Titanium-containing Blast Furnace Slag Produced Titanium-silicon-aluminum Alloy by Aluminothermic Reduction

-

摘要:

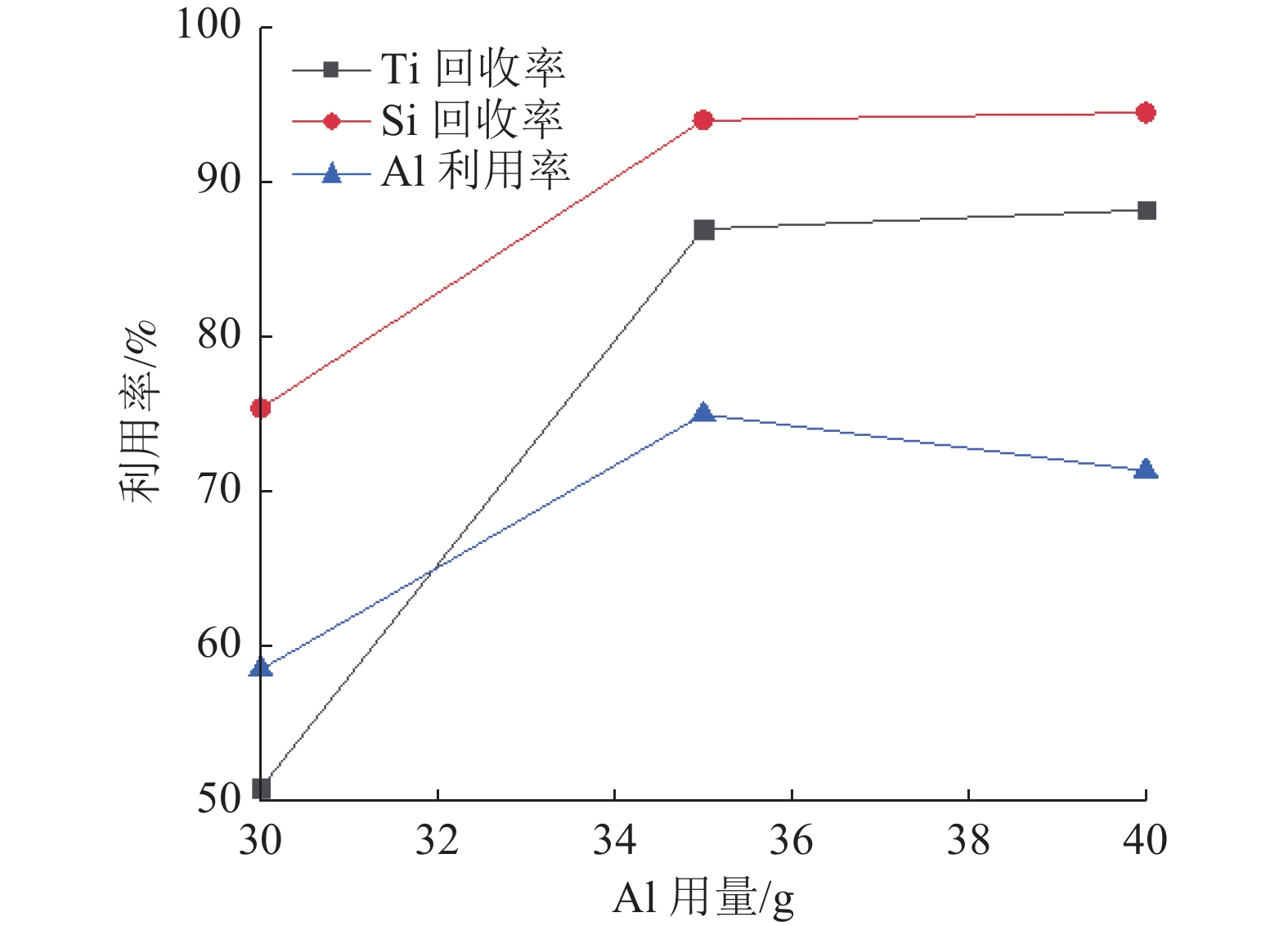

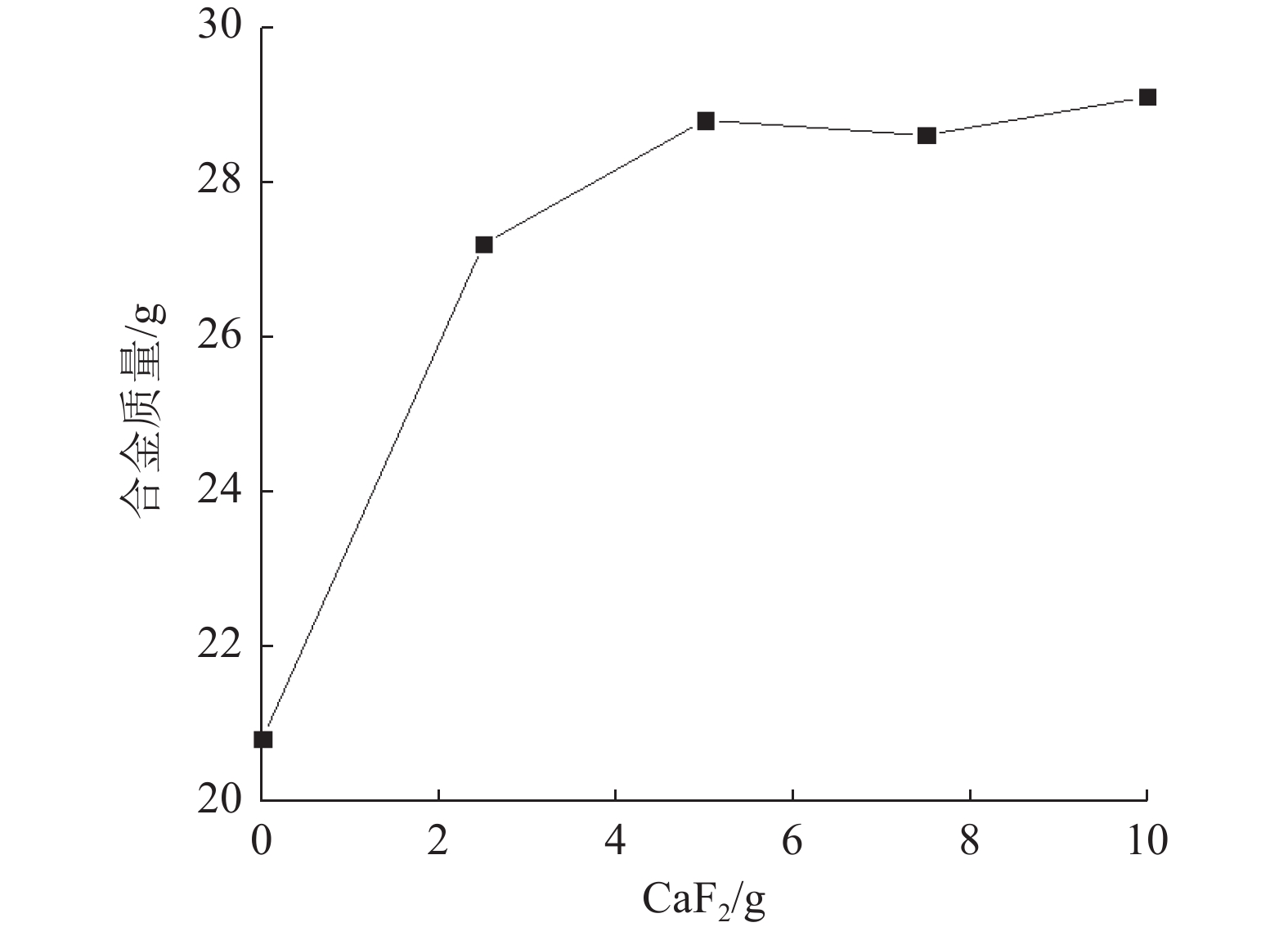

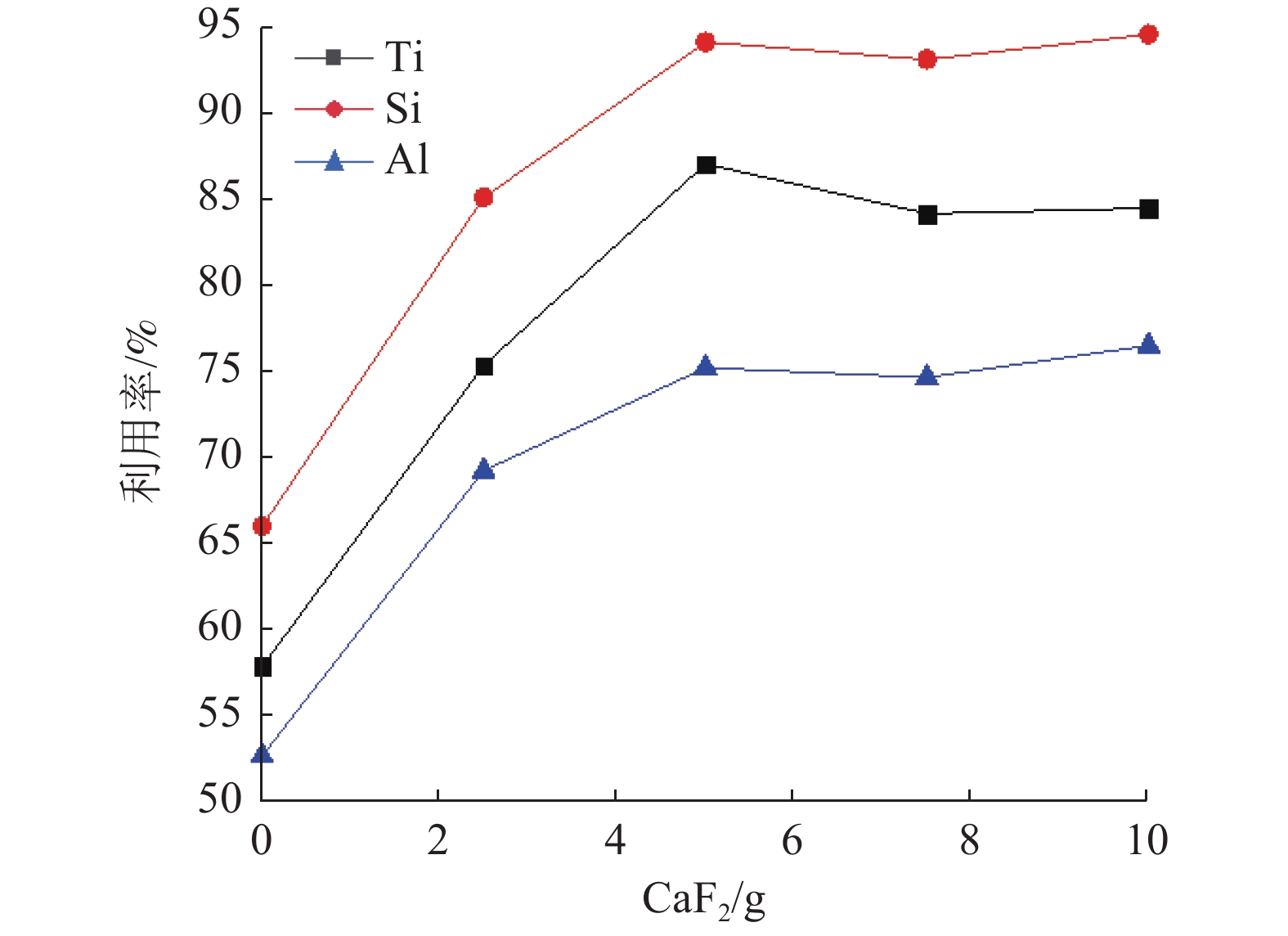

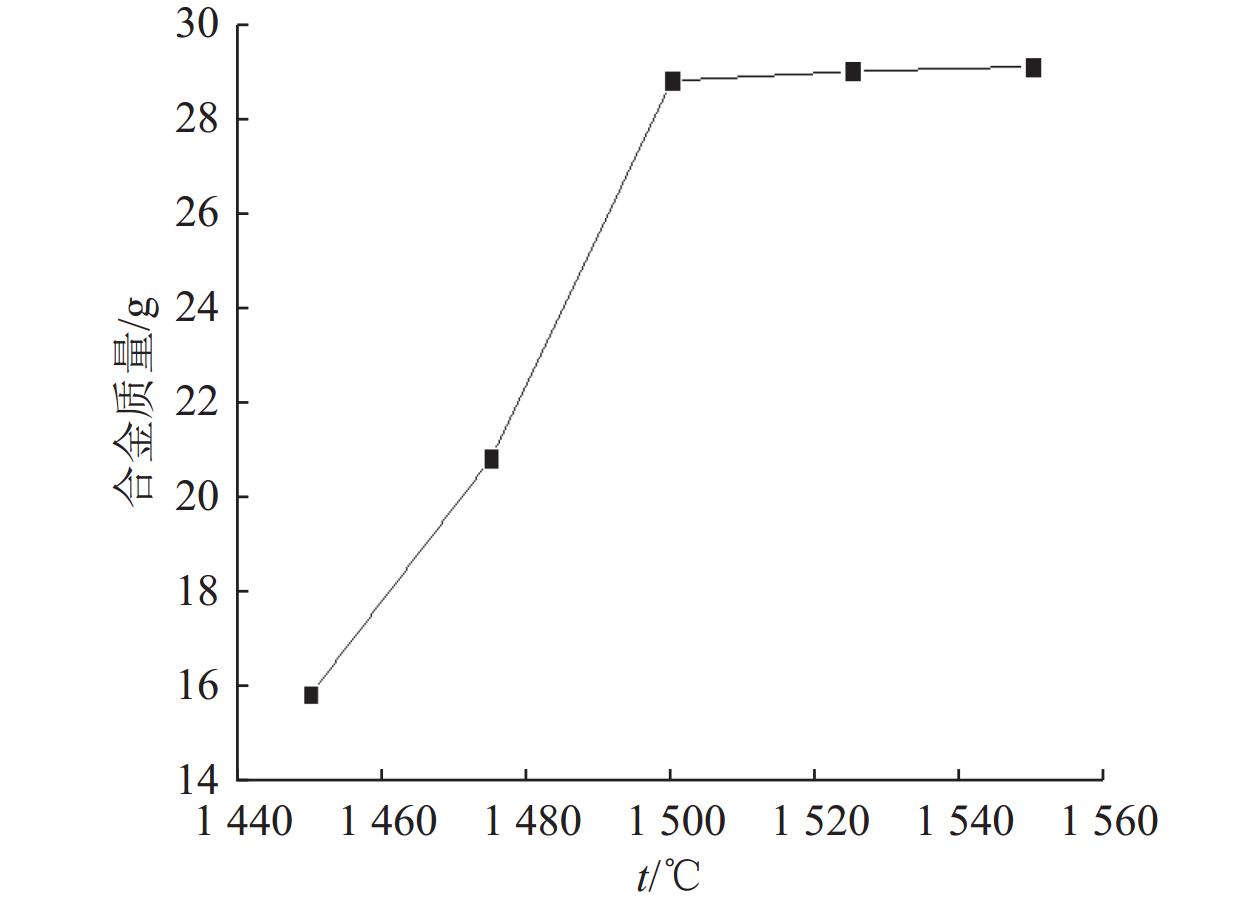

这是一篇冶金工程领域的文章。在氩气保护下,用铝还原含钛高炉渣制得钛硅铝合金。实验结果显示:在1 500 ℃,氩气保护下,铝粉占高炉渣的30%~40%、石灰占5%~15%、萤石≥5%时,还原得到的合金主要为钛硅相、铝硅相、钛相;合金中钛、硅、铝的含量为分别35%~40%、26%~33%、23%~32%,钛、硅、铝的回收率分别为73%~88%、84%~95%、67%~77%。

Abstract:This is an article in the field of metallurgical engineering. At the protection of argon gas, titanium-containing blast furnace slag produced titanium-silicon-aluminum alloy by aluminothermic reduction. The test result shows at 1 500 ℃, at the protection of argon gas, when aluminum powder accounts for 30%~40% of blast furnace slag, lime accounts for 5%~15% and fluorite ≥ 5%, the alloys obtained by reduction are mainly titanium-silicon phase, aluminum-silicon phase, titanium phases. In the alloy, the content of titanium, silicon, aluminum were 35%~40%, 26%~33%, 23%~32%, respectively. The recoveries of titanium, silicon, aluminum were 73%~88%, 84%~95%, 67%~77%, respectively.

-

-

表 1 攀枝花高钛型高炉渣成分/%

Table 1. Composition of Panzhihua high titanium blast furnace slags

TiO2 CaO MgO SiO2 Al2O3 TFe MFe V2O5 MnO2 20~24 20~30 8.0~8.9 17~19 14~16 3.0~4.2 1~3 0.2~0.25 0.3~0.5 -

[1] 赵青娥, 张继东, 杨仰军, 等. 快速还原熔炼含钛炉渣的方法[P]. 中国专利201510711318.5ZHAO Q E, ZHANG J D, YANG Y J, et al. Method for rapid reduction and smelting of titanium-containing slag[P]. China Patent, 201510711318.5

ZHAO Q E, ZHANG J D, YANG Y J, et al. Method for rapid reduction and smelting of titanium-containing slag[P]. China Patent, 201510711318.5

[2] 王勋, 韩跃新, 李艳军, 等. 钒钛磁铁矿综合利用研究现状[J]. 金属矿山, 2019(6):33-37.WANG X, HAN Y X, LI Y J, et al. Research status on comprehensive development and utilization of vanadium-titanium magnetite[J]. Metal Mine, 2019(6):33-37.

WANG X, HAN Y X, LI Y J, et al. Research status on comprehensive development and utilization of vanadium-titanium magnetite[J]. Metal Mine, 2019(6):33-37.

[3] SUI L, ZHAI Y. Reaction kinetics of roasting high-titanium slag with concentrated sulfuric acid[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(3):848-853. doi: 10.1016/S1003-6326(14)63134-4

[4] 高洋 . 高钛高炉渣综合利用现状及展望[J]. 矿产综合利用, 2019(1):6-10.GAO Y. Present situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(1):6-10.

GAO Y. Present situation and prospect of comprehensive utilization of high titanium blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2019(1):6-10.

[5] 龙雨, 张新建, 李书兰, 等. 含钛高炉渣高温碳化制备TiC影响因素研究[J]. 重庆理工大学学报, 2017, 31(8):93-97LONG Y, ZHANG X J, LI S L, et al. Study on influence factors of high temperature carbonization of Ti-bearing blast furnace slag for preparation of TiC[J]. Journal of Chongqing University of Technology( Natural Science), 2017, 31(8):93-97

LONG Y, ZHANG X J, LI S L, et al. Study on influence factors of high temperature carbonization of Ti-bearing blast furnace slag for preparation of TiC[J]. Journal of Chongqing University of Technology( Natural Science), 2017, 31(8):93-97

[6] 张利凡, 丁满堂, 何翠萍, 等. 含钛高炉渣火法提钛研究[J]. 中国资源综合利用, 2020, 38(10):94-96ZHANG L F, DING M T, HE C P, et al. Extracting titanium from titanium-containing blast furnace slag by pyrometallurgy[J]. China Resources Comprehensive Utilization, 2020, 38(10):94-96 doi: 10.3969/j.issn.1008-9500.2020.10.026

ZHANG L F, DING M T, HE C P, et al. Extracting titanium from titanium-containing blast furnace slag by pyrometallurgy[J]. China Resources Comprehensive Utilization, 2020, 38(10):94-96 doi: 10.3969/j.issn.1008-9500.2020.10.026

[7] 丁满堂. 含钛高炉渣真空减压碳化还原提钛研究[J]. 中国资源综合利用, 2020, 38(1):39-41.DING M T. Study on vacuum carbonization reduction of extraction titanium from titanium-bearing blast furnace[J]. China Resources Comprehensive Utilization, 2020, 38(1):39-41.

DING M T. Study on vacuum carbonization reduction of extraction titanium from titanium-bearing blast furnace[J]. China Resources Comprehensive Utilization, 2020, 38(1):39-41.

[8] 郝百川, 李子越, 贾东方, 等. 含钛高炉渣的综合利用[J]. 矿产综合利用, 2020(6):1-6.HAO B C, LI Z Y, JIA D F, et al. Comprehensive utilization of blast furnace slag containing titanium[J]. Multipurpose Utilization of Mineral Resources, 2020(6):1-6. doi: 10.3969/j.issn.1000-6532.2020.06.001

HAO B C, LI Z Y, JIA D F, et al. Comprehensive utilization of blast furnace slag containing titanium[J]. Multipurpose Utilization of Mineral Resources, 2020(6):1-6. doi: 10.3969/j.issn.1000-6532.2020.06.001

[9] 许莹, 李单单, 杨姗姗, 等. 含钛高炉渣综合利用研究进展[J]. 矿产综合利用, 2021(1):23-28.XU Y, LI D D, YANG S S, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1):23-28. doi: 10.3969/j.issn.1000-6532.2021.01.004

XU Y, LI D D, YANG S S, et al. Research progress of comprehensive utilization of Ti-bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2021(1):23-28. doi: 10.3969/j.issn.1000-6532.2021.01.004

-

下载:

下载: