Influence of Calcium Chloride on Crystallization Process of Nesquehonite Crystals

-

摘要:

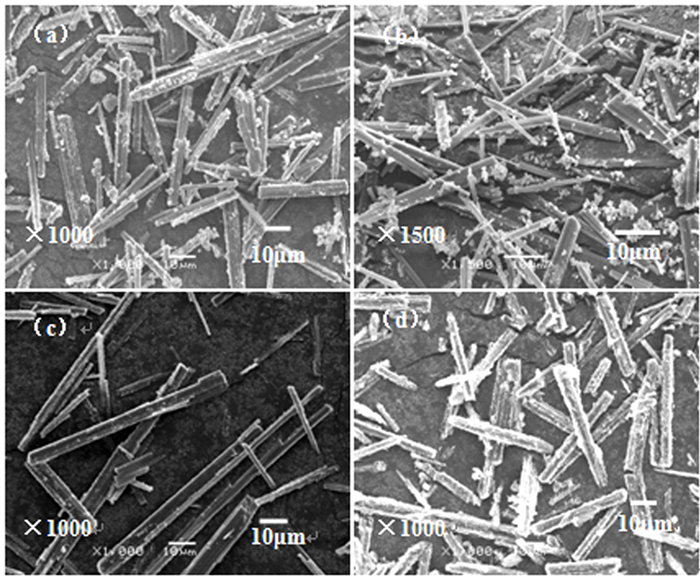

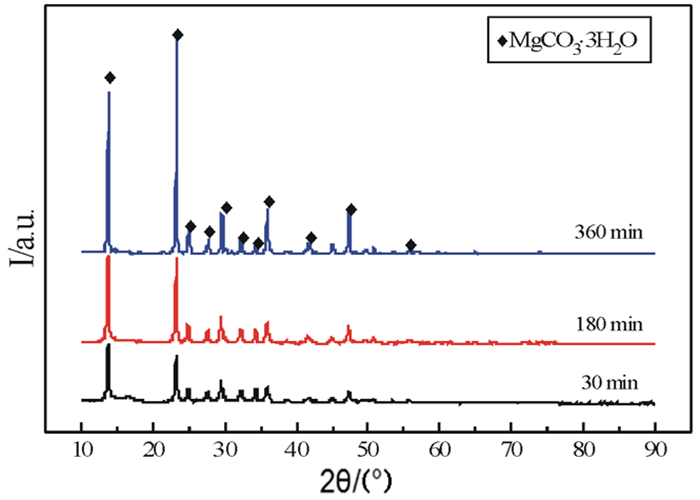

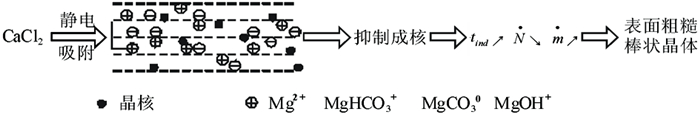

以菱镁矿煅烧所得活性氧化镁为原料,氯化钙为添加剂,采用热分解法制备了MgCO3·3H2O晶体,主要研究添加剂种类、氯化钙用量及热解时间对结晶过程的影响,并分析氯化钙的作用机理。借助X射线衍射(XRD)和扫描电镜(SEM)表征产物的物相结构和微观形貌。结果表明,氯化钙用量为5.0 g/L时,获得表面长着球状颗粒、平均长度45 μm、长径比15的棒状MgCO3·3H2O晶体。氯化钙对MgCO3·3H2O晶体的定向生长无调控作用,主要通过静电吸附的方式参与MgCO3·3H2O晶体的结晶过程,其作用下,诱导期延长,成核速率减缓,生长速率增大。

Abstract:MgCO3·3H2O crystals were prepared by thermal decomposition method with the magnesium solution as precursor, calcium chloride as additives. The influence of types of additives, the amount of calcium chloride and pyrolytic time on the crystallization process was investigated. The mechanism of calcium chloride was further analyzed. The phase structure and morphology of the products was characterized with X-ray diffraction (XRD) and scanning electron microscope (SEM). The results show that rod-like MgCO3·3H2O crystals with spherical particles on the surface was obtained when the amount of calcium chloride is 5.0 g/L. The average length and aspect ratio of rod-like crystals is 45 μm and 15. The calcium chloride has no regulation to the directional growth of MgCO3·3H2O crystals. The calcium chloride takes part in the crystallization of MgCO3·3H2O crystals with the electrostatic adsorption. The induction period is prolonged, the nucleation rate decreases and the growth rate increases with the participation of calcium chloride.

-

Key words:

- magnesite /

- nesquehonite /

- calcium chloride /

- preparation

-

-

表 1 50 ℃时,氯化钙对溶液浓度、结晶过程诱导期时间和结晶速率的影响

Table 1. The influence of calcium chloride on concentration of the solution, induction time and crystallization rate during the crystallization for 50 ℃

添加剂

种类初始浓度

c0 /(g·L-1)初始浓度

c′0 /(g·L-1)诱导期时

间/min结晶速率

tind/ (g·L-1·min-1)无 3.20 3.20 10 0.1608 氯化钙 3.20 5.34 18 0.2447 -

[1] Ding Wenjin, Ouyang Jing, Yang Huaming. Synthesis and characterization of nesquehonite (MgCO3 center dot 3H2O) powders from natural talc[J]. Powder technology, 2016, 292(3):169-175.

[2] 闫平科, 田海山, 高玉娟, 等.高长径比三水碳酸镁晶须的合成研究[J].人工晶体学报, 2012, 41(1):158-164. doi: 10.3969/j.issn.1000-985X.2012.01.032

[3] Freitag F, Kleinebudde P. How roll compaction and dry granulation affect the tableting behaviour of inorganic materials:Comparison of four magnesium carbonates[J]. Eur. J. pharm. sci., 2003, 19:281-289. doi: 10.1016/S0928-0987(03)00133-7

[4] 王余莲, 印万忠, 张夏翔, 等.三水碳酸镁法制备碱式碳酸镁过程研究[J].矿产保护与利用, 2017(4):81-86. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=8bce82b4-d761-4057-afe7-79b47f241bbf

[5] 田朋.碳酸镁模板化制备复杂微纳米结构及性能表征[D].大连: 大连理工大学, 2013.

[6] Kovacheva A, Rabadjieva D, Tepavitcharova St. Simulation of stable and metastable sea-type carbonate systems for optimization of MgCO3 center dot 3H2O precipitation from waste sea brines[J]. Desalination, 2014, 348(9):66-73.

[7] G. Jauffret, J. Morrison, F.P. Glasser. On the thermal decomposition of nesquehonite[J]. J. therm. anal. calorim., 2015, 122:601-609. doi: 10.1007/s10973-015-4756-0

[8] Wang Y, Li Z B. Demopoulos GR controlled precipitation of nesquehonite (MgCO3·3H2O) by the reaction of MgCl2 with (NH4)2CO3[J]. Journal of crystal growth, 2008, 310(6):1220-1227. doi: 10.1016/j.jcrysgro.2008.01.002

[9] 杨晨.多晶相水合碳酸镁结晶生长过程调控研究[D].上海: 华东理工大学, 2013.

[10] Yang Chen, Song Xingfu, Sun Shuying, et al. Effects of sodium dodecyl sulfnate on the oriented growth of nesquehonite whiskers[J]. Advanced powder technology, 2013, 24:585-592. doi: 10.1016/j.apt.2012.10.005

[11] 王余莲, 印万忠, 张夏翔, 等.大长径比三水碳酸镁晶须的制备及晶体生长机理[J].硅酸盐学报, 2018, 46(7):944-951. http://d.old.wanfangdata.com.cn/Periodical/gsyxb201807008

[12] 王余莲, 印万忠, 钟文兴, 等.微纳米三水碳酸镁晶须的制备及性能[J].中南大学学报(自然科学版), 2014, 45(3):708-713. http://cdmd.cnki.com.cn/Article/CDMD-10145-1016009242.htm

[13] 王余莲, 印万忠, 姚金, 等.菱镁矿法合成微纳米三水碳酸镁晶须的研究[J].东北大学学报(自然科学版), 2014, 35(9):1335-1339. doi: 10.3969/j.issn.1005-3026.2014.09.027

[14] 闫平科, 卢智强, 高玉娟, 等.束状三水碳酸镁晶体合成及动力学研究[J].人工晶体学报, 2015, 44(12):3606-3611. doi: 10.3969/j.issn.1000-985X.2015.12.044

[15] 闫平科, 程书林, 卢智强, 等.油酸钠对三水碳酸镁晶须稳定性的研究[J].硅酸盐通报, 2016, 35(3):732-735. http://d.old.wanfangdata.com.cn/Periodical/gsytb201603012

[16] 闫平科, 薛国梁, 高玉娟, 等.表面活性剂对三水碳酸镁晶须形貌的影响研究[J].硅酸盐通报, 2013, 32(9):1729-1740. http://d.old.wanfangdata.com.cn/Periodical/gsytb201309007

[17] 王素平, 肖殷, 王世荣, 等.高镁转化率三水碳酸镁晶须生长条件的研究[J].功能材料, 2016, 47(2):2116-2129. doi: 10.3969/j.issn.1001-9731.2016.02.024

[18] 王余莲.微/纳米水合碳酸镁的制备及应用研究[D].沈阳: 东北大学, 2015.

[19] 叶铁林.化工结晶过程原理及应用[M], 北京:北京工业大学出版社, 2006.

-

下载:

下载: