Optimization of Digestion Conditions in the Kjeldahl Method for Nitrogen Analysis Using Response Surface Methodology

-

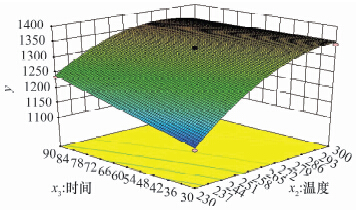

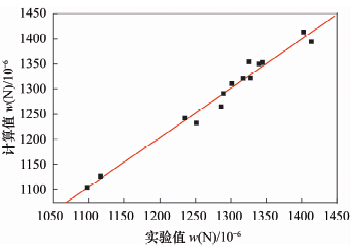

摘要: 经典凯氏定氮法是通过观察消解反应现象来控制温度和时间,对于数量较多的样品同时消解会耗费大量的人力及时间,因此需要采用合理的试验设计方法确定最佳消解温度和时间,以实现批量消解样品,提高分析效率。本文利用响应曲面法对凯氏定氮法中的消解条件进行了优化分析,选择料液比、消解温度和消解时间作为优化因素,研究三因素的不同水平对氮含量测定的影响。通过响应曲面分析得到最优的消解条件为:料液比(g/mL)=0.3 : 5,消解温度260℃,消解时间60 min。重复实验结果表明,样品在优化的条件下能够很好地消解,重现性较好;标准物质的氮含量的实验测定值(1310×10-6)与标准值(1300×10-6)基本一致,两者的对数误差绝对值为0.003,方法的准确性高。应用响应曲面试验设计方法,对于评价凯氏定氮法中三个消解条件对氮含量的非线性影响起到了很好的优选作用,能更好地预测实验因素对分析结果的影响趋势,可以准确控制消解温度和消解时间,对于提高分析效率具有实用意义。Abstract: Reaction phenomenon has always been observed to control digestion conditions such as temperature and time in classical Kjeldahl method for nitrogen analysis, but it is not suitable for a large number of samples which need a lot of manual labour and time. Therefore it is necessary to optimize digestion conditions for simultaneous digestion of a large number of samples in order to increase efficiency. In this experiment, response surface methodology (RSM) was applied for the optimization of digestion conditions in the Kjeldahl method for nitrogen analysis. In RSM analysis, solid/liquid ratio, digestion temperature and digestion time which affect the determination of nitrogen content were examined. Results show that the optimal parameters were determined as follows: solid/liquid ratio of 0.3 : 5 (g/mL), digestion temperature of 260℃, and digestion time of 60 min. Under the optimized conditions, the calculated value (1310×10-6) and certified value (1300×10-6) of nitrogen content are basically consistent with the absolute value of logarithmic error of 0.003 giving it practical significance. The BBD experiment of digestion condition in Kjeldahl method plays a very good role in optimizing the nonlinear effects of measuring nitrogen content, which can better predict the trend of the impact of experimental factors on the results. The research provided the scientific basis and theory guidance for optimization research of digestion conditions by correctly using RSM. It will speed up analysis and also save time by adjusting the digestion temperature and digestion time accurately.

-

-

表 1 BBD实验设计的因素水平

Table 1. Factors and levels in BBD design

因素 符号 水平 平均值x 标准差Δ -1 0 +1 料液比/(g·mL-1) x1 0.1 : 5 0.3 : 5 0.5 : 5 0.3 0.2 消解温度/℃ x2 230 265 300 265 35 消解时间/min x3 30 60 90 60 30 表 2 BBD设计及氮含量的实验值和计算值

Table 2. BBD matrix,experimental values and calculated values of nitrogen content

试验

编号x1 x2 x3 y 实验值 计算值 1 -1 +1 0 1415 1393 2 0 +1 -1 1341 1350 3 0 0 0 1329 1321 4 0 0 0 1317 1321 5 +1 0 +1 1290 1290 6 -1 -1 0 1286 1264 7 0 -1 -1 1117 1126 8 0 0 0 1329 1321 9 0 -1 +1 1235 1242 10 +1 -1 0 1097 1104 11 0 +1 +1 1345 1352 12 +1 0 -1 1253 1231 13 +1 +1 0 1302 1309 14 -1 0 +1 1404 1412 15 -1 0 -1 1327 1353 表 3 BBD设计的方差分析结果

Table 3. Results of variance analysis from stepwise quadratic regression model using BBD design

方差来源 平方和 自由度 均方 F值 P值 模型 108346 6 18058 53.87 <0.0001 x1 30012 1 30012 89.54 <0.0001 x2 55778 1 55778 166.4 <0.0001 x3 6962 1 6962 20.77 0.0019 x1x2 1444 1 1444 4.308 0.0716 x2x3 3249 1 3249 9.693 0.0144 x22 10901 1 10901 32.52 0.0005 残差 2681 8 335.2 - - 失拟项 2585 6 430.9 8.977 0.1036 纯误差 96 2 48 - - 总和 111027 14 - - - 表 4 验证试验的结果对比

Table 4. Verification tests of the method

土壤标准物质编号 w(N)/10-6 对数误差绝对值 氮含量的标准值与不确定度 氮含量的实验值 GBW 07402 630±59 625 0.004 GBW 07403 640±50 648 0.006 GBW 07404 1000±62 990 0.004 GBW 07405 610±31 636 0.018 GBW 07406 740±59 719 0.013 GBW 07407 660±62 648 0.008 GBW 07408 370±54 389 0.022 GBW 07424 1260±110 1308 0.010 GBW 07425 950±100 1002 0.016 GBW 07426 550±60 566 0.023 GBW 07427 720±90 742 0.012 GBW 07428 810±120 872 0.013 GBW 07429 940±100 1002 0.032 GBW 07430 1020±110 1049 0.028 GBW 07446 106 97 0.037 GBW 07447 273±33 318 0.066 GBW 07448 1030±109 1002 0.012 -

[1] 岩石矿物分析编委会.岩石矿物分析(第四版 第四分册)[M].北京:地质出版社,2011: 862-864.

[2] LY/T 1228——1999,森林土壤全氮的测定[S].

[3] 许禄,邵学广.化学计量学方法(第二版)[M].北京:科学出版社,2004: 114.

[4] 严浩,彭文杰,王志兴,李新海,郭华军,胡启阳.响应曲面法优化电解锰阳极渣还原浸出工艺[J].中国有色金属学报,2013, 23(2): 528-534. http://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201302033.htm

[5] 刘永乐,王发祥,俞健,王建辉,李向红,武玮芸.响应曲面法优化莲子蛋白质的提取条件[J].长沙理工大学学报(自然科学版),2012, 9(4): 1-4. http://www.cnki.com.cn/Article/CJFDTOTAL-HNQG201204002.htm

[6] 汪伦记,董英.马克斯克鲁维酵母固态发酵菊粉酶培养条件的优化[J].食品科学,2008,29(8): 402-406. http://www.cnki.com.cn/Article/CJFDTOTAL-SPKX200808092.htm

[7] 牟新利,吴汉夔,祁俊生,程聪,张丽,朱文彬.响应曲面法提取水松总黄酮的工艺研究[J].光谱实验室,2008,27(1): 165-168. http://www.cnki.com.cn/Article/CJFDTOTAL-GPSS201001038.htm

[8] 孟宪军,李冬男,汪艳群,刘小鸣,刘菊,李斌.响应曲面法优化五味子多糖的提取工艺[J].食品科学,2010,31(4): 111-115. http://www.cnki.com.cn/Article/CJFDTOTAL-SPKX201004026.htm

[9] 王艳,张爱珍,任春生.正交试验设计与优化的理论基础与应用进展[J].分析试验室,2008,27(增刊): 333-334. doi: 10.3969/j.issn.1000-0720.2008.z1.100 http://www.cnki.com.cn/Article/CJFDTOTAL-FXSY2008S2101.htm

[10] 秦荣大,郑永章.土壤分析标准方法[M]//[日]土壤标准分析测定法委员会.分析化学译丛(第三集).北京:北京大学出版社,1988: 58-62.

[11] 徐向宏,何明珠.试验设计与Design-Expert、SPSS应用[M].北京:科学出版社,2012: 155.

[12] 王雅.催化剂与浓硫酸组成比例对凯氏定氮消化时间的影响[J].甘肃科技,2005,21(9): 91-92. http://www.cnki.com.cn/Article/CJFDTOTAL-GSKJ200509044.htm

-

下载:

下载: