Numerical Simulation Analysis on Flow Field of CK Stirred Tank

-

摘要:

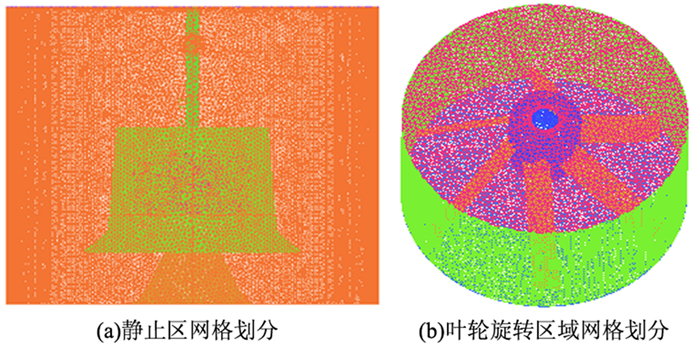

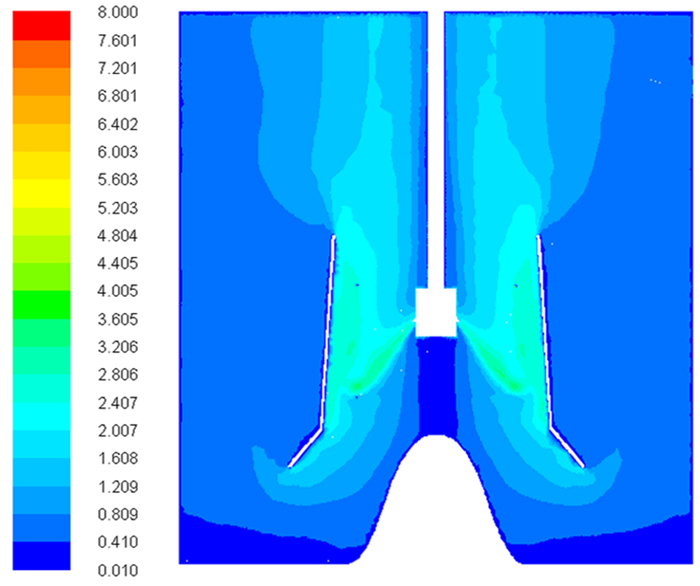

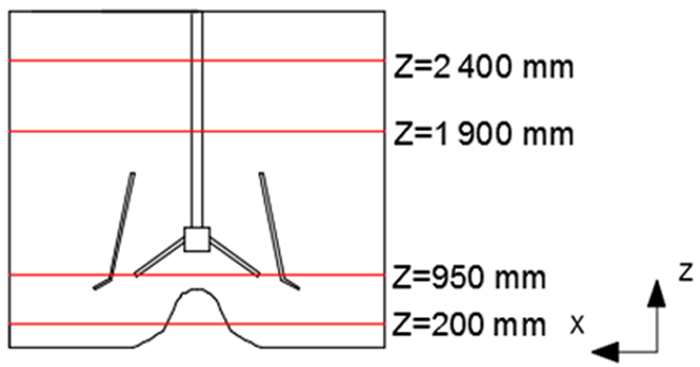

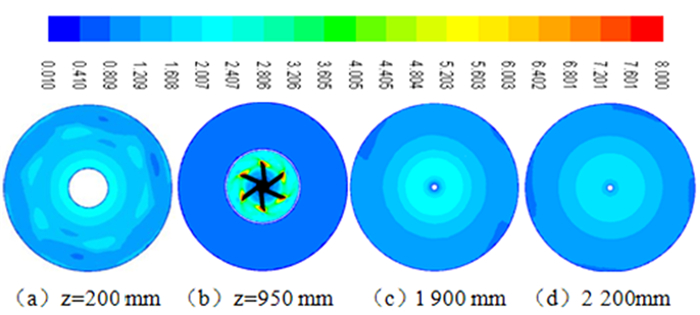

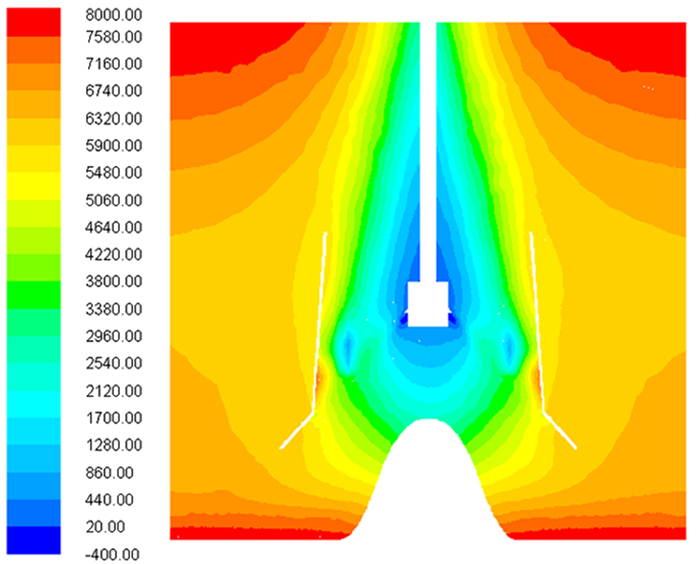

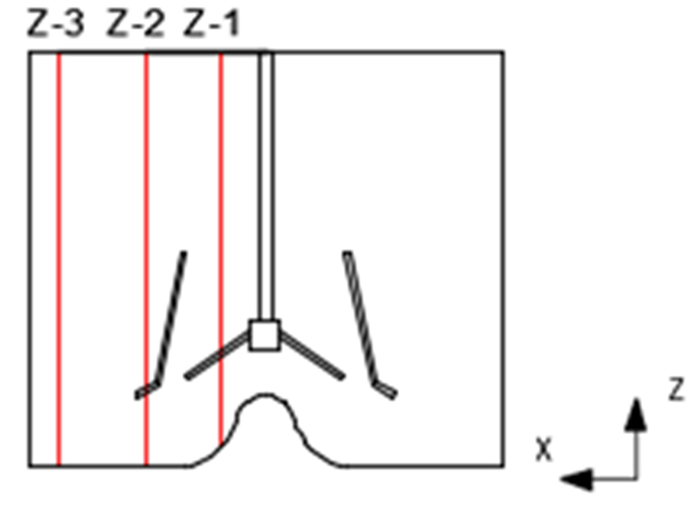

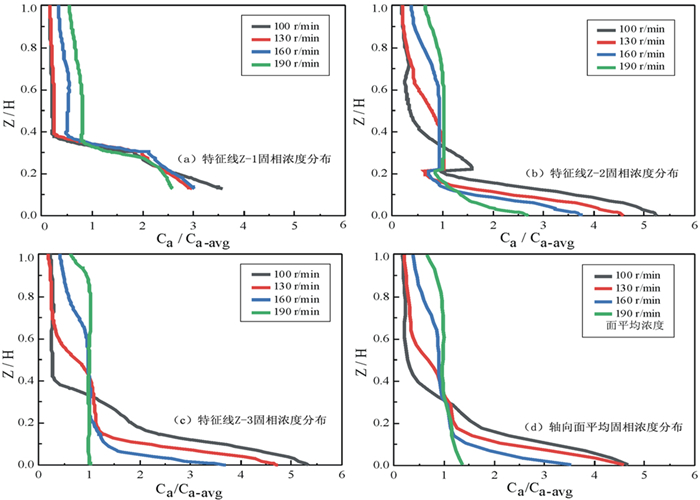

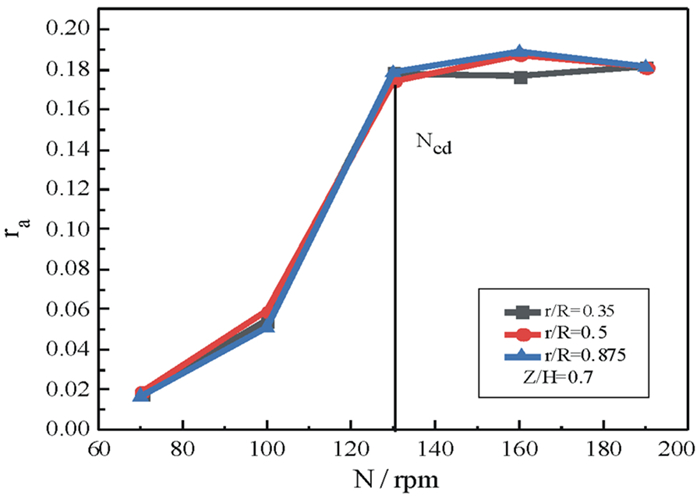

采用Mixture模型、多重参考系(Multiple reference frame,MRF)对CK式搅拌槽内流场进行数值模拟,分析其内部流场特性。结果表明,CK式搅拌槽内部流场主要由一个主循环流与两个小循环流构成,搅拌槽内流体呈"W"形进行上下循环运动;其内部压力槽顶部与底部的压力最大然后逐渐向搅拌中心减小,这种压力分布有利于促进搅拌混合;提高搅拌转速,可加速搅拌槽内介质混合过程,缩短混合时间;该结构搅拌槽的临界悬浮转速为130.51 r/min,当转速达到190 r/min时桨叶运转100转时搅拌槽内固相基本达到均匀悬浮,表明该结构搅拌槽具有较高效率的搅拌效果。

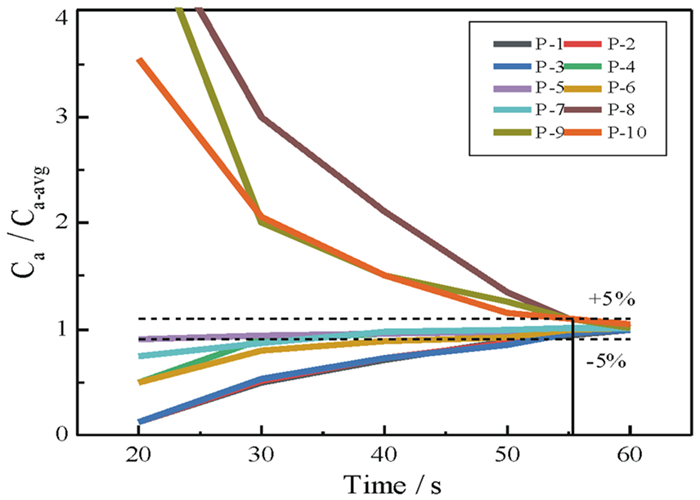

Abstract:The mixture model and the multiple reference frame (MRF) were used to simulate the flow field in a CK stirred tank to analyze the internal flow field characteristics. The results showed that the flow field of CK stirred tank was mainly composed of one main circulation flow and two small circulation flows. The fluid in stirred tank undergone upward and downward circulation followed the "W" cycle trajectory. The pressure on the top and bottom of the tank was the highest and then gradually decreased towards to the stirring center, and the pressure distribution can facilitate mixing. A short mixing time was obtained with increasing stirring speed. The critical suspension speed of the stirred tank was 130.51 r/min. When the stirring speed reached 190 r/min, the solid phase in stirred tank could be uniformly suspended after the blade ran 100 r, which indicated that the stirred tank had a high stirring efficiency.

-

Key words:

- stirred tank /

- multi-phase flow /

- numerical simulation /

- CK

-

-

表 1 搅拌槽混合均匀时的悬浮时间

Table 1. Suspension time when the mixture is uniformly mixed in the stirred tank

转速/(r·min-1) 时间/s 100 138.56 130 105.45 160 75.82 190 55.28 -

[1] 长沙矿冶院.CK系列高效矿浆搅拌槽[EB/OL].(2016-08-23)[2018-06-09]. http://www.crimm.com.cn/cpyfw/tjcp/201507/t20150701_106606.html.

[2] Nere N K, A W P, Joshi J B. Liquid-hase mixing in stirred vessels:turbulent flow regime[J]. Industrial & engineering chemistry research, 2003, 42(12):2661-2698. http://pubs.acs.org/doi/pdf/10.1021/ie0206397

[3] 郭聪聪, 赵恒文, 许卓, 等.搅拌槽内挡板对搅拌效果的数值模拟[J].给水排水, 2011(S1):199-202. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201102933395

[4] 房关考, 王克用.基于SC/Tetra的搅拌槽挡板数目优化[J].上海工程技术大学学报, 2014, 28(4):302-307. doi: 10.3969/j.issn.1009-444X.2014.04.003

[5] 刘利宝, 赵晶, 王世杰.大型矿浆搅拌槽不同挡板结构对矿浆云密度的影响[J].中国矿业, 2017, 26(6):131-136. doi: 10.3969/j.issn.1004-4051.2017.06.025

[6] 王立成.带导流筒搅拌槽中液-固-固三相流场的实验与模拟研究[D].天津: 天津大学, 2010.

http://cdmd.cnki.com.cn/Article/CDMD-10056-1011266486.htm [7] 牛福生, 李卓林, 张晋霞.搅拌流场中微细粒赤铁矿絮凝动力学研究[J].矿产保护与利用, 2017(5):58-63. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=d78c9317-409e-4c73-9a9d-81d9262ac810

[8] 王福军.计算流体动力学分析[M].北京:清华大学出版社, 2004:4-12.

[9] 于勇.FLUENT入门与进阶教程[M].北京:北京理工大学出版社, 2008:206-219.

[10] Zwietering T N. Suspending of solid particles in liquid by agitators[J]. Chemical engineering science, 1958, 8(3-4):244-253. doi: 10.1016/0009-2509(58)85031-9

[11] Armenante P M, Huang Y T. Experimental determination of the minimum agitation speed for complete liquid-liquid dispersion in mechanically agitated vessels[J]. Industrial & engineering chemistry research, 1992, 31(5):1398-1406. http://pubs.acs.org/doi/abs/10.1021/ie00005a022

[12] Kasat G R, Khopkar A R, Ranade V V, et al. CFD simulation of liquid-phase mixing in solid-liquid stirred reactor[J]. Chemical engineering science, 2016, 63(15):3877-3885. http://www.sciencedirect.com/science/article/pii/S0009250908001929

[13] Yamazaki H, Tojo K, Miyanami K. Concentration profiles of solids suspended in a stirred tank[J]. Powder technology, 1986, 48(3):205-216. doi: 10.1016/0032-5910(86)80043-2

-

下载:

下载: