Full Slime Cyanidation Leaching of the Primary Gold Ore from a Metallurgical Processing Plant in Gansu

-

摘要:

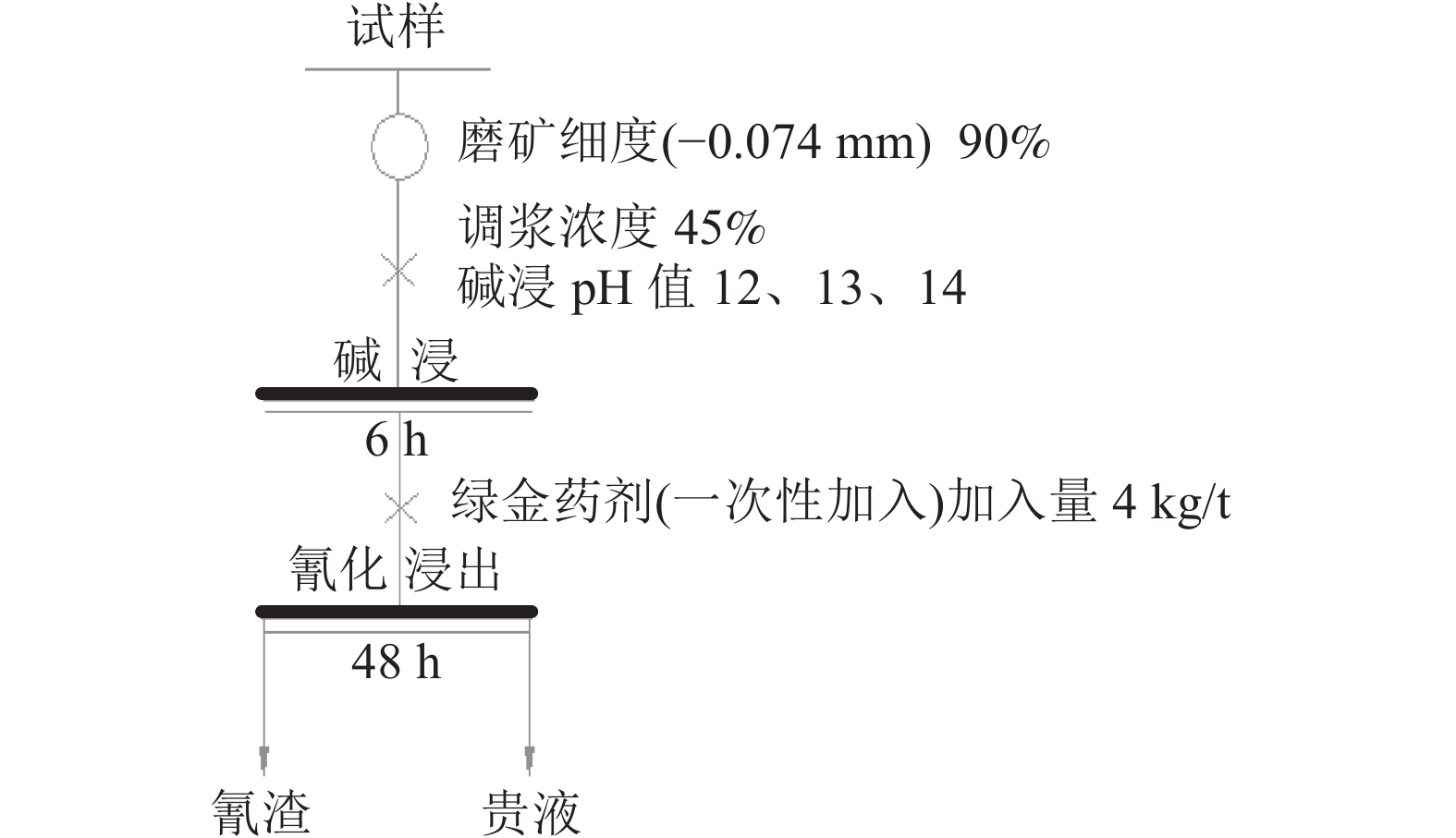

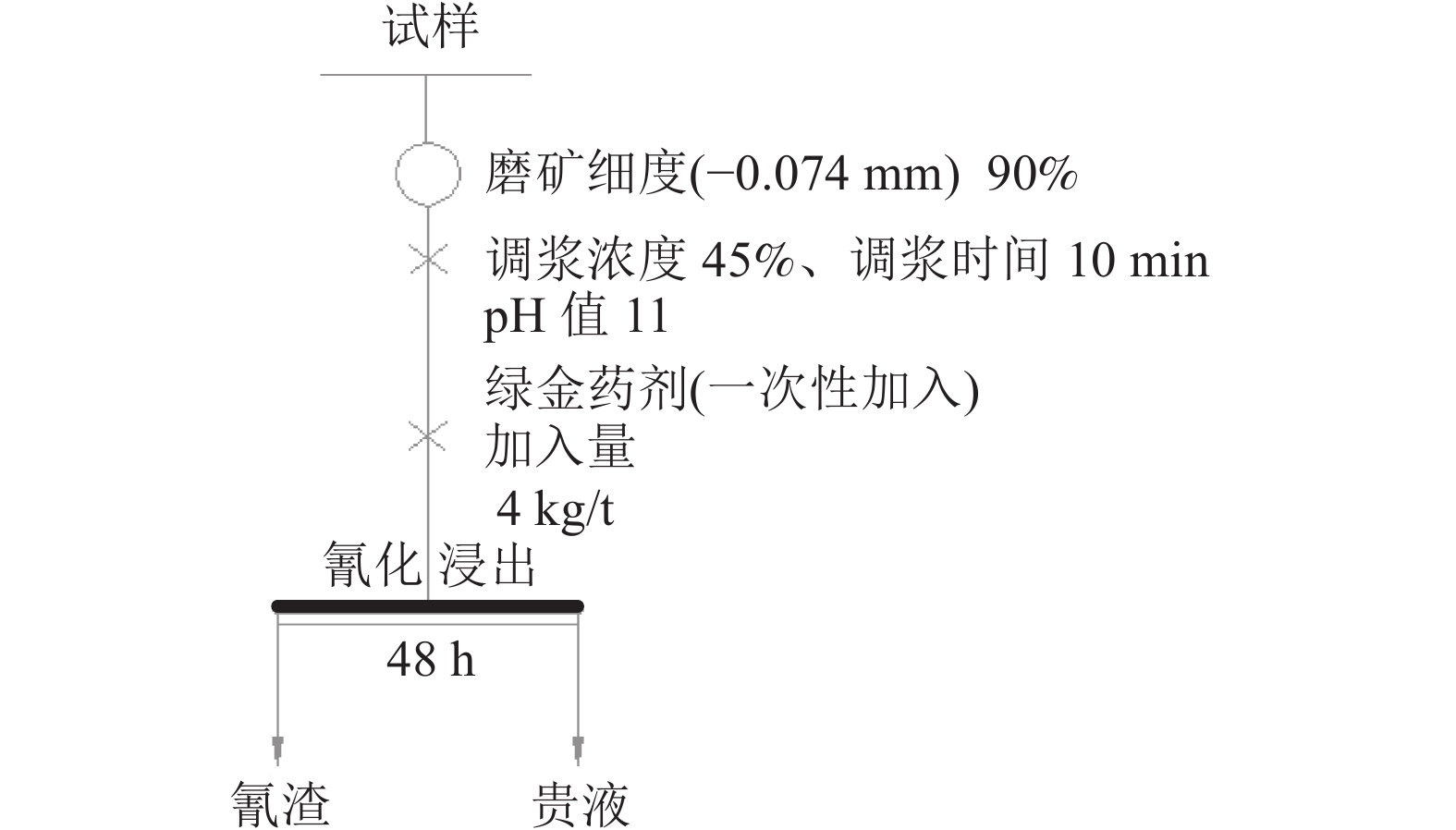

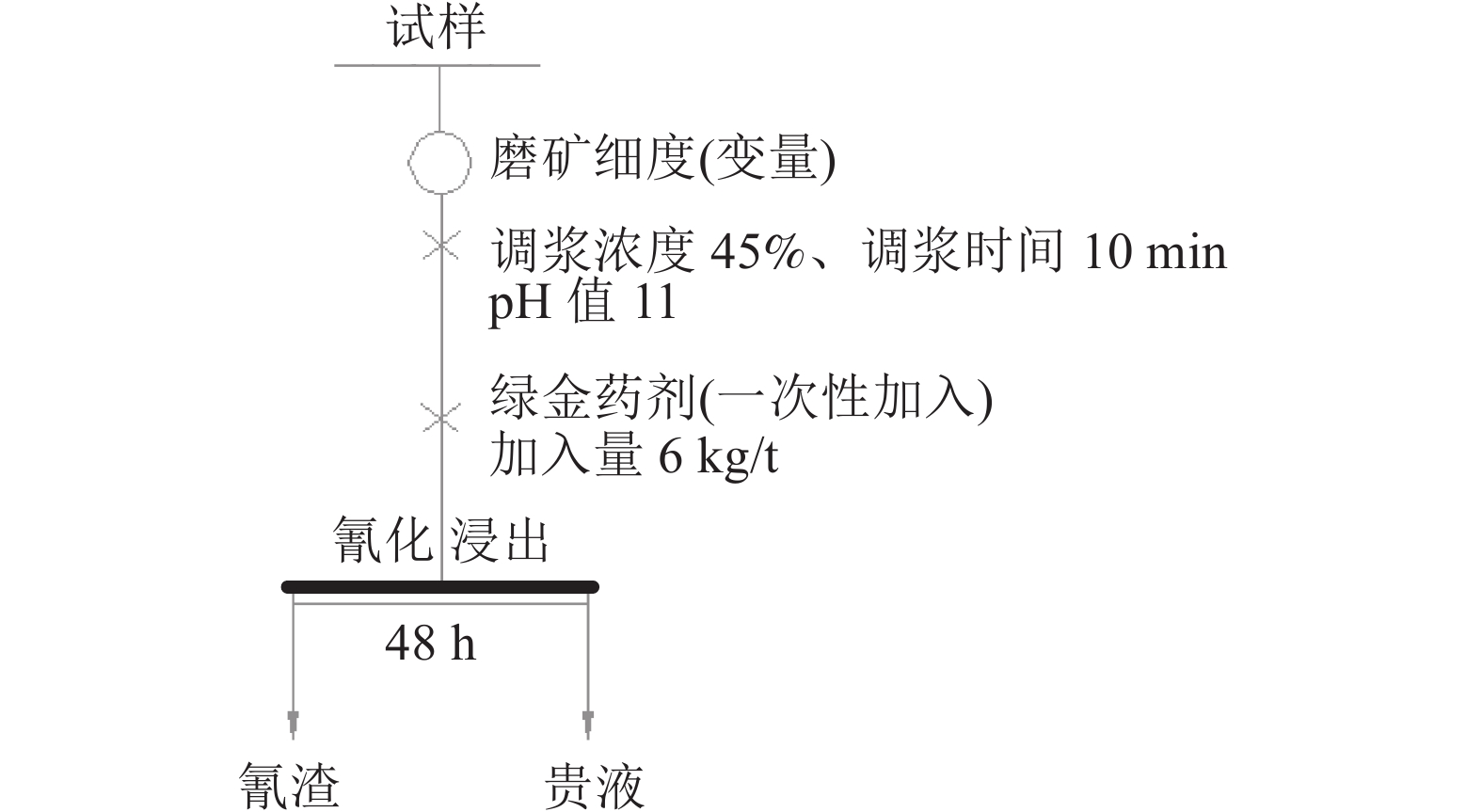

这是一篇冶金工程领域的论文。某选冶厂处理原生矿和氧化矿两种金矿石,原生矿采用常规浮选工艺处理,浮选精矿金回收率85%左右,外售至省外冶炼企业氰化浸出;氧化矿采用搅拌氰化浸出-活性炭吸附-载金炭解析电积-金泥熔炼铸锭工艺处理,产出金锭外售,金选冶总回收率90%左右。目前,随着开采深度加深,矿石性质发生变化,氧化矿矿量逐渐降低,原生矿矿量逐渐增加,使浮选系统来矿量过大,浸出系统处理量不足,影响企业经济效益。为此,企业考虑将浮选系统处理不了的原生矿混入现有氧化矿全泥氰化浸出系统,增加企业金锭产量和经济效益。为使现有全泥氰化浸出系统能够浸出原生矿,基于现场调研,针对原生矿开展了磨矿细度、药剂用量、溶氧量条件实验,并结合生产实际开展了碱浸预处理实验、混合氧化矿浸出实验。基于这些实验研究结果,给生产现场提出了具体整改要求和措施。

Abstract:This is an article in the field of metallurgical engineering. A beneficiation and smelting plant processes two kinds of gold ores: primary ore and oxidized ore. The primary ore is treated by conventional flotation process. The gold recovery rate of flotation concentrate is about 85%, which is sold to smelting enterprises outside the province for cyanide leaching. The oxidized ore is treated by stirring cyanidation leaching activated carbon adsorption gold loaded carbon analytical electrodeposition gold slime smelting ingot casting process. The output gold ingot is sold outside, and the total recovery rate of gold dressing and metallurgy is about 90%. At present, with the deepening of mining depth, the ore properties change, the amount of oxidized ore gradually decreases, and the amount of primary ore gradually increases, resulting in excessive ore treatment in flotation system and insufficient ore treatment in leaching system, affecting the economic benefits of enterprises. Therefore, the enterprise considers adding the primary ore that cannot be treated by the flotation system to the existing oxidized ore all slime cyanidation leaching system to increase the gold ingot output and economic benefits of the enterprise. In order to enable the existing full slime cyanidation leaching system to leach the primary ore, based on the field investigation, the grinding fineness, reagent dosage and dissolved oxygen condition tests were carried out for the primary ore, and the alkali leaching pretreatment test and mixed oxidation ore leaching test were carried out in combination with the actual production. Based on these test and research results, specific rectification requirements and measures are put forward for the production site.

-

-

表 1 化学主要元素分析结果 /%

Table 1. Chemical main element analysis results

Au* Ag* Cu Pb Zn Fe S As SiO2 Al2O3 MgO CaO Na2O K2O 6.64 2.62 0.013 0.027 0.015 14.47 3.69 1.65 18.99 1.12 0.80 23.45 0.03 0.36 *单位为g/t。 表 2 矿物组成及相对含量

Table 2. Mineral composition and relative content

金属矿物 含量/% 非金属矿物 含量/% 黄铁矿 5.41 石英 19.95 磁黄铁矿 0.68 长石 3.43 褐铁矿 4.82 方解石 39.98 菱铁矿 1.51 鲕绿泥石 1.78 磁铁矿 7.56 白云石 6.62 毒砂 3.59 绿帘石 1.41 其他 0.09 整柱石 0.42 其他 2.75 合计 100.00 表 3 样品中金矿物解离特征

Table 3. Dissociation characteristics of gold minerals in samples

解离度X 单体X=100% 75%≤X<100% 50%≤X<75% 25%≤X<50% 0<X<25% 包裹X=0 合计 金矿物 6.86 14.12 59.35 2.08 0.66 16.93 100.00 表 4 样品中金矿物粒度分析

Table 4. Particle size analysis of gold minerals in samples

分级/μm 含量/% 累积量/% 中粒 (-74+37) 0.00 0.00 细粒 (-37+10) 63.11 63.11 微细 (-10+5) 24.57 87.68 -5 12.32 100.00 表 5 磨矿细度实验结果

Table 5. Grinding fineness test results

磨矿细度-74 μm/% 浸渣金品位/(g/t) 金浸出率/% 85 1.21 79.49 90 1.08 81.69 95 1.05 82.20 98 1.02 82.71 表 6 药剂用量实验结果

Table 6. Reagent dosage test results

绿金药剂用量/(kg/t) 品位/(g/t) 金浸出率/% 2 1.57 73.39 4 1.03 82.54 6 1.03 82.54 表 7 溶氧量实验结果

Table 7. Dissolved oxygen test results

溶氧量/(mg/L) 浸渣金品位/(g/t) 金浸出率/% 0.1 5.29 10.34 7.0 1.16 80.34 表 8 “碱浸预处理+氰化浸出”实验结果

Table 8. Test results of "alkali leaching pretreatment + cyanide leaching"

碱浸预处理pH值 金品位/(g/t) 金浸出率/% 未碱浸 1.21 79.49 12 1.21 79.49 13 1.38 76.61 14 4.33 26.61 表 9 液体样铁与硫氰检测结果

Table 9. Test results of iron and thiocyanate in liquid samples

碱浸预处理pH值 铁/(mg/L) 硫氰根离子/(g/L) 未碱浸 56.11 0.61 12 101.80 0.64 13 133.10 0.80 14 530.60 0.49 表 10 分别磨矿混合浸出实验结果

Table 10. Test results of separate grinding and mixed leaching

氧化矿∶

原生矿原矿金

品位/(g/t)浸渣金

品位/(g/t)金浸

出率/%残余氰根离子

浓度/(mg/L)1∶0 3.35 0.37 88.96 3.6 3∶1 3.99 0.58 85.45 3.2 1∶1 4.63 0.78 83.14 3.2 0∶1 5.90 1.21 79.49 2.8 表 11 实验结果评价

Table 11. Evaluation of test results

氧化矿∶原生矿 氰渣金品位/(g/t) 金浸出率/% 测算结果 实验结果 测算结果 实验结果 3∶1 0.58 0.58 85.45 85.45 1∶1 0.79 0.78 82.92 83.14 表 12 混合磨矿浸出实验结果

Table 12. Results of mixed grinding leaching test

氧化矿∶

原生矿原矿金

品位/(g/t)浸渣金

品位/(g/t)金浸

出率/%残余氰根离子

浓度/(mg/L)1∶1 4.63 0.84 81.86 3.2 表 13 混合矿整体磨矿细度测算

Table 13. Calculation of overall grinding fineness of the mixed ore

混合矿中氧

化矿含量/%20 25 35 50 65 75 80 85 磨矿细度测算

结果-74 μm/%92.00 92.50 93.33 95.00 96.67 97.50 98.00 98.33 -

[1] 陈福林, 杨晓军, 杨道广, 等. 甘肃某低品位钒钛磁铁矿工艺矿物学研究[J]. 矿产综合利用, 2020(6):64-68.CHEN F L, YANG X J, YANG D G, et al. Study on process mineralogy of a low grade vanadium titanium magnetite in Gansu[J]. Multipurpose Utilization of Mineral Resources, 2020(6):64-68. doi: 10.3969/j.issn.1000-6532.2020.06.011

CHEN F L, YANG X J, YANG D G, et al. Study on process mineralogy of a low grade vanadium titanium magnetite in Gansu[J]. Multipurpose Utilization of Mineral Resources, 2020(6):64-68. doi: 10.3969/j.issn.1000-6532.2020.06.011

[2] 洪秋阳, 李美荣, 李波, 等. 国外某难选冶钒钛铁矿石工艺矿物学特征[J]. 矿产综合利用, 2020(6):48-54.HONG Q Y, LI M R, LI B, et al. Process mineralogical characteristics of a refractory vanadium titanium iron ore abroad[J]. Multipurpose Utilization of Mineral Resources, 2020(6):48-54. doi: 10.3969/j.issn.1000-6532.2020.06.009

HONG Q Y, LI M R, LI B, et al. Process mineralogical characteristics of a refractory vanadium titanium iron ore abroad[J]. Multipurpose Utilization of Mineral Resources, 2020(6):48-54. doi: 10.3969/j.issn.1000-6532.2020.06.009

[3] 邓元良, 明平田, 王广伟, 等. 某金精矿焙烧氧化 - 氰化尾矿工艺矿物学研究[J]. 矿产综合利用, 2020(4):121-124.DENG Y L, MING P T, WANG G W, et al. Mineralogical study on roasting oxidation cyanidation tailings of a gold concentrate[J]. Multipurpose Utilization of Mineral Resources, 2020(4):121-124. doi: 10.3969/j.issn.1000-6532.2020.04.020

DENG Y L, MING P T, WANG G W, et al. Mineralogical study on roasting oxidation cyanidation tailings of a gold concentrate[J]. Multipurpose Utilization of Mineral Resources, 2020(4):121-124. doi: 10.3969/j.issn.1000-6532.2020.04.020

[4] 邱 沙, 郭鹏志, 谢建平. 苏丹某金矿尼尔森重选-氰化浸出实验研究[J]. 矿产综合利用, 2017(2):19-23.QIU S, GUO P Z, XIE J P. Experimental study on Nelson gravity separation cyanidation leaching of a gold mine in Sudan[J]. Multipurpose Utilization of Mineral Resources, 2017(2):19-23. doi: 10.3969/j.issn.1000-6532.2017.02.005

QIU S, GUO P Z, XIE J P. Experimental study on Nelson gravity separation cyanidation leaching of a gold mine in Sudan[J]. Multipurpose Utilization of Mineral Resources, 2017(2):19-23. doi: 10.3969/j.issn.1000-6532.2017.02.005

[5] 孟宇群 , 吴敏杰 , 宿少玲 , 等. 某含砷难浸金精矿常温常压强化碱浸预处理试验研究[J]. 黄金, 2002(6): 25-31.MENG Y Q, WU M J, SU S L, et al. Experimental study on enhanced alkali leaching pretreatment of an arsenic containing refractory gold concentrate at room temperature and pressure[J]. Gold, 2002(6): 25-31.

MENG Y Q, WU M J, SU S L, et al. Experimental study on enhanced alkali leaching pretreatment of an arsenic containing refractory gold concentrate at room temperature and pressure[J]. Gold, 2002(6): 25-31.

[6] 祁磊, 席欣月, 蔡鑫, 等. 北衙硫化矿选厂尾矿中金银铁综合回收实验研究[J]. 矿产综合利用, 2021(4): 182-187.QI L, XI X Y, CAI X, et al. Experimental study on comprehensive recovery of gold, silver and iron from tailings of Beiya sulfide ore concentrator[J]. Multipurpose Utilization of Mineral Resources, 20021(4): 182-187.

QI L, XI X Y, CAI X, et al. Experimental study on comprehensive recovery of gold, silver and iron from tailings of Beiya sulfide ore concentrator[J]. Multipurpose Utilization of Mineral Resources, 20021(4): 182-187.

[7] 王越, 王婧, 李潇雨, 等. 川西某金矿工艺矿物学研究及对选矿工艺的影响[J]. 矿产综合利用, 2021(4):206-210.WANG Y, WANG J, LI X Y, et al. Study on process mineralogy of a gold mine in Western Sichuan and its influence on beneficiation process[J]. Multipurpose Utilization of Mineral Resources, 2021(4):206-210. doi: 10.3969/j.issn.1000-6532.2021.04.034

WANG Y, WANG J, LI X Y, et al. Study on process mineralogy of a gold mine in Western Sichuan and its influence on beneficiation process[J]. Multipurpose Utilization of Mineral Resources, 2021(4):206-210. doi: 10.3969/j.issn.1000-6532.2021.04.034

[8] 宁阳坤, 赵恒勤, 刘红召, 等. 某白烟尘碱浸实验研究[J]. 矿产综合利用, 2017(4):90-93.NING Y K, ZHAO H Q, LIU H Z, et al. Experimental study on alkali leaching of white smoke dust[J]. Multipurpose Utilization of Mineral Resources, 2017(4):90-93. doi: 10.3969/j.issn.1000-6532.2017.04.020

NING Y K, ZHAO H Q, LIU H Z, et al. Experimental study on alkali leaching of white smoke dust[J]. Multipurpose Utilization of Mineral Resources, 2017(4):90-93. doi: 10.3969/j.issn.1000-6532.2017.04.020

-

下载:

下载: