Comparison of Different Breakage Mechanisms in Terms of RO Phase Liberation Properties in Steel Slag

-

摘要:

为寻求钢渣中RO相解离的最佳粉碎机制,选取高压辊磨机(辊压机)、立式辊磨机(立磨)和球磨机制备的4种粒度分布钢渣粉,每种钢渣粉机械筛分为7个粒级并制成光片。人工统计RO相在5种解离类中分布率、相表面参数,以单体解离度和解离>75%的含量,2个指标表征解离性能;以相比界面面积和自由表面率,2个参数表征脱离解离量。4种钢渣粉中脱离解离量都高,RO相属于易解离矿物。粉碎设备脱离解离量高低次序为辊压机、立磨、球磨,同一设备粉磨细度越高,脱离解离量越大。RO相粒级解离度以嵌布粒度为界分为解离度平稳区和下降区,平稳区解离度稳定在高值且与设备无关;下降区挤压粉碎设备解离度高,粒级解离度随粒度增大降低幅度较大。

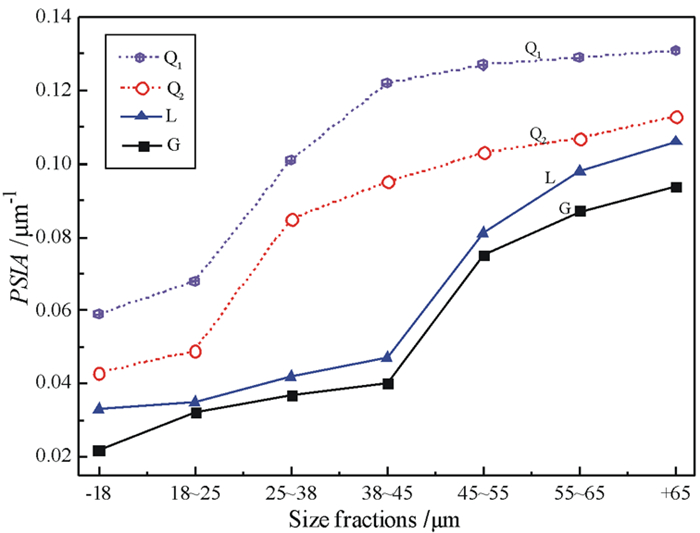

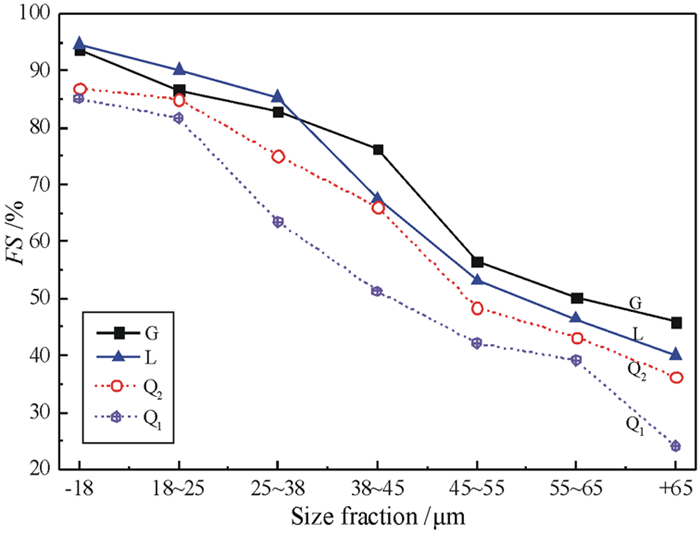

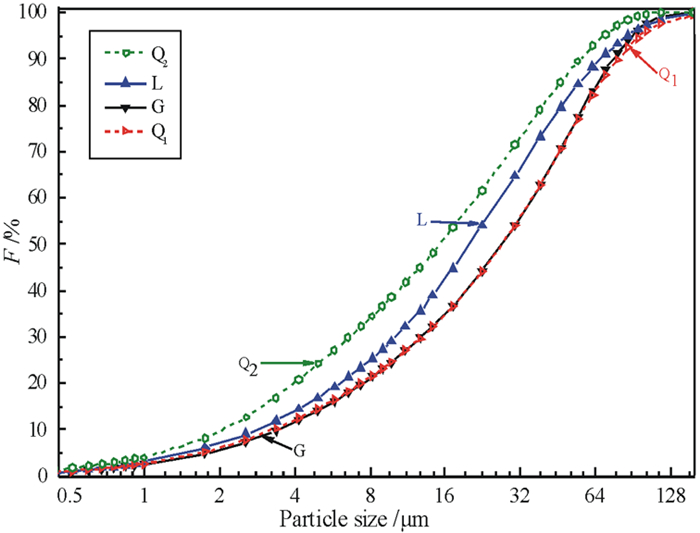

Abstract:In order to find the best breakage mechanism of RO phase liberation in steel slag, four kinds of steel slag powder with different particle size distribution have been comminuted respectively by high-pressure grinding rolls (roller press), vertical roller mill (vertical mill) and ball mill. Each of them was actually sieved into 7 size fractions then made into polished section. The proportion of RO phase grain in the five liberation classes and the phase surface parameters were manually counted. The liberation properties were characterized by the two index parameters of liberation degree and the amount of 75%~100% liberated, while the amount of liberation by detachment was described by phase specific interfacial area and free surface percentage. As the RO phase in steel slag is easy to be released from the rock matrix, the amount of liberation by detachment of four steel slag powders is large. The priority sequence of comminution equipment in terms of the amount of liberation by detachment is roller press, vertical mill, ball mill. The finer the steel slag powder made by the same equipment, the better the amount of liberation by detachment. Liberated minerals could be divided into two regions by the average dissemination size of RO phase. The first region is a stability zone for liberation properties, in which the degree of liberation is independent of particle size and device. The second region is a decline zone, in which the liberation degree significantly decreases with increasing the particle size.

-

-

表 1 钢渣的化学成分 /%

Table 1. Chemical compositions of steel slag

成分 CaO SiO2 Fe2O3 FeO Al2O3 MgO MnO LOI P2O5 Total f-CaO - 含量 40.93 13.87 11.16 13.29 4.29 9.40 1.06 2.57 1.30 97.87 2.79 - 表 2 钢渣粉粒级百分数、统计颗粒数和RO相在解离类中分布率

Table 2. The distribution of steel slag size fraction and measured particle numbers and proportion of RO phase in liberation classes

编号 粒级/μm 产率/% 统计数 RO相在解离类中分布率/% <1/4 1/4~2/4 2/4~3/4 3/4~4/4 4/4 G -18 39.4 907 1.7 2.4 3.8 7.0 85.1 L 50.6 1 223 1.7 1.5 1.7 9.3 85.8 Q1 42.9 1 360 1.7 1.8 2.5 8.0 86.0 Q2 57.6 1 458 0.8 1.1 1.8 9.9 86.4 G 18~25 4.9 1 161 1.8 2.7 4.4 8.6 82.5 L 6.1 926 2.1 1.5 2.9 9.9 83.7 Q1 9.4 828 2.2 2.8 2.6 10.1 82.3 Q2 5.0 1 325 1.3 1.4 2.4 11.4 83.4 G 25~38 13.9 1 131 2.4 2.1 4.5 10.5 80.5 L 11.8 1 248 2.4 1.9 3.9 12.1 79.6 Q1 7.9 1 244 2.3 2.8 2.4 10.5 81.9 Q2 12.9 1 468 1.8 2.2 2.3 11.6 82.1 G 38~45 10.8 1 184 3.1 2.3 4.4 14.0 76.2 L 9.5 1 315 4.0 4.5 4.3 8.8 78.4 Q1 12.7 1 613 2.7 3.0 7.3 8.0 79.0 Q2 11.2 1 433 2.0 2.8 3.5 11.2 80.5 G 45~55 9.3 1 573 5.6 4.7 6.2 16.5 67.0 L 6.1 1 534 5.0 5.9 8.7 15.4 65.1 Q1 11.1 1 337 5.0 9.2 9.2 19.1 57.5 Q2 7.0 1 546 7.7 6.2 7.2 16.0 62.9 G 55~65 8.1 1 632 8.7 7.8 10.0 18.8 54.7 L 7.2 1 320 8.2 6.8 13.5 21.3 50.2 Q1 8.9 1 057 11.6 15.6 19.9 31.2 21.6 Q2 5.1 1 389 14.5 10.6 9.9 19.2 45.7 G +65 13.6 1 024 15.5 11.4 11.0 16.5 45.6 L 8.6 1 011 12.8 12.9 13.0 18.8 42.5 Q1 7.1 978 17.5 19.6 16.7 27.3 18.8 Q2 1.2 1 138 16.0 13.3 11.4 20.6 38.7 表 3 RO相的相面积、界面长度和自由面长度

Table 3. Phase area, interfacial boundary and free surface boundary of RO phase

编号 粒级/μm 面积/μm2 界面长/μm 自由面长/μm G -18 17 550 383 5 677 L 7 927 262 4 566 Q1 15 712 926 5 296 Q2 22 259 967 6 395 G 18~25 45 879 1 460 9 398 L 16 866 587 5 318 Q1 15 100 1 022 4 567 Q2 74 493 3 630 20 632 G 25~38 48 275 1 783 8 557 L 42 144 1 761 10 211 Q1 44 513 4 517 7 875 Q2 26 390 2 242 6 775 G 38~45 67 425 2 665 8 595 L 108 402 5 107 10 657 Q1 57 517 7 026 7 408 Q2 31 963 3 033 5 910 G 45~55 83 961 6 289 8 204 L 89 324 7 205 8 152 Q1 59 920 7 596 5 548 Q2 114 459 11 764 11 024 G 55~65 97 345 8 493 8 597 L 83 369 8 208 7 098 Q1 61798 7 999 5 161 Q2 69 641 7 454 5 689 G +65 130 978 12 370 10 506 L 209 730 22 327 14 962 Q1 88 898 11 659 3 696 Q2 170 149 19 222 10 955 -

[1] 侯新凯, 梁爽, 刘柱燊, 等.钢渣生产高活性钢渣粉和惰性矿物产品的工艺: 201611105595.2[P].2017-05-31.

[2] Tromans D. Mineral comminution:energy efficiency considerations[J]. Minerals engineering, 2008, 21(8):613-620. doi: 10.1016/j.mineng.2007.12.003

[3] Lewis F M, Coburn J L, Bhappu R B. Comminution:a guide to size-reduction system design-1[J]. Mining engineering, 1976, 28(9):29-34. http://d.old.wanfangdata.com.cn/Periodical/zgftjs200903018

[4] Schönert K. A first survey of grinding with high-compression roller mills[J]. International journal of mineral processing, 1988, 22(1):401-412. https://www.sciencedirect.com/science/article/abs/pii/0301751688900750

[5] Han Y X, Liu L, Yuan Z T, et al. Comparison of low-grade hematite product characteristics in a high-pressure grinding roller and jaw crusher[J]. Minerals and metallurgical processing, 2012, 29(2):75-80. https://link.springer.com/article/10.1007%2FBF03402397

[6] Celik I B, Oner M. The influence of grinding mechanism on the liberation characteristics of clinker minerals[J]. Cement and concrete research, 2006, 36(3):422-427. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=JJ028879439

[7] Hoşten Ç, Özbay C. A comparison of particle bed breakage and rod mill grinding with regard to mineral liberation and particle shape effects[J]. Minerals engineering, 1998, 11(9):871-874. doi: 10.1016/S0892-6875(98)00074-0

[8] Vizcarra T G, Wightman E M, Johnson N W, et al. The effect of breakage mechanism on the mineral liberation properties of sulphide ores[J]. Minerals engineering, 2010, 23(5):374-382. doi: 10.1016/j.mineng.2009.11.012

[9] Stutzman P E. Microscopy of clinker and hydraulic cements[J]. Reviews in mineralogy and geochemistry, 2012, 74(1):101-146. doi: 10.2138/rmg.2012.74.3

[10] Wang E, Shi F N, Manlapig E. Mineral liberation by high voltage pulses and conventional comminution with same specific energy levels[J]. Minerals engineering, 2012, 27-28:28-36. doi: 10.1016/j.mineng.2011.12.005

[11] 袁致涛, 马玉新, 毛卫东, 等.马耳岭选矿厂尾矿中磁铁矿再回收试验研究[J].矿产保护与利用, 2014(2):44-48. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=83f15fe0-4961-4c31-8a3b-5775c85d30e4

[12] 侯新凯, 贺宁, 袁静舒, 等.钢渣中二价金属氧化物固溶体的选别性研究[J].硅酸盐学报, 2013, 41(8):1142-1150. http://d.old.wanfangdata.com.cn/Periodical/gsyxb201308018

[13] Leißner T, Hoang D H, Rudolph M, et al. A mineral liberation study of grain boundary fracture based on measurements of the surface exposure after milling[J]. International journal of mineral processing, 2016, 156:3-13. doi: 10.1016/j.minpro.2016.08.014

[14] Meloy T P. Liberation theory -eight, modern, usable theorems[J]. International journal of mineral processing, 1984, 13(4):313-324. doi: 10.1016/0301-7516(84)90051-6

[15] Barbery G. Mineral liberation:measurement, simulation and practical use in mineral processing[M]. Quebec:editions GB, 1991.

[16] Singh V, Venugopal R, Banerjee P K, et al. Effect of morphology on breakage and liberation characteristics of minerals and coal[J]. Minerals and metallurgical processing, 2014, 31(4):186-192. https://link.springer.com/article/10.1007%2FBF03402469

-

下载:

下载: