Low Temperature Sulfuric Acid Ripening-water Leaching for Vanadium Extraction from Stone Coal Vanadium Ore

-

摘要:

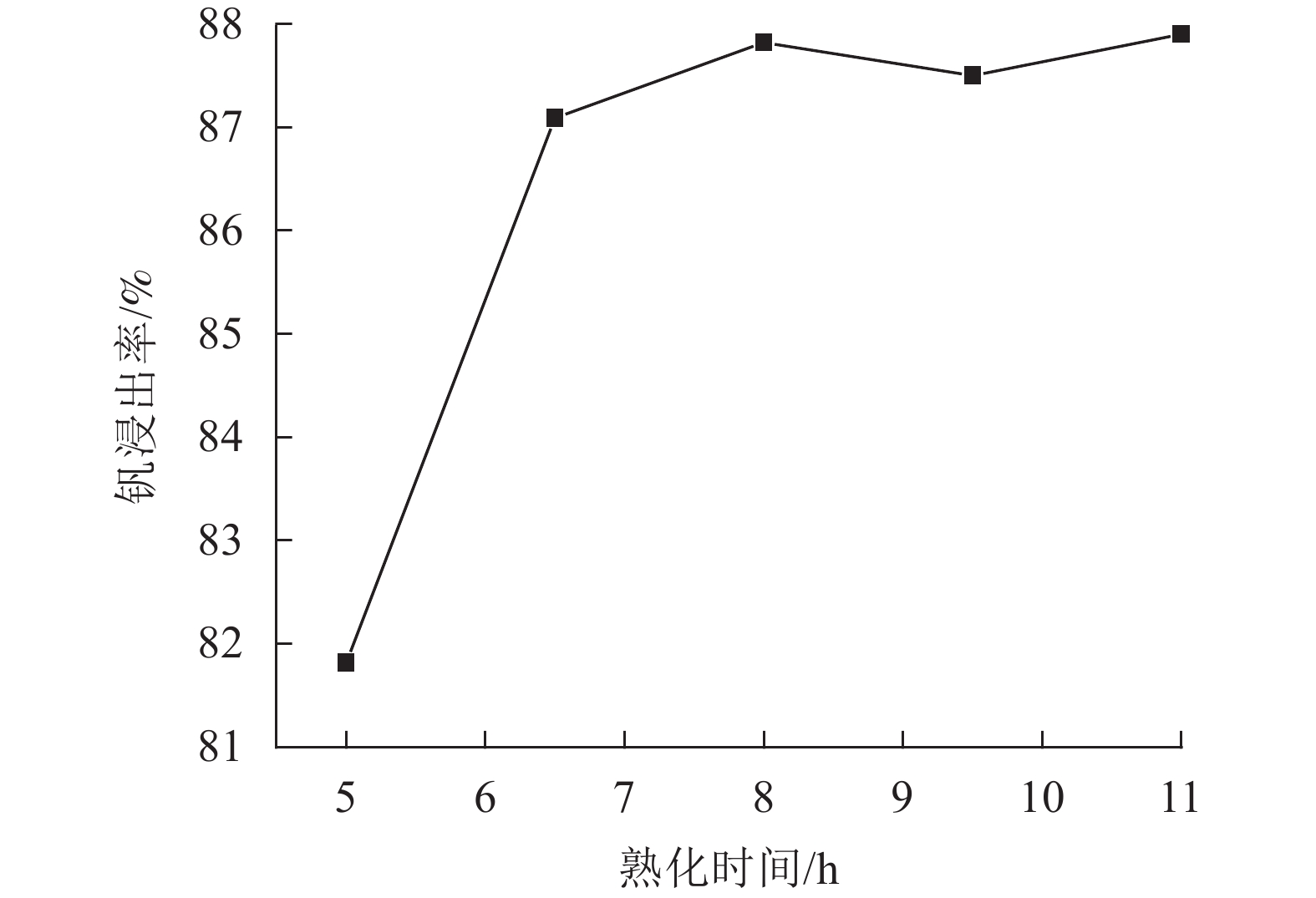

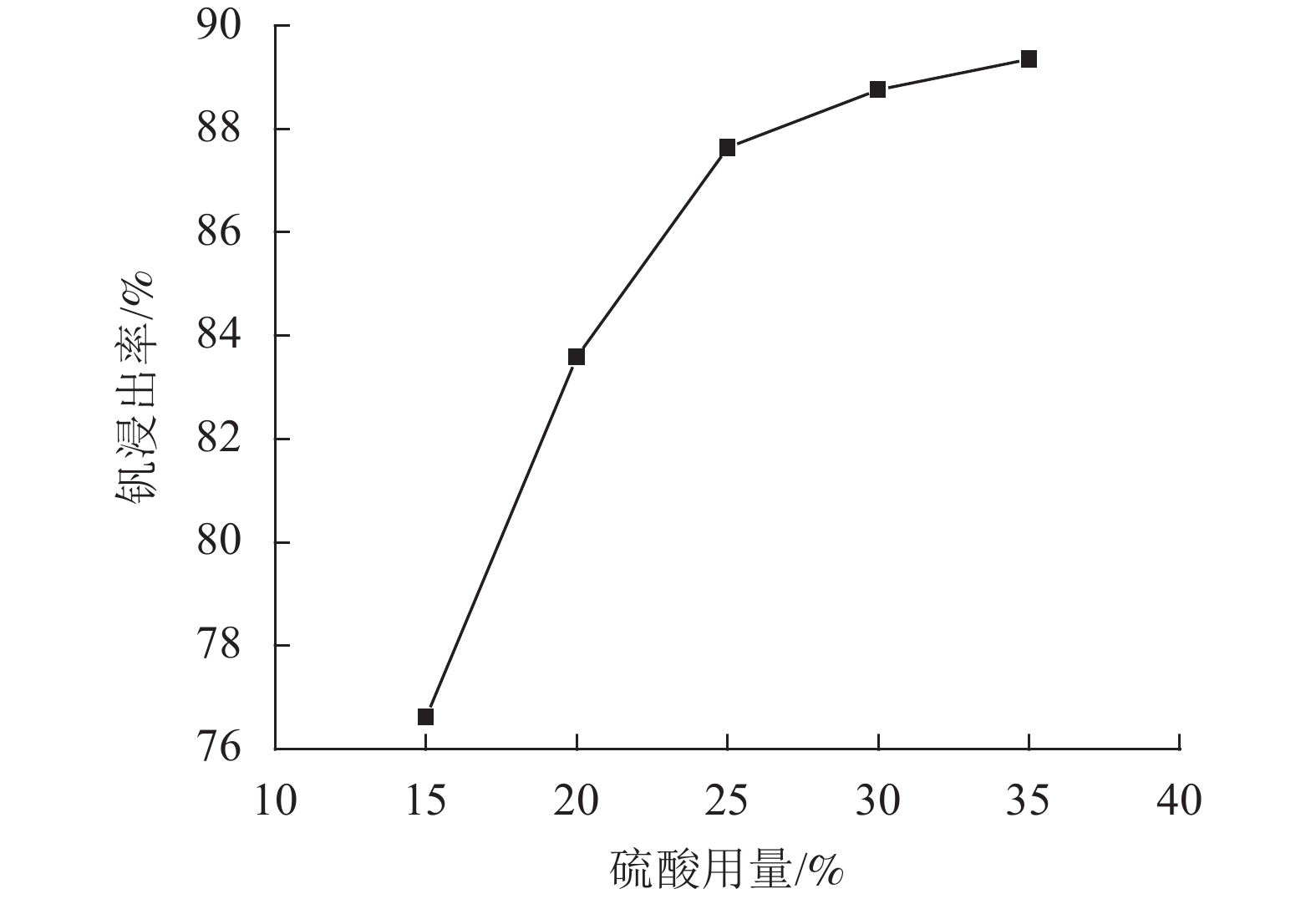

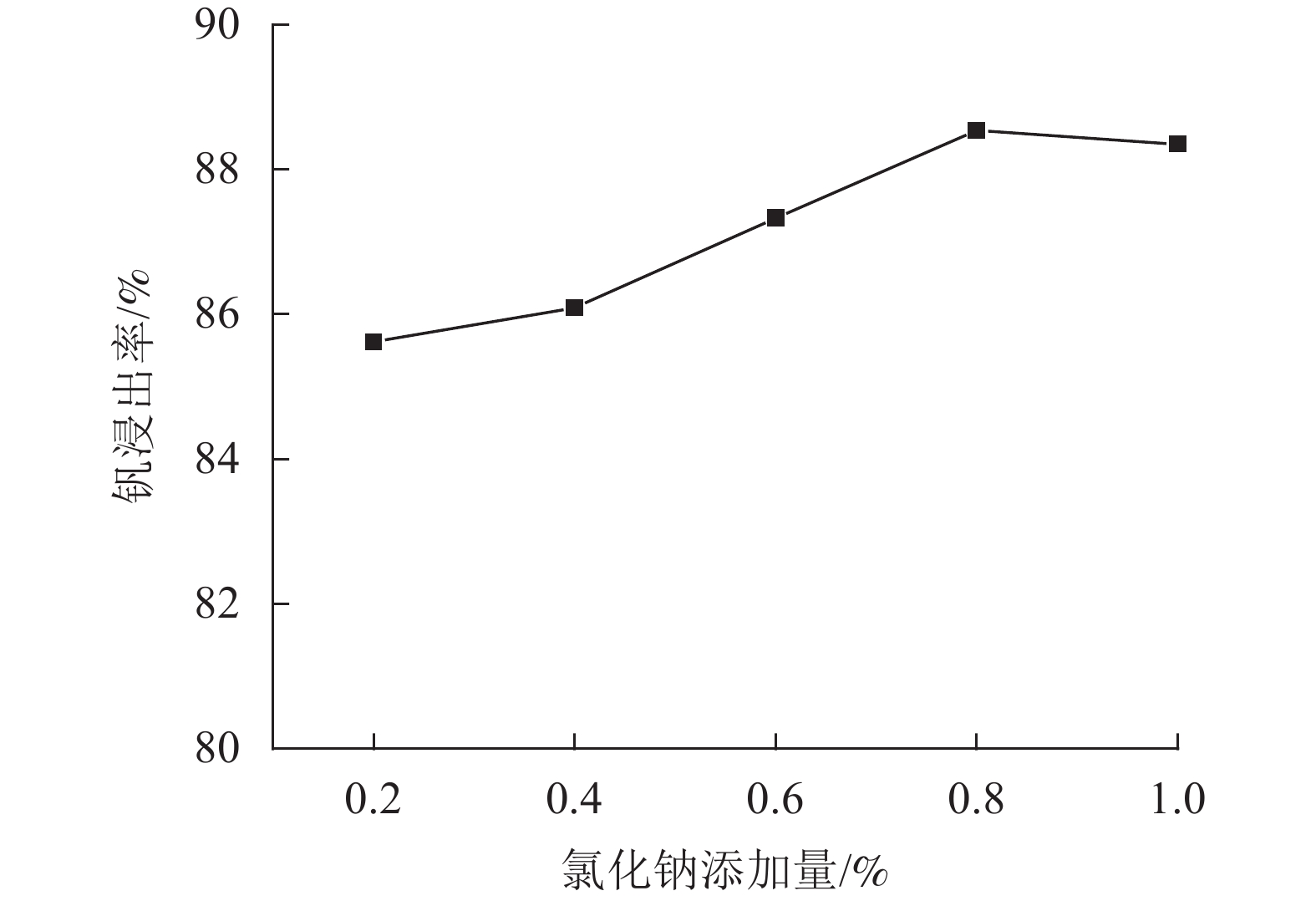

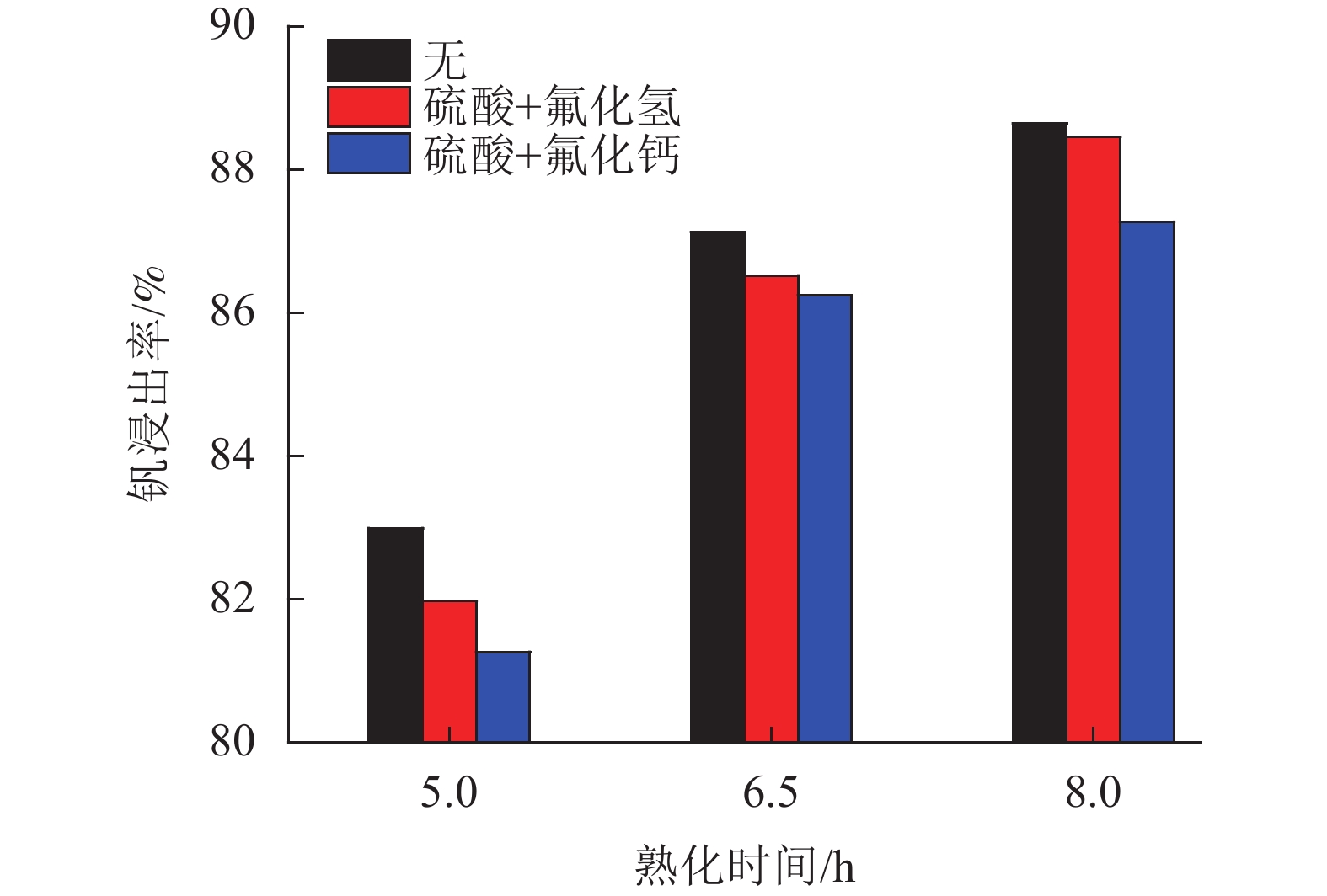

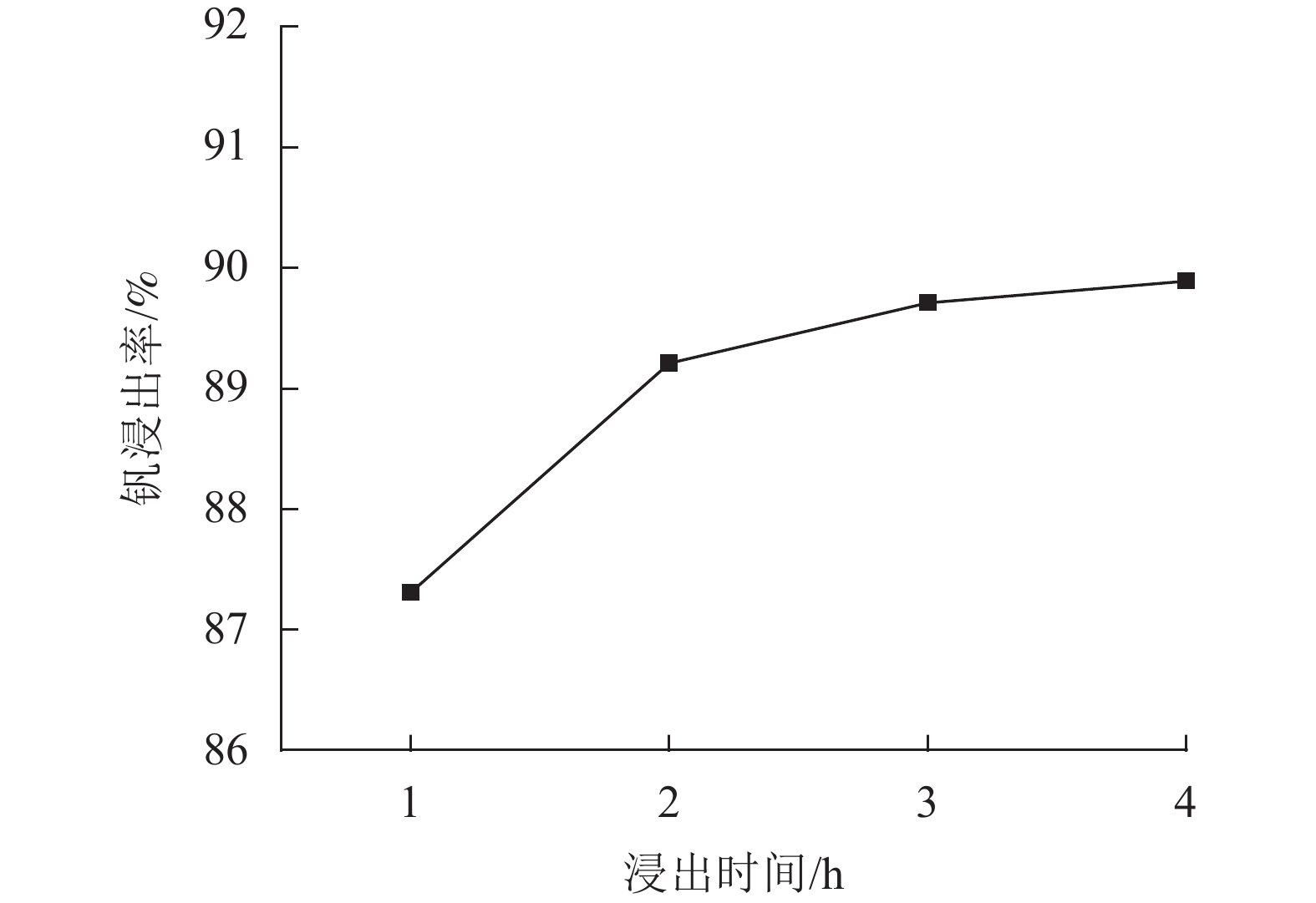

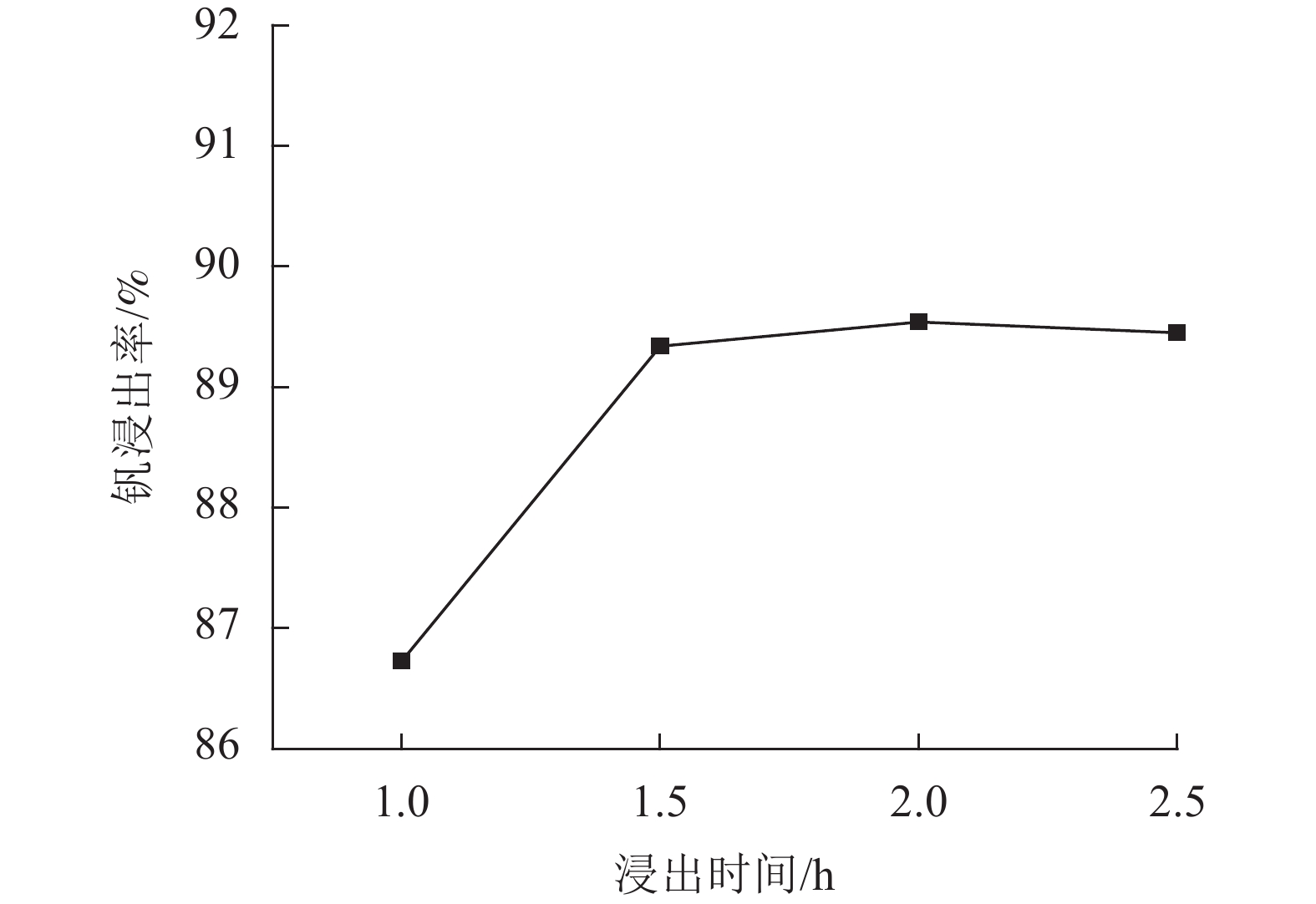

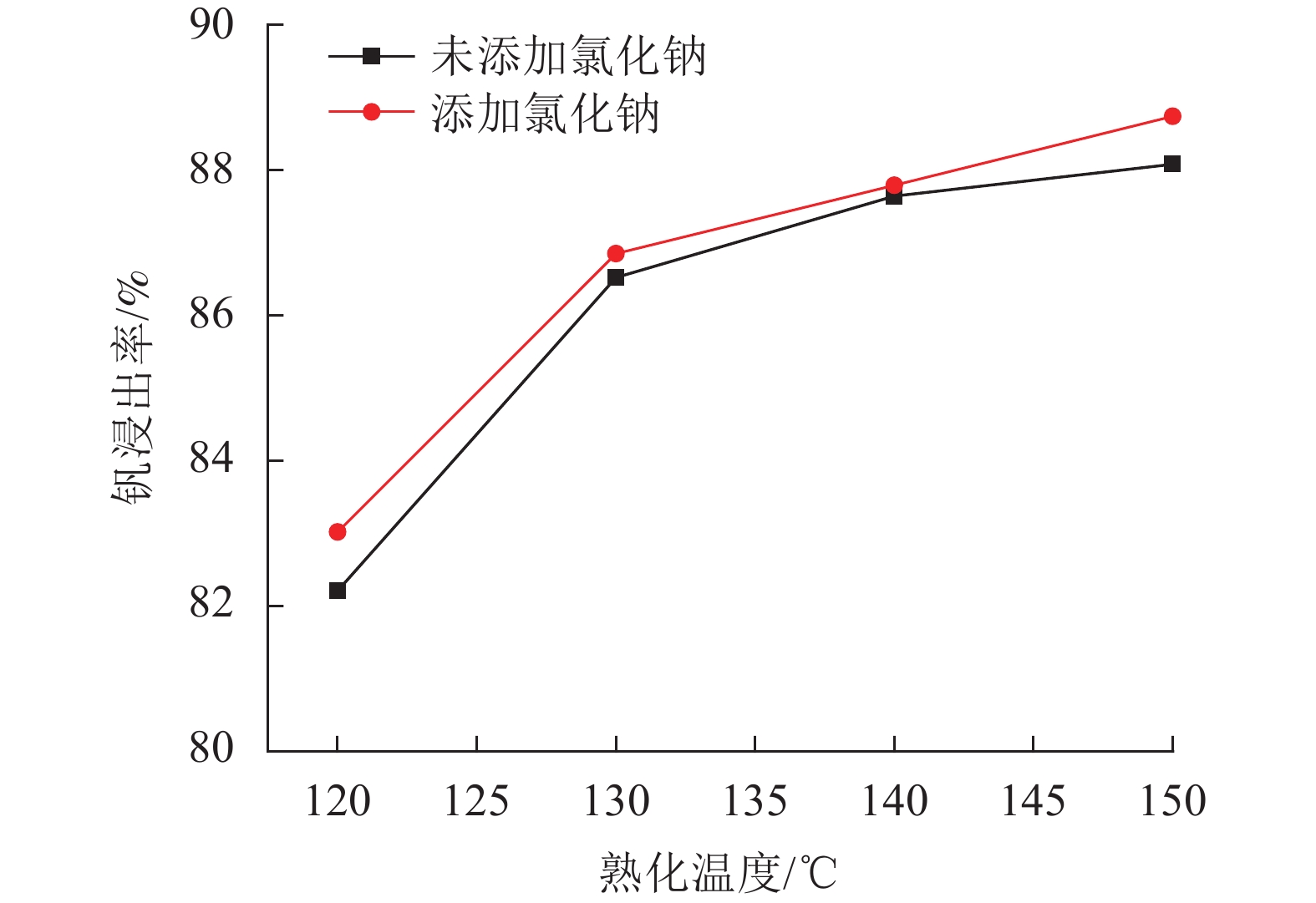

这是一篇冶金工程领域的论文。以陕西某地含钒矿物为绢云母、伊利石的石煤钒矿为研究对象,采用低温硫酸熟化-水浸工艺提钒,考查了熟化温度、熟化时间、硫酸用量、氯化钠用量,浸出温度、浸出时间及浸出液固比对钒浸出率的影响。结果表明:向石煤钒矿中加入25%的硫酸、0.8%的氯化钠,在130 ℃下熟化8 h,熟化样品在浸出温度 55 ℃、液固比 1.5∶1的条件下浸出时间2 h,钒浸出率可达89%。这说明采用低温(130 ℃)硫酸熟化-水浸工艺提取石煤型钒矿是可行的。

Abstract:This is an article in the field of metallurgical engineering. The vanadium ore with vanadium containing sericite and illite in Shaanxi province was taken as the research object, low-temperature sulfuric acid ripening-water leaching process was used to extract vanadium. The effects of ripening temperature, ripening time, sulfuric acid dosage, sodium chloride dosage, leaching temperature, leaching time and liquid-solid ratio on vanadium leaching rate were investigated. The results show when 25% sulfuric acid and 0.8% sodium chloride are added to the stone coal vanadium ore, the sample is aged at 130 ℃ for 8 h, and the sample is leached at 55 ℃ for 2 h under the conditions of liquid-solid ratio of 1.5∶1, the vanadium leaching rate can reach more than 89%. This indicates that it is feasible to adopt low temperature sulfuric acid ripening and water leaching process to extract stone coal type vanadium ore.

-

-

表 1 原矿多元素分析结果/%

Table 1. Multi-element analysis results of the ore

SiO2 K2O Na2O Al2O3 CaO MgO TiO2 SO3 BaO TFe MnO P2O3 V2O5 LOI 79.35 1.13 0.01 3.75 2.72 1.49 0.21 0.72 1.91 3.00 0.01 0.51 0.88 4.86 表 2 原矿钒价态分析结果

Table 2. Analysis results of vanadium valence state in the ore

名称 价态 V4+ V3+ 总钒 1#样品 含量/% 0.39 1.78 2.18 分布率/% 18.03 82.02 100.00 2#样品 含量/% 0.23 0.88 1.11 分布率/% 21.05 79.00 100 3#样品 含量/% 0.02 0.09 0.11 分布率/% 18.16 81.89 100 表 3 原矿样品筛析结果

Table 3. Sieve analysis results of the raw ore

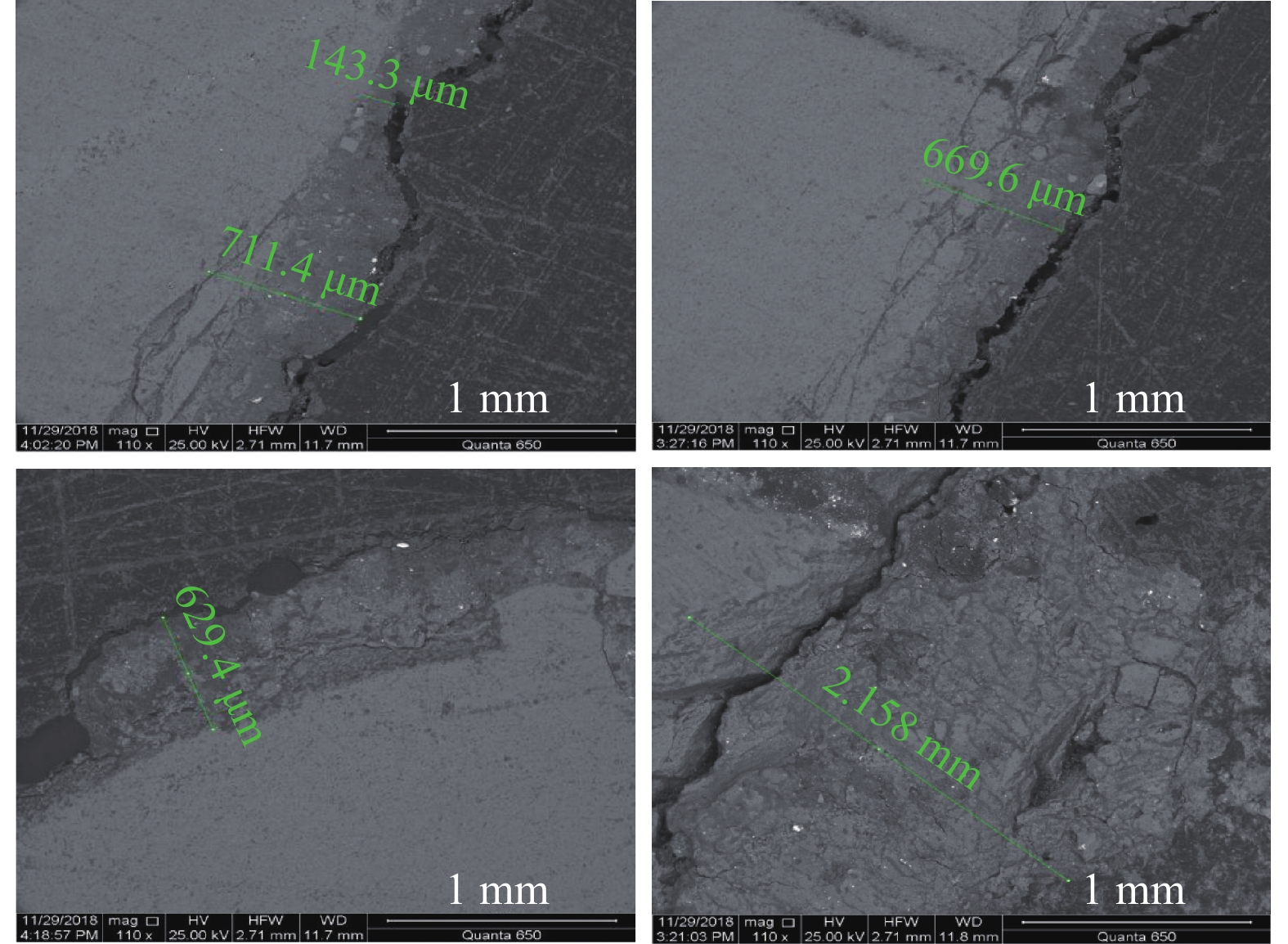

样品粒级/mm 产率/% V2O5品位/% 分布率/% +6 13.69 0.230 3.54 -6+3 16.28 0.270 4.94 -3+1.5 16.28 0.330 6.04 -1.5+0.9 5.92 0.410 2.73 -0.9+0.5 8.51 0.470 4.49 -0.5+0.1 8.88 0.650 6.49 -0.1 30.42 2.100 71.78 合计 100.00 0.890 100.00 表 4 硫酸浸入不同程度能谱分析S结果/%

Table 4. S results of energy spectrum analysis of sulfuric acid immersed in different degrees

硫酸浸入 深 7.02 2.22 11.52 11.13 程度 浅 0.33 0.42 0.15 0.43 -

[1] 严伟平, 曾小波. 攀西地区钒钛磁铁矿资源开发利用水平评估方法研究[J]. 矿产综合利用, 2020(6):79-83.YAN W P, ZENG X B. Study on the evaluation method of development and utilization level of vanadium-titanium magnetite mine in Panxi district[J]. Multipurpose Utilization of Mineral Resources, 2020(6):79-83. doi: 10.3969/j.issn.1000-6532.2020.06.014

YAN W P, ZENG X B. Study on the evaluation method of development and utilization level of vanadium-titanium magnetite mine in Panxi district[J]. Multipurpose Utilization of Mineral Resources, 2020(6):79-83. doi: 10.3969/j.issn.1000-6532.2020.06.014

[2] 史政良, 严海军, 周玉娟. 甘肃某石煤钒矿焙烧灰渣综合利用工艺研究[J]. 矿产综合利用, 2020(3):158-163.SHI Z L, YAN H J, ZHOU Y J. Study on comprehensive utilization technology of sulphate roasting ash and slag of vanadium ore from stone coal in Gansu Province[J]. Multipurpose Utilization of Mineral Resources, 2020(3):158-163. doi: 10.3969/j.issn.1000-6532.2020.03.027

SHI Z L, YAN H J, ZHOU Y J. Study on comprehensive utilization technology of sulphate roasting ash and slag of vanadium ore from stone coal in Gansu Province[J]. Multipurpose Utilization of Mineral Resources, 2020(3):158-163. doi: 10.3969/j.issn.1000-6532.2020.03.027

[3] 王明, 程倩, 齐建云, 等. 石煤钒矿硫酸低温熟化—柱浸提钒工艺[J]. 矿冶, 2020, 29(3):62-67.WANG M, CHENG Q, QI J Y, et al. Sulfuric acid low-temperature maturation of stone coal vanadium ore-column leaching vanadium extraction process[J]. Mining and Metallurgy, 2020, 29(3):62-67. doi: 10.3969/j.issn.1005-7854.2020.03.013

WANG M, CHENG Q, QI J Y, et al. Sulfuric acid low-temperature maturation of stone coal vanadium ore-column leaching vanadium extraction process[J]. Mining and Metallurgy, 2020, 29(3):62-67. doi: 10.3969/j.issn.1005-7854.2020.03.013

[4] 赵玉卿, 王守敬, 田滔, 等. MLA在青海某石煤钒矿钒的赋存状态研究中的应用[J]. 矿产综合利用, 2020(1):89-93.ZHAO Y Q, WANG S J, TIAN T, et al. Application of MLA in the study of the occurrence state of vanadium in a rock coal vanadium ore in Qinghai[J]. Multipurpose Utilization of Mineral Resources, 2020(1):89-93. doi: 10.3969/j.issn.1000-6532.2020.01.018

ZHAO Y Q, WANG S J, TIAN T, et al. Application of MLA in the study of the occurrence state of vanadium in a rock coal vanadium ore in Qinghai[J]. Multipurpose Utilization of Mineral Resources, 2020(1):89-93. doi: 10.3969/j.issn.1000-6532.2020.01.018

[5] ZHANG Y M, BAO S X, LIU T, et al. The technology of extracting vanadium from stone coal in China: History, current status and future prospects[J]. Hydrometallurgy, 2011, 109(1/2):116-124.

[6] 邢学永. 石煤钒矿低温碱性焙烧—水浸钒试验研究[J]. 湿法冶金, 2015, 34(4):275-278.XING X Y. Low-temperature alkaline roasting of stone coal vanadium ore—experimental research on water leaching vanadium[J]. Hydrometallurgy, 2015, 34(4):275-278.

XING X Y. Low-temperature alkaline roasting of stone coal vanadium ore—experimental research on water leaching vanadium[J]. Hydrometallurgy, 2015, 34(4):275-278.

[7] 贾秀敏, 李培佑, 黄永, 等. 陕西某钒矿石钙化焙烧-酸浸工艺研究[J]. 湿法冶金, 2015, 34(3):182-185+196.JIA X M, LI P Y, HUANG Y, et al. Study on the calcification roasting-acid leaching process of a vanadium ore in Shaanxi[J]. Hydrometallurgy, 2015, 34(3):182-185+196.

JIA X M, LI P Y, HUANG Y, et al. Study on the calcification roasting-acid leaching process of a vanadium ore in Shaanxi[J]. Hydrometallurgy, 2015, 34(3):182-185+196.

[8] 成宝海, 张廷安. 高温高压石煤提钒实验研究[J]. 长春师范大学学报, 2018, 37(12):73-74+96.CHENG B H, ZHANG T A. Experimental study on extracting vanadium from stone coal at high temperature and high pressure[J]. Journal of Changchun Normal University, 2018, 37(12):73-74+96.

CHENG B H, ZHANG T A. Experimental study on extracting vanadium from stone coal at high temperature and high pressure[J]. Journal of Changchun Normal University, 2018, 37(12):73-74+96.

[9] 张成强, 孙传尧, 印万忠, 等. 以氟化钙为助浸剂的某伊利石型含钒石煤提钒工艺[J]. 矿产综合利用, 2019(5):42-47.ZHANG C Q, SUN C Y, YIN W Z, et al. Acid leaching of vanadium from an illite-type vanadium- containing stone using calcium fluoride as aid-leaching reagent[J]. Multipurpose Utilization of Mineral Resources, 2019(5):42-47. doi: 10.3969/j.issn.1000-6532.2019.05.009

ZHANG C Q, SUN C Y, YIN W Z, et al. Acid leaching of vanadium from an illite-type vanadium- containing stone using calcium fluoride as aid-leaching reagent[J]. Multipurpose Utilization of Mineral Resources, 2019(5):42-47. doi: 10.3969/j.issn.1000-6532.2019.05.009

[10] 伍永国, 颜文斌, 蔡俊, 等. 复合添加剂对石煤中钒浸出率的影响[J]. 矿冶工程, 2019, 39(5):84-86+91.WU Y G, YAN W B, CAI J, et al. The effect of compound additives on the leaching rate of vanadium in stone coal[J]. Mining and Metallurgical Engineering, 2019, 39(5):84-86+91. doi: 10.3969/j.issn.0253-6099.2019.05.022

WU Y G, YAN W B, CAI J, et al. The effect of compound additives on the leaching rate of vanadium in stone coal[J]. Mining and Metallurgical Engineering, 2019, 39(5):84-86+91. doi: 10.3969/j.issn.0253-6099.2019.05.022

[11] 李丽洁, 石美莲, 华骏, 等. 二氧化锰氧化浸出石煤钒矿动力学研究[J]. 稀有金属与硬质合金, 2020, 48(6):24-29.LI L J, SHI M L, HUA J, et al. Study on the kinetics of manganese dioxide oxidation leaching stone coal Vanadium ore[J]. Rare Metals and Cemented Carbides, 2020, 48(6):24-29.

LI L J, SHI M L, HUA J, et al. Study on the kinetics of manganese dioxide oxidation leaching stone coal Vanadium ore[J]. Rare Metals and Cemented Carbides, 2020, 48(6):24-29.

[12] 王学文, 王明玉, 李青刚, 等. 一种石煤提钒矿石分解方法[P]. 中国: ZL 200810031050. 0, 2009.WANG X W, WANG M Y, LI Q G et al. A method for decomposing vanadium ore from stone coal[P]. China: ZL 200810031050. 0, 2009.

WANG X W, WANG M Y, LI Q G et al. A method for decomposing vanadium ore from stone coal[P]. China: ZL 200810031050. 0, 2009.

[13] 杨德芹, 梁晓峰, 郭学, 等. 含钒石煤硫酸化焙烧-超声浸出试验[J]. 金属矿山, 2014(7): 101-105.YANG D Q, LIANG X F, GUO X , et al. Sulfated roasting of vanadium-bearing stone coal-ultrasonic leaching test[J]. Metal Mine, 2014(7): 101-105.

YANG D Q, LIANG X F, GUO X , et al. Sulfated roasting of vanadium-bearing stone coal-ultrasonic leaching test[J]. Metal Mine, 2014(7): 101-105.

[14] 叶国华, 谢禹, 胡艺博, 等. 低品位石煤钒矿低温硫酸化焙烧-水浸提钒研究[J]. 稀有金属, 2020, 44(7):753-761.YE G H, XIE Y, HU Y B, et al. Study on Low-temperature Sulfated Roasting-Water Leaching Vanadium Extraction from Low-grade Stone Coal Vanadium Ore[J]. Rare Metals, 2020, 44(7):753-761.

YE G H, XIE Y, HU Y B, et al. Study on Low-temperature Sulfated Roasting-Water Leaching Vanadium Extraction from Low-grade Stone Coal Vanadium Ore[J]. Rare Metals, 2020, 44(7):753-761.

[15] 杨鑫龙, 冯雅丽, 李浩然. Na2CO3促进某硅质页岩中低价钒的钠化氧化作用研究[J]. 金属矿山, 2019(3):105-110.YANG X L, FENG Y L, LI H R. Research on Na2CO3 promoting sodium oxidation of low valence vanadium in a siliceous shale[J]. Metal Mine, 2019(3):105-110.

YANG X L, FENG Y L, LI H R. Research on Na2CO3 promoting sodium oxidation of low valence vanadium in a siliceous shale[J]. Metal Mine, 2019(3):105-110.

[16] 朱军, 康敏, 李维亮, 等. 粘土钒矿钡盐焙烧-酸浸提钒工艺研究[J]. 材料导报, 2020, 34(24):24061-24067.ZHU J, KANG M, LI W L et al. Study on the technology of extracting vanadium from clay vanadium ore by roasting and acid leaching[J]. Materials Review, 2020, 34(24):24061-24067. doi: 10.11896/cldb.19100158

ZHU J, KANG M, LI W L et al. Study on the technology of extracting vanadium from clay vanadium ore by roasting and acid leaching[J]. Materials Review, 2020, 34(24):24061-24067. doi: 10.11896/cldb.19100158

[17] 吕昌晓, 张廷安, 张莹, 等. 从钙化焙烧-酸浸尾渣中综合回收钒的研究[J]. 稀有金属, 2020, 44(11):1208-1214.LYU C X, ZHANG T A, ZHANG Y, et al. Comprehensive recovery of vanadium from calcification roasting-acid leaching tailings[J]. Rare Metals, 2020, 44(11):1208-1214.

LYU C X, ZHANG T A, ZHANG Y, et al. Comprehensive recovery of vanadium from calcification roasting-acid leaching tailings[J]. Rare Metals, 2020, 44(11):1208-1214.

-

下载:

下载: