The Experimental Study on Synchronus Desulfurization and Desilication Flotation for the Bauxite in Southwest China

-

摘要:

西南某铝土矿Al2O3和SiO2的品位分别为56.86%和14.86%,S含量为1.57%,为高效开发利用该铝土矿,对其进行同步脱硫脱硅试验研究。浮选研究结果表明:在Na2CO3为pH调整剂、CuSO4为活化剂、SNS为抑制剂、BA-1为脱硫捕收剂、松醇油为起泡剂、EXA为脱硅捕收剂的条件下,原矿经过"一次粗选—一次精选—三次扫选"的同步脱硫脱硅工艺处理后,可以得到Al2O3含量为61.03%,SiO2为11.95%,S为0.19%,A/S为5.11的铝土矿精矿。该工艺可以为该矿的利用提供指导,同时也为该类型铝土矿的开发利用提供一种全新的技术思路。

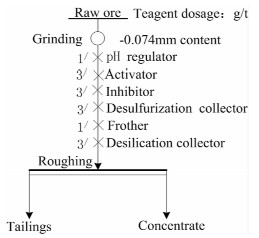

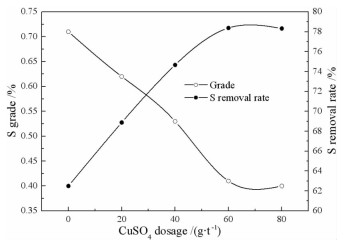

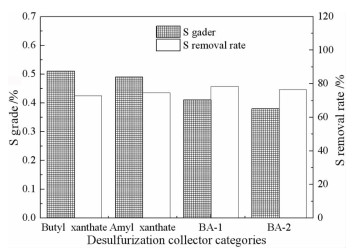

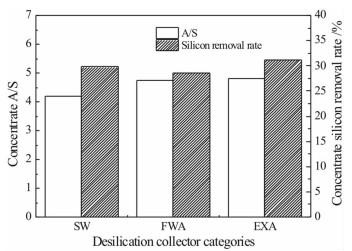

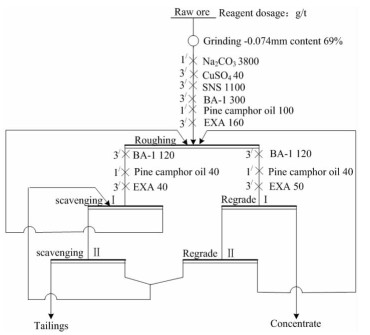

Abstract:The grade of Al2O3 and SiO2 of a bauxite in southwest China is 56.86% and 14.86% respectively, and the sulfur content is 1.57%. A Synchronous desulfurization and desiliconization experiments were carried out to develop and utilize this bauxite efficiently. The flotation research results show that under the conditions of Na2CO3 as pH regulator, CuSO4 as activator, SNS as inhibitor, BA-1 as desulfurization collector, terpenic oil as frother and EXA as desilication collector, the concentrate of 61.03% Al2O3 and 11.95% SiO2 were achieved after "one roughing-one cleaning-three scavenging" circuit. The sulfur content of concentrate is 0.19% and the rate of aluminum to silicon is 5.11.This process can provide guidance for the utilization of the mine and a new technical idea for the development and utilization of this type of bauxite.

-

Key words:

- diaspore /

- pyrite /

- synchrous desulfurization and desilication flotation

-

-

表 1 原矿化学多元素分析结果

Table 1. The chemical multielement analysis results of raw ore

/% Element Al2O3 SiO2 Fe2O3 TiO2 K2O CaO MgO S A/S Content 56.86 14.86 8.82 2.37 0.60 0.35 0.40 1.57 3.83 表 2 原矿矿物组成分析结果

Table 2. The phase analysis results of raw ore

/% Mineral Diaspore Boehmite Chlorite Kaolinite Illite Pyrite Quartz Siderite Anatase Calcite Rutile Content 42.0 10.0 11.0 15.0 6.5 3.6 2.0 2.0 2.0 0.6 0.5 表 3 磨矿细度试验结果

Table 3. The test results of grinding fineness

Grinding fineness

(-0.074 mm)Product Yield/% Grade/% A/S Recovery/% Al2O3 SiO2 S Al2O3 SiO2 S 63% Concentrate 86.08 58.33 13.55 0.85 4.30 88.31 78.50 46.61 Tailings 13.92 47.77 22.96 6.02 2.08 11.69 21.50 53.39 Raw ore 100.00 56.86 14.86 1.57 3.83 100.00 100.00 100.00 69% Concentrate 82.77 59.25 12.35 0.41 4.80 86.25 68.79 21.62 Tailings 17.23 45.38 26.92 7.14 1.69 13.75 31.21 78.38 Raw ore 100.00 56.86 14.86 1.57 3.83 100.00 100.00 100.00 75% Concentrate 79.97 59.05 12.96 0.52 4.56 83.05 69.74 26.49 Tailings 20.03 48.12 22.45 5.76 2.14 16.95 30.26 73.51 Raw ore 100.00 56.86 14.86 1.57 3.83 100.00 100.00 100.00 81% Concentrate 78.16 58.36 13.52 0.77 4.32 80.22 71.11 38.33 Tailings 21.84 51.49 19.66 4.43 2.62 19.78 28.89 61.67 Raw ore 100.00 56.86 14.86 1.57 3.83 100.00 100.00 100.00 表 4 矿浆pH值试验结果

Table 4. The test results of pulp pH

pH value Product Yield/% Grade/% A/S Recovery/% Al2O3 SiO2 S Al2O3 SiO2 S 5 Concentrate 83.29 58.92 13.04 0.34 4.52 86.31 73.09 18.04 Tailings 16.71 46.59 23.93 7.70 1.95 13.69 26.91 81.96 Raw ore 100.00 56.86 14.86 1.57 3.83 100.00 100.00 100.00 6 Concentrate 82.77 59.25 12.35 0.41 4.80 86.25 68.79 21.62 Tailings 17.23 45.38 26.92 7.14 1.69 13.75 31.21 78.38 Raw ore 100.00 56.86 14.86 1.57 3.83 100.00 100.00 100.00 7 Concentrate 80.78 57.05 12.96 0.52 4.40 81.05 70.45 26.76 Tailings 19.22 56.06 22.85 5.98 2.45 18.95 29.55 73.24 Raw ore 100.00 56.86 14.86 1.57 3.83 100.00 100.00 100.00 8 Concentrate 81.98 58.76 13.52 0.55 4.35 84.72 74.59 28.72 Tailings 18.02 48.22 20.96 6.21 2.30 15.28 25.41 71.28 Raw ore 100.00 56.86 14.86 1.57 3.83 100.00 100.00 100.00 表 5 药剂用量试验影响因素及水平

Table 5. The influence factors and levels of reagent dosage tests

A(SNS) B(BA-1) C(EXA) 1 0 200 160 2 800 300 180 3 1 000 400 200 表 6 药剂用量正交试验结果

Table 6. The orthogonal test results of reagent dosage

Factor combination level Yield/% Grade/% A/S Recovery/% Al2O3 SiO2 S Al2O3 SiO2 S A1B1C1 84.55 57.56 13.21 0.51 4.36 85.59 75.16 27.47 A1B2C2 82.32 58.12 13.71 0.46 4.24 84.14 75.95 24.12 A1B3C3 78.99 56.92 14.26 0.42 3.99 79.07 75.80 21.13 A2B1C2 80.55 58.37 13.15 0.49 4.44 82.69 71.28 25.14 A2B2C3 79.02 58.85 12.78 0.43 4.60 81.79 67.96 21.64 A2B3C1 81.55 58.52 13.75 0.41 4.26 83.93 75.46 21.30 A3B1C3 79.52 59.02 12.02 0.44 4.91 82.54 64.32 22.29 A3B2C1 82.77 59.25 12.35 0.41 4.80 86.25 68.79 21.62 A3B3C2 80.25 59.42 12.43 0.36 4.78 83.86 67.13 18.40 表 7 闭路流程试验结果

Table 7. The test results of closed circuit

Product Yield

/%Grade/% A/S Recovery/% Al2O3 SiO2 S Al2O3 SiO2 S Concentrate 78.95 61.03 11.95 0.19 5.11 84.74 63.49 1.01 Tailings 21.05 41.22 25.77 7.38 1.60 15.26 36.51 98.99 Raw ore 100.00 56.86 14.86 1.57 3.83 100.00 100.00 100.00 -

[1] 熊道陵, 马智敏, 彭建城, 等.高硫铝土矿中硫的脱除研究现状[J].矿产保护与利用, 2012(5):53-58. doi: 10.3969/j.issn.1001-0076.2012.05.015 http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=48b78022-f5a3-4452-a52a-1d92268ab110

[2] 杨卉芃, 张亮, 冯安生, 等.全球铝土矿资源概况及供需分析[J].矿产保护与利用, 2016(6):64-70. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=96c5b0bc-62ba-4202-8c89-e79bd77f7483

[3] 杜五星, 戴惠新, 翟德平.高硅铝土矿选矿脱硅的研究现状及进展[J].轻金属, 2016(11):12-17. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=qjs201611002

[4] 陈喜峰.中国铝土矿资源勘查开发现状及可持续发展建议[J].资源与产业, 2016, 18(3):16-22. http://d.old.wanfangdata.com.cn/Periodical/zycy201603004

[5] 王淀佐, 胡岳华.细粒难分离矿物浮选组装表面化学——以铝土矿资源的高效综合利用为例介绍矿物浮选组装表面化学新技术的应用[C]//中国工程院化工冶金与材料工程学部学术会议.2008.

[6] 蔡振波, 徐会华, 陈秋虎, 等.广西某高硫铝土矿反浮选脱硫-聚团浮选脱硅试验[J].金属矿山, 2016(3):98-102. doi: 10.3969/j.issn.1001-1250.2016.03.021

[7] 胡岳华, 印万忠, 张凌燕, 等.矿物浮选[M].长沙:中南大学出版社, 2014:35.

[8] 陈建华, 童雄, 甘恒, 等.多金属硫化矿混合浮选高效活化剂试验研究[J].有色金属(选矿部分), 2018(3):102-105. http://d.old.wanfangdata.com.cn/Periodical/ysjs-xk201803020

[9] 梁爽, 路亮, 吴桂叶.硫化矿捕收剂的研究进展[J].中国矿业, 2018, 27(S2):163-165. http://d.old.wanfangdata.com.cn/Periodical/sxhg201210034

[10] 刘冰, 邱跃琴.铝土矿浮选脱硅研究现状与展望[J].现代矿业, 2012(5):131-133. doi: 10.3969/j.issn.1674-6082.2012.05.050

[11] 刘炯天, 樊民强, 杨小生, 等.试验研究方法[M].徐州:中国矿业大学出版社, 2006:12.

-

下载:

下载: