料的配比、高炉渣骨料的粒度、成型压力、烧结温度、保温时间对透水砖性能的影响,确定了透水砖适宜的制备工艺参数。结果表明:选取高炉渣0.18~0.25 mm,高炉渣∶高岭土∶钾长石(质量分数)配比为75∶10∶15,成型压力为10 MPa,烧结温度为1 095 ℃,保温时间为3 h,此时透水砖的透水系数为0.064 cm/s,抗折强度为12 MPa,具备高透水性和高强度的特性,满足《透水路面砖和透水路面板》(GB/T 25933-2010)的要求。

Abstract:This is an essay in the field of ceramics and composites. In order to realize the reuse of solid waste of high titanium furnace slag and solve the problem of making permeable bricks with large amount of high titanium furnace slag, the permeable bricks were prepared by forming and sintering the billet with the furnace slag as aggregate, kaolin and potassium feldspar as binder and melting aid. TG-DSC comprehensive thermal analysis and SEM morphology analysis were used to study the thermal properties of the material and the morphology change at high temperature. The effects of the proportion of furnace slag and auxiliary materials, the particle size of furnace slag aggregate, forming pressure, sintering temperature and holding time on the properties of permeable bricks were discussed, and the suitable preparation process parameters of permeable bricks were determined. The results show that the ratio of blast furnace slag: Kaolin: K Feldspar (mass fraction) is 75∶10∶15, the molding pressure is 10 MPa, the sintering temperature is 1095 °C, and the holding time is 3 h, the permeability Coefficient of permeable brick is 0.064 cm/s, the flexural strength is 12 MPa, which has the characteristics of high permeability and high strength, and meets the requirements of “Permeable pavement brick and permeable pavement board” (GB/T 25933-2010).

-

-

表 1 原料成分及含量/%

Table 1. Composition and content of blast furnace slag

名称 TiO2 Fe2O3 SiO2 MgO Al2O3 CaO V2O5 F K2O Na2O 高炉渣 23.16 2.64 24.01 7.47 13.49 27.19 0.82 0.12 / / 钾长石 0.08 0.11 74.00 0.10 10.88 0.24 / / 11.8 0.39 高岭土 1.00 0.80 55.70 / 42.50 / / / / / 表 2 不同配方试样的透水系数与抗折强度

Table 2. Permeability coefficient and flexural strength of the samples with different formulations

配方比例

(高炉渣∶高岭土∶钾长石)透水系数/(cm/s) 抗折强度/MPa 75∶10∶15 0.0504 12 70∶15∶15 0.0401 13 90∶10∶0 0.122 5 80∶15∶5 0.078 7 60∶20∶20 0.016 13 50∶25∶25 0.006 15 -

[1] 仇圣桃, 张明博, 李建新, 等. 含钛高炉渣资源化综合利用研究现状与展望[J]. 钢铁, 2016, 51(7):1-8. QIU S T, ZHANG M B, LI J X, et al. Research status and prospect of comprehensive utilization of titanium bearing furnace slag[J]. Iron and Steel, 2016, 51(7):1-8.

QIU S T, ZHANG M B, LI J X, et al. Research status and prospect of comprehensive utilization of titanium bearing furnace slag [J]. Iron and Steel, 2016, 51 (7) : 1-8.

[2] 许莹, 李单单, 杨姗姗, 等. 含钛高炉渣综合利用研究进展[J]. 矿产综合利用, 2021(1):23-31. XU Y, LI D D, YANG S S, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1):23-31. doi: 10.3969/j.issn.1000-6532.2021.01.004

XU Y, LI D D, YANG S S, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1): 23-31. doi: 10.3969/j.issn.1000-6532.2021.01.004

[3] 蒋建忠. 海绵城市建设中透水路面在市政道路中的应用[J]. 四川水泥, 2021(12):121-122. JIANG J Z. The application of permeable pavement in the construction of sponge city[J]. Sichuan Cement, 2021(12):121-122.

JIANG J Z. The application of permeable pavement in the construction of sponge city[J]. Sichuan Cement, 2021, (12): 121-122.

[4] 王海. 再论海绵城市和陶瓷透水路面[J]. 陶瓷, 2020(4):9-14. WANG H. Sponge city and ceramic permeable pavement[J]. Ceramics, 2020(4):9-14. doi: 10.19397/j.cnki.ceramics.2020.04.001

WANG H. Sponge city and ceramic permeable pavement[J]. Ceramics, 2020(4): 9-14. doi: 10.19397/j.cnki.ceramics.2020.04.001

[5] 武晓宇. 固废基烧结透水砖的制备及其性能研究[D]. 太原: 太原理工大学, 2018.

WU X Y. Preparation and properties of solid waste foundation sintered permeable brick[D]. Taiyuan: Taiyuan University of Technology, 2018.

[6] 赵礼兵, 王帅, 李国峰, 等. 透水砖研究现状及影响因素[J]. 矿产综合利用, 2019(5):6-8. ZHAO L B, WANG S, LI G F, et al. Current situation and influencing factors of permeable brick[J]. Multipurpose Utilization of Mineral Resources, 2019(5):6-8. doi: 10.3969/j.issn.1000-6532.2019.05.002

ZHAO L B, WANG S, LI G F, et al. Current situation and influencing factors of permeable brick[J]. Multipurpose Utilization of Mineral Resources, 2019(5): 6-8. doi: 10.3969/j.issn.1000-6532.2019.05.002

[7] 王恬君, 刘立伟, 李国峰, 等. 焙烧尾矿制备透水砖的孔隙特征研究[J]. 矿产综合利用, 2021(6):85-90. WANG T J, LIU L W, LI G F, et al. Study on pore characteristics of permeable brick prepared from roasted tailings[J]. Multipurpose Utilization of Mineral Resources, 2021(6):85-90. doi: 10.3969/j.issn.1000-6532.2021.06.015

WANG T J, LIU L W, LI G F, et al. Study on pore characteristics of permeable brick prepared from roasted tailings[J]. Multipurpose Utilization of Mineral Resources, 2021(6): 85-90. doi: 10.3969/j.issn.1000-6532.2021.06.015

[8] 张飞, 王浩, 李家茂, 等. 高炉矿渣烧结透水砖的制备与其性能表征[J]. 安徽工业大学学报(自然科学版), 2018, 35(1):5-9. ZHANG F, WANG H, LI J M, et al. Preparation of sintered pervious brick of blast furnace slag and its characterization[J]. Journal of Anhui University of Technology(Natural Science), 2018, 35(1):5-9.

ZHANG F, WANG H, LI J M, et al. Preparation of sintered pervious brick of blast furnace slag and its characterization [J]. Journal of Anhui University of Technology(Natural Science), 2018, 35(1): 5-9.

[9] 蔡作乾, 王琏, 杨根. 陶瓷材料辞典[M]. 北京: 化学工业出版社, 2004.

CAI Z Q, WANG L, YANG G. Dictionary of ceramic materials[M]. Beijing: Chemical Industry Press, 2004.

[10] 廖奇丽, 江伟辉, 虞澎澎, 等. 工艺参数对陶瓷透水砖性能影响的研究[J]. 新型建筑材料, 2007(4):29-31. LIAO Q L, JIANG W H, YU P P, et al. Study on effect of process parameters on properties of ceramic permeable brick[J]. New Building Materials, 2007(4):29-31. doi: 10.3969/j.issn.1001-702X.2007.04.010

LIAO Q L, JIANG W H, YU P P, et al. Study on effect of process parameters on properties of ceramic permeable brick[J]. New Building Materials, 2007(4): 29-31. doi: 10.3969/j.issn.1001-702X.2007.04.010

[11] 焦宝祥, 管浩. 陶瓷工艺学[M]. 北京: 化学工业出版社, 2019.

JIAO B X, GUAN H. Ceramic technology[M]. Beijing: Chemical Industry Press, 2019.

[12] 王绍熙, 张凯帆, 张苏花, 等. 多元固废制备高强烧结透水砖及其性能研究[J]. 金属矿山, 2021(9):206-215. WANG S X, ZHANG K F, ZHANG S H, et al. Preparation and properties study of high-strength sintered permeable brick with multiple solid waste[J]. Metal Mine, 2021(9):206-215. doi: 10.19614/j.cnki.jsks.202109029

WANG S X, ZHANG K F, ZHANG S H, et al. Preparation and properties study of high-strength sintered permeable brick with multiple solid waste[J]. Metal Mine, 2021(9): 206-215. doi: 10.19614/j.cnki.jsks.202109029

-

下载:

下载: