Preparation of A New Amphoteric Collector and Its Flotation Performance for Phosphate Rock

-

摘要:

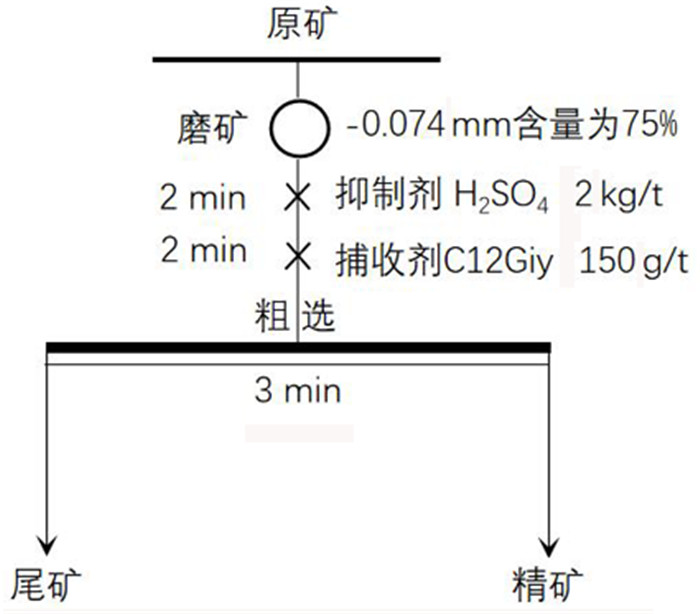

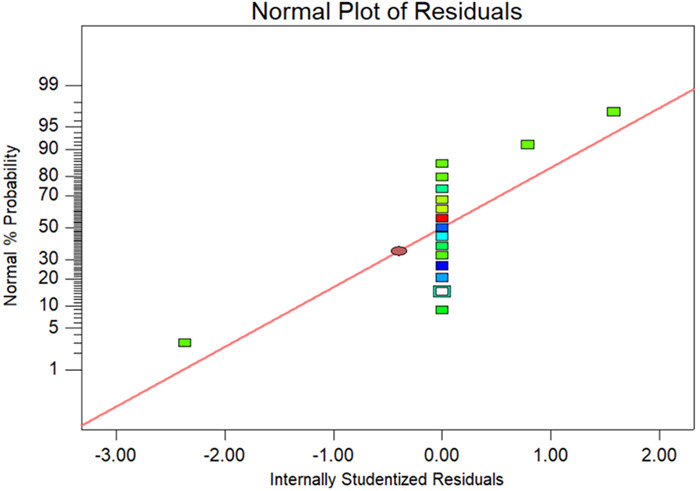

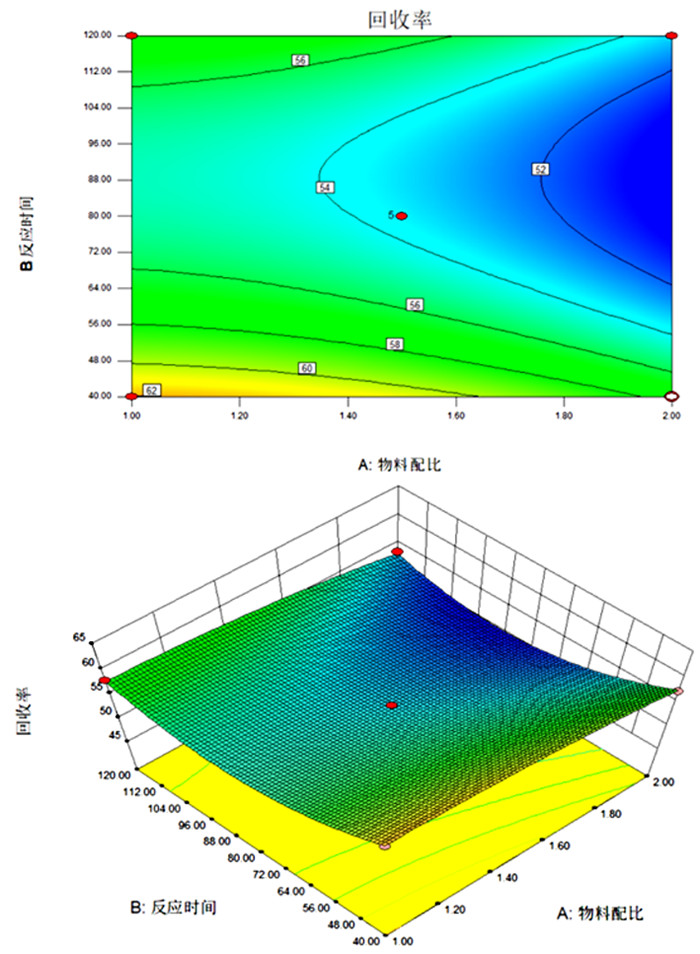

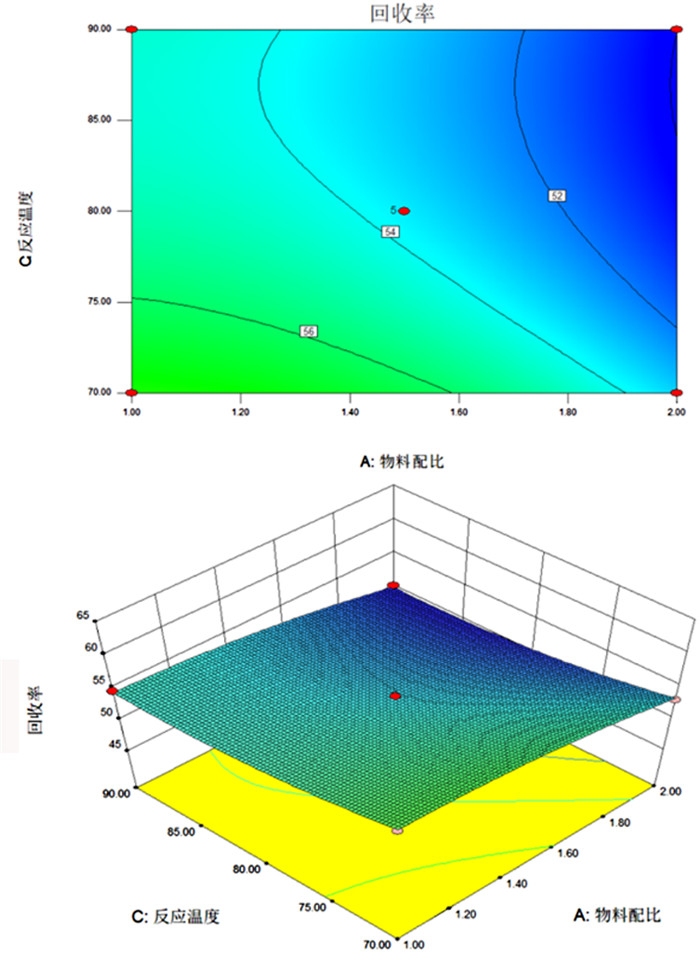

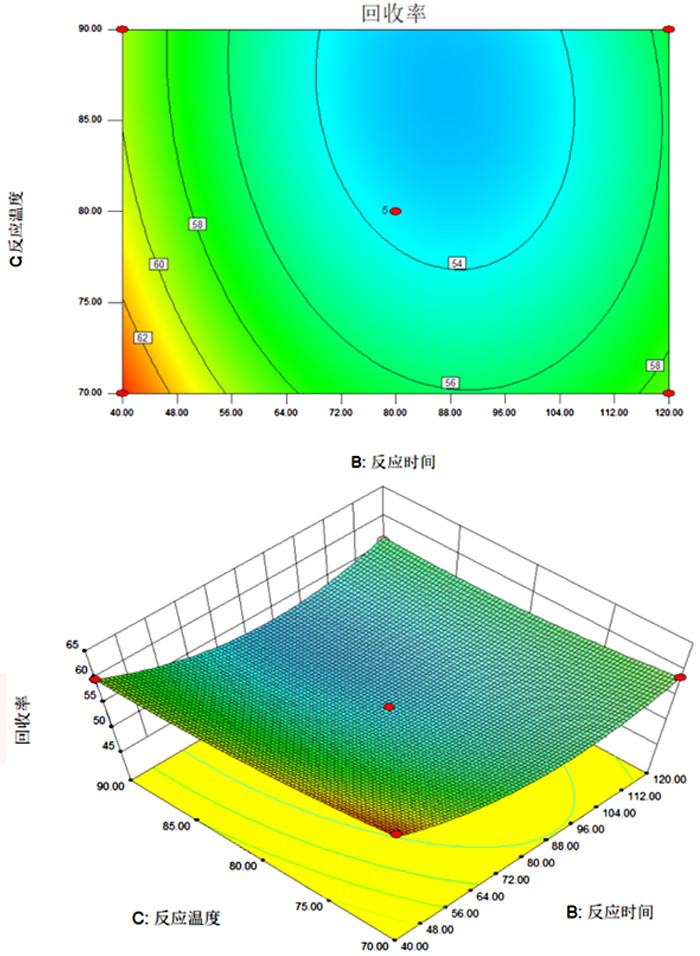

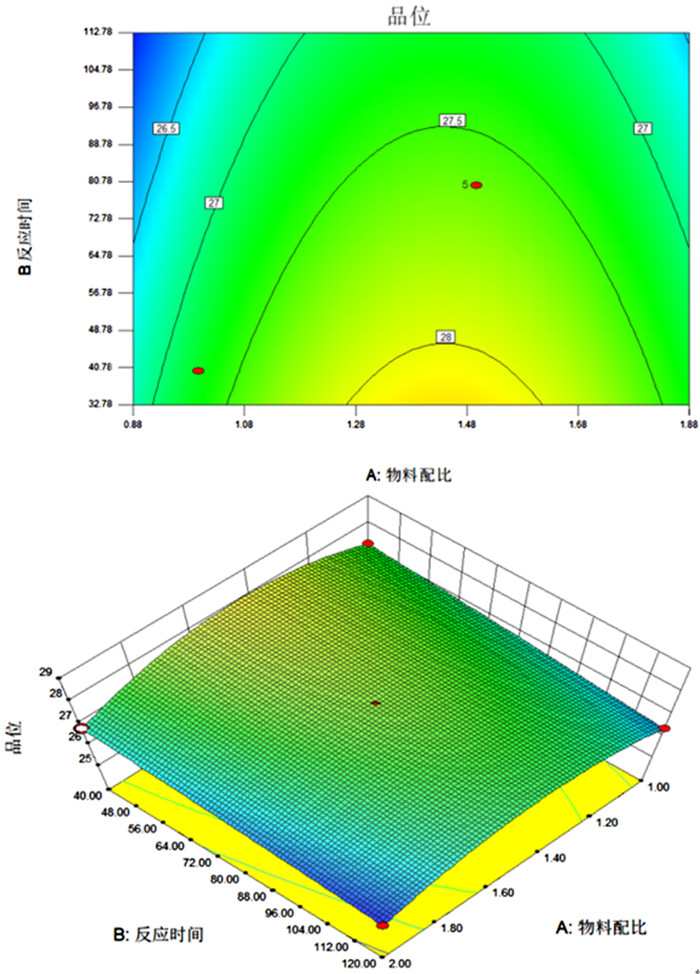

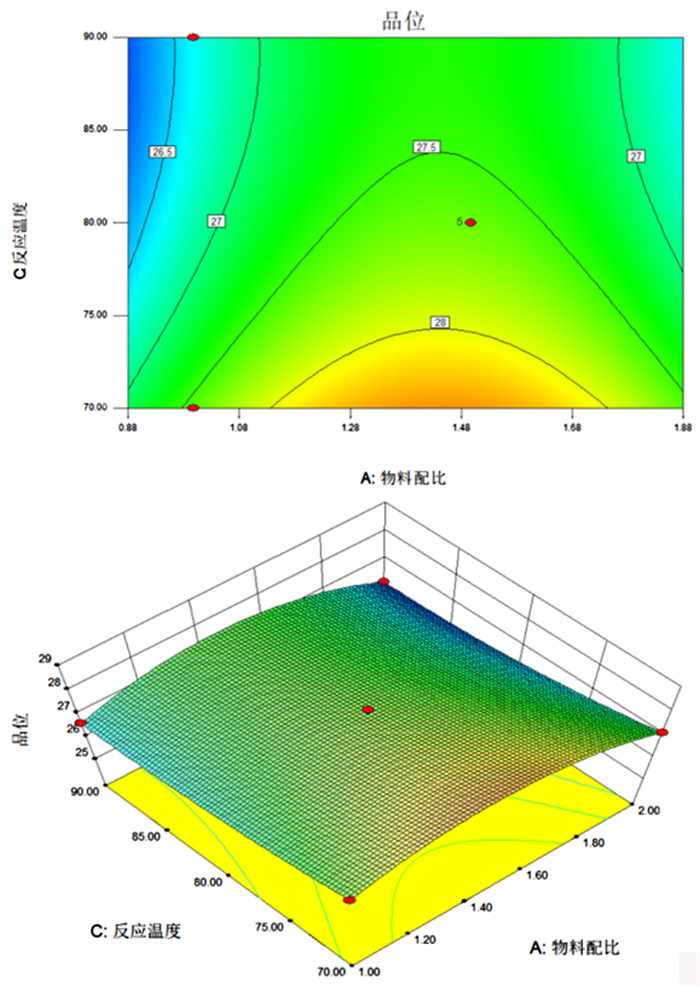

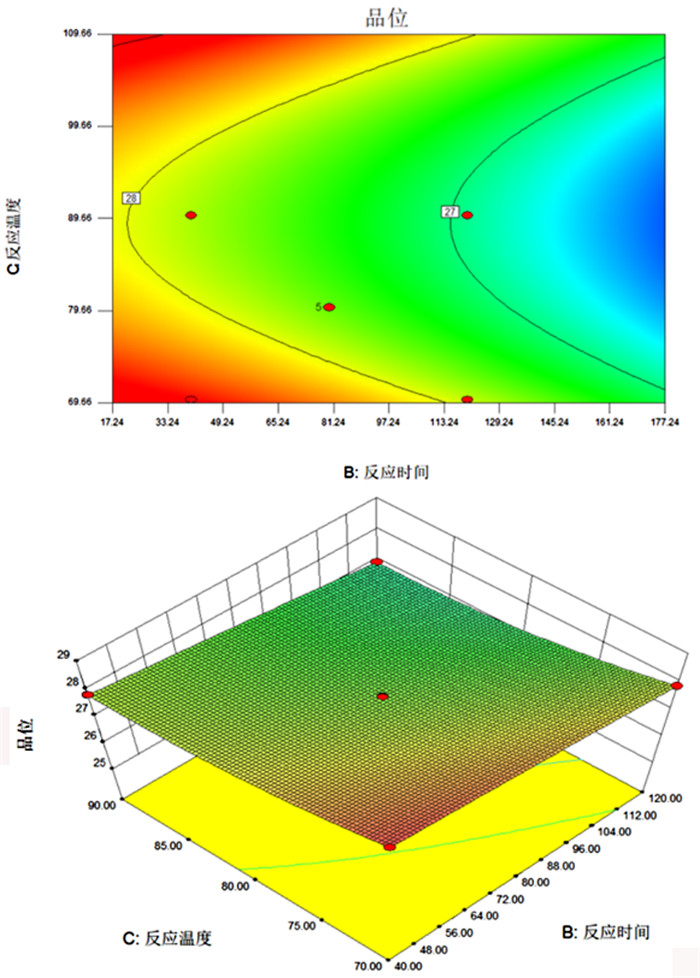

近年来,氨基酸型两性捕收剂在磷矿选矿过程中已经取得了较好的分选效果。以丙烯酸甲酯法制备N-十二烷基-β-氨基丙酸钠(C12Giy),并采用响应面法构建回归模型和响应面曲线分析对其合成工艺条件进行优化。结果表明,反应温度对浮选磷精矿回收率的影响最显著,而反应时间对磷精矿品位的影响最显著,反应时间与反应温度的交互作用对磷精矿回收率与品位的影响最显著。通过Design Expert软件分析可知,两性捕收剂C12Giy性能最优的合成条件为:十二胺与丙烯酸甲酯的物料质量配比为1:1.5,反应时间40 min,反应温度为70 ℃。在该条件下合成的C12Giy用作浮选捕收剂时,磷精矿的品位与回收率分别达到28.78%与64.04%,理论综合效率值与实际综合效率值分别为5.74%与5.49%,表明该模型的预测结果较可靠。

Abstract:In recent years, amino acid-based amphoteric collectors have achieved good separation effects in the process of phosphate ore beneficiation. In this study, sodium N-dodecyl-β-aminopropionic acid (C12Giy) was prepared by methyl acrylate method, and the regression model and response surface curve analysis were used to optimize the synthesis conditions. The results show that the influence of reaction temperature on the recovery of flotation phosphate concentrate is the most obvious, and the influence of reaction time on the grade of phosphate concentrate is the most obvious. The interaction between reaction time and reaction temperature has the most obvious influence on the recovery and grade of phosphate concentrate. Through the analysis of Design Expert software, the optimal synthesis conditions of amphoteric collector C12Giy are as follows: the molar ratio of dodecylamine and methyl acrylate is 1 : 1.5, the reaction time is 40 min and the reaction temperature is 70 ℃. When C12Giy synthesized under this condition was used as flotation collector, the grade and recovery of phosphate concentrate were 28.78 % and 64.04 %, respectively. The theoretical comprehensive efficiency value and the actual comprehensive efficiency value were 5.74 % and 5.49 %, respectively, indicating that the prediction results of the model were reliable.

-

Key words:

- new amphoteric collector /

- synthesis /

- response surface methodology /

- interaction /

- phosphate /

- flotation

-

-

表 1 硅钙质磷矿原矿化学多元素分析结果

/% Table 1. Results of chemical multi-element analysis of silicon-calcium phosphate ore

成分 P2O5 SiO2 CaO MgO Al2O3 Fe2O3 F 含量 25.29 24.20 33.19 2.23 8.05 1.55 1.41 表 2 试验因素水平及编码

Table 2. Test factor level and coding

因素 编码 单位 水平 -1 0 1 物料配比 A 1:1 1:1.5 1:2 反应时间 B min 40 80 120 反应温度 C ℃ 70 80 90 表 3 响应面设计试验及结果

Table 3. Response surface design test and results

编号 因素 E/% ε/% β/% A B C 1 1:1 40 80 4.32 61.80 27.26 2 1:2 40 80 3.32 57.31 26.79 3 1:1 120 80 2.72 58.06 26.37 4 2:1 120 80 1.83 53.57 25.9 5 1:1 80 70 4.48 57.50 27.58 6 1:2 80 70 3.51 53.01 27.11 7 1:1 80 90 2.95 54.76 26.63 8 1:2 80 90 2.07 50.27 26.16 9 1:1.5 40 70 5.49 64.55 28.78 10 1:1.5 120 70 5.02 58.75 27.89 11 1:1.5 40 90 5.01 59.75 27.83 12 1:1.5 120 90 3.46 56.01 26.94 13 1:1.5 80 80 4.26 53.72 27.64 14 1:1.5 80 80 4.27 53.60 27.65 15 1:1.5 80 80 4.23 53.52 27.63 16 1:1.5 80 80 4.24 53.58 27.63 17 1:1.5 80 80 4.21 53.71 27.60 表 4 磷精矿回收率模型方差分析结果

Table 4. Variance analysis result of concentrate recovery rate model

方差来源 平方和 自由度 均方 F值 P值 显著性 模型 212.78 9 23.64 151.72 < 0.0001 极显著 A 40.32 1 40.32 258.74 < 0.0001 极显著 B 36.21 1 36.21 232.37 < 0.0001 极显著 C 21.19 1 21.19 135.98 < 0.0001 极显著 AB 0 1 0 0 1 不显著 AC 0 1 0 0 1 不显著 BC 1.06 1 1.06 6.81 0.035 显著 A2 3.49 1 3.49 22.40 0.0021 极显著 B2 103.98 1 103.98 667.28 < 0.0001 极显著 C2 5.76 1 5.76 36.96 0.0005 极显著 残差 1.09 7 0.16 失拟 1.06 3 0.35 47.28 0.0014 极显著 纯误差 0.03 4 7.48E-003 总离差 213.87 16 表 5 磷精矿品位回归模型方差分析结果

Table 5. Analysis of variance of concentrate grade regression model

方差来源 平方和 自由度 均方 F值 P值 显著性 模型 8.41 9 0.93 4 674.14 < 0.0001 极显著 A 0.44 1 0.44 2 209 < 0.0001 极显著 B 1.58 1 1.58 7921 < 0.0001 极显著 C 1.80 1 1.80 9025 < 0.0001 极显著 AB 0 1 0 0 1 不显著 AC 0 1 0 0 1 不显著 BC 0 1 0 0 1 不显著 A2 4.38 1 4.38 21 903.16 < 0.0001 极显著 B2 3.789E-003 1 3.789E-003 18.95 0.0033 极显著 C2 0.28 1 0.28 1 423.16 < 0.0001 极显著 残差 1.400E-003 7 2.00E-004 失拟 0 3 0 0 1 不显著 纯误差 1.400E-003 4 3.500E-004 总离差 8.41 16 -

[1] 余永富, 葛英勇, 潘昌林. 磷矿选矿进展及存在的问题[J]. 矿冶工程, 2008(1): 29-33. doi: 10.3969/j.issn.0253-6099.2008.01.008

[2] 李晓波, 闫卫东, 郭娟, 等. 中国矿产资源报告2020[R]. 北京: 中国地质出版社, 2020.

[3] 赵鑫, 蔡慢弟, 董倩倩, 等. 中低品位磷矿资源高效利用机制与途径研究进展[J]. 植物营养与肥料学报, 2018(4): 1121-1130. https://www.cnki.com.cn/Article/CJFDTOTAL-ZWYF201804029.htm

[4] 薛珂, 张润宇. 中国磷矿资源分布及其成矿特征研究进展[J]. 矿物学报, 2019(1): 7-14. https://www.cnki.com.cn/Article/CJFDTOTAL-KWXB201901002.htm

[5] 刘长淼, 卫敏, 吴东印, 等. 青海低品位磷灰石型磷矿浮选试验研究[J]. 矿冶工程, 2014(3): 29-32. doi: 10.3969/j.issn.0253-6099.2014.03.009

[6] ABOUZEID A M. Physical and thermal treatment of phosphate ores — An overview[J]. International Journal of Mineral Processing, 2008, 85(4): 59-84. doi: 10.1016/j.minpro.2007.09.001

[7] FANG G, JUN L. Selective separation of silica from a siliceous-calcareous phosphate rock[J]. Mining Science and Technology (China), 2011(1): 135-139. https://www.sciencedirect.com/science/article/pii/S1674526410000293

[8] 王秀兰, 张乾伟, 任瑞晨. 钼尾矿中有用矿物回收试验研究[J]. 硅酸盐通报, 2014(10): 2472-2476.

[9] HOANG D H, KUPKA N, PEUKER U A, et al. Flotation study of fine grained carbonaceous sedimentary apatite ore - Challenges in process mineralogy and impact of hydrodynamics[J]. Minerals Engineering, 2018, 121: 196-204. doi: 10.1016/j.mineng.2018.03.021

[10] CHEN Y, FENG Q, ZHANG G, et al. Effect of sodium pyrophosphate on the reverse flotation of dolomite from apatite[J]. Minerals, 2018, 8(7): 278. doi: 10.3390/min8070278

[11] 刘鸿儒, 夏鹏飞, 朱建光. 两性捕收剂的合成[J]. 湖南化工, 1991(2): 29-32. https://www.cnki.com.cn/Article/CJFDTOTAL-HNHG199102011.htm

[12] BORDES R, HOLMBERG K. Amino acid-based surfactants - do they deserve more attention[J]. Advances in Colloid and Interface Science, 2015, 222: 79-91. doi: 10.1016/j.cis.2014.10.013

[13] KARLKVIST T, PATRA A, RAO K H, et al. Flotation selectivity of novel alkyl dicarboxylate reagents for apatite-calcite separation[J]. Journal of Colloid and Interface Science, 2015, 445: 40-47. doi: 10.1016/j.jcis.2014.11.072

[14] CAO Q, ZOU H, CHEN X, et al. Flotation selectivity of N-hexadecanoylglycine in the fluorapatite-dolomite system[J]. Minerals Engineering, 2019, 131: 353-362. doi: 10.1016/j.mineng.2018.11.033

[15] BLUESTEIN B R, HITION C L. Amphoteric surfactants[M]. New York: Marcel dekker incorporated, 1982: 175-228.

[16] 刘军海. N-十二烷基-β-氨基丙酸型表面活性剂的合成方法及应用[J]. 中国洗涤用品工业, 2008(3): 45-46. doi: 10.3969/j.issn.1672-2701.2008.03.013

[17] Box G, Wilson K B. On the experimental attainment of optimum conditions[J]. Journal of the Royal Statistical Society Series B: Statistical Methodology, 1951(1): 1-45. https://link.springer.com/chapter/10.1007/978-1-4612-4380-9_23

[18] Mason R L, Gunst R F, Hess J L. Statistical Design and Analysis of Experiments with Applications to Engineering and Science[M]. The United States of America: John Wiley and Sons Publication, 2003.

[19] 秦俊哲, 吕嘉枥. 食用菌栽培[M]. 西安: 西北农林科技大学出版社, 2002.

[20] 杨婕, 罗惠华, 饶欢欢, 等. 一种新型两性捕收剂的制备及其浮选性能[J]. 武汉工程大学学报, 2016(1): 68-73. doi: 10.3969/j.issn.1674-2869.2016.01.012

[21] 王志强, 聂光华, 李德伟, 等. 响应面曲线法优化贵州某磷块岩浮选工艺研究[J]. 矿冶工程, 2020, 40(3): 54-57. doi: 10.3969/j.issn.0253-6099.2020.03.014

[22] Montgomery D C. Design and Analysis of Experiments[M]. London: John Wiley and Sons Inc, 1991.

[23] 王振宇, 周芳, 赵鑫. 响应面分析法优化超声波提取大果沙棘总黄酮工艺[J]. 中国食品学报, 2007(6): 44-51. doi: 10.3969/j.issn.1009-7848.2007.06.008

[24] 力亚男, 谭冲, 李俊生, 等. 响应面法优化TiO2-NTs电极的制备[J]. 哈尔滨商业大学学报(自然科学版), 2019, 35(6): 657-661. doi: 10.3969/j.issn.1672-0946.2019.06.005

-

下载:

下载: