Study on the Protection of Large Scale Graphite by Particle Bed Breakage-grading Separation Technology

-

摘要:

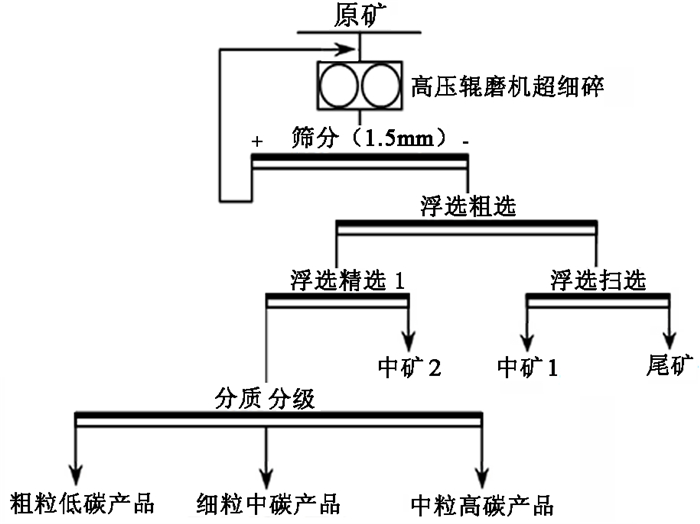

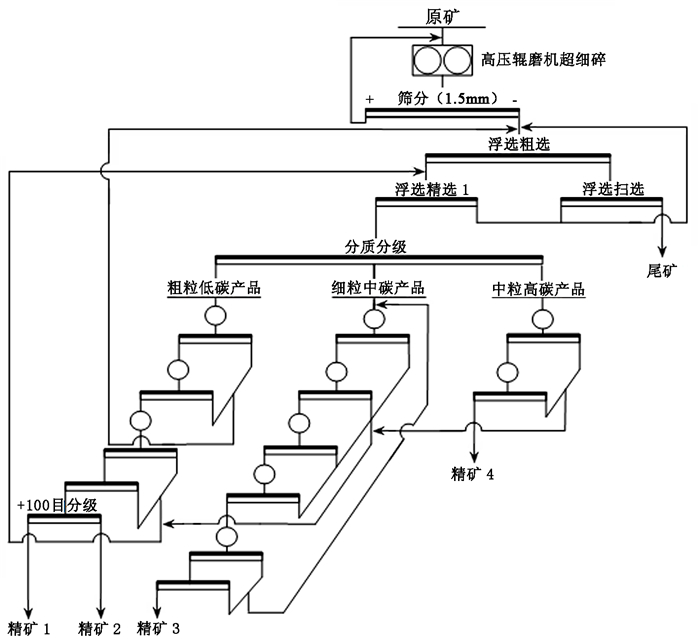

对内蒙古某鳞片石墨进行层压粉碎—分质分选试验研究,实现精矿产品的多元化。在工艺矿物学研究基础上,对原矿采用高压辊磨机超细碎后进行"一粗一精一扫"浮选抛尾。粗精矿经分质分级得到粗粒低碳、中粒高碳和细粒中碳三种中间产品。粗粒低碳产品和中粒高碳产品采用搅拌磨机进行再磨再选;细粒中碳产品采用棒磨机进行再磨再选。在最优条件下闭路试验最终精矿指标为:正目高碳产品固定碳含量94.52%,正目中碳产品固定碳含量91.34%,负目高碳产品固定碳含量94.38%,负目中碳产品固定碳含量91.21%;精矿总回收率为88.18%,精矿正目回收率为49.41%。该技术创新性的将鳞片保护思路从粗精矿再磨精选阶段延伸至低品位原矿的破碎与粗磨阶段,首次将高压辊磨机用于石墨矿山,采用该技术可实现该地区晶质石墨矿的精矿产品多元化,最大限度的提高其应用价值。

Abstract:The method of "particle bed breakage-grading and separation" was used in a flake graphite ore in Inner Mongolia to realize the diversification of the final concentrate products. Based on the mineralogy study, the raw ore was crushed by a high-pressure grinding roller, and the tailings were discharged by a flotation process consisting of one stage roughing, one stage cleaning and one stage scavenging. The rough concentrate was divided into three kinds of stage-products by grading and classification, which were coarse-grained and low fixed carbon (FC), middle-grained and high FC, and fine-grained and medium FC. The first two stage-products were reground using the vertical stirred mill in cleaning process, while the last one was reground using the rod mill. After the closed-circuit flotation, FC content of the high-carbon concentrate was 94.52% in +0.147 mm size fraction and 94.38% in -0.147+0.074 mm size fraction, FC content of middling carbon concentrate was 91.34% in +0.147 mm size fraction and 91.21% in -0.074 mm size fraction. The recovery of final concentrate was 88.18%, of which the recovery of +0.147 mm size fraction is 49.41%. The technology extends innovatively the scale protection idea from the coarse concentrate regrind and refloation stage to the crushing and coarse grinding stage of the raw ore and the high pressure grinding rolls is used in graphite mines firstly. Distillation products of graphite are diversified to maximize their application value in this area.

-

-

表 1 原矿化学组成分析结果 /%

Table 1. Chemical compositions of the raw ore

元素 固定C SiO2 Al2O3 K2O Na2O CaO MgO Fe2O3 TiO2 P SO3 含量 4.73 37.36 10.85 6.19 0.76 18.88 6.08 16.92 1.25 0.11 0.46 表 2 石墨原生片径统计结果

Table 2. Statistical results of primary particle diameter

片径/mm -0.074 -0.147+0.074 -0.175+0.147 -0.287+0.175 +0.287 分布率/% 16.55 20.43 8.19 24.45 30.38 表 3 -1.5 mm原矿粒度筛析和固定碳含量分布

Table 3. Screen analysis and fixed carbon content of -1.5 mm size fraction

粒级/mm 产率/% 累计产率/% 固定C含量/% 分布率/% +1.00 4.7 4.7 3.35 3.36 -1.00+0.500 33.3 38.0 4.93 34.99 -0.500+0.147 16.9 54.9 5.85 21.08 -0.147+0.106 7.0 61.9 5.11 7.62 -0.106+0.074 7.8 69.7 4.52 7.52 -0.074+0.045 6.9 76.6 3.42 5.03 -0.045 23.4 100.0 2.91 14.54 原矿 100.0 4.69 100.00 表 4 层压粉碎—分质分级工艺流程试验结果

Table 4. Results of "particles bed breakage-grading and classification"

产品名称 产率/% 固定碳含量/% 回收率/% 粗粒低碳产品 3.31 47.86 33.49 细粒中碳产品 2.12 70.83 31.75 中粒高碳产品 1.29 78.09 21.30 中矿1 3.67 2.72 2.31 中矿2 3.91 4.52 6.04 尾矿 85.70 0.43 7.73 原矿 100.00 4.72 100.00 表 5 不同再磨方式下各产品指标

Table 5. Indexes of concentrates with different regrinding methods

再磨方式 产品名称 产率/% 固定碳含量/% 回收率/% 精矿1 0.27 95.92 5.48 精矿2 0.96 91.42 18.55 精矿3 1.16 94.66 23.21 棒磨机 精矿4 0.52 96.32 10.59 中矿 8.82 19.12 35.65 尾矿 87.76 0.45 8.35 原矿 100.00 4.73 100.00 精矿1 1.27 93.51 25.11 精矿2 0.09 92.88 1.77 精矿3 0.98 80.81 16.74 搅拌磨 精矿4 0.71 95.81 14.38 中矿 7.51 21.01 33.36 尾矿 90.04 0.43 8.19 原矿 100.00 4.73 100.00 表 6 闭路浮选精矿指标

Table 6. Concentrate indexes of the closed-circuit flotation

产品名称 产率/% 固定碳含量/% 回收率/% 精矿1 1.76 91.34 34.29 精矿2 0.57 92.11 11.20 精矿3 1.39 92.95 27.56 精矿4 0.75 94.52 15.12 尾矿 95.53 0.58 11.82 原矿 100.00 4.69 100.00 表 7 负目精矿筛析结果

Table 7. Screening results of the concentrate in -0.147 mm size fraction

产品名称 筛分粒级/mm 产率/% 固定碳含量/% 回收率/% -0.074 52.63 91.21 51.78 负目精矿 -0.147+0.074 47.37 94.38 48.27 ∑ 100.00 92.71 100.00 -

-

下载:

下载: