Research Status of Sulfur Containing Iron Materials Desulfurization Technology

-

摘要:

硫在含铁物料的开发利用中是有害杂质元素,因此需要脱除。本文介绍了含铁物料中硫的来源、产出特征与危害,归纳了以浮选法、焙烧法、浸出法处理含铁物料脱硫的技术现状,介绍了此3种脱硫方法的适用条件、应用特色,并比较了各自的优缺点。展望未来含硫铁物料脱硫研究与发展方向,指出浮选法需合理选择磨选流程和药剂制度,注重铜离子复合活化剂、黄药类组合捕收剂提高浮选脱硫指标;焙烧法根据含硫矿物组成和热力学性质选择合适的焙烧炉型、筛选适宜的热工制度;生物浸出应结合多形态硫元素的迁移演变特征,培育良性高效菌种、实施短周期高效浸出,以实现高效脱硫。

Abstract:Sulfur is a harmful impurity element that needs to be removed in the development and utilization of iron-containing materials. The sources, occurrence characteristics and hazards of sulfur in iron-containing materials were introduced successively. The technical status of desulfurization of iron-containing materials from three aspects of flotation, roasting and hydrometallurgy was summarized in proper sequence. Moreover, the applicable conditions and application characteristics of these three desulfurization methods were discussed and the advantages and disadvantages of each other were compared. Looking forward to the future research and development direction of sulfur-containing iron material desulfurization, it is pointed out that the flotation method needs to be chosen the grinding flowsheets and reagent systems reasonably, and pay attention to the copper ion composite activator and the xanthate-type composite collector to improve the flotation desulfurization index. The roasting method will be selected the appropriate roaster type and selected the appropriate thermal system according to the composition and thermodynamic properties of sulfur-containing minerals. Biological leaching should be combined the migration and evolution characteristics of multi-form sulfur elements, by cultivating benign and high-efficiency bacteria, and implementing short-period high-efficiency leaching to achieve high-efficiency desulfurization.

-

Key words:

- Iron-containing materials /

- Desulfurization /

- Pyrite /

- Oxidation roasting /

- Bioleaching

-

-

表 1 含铁物料中硫的产出与特征

Table 1. Output and characteristics of sulfur in iron-containing materials

硫的形式 硫化物 硫酸盐 自然硫 硫的产出 黄铁矿、磁黄

铁矿、白铁矿绿矾 硫单质 硫的价态 S2-,S- SO42- S 矿物晶体特性 立方体单晶,粒状,致密块状集合体 浅绿色单斜晶体 斜方晶系 可选性 随矿物表面氧化可浮性逐渐降低 高温分解为氧化铁和二氧化硫 高温下与氧强烈作用生成二氧化硫 表 2 含硫矿物的性质与浮选药剂制度

Table 2. Nature and flotation agent system of sulfur-containing iron minerals

含硫矿物 化学式 密度 磁性 矿浆pH值 抑制剂 活化剂 捕收剂 黄铁矿

(白铁矿)FeS2 4.9~5.2 弱磁性 酸性,大于11被抑制 石灰、硫化物、淀粉、CMC 硫酸铜,草酸 组合黄药类 磁黄铁矿 Fe1-xS,FeS,

Fe7S84.6~4.7 强磁性矿物 5~6硫酸活化 石灰、有机抑制剂RC 硫化钠、草酸、

硫酸铵、硫酸铜[8]组合黄药类 表 3 浮选法脱硫工艺研究现状

Table 3. Flotation desulfurization process research status

矿物来源 选别流程 硫的存在形式 原矿/%

TFe S精矿/%

TFe S铁回收率/% 参考文献作者 江西省 两次反浮选粗选 磁黄铁矿

黄铁矿62.36 1.87 64.03 0.39 95.64 张建超[17] 内蒙古 一次粗选四次精选 磁黄铁矿

黄铁矿63.83 1.59 67.59 0.35 96.51 杨峰涛[20] 山东省 一粗一扫混合浮选 磁黄铁矿 44.47 0.536 68.81 0.201 92.23 韩西鹏[21] 安徽省 浮选强磁再磨再浮选 黄铁矿 43.29 20.58 59.00 0.42 42.00 赵忠花[22] 四川省 一段磨矿一段选别 黄铁矿 14.34 0.378 62.85 0.076 48.45 张敏[23] / 一粗二精一扫 磁黄铁矿

黄铁矿41.55 1.59 67.00 0.078 91.88 彭会清[16] 新疆省 一粗三精三扫 磁黄铁矿

黄铁矿

闪锌矿35.65 1.56 67.40 0.29 86.78 卜显忠[24] 山西省 一次粗选反浮选 磁黄铁矿 66.39 0.32 67.35 0.17 86.91 张洋洋[25] 表 4 含铁物料中4种含硫矿物的热力学性质

Table 4. Hermodynamic properties of four sulfur-bearing minerals in iron-bearing materials

硫化物 PbS ZnS FeS FeS2 着火温度/K(0.1 mm) 827 920 598 熔点/K 1408 升华 >923 1444 沸点/K 1554 1938 无 △H°/(kJ·mol-1) -94.23 -202.90 △G°/(kJ·mol-1) -92.6 -197.90 放出反应热/ (kJ·kg-1) 146.5 172 92.8 表 5 生物浸出脱硫的机理与特点

Table 5. Mechanism and characteristics of bioleaching desulfurization

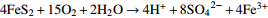

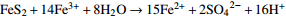

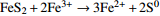

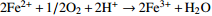

浸出方式 反应式及作用机理 影响因素 微生物直接作用

利用微生物自身的氧化或还原特性,使矿物的某些组分氧化或还原,接着使硫化物溶解氧化Fe3+的浓度及作用机理、电动电位、pH值、微生物代谢产物层等因素对浸出有明显影响。 微生物间接作用

利用微生物的代谢产物如三价铁为氧化剂浸出金属硫化物、单质硫作为能量在细菌的作用下生成硫酸根据上述影响因素探究强化生物浸出的途径有:添加催化离子、添加表面活性剂、超声波处理、合理利用菌种等。 微生物复合作用 既有微生物直接作用又有间接作用 黄铁矿生物氧化浸出以直接作用为主。 -

[1] 丁湛, 文书明, 李春龙, 等. 铁矿石脱磷硫工艺现状及同步脱除新方法[J]. 矿产综合利用, 2020(3):56-62+32. doi: 10.3969/j.issn.1000-6532.2020.03.009

DING Z, WEN S M, LI C L, et al. Status of iron phosphorus and sulfur removal process and new method of simultaneous removal[J]. Multipurpose Utilization of Mineral Resources, 2020(3):56-62+32. doi: 10.3969/j.issn.1000-6532.2020.03.009

[2] 侯卉, 胡旺阳, 李兵. 我国铁矿石资源可持续发展的战略分析[J]. 金属矿山, 2007(10):18-21. doi: 10.3321/j.issn:1001-1250.2007.10.005

HOU H, HU W Y, LI B. Strategic analysis of the sustainable development of China's iron ore resources[J]. Metal Mine, 2007(10):18-21. doi: 10.3321/j.issn:1001-1250.2007.10.005

[3] 李丹龙, 赵艺, 孟宇航, 等. 一种新型阻垢剂对黄铁矿浮选的应用研究[J]. 矿产综合利用, 2019(5):52-55. doi: 10.3969/j.issn.1000-6532.2019.05.011

LI D L, ZHAO Y, MENG Y H, et al. Research on the application of a new type scale inhibitor on the flotation of pyrite[J]. Multipurpose Utilization of Mineral Resources, 2019(5):52-55. doi: 10.3969/j.issn.1000-6532.2019.05.011

[4] 余永富. 国内外铁矿选矿技术进展及对炼铁的影响[J]. 矿冶工程, 2004, 24(1):26-29. doi: 10.3969/j.issn.0253-6099.2004.01.008

YU Y F. Progress of iron ore proecssing technology at home and abroad and its influence on ironmaking[J]. Mining and Metallurgical Engineering, 2004, 24(1):26-29. doi: 10.3969/j.issn.0253-6099.2004.01.008

[5] 任海兵. 对我国硫铁矿资源开发及利用的思考[J]. 中国矿业, 2010, 19(3):36-39. doi: 10.3969/j.issn.1004-4051.2010.03.012

REN H B. Reflections on the development and utilization of sulfur iron ore resources in China[J]. China Mining Magazine, 2010, 19(3):36-39. doi: 10.3969/j.issn.1004-4051.2010.03.012

[6] Rezvanipour Hassan, Mostafavi Ali, Ahmadi Ali, et al. Desulfurization of iron ores: Processes and challenges[J]. Steel Research International, 2018, 89(7):1-14.

[7] 胡天喜, 文书明. 硫铁矿选矿现状与发展[J]. 化工矿物与加工, 2007(8):1-4. doi: 10.3969/j.issn.1008-7524.2007.08.001

HU T X, WEN S M. Status and development of sulfur iron ore beneficiation[J]. Industrial Minerals & Processing, 2007(8):1-4. doi: 10.3969/j.issn.1008-7524.2007.08.001

[8] 耿郑州. 难处理高硫铁精矿浮选脱硫及其机理研究[D]. 包头: 内蒙古科技大学, 2014.

GENG Z Z. Flotation desulfurization and its mechanism of difficult-to-treat high-sulfur iron ore concentrate[D]. Baotou: Inner Mongolia University of Science and Technology, 2014.

[9] 张元龙. 含硫铁矿提铁降杂试验及机理研究[D]. 武汉: 武汉理工大学, 2013.

ZHANG Y L. Iron extraction and impurity reduction test and mechanism study of iron ore containing sulfur[D]. Wuhan: Wuhan University of Technology, 2013.

[10] QIU T S, WU C Y, AI G H, et al. Effects of multi-stage grinding process and grinding fineness on desulfurization separation of high-sulfurous iron ore[J]. Procedia Engineering, 2015, 102:722-730. doi: 10.1016/j.proeng.2015.01.174

[11] 王晓伟. 浅谈白铁矿、黄铁矿和磁黄铁矿的电子结构及其可浮性[J]. 电子测试, 2016(11):166-167. doi: 10.3969/j.issn.1000-8519.2016.11.082

WANG X W. Discussion on electronic structure and floatability of white iron, pyrite and pyrrhotite[J]. Electronic Test, 2016(11):166-167. doi: 10.3969/j.issn.1000-8519.2016.11.082

[12] Adkins S J, Pearse M J. The influences of collector chemistry on kinetics and selectivity in base-metal sulphide flotation[J]. Minerals Engineering, 1992, 5(3/4/5):295-310.

[13] Lotter N O, Bradshaw D J. The formulation and use of mixed collectors in sulphide flotation[J]. Minerals Engineering, 2010, 23(11):945-951.

[14] Allison S A, O'connor C T. An investigation into the flotation behaviour of pyrrhotite[J]. International Journal of Mineral Processing, 2010, 98(3):202-207.

[15] Arvidson B, Klemetti M, Knuutinen T, et al. Flotation of pyrrhotite to produce magnetite concentrates with a sulphur level below 0.05% w/w[J]. Minerals Engineering, 2013:50-51.

[16] 彭会清, 李禄宏, 徐林. 某铁精矿浮选脱硫试验研究[J]. 金属矿山, 2005(12):35-37. doi: 10.3321/j.issn:1001-1250.2005.12.010

PENG H Q, LI L H, XU L. Experimental study on flotation desulfurization of an iron concentrate[J]. Metal Mine, 2005(12):35-37. doi: 10.3321/j.issn:1001-1250.2005.12.010

[17] 张建超. 高硫铁精矿反浮选脱硫试验[J]. 现代矿业, 2020, 36(7):125-127.

ZHANG J C. Desulfurization test of high sulphide iron concentrate by reverse flotation[J]. Modern Mining, 2020, 36(7):125-127.

[18] YU J, GE Y Y, CAI X W. The Desulfurization of magnetite ore by flotation with a mixture of xanthate and dixanthogen[J]. Minerals, 2016, 6(3):70. doi: 10.3390/min6030070

[19] 刘兴华, 廖振鸿, 严小虎, 等. 磁铁矿与磁黄铁矿综合回收试验研究[J]. 矿冶工程, 2014, 34(4):47-51. doi: 10.3969/j.issn.0253-6099.2014.04.011

LIU X H, LIAO Z H, YAN X H, et al. Experimental study on comprehensive recovery of magnetite and pyrrhotite[J]. Mining and Metallurgical Engineering, 2014, 34(4):47-51. doi: 10.3969/j.issn.0253-6099.2014.04.011

[20] 杨峰涛, 李玉凤, 王晓旭. 内蒙某铁精矿浮选脱硫试验[J]. 华北理工大学学报(自然科学版), 2016, 38(4):13-18.

YANG F T, LI Y F, WANG X X. Flotation desulfurization test of an iron concentrate in Inner Mongolia[J]. Journal of North China University of Science and Technology(Natural Science Edition), 2016, 38(4):13-18.

[21] 韩西鹏. 金鼎铁矿浮选脱硫试验[J]. 现代矿业, 2017, 33(10):112-113,116. doi: 10.3969/j.issn.1674-6082.2017.10.027

HAN X P. Flotation desulfurization test of jingding iron ore[J]. Modern Mining, 2017, 33(10):112-113,116. doi: 10.3969/j.issn.1674-6082.2017.10.027

[22] 赵忠花. 某硫铁矿选矿工艺流程优化设计[J]. 化工矿物与加工, 2016, 45(12):56-58. doi: 10.16283/j.cnki.hgkwyjg.2016.12.016

ZHAO Z H. Optimization design of beneficiation process of a pyrite mine[J]. Industrial Minerals & Processing, 2016, 45(12):56-58. doi: 10.16283/j.cnki.hgkwyjg.2016.12.016

[23] 张敏. 攀西某铁矿选矿试验研究[J]. 矿冶工程, 2017, 37(1):57-59. doi: 10.3969/j.issn.0253-6099.2017.01.016

ZHANG M. Experimental study on beneficiation of an iron ore in panxi[J]. Mining and Metallurgical Engineering, 2017, 37(1):57-59. doi: 10.3969/j.issn.0253-6099.2017.01.016

[24] 卜显忠, 陈彤, 薛季玮,等. 新疆某铁矿降锌脱硫工艺研究[J]. 金属矿山, 2021(2):77-84. doi: 10.19614/j.cnki.jsks.202102012

BU X Z, CHEN T, XUE J W, et al. Studying on zinc reduction and desulfurization technology of an iron ore in Xinjiang[J]. Metal Mine, 2021(2):77-84. doi: 10.19614/j.cnki.jsks.202102012

[25] 张洋洋, 吴雪兰, 陈意帆,等. 某铁精矿浮选脱硫探究试验[J]. 科技视界, 2020(28):115-118. doi: 10.19694/j.cnki.issn2095-2457.2020.28.46

ZHANG Y Y, WU X L, CHEN Y F, et al. Experimental study on flotation desulfurization of an iron concentrate[J]. Science & Technology Vision, 2020(28):115-118. doi: 10.19694/j.cnki.issn2095-2457.2020.28.46

[26] Soltanmohmmadi Valid, Noaparast Mohammad, Kohsari Amir Hossein, et al. Influence of flotation parameters on decreasing sulfur and phosphorus content in the gol-e-gohar iron ore concentrate[J]. Physicochemical Problems of Mineral Processing, 2011, 46: 173-190.

[27] Nakhaei Fardis, Irannajad Mehdi. Sulphur removal of iron ore tailings by flotation[J]. Taylor & Francis, 2017, 38(12):1755-1763.

[28] 邱廷省, 赵冠飞, 朱冬梅,等. 含硫铁矿石脱硫技术研究现状[J]. 矿山机械, 2013, 41(3):12-16. doi: 10.16816/j.cnki.ksjx.2013.03.003

QIU T S, ZHAO G F, ZHU D M, et al. Research status of desulfurization technology of ferrite bearing ore[J]. Mining & Processing Equipment, 2013, 41(3):12-16. doi: 10.16816/j.cnki.ksjx.2013.03.003

[29] LV C, WEN S M, BAI S J, et al. Recovery of iron from a high phosphorus and sulphur iron ore by using various methods[J]. Advanced Materials Research, 2014, 2913:437-441.

[30] 马淑贤, 孙春宝, 张晓亮,等. 微波焙烧黄铁矿热分解动力学研究[J]. 中国矿业, 2018, 27(5):138-142. doi: 10.12075/j.issn.1004-4051.2018.05.014

MA S X, SUN C B, ZHANG X L, et al. Study on the kinetics of thermal decomposition of microwave roasted pyrite[J]. China Mining Magazine, 2018, 27(5):138-142. doi: 10.12075/j.issn.1004-4051.2018.05.014

[31] 王伟伟, 黄帮福, 刘江伟,等. 低品位矿高炉锌平衡探究[J]. 河北冶金, 2018(1):38-41,63. doi: 10.13630/j.cnki.13-1172.2018.0109

WANG W W, HUANG B F, LIU J W, et al. Study on zinc balance in blast furnace of low grade ore[J]. Hebei Metallurgy, 2018(1):38-41,63. doi: 10.13630/j.cnki.13-1172.2018.0109

[32] 刘占华, 孙体昌, 孙昊,等. 从内蒙古某高硫铁尾矿中回收铁的研究[J]. 矿冶工程, 2012, 32(1):46-49. doi: 10.3969/j.issn.0253-6099.2012.01.013

LIU Z H, SUN T C, SUN H, et al. Research on recovery from a high sulphur iron tailings in inner mongolia[J]. Mining and Metallurgical Engineering, 2012, 32(1):46-49. doi: 10.3969/j.issn.0253-6099.2012.01.013

[33] 魏晨曦, 罗立群, 郑波涛,等. 含铅锌难选赤褐铁矿还原焙烧及铅锌杂质同步脱除效果研究[J]. 中国矿业, 2019, 28(12):161-166. doi: 10.12075/j.issn.1004-4051.2019.12.022

WEI C X, LUO L Q, ZHENG B T, et al. Study on reduction roasting and synchronous removing of lead and zinc impurities of rerefractory hematitecontaining lead and zinc[J]. China Mining Magazine, 2019, 28(12):161-166. doi: 10.12075/j.issn.1004-4051.2019.12.022

[34] Asaki Z, Kondo Y. Oxidation kinetics of iron sulfide in the form of dense plate, pellet and single particle[J]. Journal of Thermal Analysis, 1989, 35(6):1751-1759. doi: 10.1007/BF01911664

[35] 张红强, 张婧, 罗果萍,等. 白云鄂博铁精矿硫氧化焙烧过程动力学研究[J]. 内蒙古科技大学学报, 2018, 37(1):30-37. doi: 10.16559/j.cnki.2095-2295.2018.01.007

ZHANG H Q, ZHANG J, LUO G P, et al. Kinetics study on sulfur oxidation roasting process of Bayan Obo iron concentrate[J]. Journal of Inner Mongolia University of Science and Technology, 2018, 37(1):30-37. doi: 10.16559/j.cnki.2095-2295.2018.01.007

[36] 张溅波, 赵青娥, 缪辉俊. 攀枝花钛铁矿氧化脱硫机理研究[J]. 钢铁钒钛, 2014, 35(6):1-5. doi: 10.7513/j.issn.1004-7638.2014.06.001

ZHANG J B, ZHAO Q E, LIAO H J. Study on oxidation desulfurization mechanism of Panzhihua ilmenite[J]. Iron Steel Vanadium Titanium, 2014, 35(6):1-5. doi: 10.7513/j.issn.1004-7638.2014.06.001

[37] 王德英, 孙广周, 罗兴,等. 微波焙烧在难选铁矿中的应用前景[J]. 矿产综合利用, 2013(1):1-3,13. doi: 10.3969/j.issn.1000-6532.2013.01.001

WANG D Y, SUN G Z, LUO X, et al. Application prospect of microwave roasting in refractory iron ore[J]. Multipurpose Utilization of Mineral Resources, 2013(1):1-3,13. doi: 10.3969/j.issn.1000-6532.2013.01.001

[38] 张文波. 加压氧化浸出工艺的机理研究[J]. 黄金科学技术, 2011, 19(5):40-44. doi: 10.3969/j.issn.1005-2518.2011.05.010

ZHANG W B. Study on the mechanism of pressure oxidation leaching process[J]. Gold Science and Technology, 2011, 19(5):40-44. doi: 10.3969/j.issn.1005-2518.2011.05.010

[39] Çavusoglu Buğra, Karaca Hüseyin. Removal of sulfur from iron ore with physical and chemical methods[J]. Journal of the Turkish Chemical Society, Section B:Chemical Engineering, 2017(1):103-114.

[40] 谢海泉, 党元林, 张富新. 黄铁矿烧渣的脱硫及资源化[J]. 矿产综合利用, 2005(3):42-45. doi: 10.3969/j.issn.1000-6532.2005.03.010

XIE H Q, DANG Y L, ZHANG F X. Desulfurization and resource utilization of pyrite cinder[J]. Multipurpose Utilization of Mineral Resources, 2005(3):42-45. doi: 10.3969/j.issn.1000-6532.2005.03.010

[41] 武彪, 温建康, 王淀佐. 黄铁矿表面XPS分析与生物浸出机制研究[J]. 稀有金属, 2017, 41(6):720-724. doi: 10.13373/j.cnki.cjrm.xy16040010

WU B, WEN J K, WANG D Z. Study on surface XPS analysis and bioleaching mechanism of pyrite[J]. Chinese Journal of Rare Metals, 2017, 41(6):720-724. doi: 10.13373/j.cnki.cjrm.xy16040010

[42] Sand Wolfgang, Gehrke Tilman, Jozsa Peter-Georg, et al. (Bio)chemistry of bacterial leaching—direct vs. indirect bioleaching[J]. Hydrometallurgy, 2001, 59(2):159-175.

[43] 刘晓荣, 姜圣才. 磁黄铁矿和黄铁矿的生物浸出研究[J]. 矿冶工程, 2006, 26(6):39-42. doi: 10.3969/j.issn.0253-6099.2006.06.011

LIU X R, JIANG S C. Bioleaching of pyrrhotite and pyrite[J]. Mining and Metallurgical Engineering, 2006, 26(6):39-42. doi: 10.3969/j.issn.0253-6099.2006.06.011

[44] SHANG H, WEN J K, WU B, et al. Study on bioleaching of sulfur in Iron ore by mixed culture[J]. Advanced Materials Research, 2015, 3929:371-374.

[45] 何威, 赵开乐. 微生物浸出磁黄铁矿的试验研究[J]. 有色金属(选矿部分), 2019(3):23-27+32.

HE W, ZHAO K L. Experimental study on microbial leaching of pyrrhotite[J]. Nonferrous Metals(Mineral Processing Section), 2019(3):23-27+32.

-

下载:

下载: